Quick Answer: Pickleball paddles come in several shapes—most notably the standard (balanced), elongated, and wide-body designs—with variations such as short/widebody paddles with short or long handles. These shapes influence power, control, and ergonomic performance, and selecting the right configuration depends on production capabilities, market needs, and player performance.

In today’s competitive sports equipment market, B2B decision makers must consider every technical detail when selecting or developing pickleball paddles. The paddle’s shape is one of the most critical design elements that can influence both the player’s performance and the manufacturing process. In this article, we compare the different paddle shapes, discuss how production techniques affect these designs, and provide a cost-performance analysis to assist product managers, procurement specialists, and distributors in making informed purchasing decisions.

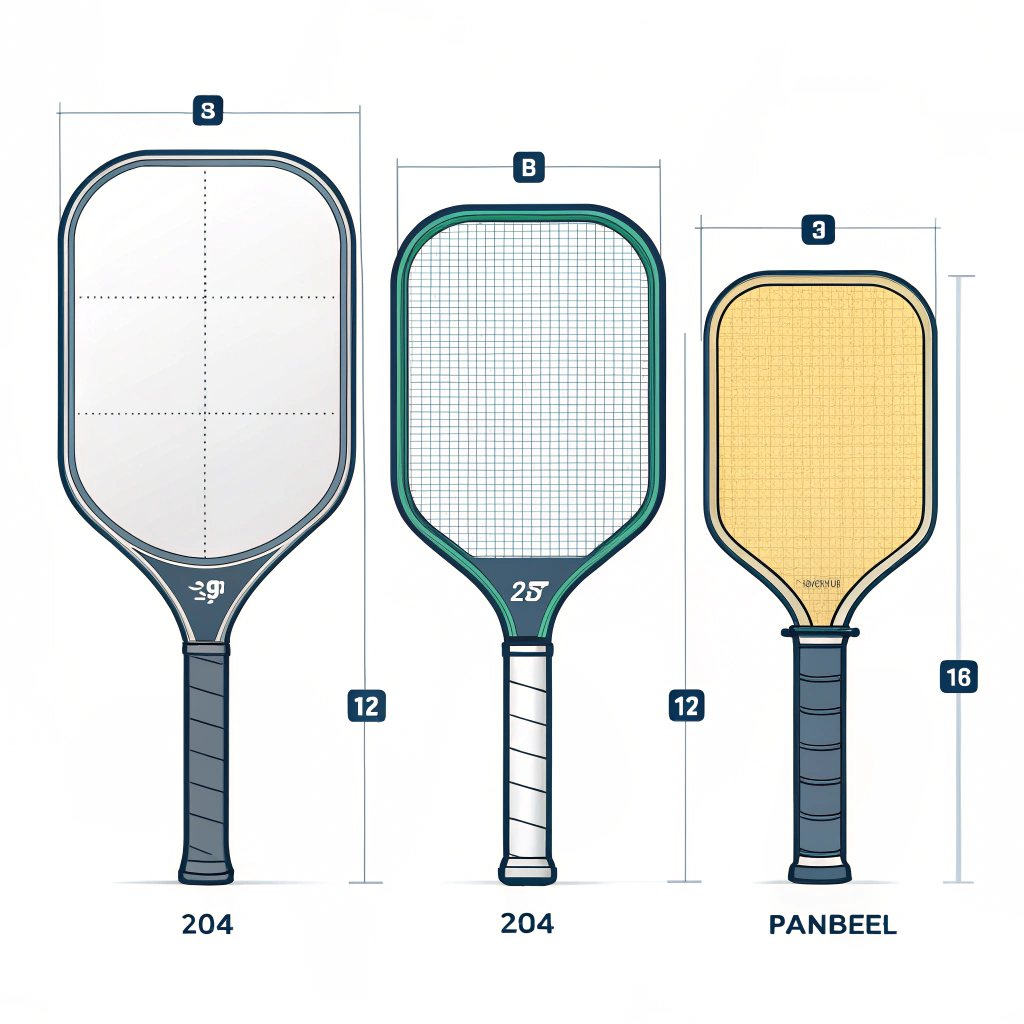

Pickleball paddle shapes play a significant role in how power, control, and overall game performance are balanced. Among the most popular shapes are:

- Standard Shape: This classic design offers a balanced mix of power and control. Its dimensions cater to players who need versatility on the court.

- Elongated Shape: Ideal for players who prioritize reach and quick response, an elongated paddle typically features a narrow body with a longer handle.

- Wide-Body Shape: With a larger hitting surface or “sweet spot,” wide-body paddles enhance control and offer better ball placement, making them perfect for dynamic play styles.

- Hybrid Variations: Some paddles blend features from different designs—such as a short/widebody paddle with a long handle, or a long/elongated shape with a short handle. While these designs are less common, they cater to niche market demands where specific performance characteristics are sought.

These shapes not only affect game performance but also determine production parameters during manufacturing. For instance, achieving precision in a wide-body design may require different materials or processes compared to an elongated paddle.

Evaluating paddle shapes involves understanding their dimensions, balance, and intended use. Below is a comparison table summarizing the key attributes of each design:

| Paddle Shape | Key Characteristics | Performance Impact | Recommended For |

|---|---|---|---|

| Standard | Classic dimensions; balanced weight | Versatile mix of power and control | Players with a balanced playing style |

| Elongated | Narrow body with extended handle | Enhanced reach; improved quick response | Solo players and those who need reach |

| Wide-Body | Larger sweet spot; thicker paddle face | Improved ball control; consistent performance | Players seeking precision and consistency |

| Hybrid Variations | Mixed dimensions (e.g., wide body with long handle) | Specific performance tweaks according to design | Niche markets and custom orders |

This table serves as a practical guide for selecting the appropriate shape based on the target market and player demands.

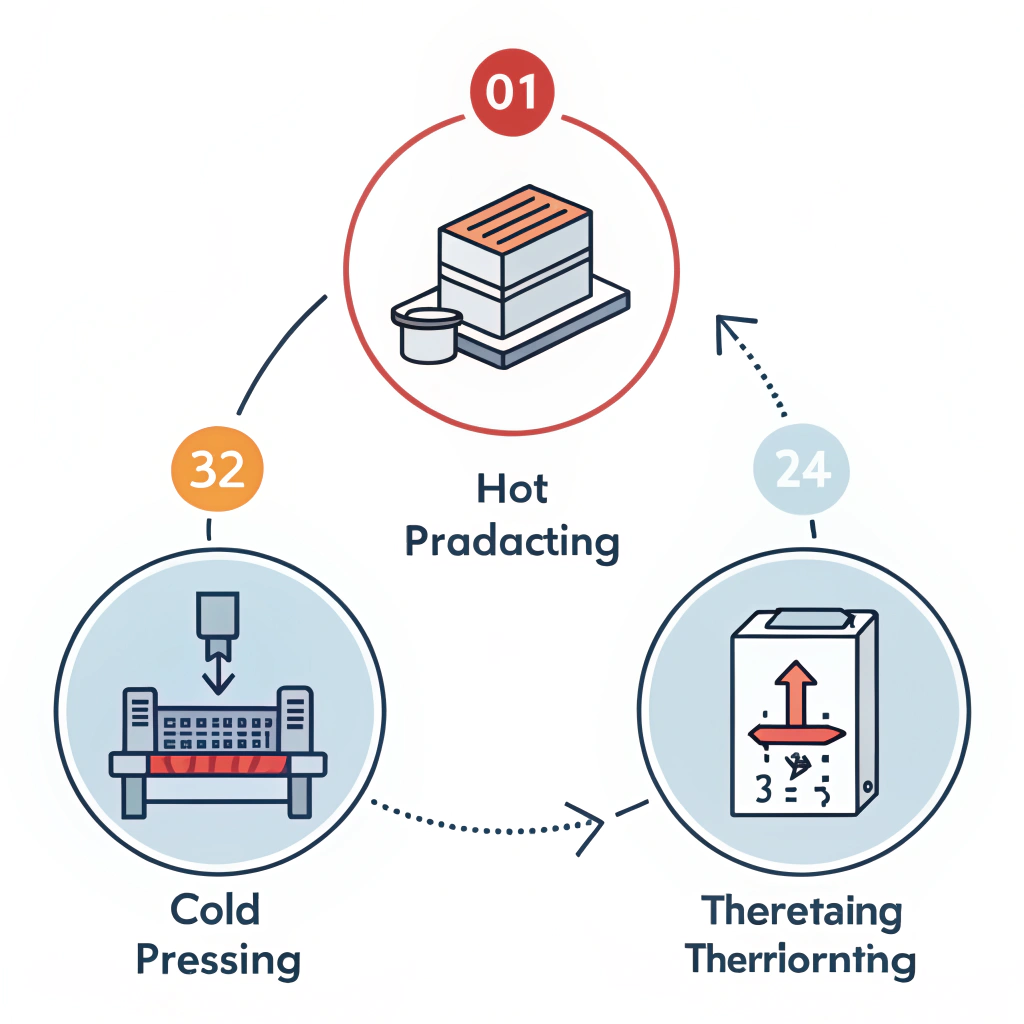

Paddle shapes are inherently tied to the manufacturing processes used to create them. The three most common production techniques are hot pressing1, cold pressing2, and thermoforming3. Each method presents its own set of advantages and challenges when it comes to shaping the paddle and ensuring quality control.

Hot pressing1 involves heating the materials and applying pressure to create a solid, uniformly shaped paddle.

- Advantages:

- High production efficiency

- Strong and durable paddles

- Excellent impact resistance

- Disadvantages:

- Potential alteration of material properties

- High equipment costs

Cold pressing2 is performed at room temperature, which allows for precise control over the paddle’s thickness and structure.

- Advantages:

- Superior control over design dimensions

- Retains material properties for better ball feel

- Ideal for delicate designs requiring precision

- Disadvantages:

- Longer production cycles

- Requires highly calibrated machinery

Thermoforming3 involves heating materials to their softening point and shaping them with molds, making it ideal for complex designs and custom shapes.

- Advantages:

- Enables intricate designs with precise material distribution

- Maintains structural stability

- Suitable for premium custom-made paddles

- Disadvantages:

- Longer production time

- Higher costs in terms of equipment and mold creation

By understanding these processes, B2B buyers can better evaluate which production method aligns with the desired paddle shape and overall performance characteristics.

The differentiation of pickleball paddles goes beyond just the shape—it encompasses weight, materials, and ergonomic considerations. Here are some key factors to assess:

Heavier paddles generally provide more power on impact, whereas lighter paddles offer increased control and better maneuverability. Most paddles on the market are designed to be within the 7 to 9 oz range, although specialty paddles may vary from 6 to 14 oz. This weight variance can largely impact the swing and overall performance, particularly for players with different strength levels.

The choice of materials (such as carbon fiber, fiberglass, or various composites) directly influences the paddle’s durability, responsiveness, and feel. For example:

- 3K Carbon Fiber delivers strength and flexibility.

- 12K Carbon Fiber offers a smoother surface and improved impact resistance.

- T300 Carbon Fiber4 strikes a balance between strength and lightweight performance.

- Fiberglass and mixed composites provide unique benefits for control and ball feel, which are especially important in wide-body designs.

The handle length and grip configuration significantly affect the paddle’s usability. A short handle may benefit those who prefer close control and a rapid swing, while a long handle can enhance reach and power. In niche market variations where the handle length is adjusted relative to the paddle’s body size, the result is a customized play experience that caters to particular gaming styles.

For procurement specialists, evaluating paddle shapes is not only about performance but also about cost efficiency and brand differentiation. Here are some considerations:

-

Manufacturing Efficiency vs. Customization:

Streamlined production methods such as hot pressing1 deliver high-volume output efficiently, making them perfect for standard shapes. However, if a paddle design necessitates intricate shapes and superior aesthetic appeal (often required in high-end or custom paddles), thermoforming3 might be the preferred method despite its higher costs. -

Material Costs:

Premium materials such as T300 Carbon Fiber4 or specialized composite cores come at a higher price point but can justify the investment if they result in enhanced player performance and durability. When approaching markets that demand both performance and cost-effectiveness, an ideal paddle may use a combination of materials—like a blend of carbon fiber and fiberglass—to strike a balance between performance upgrades and budget constraints.

- Standard vs. Niche Markets:

In standard markets where the majority of players seek balanced performance, the classic standard shape remains optimal. However, some markets—such as professional or specialty segments—may look for performance enhancements that drive the adoption of elongated or hybrid paddle shapes. - Customization Potential:

With capabilities for on-demand printing and custom designs, selecting a paddle shape that supports personalized branding and player-specific ergonomics can provide a competitive edge in B2B negotiations.

Below is a table summarizing the cost-performance attributes associated with different paddle shapes:

| Paddle Shape | Manufacturing Process Suitability | Material Options | Cost-Performance Consideration |

|---|---|---|---|

| Standard | Hot Pressing or Cold Pressing | Various composites | Best for balanced performance and mass production |

| Elongated | Cold Pressing (for precision) | Premium carbon fibers | Ideal for players stressing reach and quick swings |

| Wide-Body | Thermoforming (for complexity) | Fiberglass, Composites | Maximizes control with a larger sweet spot |

| Hybrid Variations | Thermoforming with custom molds | Combination materials | Niche customization with specific performance attributes |

This detailed comparison helps B2B buyers understand that paddle shape selection is not merely aesthetic. The decision influences manufacturing strategy, material selection, and ultimately the paddle’s performance in the market.

To sum up, the variety of pickleball paddle shapes—from the classic standard design to more specialized elongated, wide-body, and hybrid variations—each brings unique performance characteristics that can be leveraged to meet different market demands. The production process plays a crucial role in shaping (in both literal and figurative terms) the final product quality and efficiency. By carefully balancing manufacturing method selections and material choices, companies can design paddles that not only meet but exceed market expectations.

For B2B buyers, the key action steps include:

- Assessing market needs and player preferences to determine which paddle shape best aligns with your product strategy.

- Evaluating production processes in terms of cost efficiency and design precision.

- Considering material options that support the desired performance characteristics while remaining cost-effective.

- Exploring customization options that offer a competitive edge in branding and performance differentiation.

By integrating these insights into your procurement and product development strategy, your next move can be both innovative and grounded in market realities—ensuring that your paddle offerings are tailored to the evolving demands of pickleball enthusiasts worldwide.

People Also Ask

Q1: What are the different shapes of pickleball paddles?

A1: Pickleball paddles come in various shapes including the short/widebody design with a short handle, elongated paddles with long handles, and hybrid forms that mix features of both. The most popular shapes are the standard, elongated, and wide-body, each offering different benefits regarding power, control, and ergonomics.

Q2: What are the three types of pickleball paddles?

A2: The three primary types of pickleball paddles are the standard (balanced design), elongated (narrow body with extended reach), and wide-body (larger hitting surface) paddles. Each type is suited to different playing styles and performance needs.

Q3: How to differentiate pickleball paddles?

A3: Differentiation is largely based on weight, material composition, and shape design. Heavier paddles tend to offer more power while lighter paddles provide better maneuverability. Key differences also include the design of the handle, the size of the hitting surface, and the production methods used, all of which affect performance and user comfort.

-

hot pressing: Click to learn more about hot pressing techniques and how they enhance manufacturing efficiency for sports equipment. Back to top ↩ ↩2 ↩3

-

cold pressing: Click to learn about cold pressing, its advantages in maintaining material integrity, and its role in precision manufacturing processes. Back to top ↩ ↩2

-

thermoforming: Click to explore thermoforming, a method ideal for creating complex shapes and custom designs, and its impact on production workflows. Back to top ↩ ↩2 ↩3

-

T300 Carbon Fiber: Click to gain insights into T300 Carbon Fiber, its properties, and why it's a popular choice for balancing strength with lightweight performance in sports equipment. Back to top ↩ ↩2