Custom Pickleball Paddle manufacturing empowers businesses to deliver high-performance, uniquely designed paddles by leveraging advanced production techniques and premium materials. This article compares the key material technologies and production processes available for custom paddle manufacturing, helping you decide on the optimal solution to enhance product performance and brand differentiation.

For companies looking to differentiate their sporting goods line, offering a custom-designed pickleball paddle can be a game changer. The unique combination of premium materials, precise manufacturing processes, and tailored design specifications ensures that each paddle maximizes performance, durability, and aesthetic appeal. However, bringing together these variables can be challenging. It requires an in-depth understanding of:

- Material Properties: Differences in carbon fiber types, fiberglass, and composites.

- Production Techniques: The nuances between hot pressing, cold pressing, and thermoforming.

- Performance Targets: Balancing rebound force, vibration reduction, and ergonomic design.

- Customization Options: Enabling brand personalization, such as custom colors, logos, and even laser engraving.

At NEX Pickleball, these challenges are met by employing state-of-the-art technologies and a flexible production mindset. Our approach provides a clear decision-making framework for procurement managers and product development specialists.

A significant element in custom paddle design is selecting the right materials. Each material comes with unique performance characteristics that cater to particular playing styles and competitive needs. Below is a detailed look at the materials you might consider:

Carbon Fiber1 Options

Carbon Fiber1 is a favorite among serious players for its durability and rebound properties. The three common types include:

- 3K Carbon Fiber: Known for its strength and flexibility, 3K reduces vibration during play while offering excellent durability.

- 12K Carbon Fiber: With a higher thread density, it provides a smoother surface and greater hardness, making it ideal for competitive play.

- T300 Carbon Fiber: Valued for its superior tensile strength, it gives a balanced mix of lightweight performance and strength.

Each variant allows you to fine-tune the paddle’s performance, balancing power and control.

Fiberglass2 Advantages

While carbon fiber focuses on strength and rebound, Fiberglass2 offers a broader sweet spot and enhanced ball control. By incorporating fiberglass, the paddle gains flexibility and an improved feel, which is essential for players who rely on quick reflexes and precision.

Composite constructions combine the best attributes of different materials to create a paddle that meets specific performance targets. Common composite solutions include:

- Carbon Fiber and Fiberglass Composite: This union offers both the strength of carbon fiber and the controlled elasticity of fiberglass.

- Bamboo Core Composite: Using bamboo cores contributes to a lightweight yet impact-resistant paddle.

- Honeycomb Core: Generally made from high-density polymer or pulp, these cores offer superior shock absorption and vibration reduction.

By selecting the right composite, manufacturers can optimize parameters such as weight distribution, impact resistance, and handling.

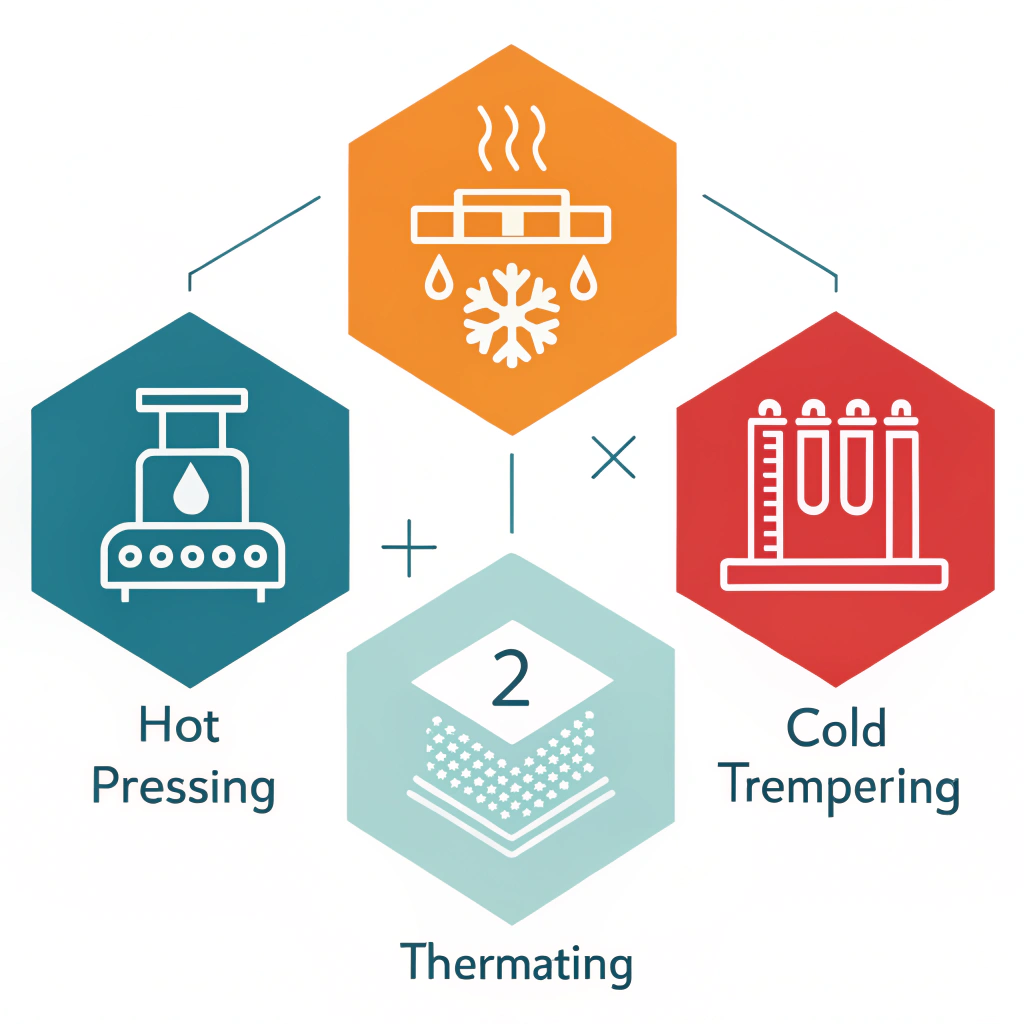

Analyzing Production Techniques: Hot Pressing, Cold Pressing, and Thermoforming4

The choice of production process is as important as the material selection itself. Each manufacturing approach affects the paddle’s final performance, durability, and feel. Below is a comparative analysis:

| Production Process | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Produces strong, impact-resistant paddles - Ensures good structural integrity | - May alter some material properties impacting feel - Requires high initial investment in equipment | Large-scale manufacturing, performance paddles needing extra strength |

| Cold Pressing | - Precise control over paddle thickness and structure - Maintains material properties for excellent control - Enhances ball feel and responsiveness | - Longer production cycles - Demands high-quality precision equipment | Niche products requiring detailed control and tailored performance |

| **Thermoforming4 | - Allows for intricate designs and precise material distribution - Maintains paddle stability - Ideal for complex designs | - Higher equipment costs - Requires longer production time | Premium or custom-made paddles with specific design requirements |

This table offers a quick reference for decision-makers to align their production needs with the most suitable process.

Selecting an OEM5 partner like NEX Pickleball is critical when aiming for high-quality custom pickleball paddles. Consider the following factors when making your decision:

-

Expertise in Material Science: Our extensive experience with carbon fiber, fiberglass, and composites ensures that every paddle is crafted with precision and tailored performance. For example, using 12K Carbon Fiber or T300 Carbon Fiber can be a competitive advantage for high-force impacts during play.

-

Advanced Production Techniques: We offer a range of production methods including hot pressing, cold pressing, and thermoforming. This flexibility permits the use of the best available technology to suit the specific design and performance requirements.

-

Customization Capabilities: NEX Pickleball provides extensive customization options. This includes not only the choice of materials and production process but also design elements such as custom colors, logos, and even personalized engravings. These options ensure the final product reflects your brand’s identity and meets competitive performance standards.

-

Quality and Consistency: Each paddle undergoes rigorous testing to ensure it meets high durability and performance standards. Our commitment to quality control has bolstered our reputation, making us a trusted OEM partner for brands like Joola and Selkirk.

-

Lead Times and On-Demand Services: Efficient production cycles, combined with on-demand printing services, ensure that custom orders are met swiftly and accurately. This is especially important in dynamic competitive markets where time-to-market is crucial.

Leveraging advanced production techniques and premium materials, companies can innovate and deliver products that provide tangible performance improvements on the court. This strategy not only meets the technical requirements but also builds a strong brand narrative around quality and high performance.

Several sporting goods companies have successfully partnered with custom manufacturers to enhance their product line’s innovation and performance. For instance, one brand improved its market presence by launching a series of paddles featuring both carbon fiber and fiberglass composites, optimized for power and control. With the use of thermoforming production methods, they were able to push the design boundaries by incorporating intricate ergonomic features that improved player comfort without sacrificing durability.

In another scenario, a well-known retailer relied on cold pressing techniques to produce paddles with a unique balance of stiffness and flexibility. This approach not only improved control during fast-paced play but also offered an enhanced tactile experience, leading to higher consumer satisfaction and repeated sales.

These case examples further emphasize the importance of aligning material choices and production processes to the intended end-user experience. In competitive B2B environments, such capable customization underpins the development of products that stand out in the crowded sports equipment market.

When deciding on a custom manufacturing solution for pickleball paddles, several action points and recommendations can help guide your investment:

- Evaluate Material Trade-Offs: Ensure that you compare the performance benefits between different carbon fiber types, fiberglass, and composite materials. Use comparative tables and prototype testing data to support your decision.

- Consider Production Efficiency and Scale: If you have a high-volume order, production techniques such as hot pressing might be more cost-effective despite the high initial investment. For smaller batches or designs requiring intricate detailing, cold pressing or thermoforming might yield better outcomes.

- Assess Customization Depth: Understand the depth of customization available. It is not just about adjusting colors or adding logos; look at structural customizations that can maximize performance, such as varying core compositions or adjusting the paddle’s weight distribution.

- Leverage OEM Expertise: Partnering with an experienced manufacturer like NEX Pickleball can significantly reduce risks associated with technical design and manufacturing errors. Our track record with premium suppliers reinforces the reliability of our production processes.

- Plan for Future Innovations: Ensure that your manufacturing partner has the flexibility to adapt to evolving design trends and technological advancements. This foresight is crucial not just for immediate production needs but also for long-term competitiveness.

To summarize, selecting the right materials, production techniques, and customization options is key to delivering a pickleball paddle that not only meets but exceeds player expectations. A carefully evaluated custom solution results in a high-performance product poised to secure a competitive edge in both recreational and professional markets.

In the competitive world of sports equipment, custom pickleball paddles represent an opportunity to combine technical excellence with unique brand identity. By comparing advanced materials such as carbon fiber, fiberglass, and composites, and evaluating production techniques like hot pressing, cold pressing, and thermoforming, decision-makers can identify the best option for their specific needs.

NEX Pickleball’s commitment to precision, innovation, and quality makes us an ideal partner for businesses seeking to offer a superior custom paddle design. With robust OEM partnerships, on-demand printing capabilities, and an agile manufacturing process, our solutions are crafted to enhance both performance and market success.

We encourage procurement managers and product development specialists to conduct thorough evaluations, consider the outlined recommendations, and choose a manufacturing partner that aligns with your strategic vision. The right custom manufacturing decision not only meets performance requirements but also paves the way for significant brand differentiation and increased customer satisfaction.

Can I design my own pickleball paddle?

Yes, you can design your own pickleball paddle by selecting custom images, logos, and text for both the front and back. Many manufacturers also offer design assistance to help refine your vision, while you can choose custom colors for different paddle components.

Can I write on my pickleball paddle?

Handwritten markings are allowed on your pickleball paddle as long as they are applied with a pen and do not affect the paddle’s surface texture or playability. Stick to tasteful markings that preserve the paddle’s optimal performance.

Can you engrave a pickleball paddle?

Absolutely. Personalized paddles often include options for laser engraving on the paddle face or customizing the end cap. You can add your name, a slogan, or even a small design element to make your paddle unique.

-

Carbon Fiber: Click to learn how carbon fiber’s unique properties, such as exceptional strength and lightweight characteristics, enhance performance in sports equipment manufacturing. ↩ ↩ ↩2

-

Fiberglass: Click to explore the advantages of fiberglass, including its flexibility and improved ball control for precision sports applications. ↩ ↩ ↩2

-

Composite Materials: Click to understand how composite materials combine different elements for optimized performance, balancing durability, weight distribution, and impact resistance. ↩ ↩

-

Thermoforming: Click to dive into thermoforming—an advanced production technique that allows for intricate designs and precise material distribution, crucial for custom manufacturing. ↩ ↩ ↩2

-

OEM: Click to discover the benefits of partnering with an Original Equipment Manufacturer (OEM), including streamlined production processes, quality control, and the scalability needed for B2B operations. ↩ ↩