Quick Answer: Gen 4 pickleball paddles represent the latest generation in paddle design, emphasizing a 100% foam core1 coupled with advanced manufacturing techniques—hot pressing2, cold pressing3, and thermoforming4—to deliver unparalleled performance, durability, and player comfort.

In today’s competitive sports equipment market, B2B procurement managers and technical buyers are continually challenged to identify innovative solutions that provide both performance and durability. The evolution from earlier paddle generations to Generation 4 (Gen 4) has introduced significant advances in paddle core construction and surface materials. In this article, we explore how Gen 4 paddles leverage advanced manufacturing techniques and premium materials to outperform previous generations and meet the rigorous demands of competitive play.

Traditionally, paddle design has evolved through several generations:

- Gen 0 (Wood Era): Heavy and rigid, these paddles were constructed from natural wood with minimal technological input.

- Gen 1 (Basic Honeycomb Paddles): Introduction of polymer honeycomb cores marked the shift towards lighter and more responsive designs.

- Gen 2 (Thermoformed Honeycomb Paddles): Hot-pressed, thermoformed designs began to incorporate foam edge walls and carbon fiber unibody constructions.

- Gen 3 (Foam-Enhanced Paddles): Enhanced by foam injection or adhesion techniques, these paddles combined various internal core materials such as honeycomb, ribs, and stringers to improve performance.

- Gen 4 (100% Foam Core): The latest generation, which employs 100% foam cores, is engineered using advanced processes to optimize weight distribution, reduce vibration, and significantly enhance player control and durability.

The leap from Gen 3 to Gen 4 illustrates a major technological shift—focusing solely on foam core technology—which allows manufacturers to fine-tune paddle characteristics with unprecedented precision.

In the manufacturing sector for sports equipment, technical buyers often face the following challenges:

- Balancing performance enhancements with durability in high-volume production.

- Integrating innovative materials such as carbon fiber (3K, 12K, T300), fiberglass, and composite combinations while maintaining cost-efficiency.

- Ensuring product consistency across various production processes.

- Adapting to rapidly evolving technological standards and consumer expectations.

For B2B buyers, it is essential to understand how advanced manufacturing processes can directly impact product quality and end-user satisfaction. Gen 4 paddle production directly addresses these challenges through innovative material adoption and diversified production processes.

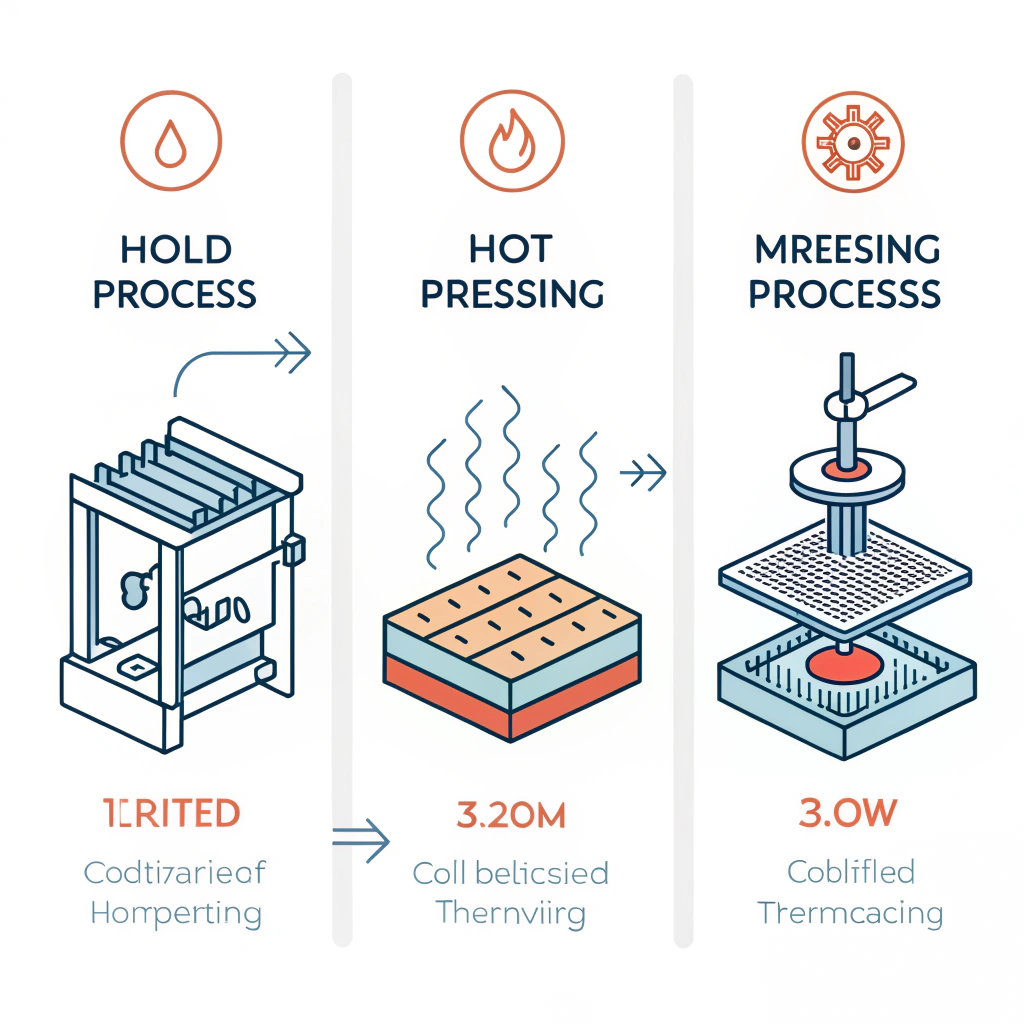

To fully appreciate Gen 4 paddles, it is crucial to understand the primary production methods used to manufacture them. NEX Pickleball employs three main production processes—hot pressing, cold pressing, and thermoforming—each contributing unique benefits to paddle performance.

Hot pressing involves heating materials and applying pressure to form a solid, durable structure. This method is suitable for large-scale production where speed and strength are prioritized.

- Key Advantages:

- High production efficiency

- Strong impact resistance and durability

- Consistent structural integrity for high-level play

- Limitations:

- Potential alteration in material properties affecting paddle feel

- High initial equipment investment

Cold pressing shapes the paddle material at room temperature using mechanical pressure. This technique is used when precise control over paddle thickness and internal structure is required.

- Key Advantages:

- Maintains the intrinsic properties of high-performance materials

- Precise thickness and weight distribution control

- Enhanced ball feel and responsiveness

- Limitations:

- Longer production cycles

- Requires high-precision equipment for quality control

Thermoforming involves heating the material to a softening point before molding it into intricate designs. This method is ideal for producing paddles with complex geometries and precise material distribution.

- Key Advantages:

- Allows for innovative paddle shapes and designs

- Improved stability through even material distribution

- Suitable for premium, custom-made paddles

- Limitations:

- Longer production time and higher costs

- Best suited for high-end products rather than budget options

The following table offers a quick comparison of these three manufacturing processes:

| Process | Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency; strong structure; durable | Material properties may change; high equipment cost |

| Cold Pressing | Precise control; retains material properties; enhanced responsiveness | Longer cycle; precision equipment required |

| Thermoforming | Intricate designs; uniform material distribution | Slower production; higher overall cost |

A major driver behind Gen 4 paddle performance is the integration of advanced materials. These materials are selected based on their mechanical properties and their ability to contribute to overall paddle performance.

Carbon Fiber5 Varieties

Carbon fiber is used in different forms:

- 3K Carbon Fiber: Offers a good balance between strength and flexibility, reducing vibration and providing excellent durability.

- 12K Carbon Fiber: Provides a higher thread density for a smoother surface, increased hardness, and superior impact resistance—ideal for competitive play.

- T300 Carbon Fiber: Known for its high tensile strength, combining lightweight with robustness for a balanced performance.

Fiberglass paddles provide enhanced ball control due to their elasticity and tensile strength. Additionally, composite materials such as carbon fiber combined with fiberglass, bamboo core composites, and honeycomb cores further optimize performance:

- Bamboo Core Composite: Delivers a lightweight and impact-resistant structure, ensuring a clear hitting feel.

- Nomex Honeycomb Core: Offers excellent shock absorption for enhanced stability.

- Aluminum and Polymer Honeycomb Cores: Balance power, control, and vibration reduction.

These materials are critical for ensuring that Gen 4 paddles offer a superior combination of power, control, and durability essential for both recreational and high-level competitive play.

One of the standout characteristics of Gen 4 paddles is the adoption of a 100% foam core. This innovation marks a significant departure from previous generations, where foam was only a component among various core materials. The benefits of a full foam core are manifold:

- Enhanced Vibration Dampening: The 100% foam core absorbs shock more effectively, reducing vibration and providing a smoother striking surface.

- Improved Weight Distribution: A homogeneous foam structure allows for precise control over paddle balance, ensuring that the paddle feels light in hand yet powerful in play.

- Customizable Feel and Performance: Manufacturers can adjust the density and elasticity of the foam to tailor the paddle’s hitting feel to various playing styles—ranging from soft, controlled rebounds to powerful, high-speed responses.

The Gen 4 paddle’s performance advantages are particularly significant for competitive players who demand precision and consistency. By eliminating the variation introduced by mixing materials in the core, manufacturers like NEX Pickleball can offer products that maintain their performance characteristics even under intense gameplay conditions.

To help illustrate the evolution from earlier generations to Gen 4, consider the following table outlining the key differences:

| Generation | Core Composition | Key Characteristics |

|---|---|---|

| Gen 0 | Wood | Heavy, stiff, low performance |

| Gen 1 | Polymer Honeycomb | Lighter weight, basic performance |

| Gen 2 | Thermoformed Honeycomb with foam edge walls | Improved performance with added foam detailing |

| Gen 3 | Foam-Enhanced (combined materials) | Enhanced responsiveness, inclusion of various fillers |

| Gen 4 | 100% Foam Core | Superior vibration dampening, precise control, enhanced customization |

This comparison not only highlights technological advancements but also the evolving expectations of players and manufacturers in the modern sports equipment market.

For B2B managers and technical buyers evaluating the capabilities of suppliers like NEX Pickleball, the combination of advanced production techniques (hot pressing, cold pressing, thermoforming) with innovative material choices is a key differentiator. Here are actionable insights for B2B decision-makers:

- Evaluate Production Consistency: Ensure that the supplier has robust quality control processes to maintain consistency in every batch, a crucial aspect when transitioning from mixed-material cores to a homogenous foam core design.

- Consider Customization Flexibility: A supplier offering on-demand production and customization (e.g., specific grip sizes, tailored weight distributions) can better meet the diverse needs of your end-customers.

- Review Material Specifications: Understanding material benefits, such as the differences between 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber, allows you to better predict the paddle’s performance under various play conditions.

- Adopt a Holistic Evaluation: Use side-by-side comparisons of production techniques and material innovations to assess overall product quality. This approach minimizes the risks associated with adopting new technologies and ensures a smoother integration into your product portfolio.

Consider a scenario where a sports equipment distributor is looking to differentiate its product portfolio in a saturated market. By partnering with a manufacturer that produces Gen 4 paddles employing a 100% foam core, the distributor can:

- Offer paddles with enhanced vibration dampening for longer gameplay sessions.

- Market the product as technologically advanced, backed by data on improved weight distribution and superior durability.

- Leverage customization options to align with team branding and individual player preferences.

This case not only reflects the practical benefits of Gen 4 technology but also underscores the importance of aligning product features with market demands.

The transition to Generation 4 paddle production marks a significant milestone in pickleball paddle technology. By adopting a 100% foam core and integrating advanced manufacturing techniques, suppliers can deliver products that offer:

- Superior vibration control and consistent ball response.

- Precisely engineered weight distribution for optimal player performance.

- Enhanced durability, ensuring longevity even under rigorous use.

For B2B procurement managers and technical buyers seeking to bolster their product portfolios, it is essential to:

- Prioritize suppliers with proven expertise in advanced materials and production processes.

- Consider the benefits of a homogenous foam core in delivering a reliable, high-performance product.

- Evaluate overall manufacturing capabilities, from process control to customization, to ensure alignment with market needs.

By focusing on these factors, decision-makers can confidently invest in products that not only meet current technical standards but also provide a competitive edge in an increasingly performance-driven industry.

What is the difference between Gen 3 and Gen 4 pickleball paddles?

Gen 4 paddles differ from Gen 3 by utilizing a 100% foam core rather than a mixed-material core. This results in improved vibration dampening, more consistent weight distribution, and enhanced control during play.

How to tell the difference in pickleball paddles?

The differences in pickleball paddles are primarily determined by the materials and construction methods. Modern paddles typically use advanced composites and precise manufacturing techniques, resulting in a larger sweet spot, improved durability, and better performance compared to older, cheaper models.

What are the different generations of pickleball paddles?

Pickleball paddle evolution begins with Gen 0, which used wood, followed by Gen 1 with basic polymer honeycomb cores. Gen 2 introduced thermoformed honeycomb paddles with added foam features, Gen 3 incorporated foam enhancement coupled with varied internal structures, and Gen 4 is distinguished by its 100% foam core, offering superior performance and consistency.

-

100% foam core: Reading the article provides insight into the benefits of using a homogeneous foam core design in paddle manufacturing, including enhanced vibration dampening and consistent weight distribution. ↩

-

hot pressing: Reading the article explains how hot pressing uses heat and pressure to form durable, high-integrity structures in large-scale production. ↩

-

cold pressing: Reading the article describes cold pressing as a process that shapes materials at room temperature, ensuring precise control over paddle thickness and internal structure. ↩

-

thermoforming: Reading the article discusses thermoforming, a method that heats a material to mold intricate designs and achieve even material distribution for innovative paddle shapes. ↩

-

Carbon fiber: Reading the article details various forms of carbon fiber used in paddle production and explains how each variety contributes to performance improvements. ↩