Advanced manufacturing techniques, such as custom UV printing1 and advanced production processes, have revolutionized the creation of premium pickleball paddles. These techniques enhance both performance and brand differentiation by ensuring superior quality, design precision, and durability.

The pickleball market continues to grow, and distributors and branded merchandise companies face increasing competition. To stand out, businesses are turning to advanced manufacturing methods, such as custom UV printing and edgeless paddle designs2, to create a truly differentiated product. A premium paddle is not just a tool for the game—it is a statement of quality and innovation, tailored precisely for players and brands. In this article, we explore the manufacturing innovations from NEX Pickleball, highlighting how custom UV printing, combined with superior materials and innovative designs, meets the high demands of B2B procurement specialists.

In today’s competitive sports equipment market, quality and customization are equally essential. Many distributors ask: Why invest in advanced manufacturing when competitors are offering standard options? The answer lies in the tangible benefits of techniques like custom UV printing and edgeless designs. Let’s break down some of the common challenges:

- Material Selection: Ensuring the paddle uses high-performance materials while maintaining comfort.

- Customization: Meeting brand-specific design requirements without sacrificing performance.

- Production Efficiency: Balancing the intricacies of custom designs with the need for large-scale production.

- Durability and Precision: Maintaining structural integrity while offering advanced design features.

- Cost-Effectiveness: Integrating premium techniques without excessively inflating the cost.

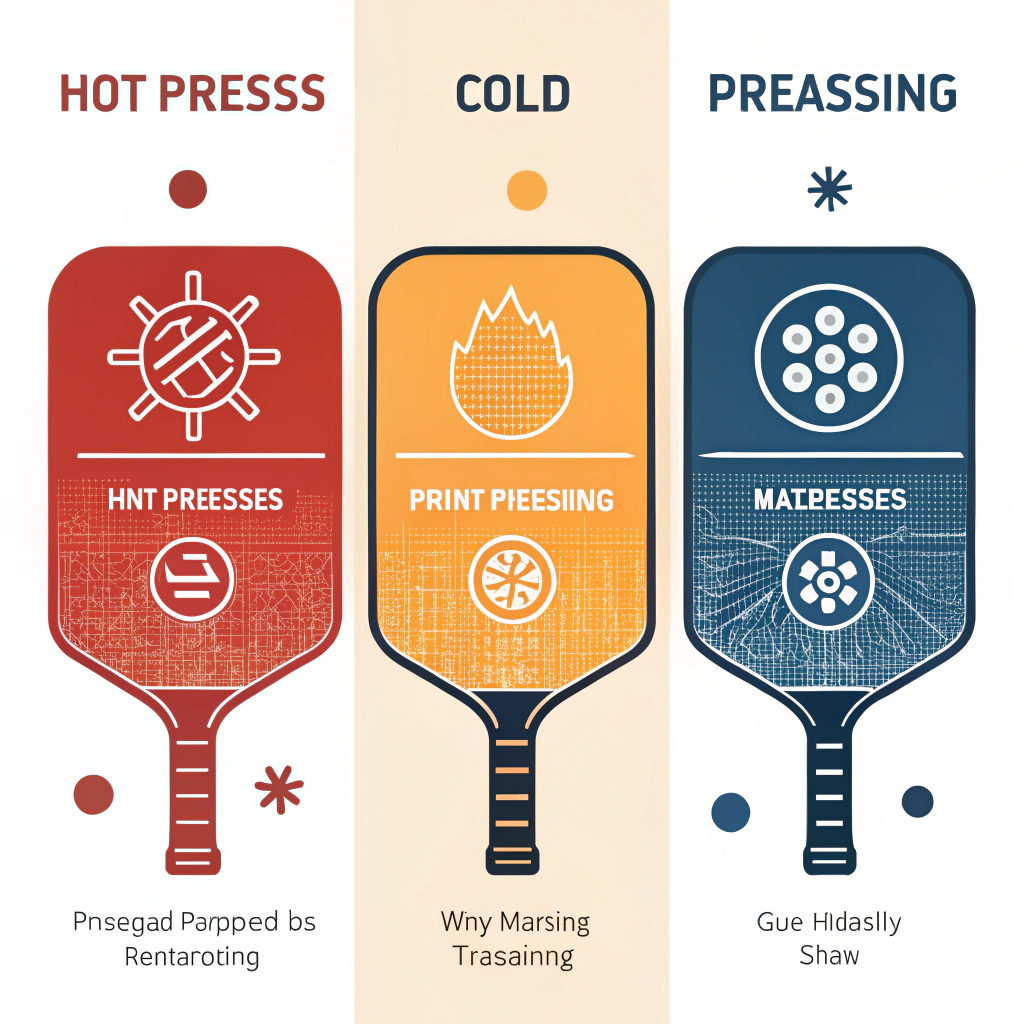

These challenges necessitate a strategic approach to manufacturing, where each process—whether hot pressing, cold pressing, or thermoforming—is evaluated in terms of its technical merits and ability to support creative customization.

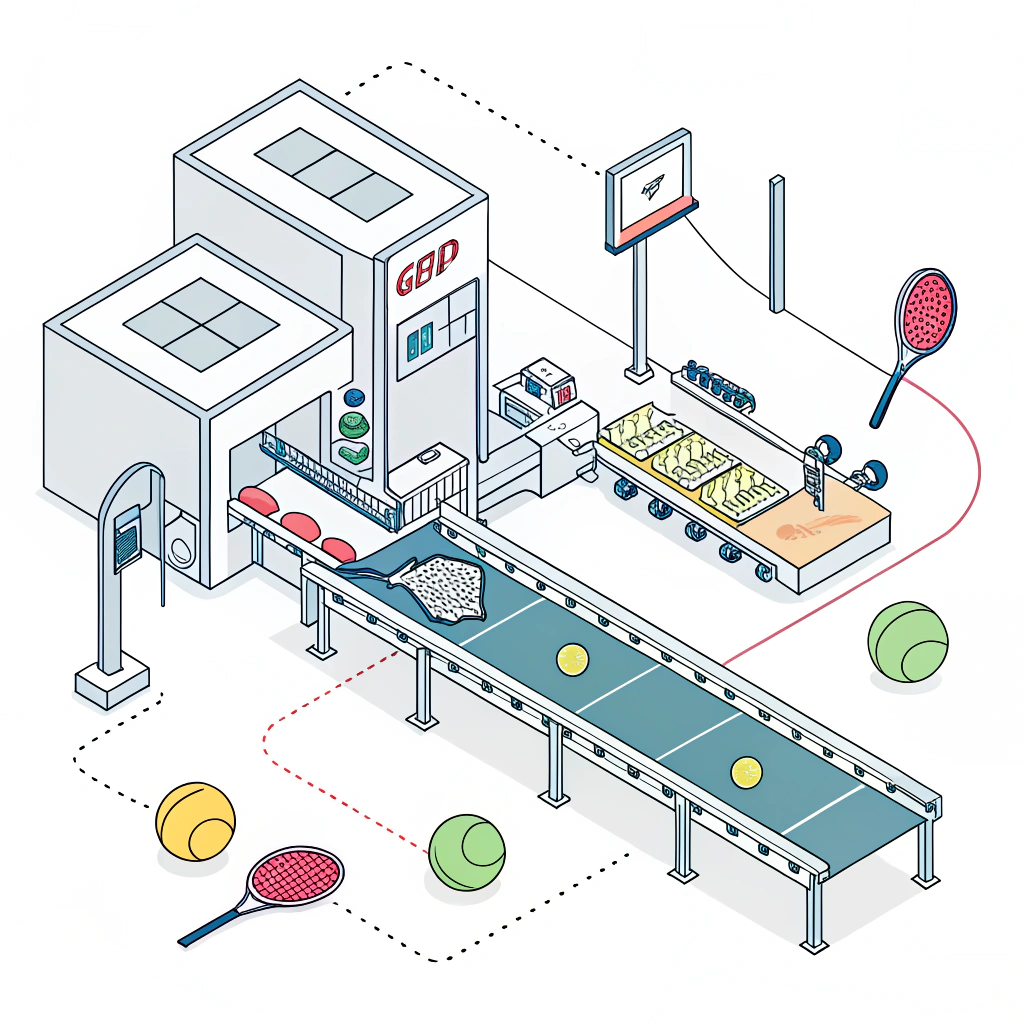

At NEX Pickleball, our manufacturing process is designed to address these challenges head-on. We employ three primary production techniques, each offering unique benefits:

Hot pressing involves heating the composite materials and applying consistent pressure. This process results in paddles with excellent impact resistance and is compatible with high-volume production.

-

Advantages:

- High production efficiency for large-scale orders.

- Robust paddle strength and improved impact resistance.

- Enhances material bonding and overall durability.

-

Disadvantages:

- Alters some material properties, potentially affecting the tactile feel.

- Requires significant capital investment in specialized equipment.

Cold pressing shapes the paddle at room temperature using mechanical pressure. This approach is ideal for achieving precise dimensions and retaining the natural properties of the materials.

-

Advantages:

- Precision in controlling paddle thickness and structure.

- Preserves the inherent flexibility and feel of the materials.

- Provides excellent control and ball responsiveness.

-

Disadvantages:

- Longer production cycles compared to hot pressing.

- Requires high precision in pressure control, which can slow down output.

Thermoforming involves heating the materials until they soften, then molding them into the desired shape. This method allows for intricate designs that might not be achievable through other processes.

-

Advantages:

- Enables complex and innovative paddle designs.

- Ensures stability and performance by precisely distributing material thickness.

- Allows the creation of custom shapes tailored to specific brand requirements.

-

Disadvantages:

- Longer production times and increased equipment costs.

- Best suited for premium products or custom order scenarios.

Below is a comparative table summarizing these processes:

| Production Process | Key Benefits | Limitations | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency; robust impact resistance | May alter material feel; high equipment cost | Large-scale, durable paddles |

| Cold Pressing | Precision control; retains material properties | Longer production cycle; requires high precision | Custom, tactically controlled paddles |

| Thermoforming | Complex designs; precise material distribution | Increased production time; higher cost | Premium, custom-designed paddles |

Custom UV printing has become indispensable in customizing pickleball paddles for branding and visual appeal. This printing technique offers several significant benefits for B2B buyers:

-

Enhanced Customization:

Custom UV printing provides the ability to print high-resolution logos, images, and intricate patterns directly on the paddle surface. This increases brand recognition and offers a new revenue stream through personalized sports gear. -

Durability and Precision:

The UV curing process solidifies the ink almost instantly, ensuring that the design remains intact even under the stress of competitive play. This durability is crucial when the paddle is used in high-impact situations. -

Aesthetic Appeal:

With vivid colors and sharp detailing, UV printed paddles catch the eye, making them ideal for both promotional activities and competitive branding. The technology supports both matte and glossy finishes, catering to different style preferences. -

Integration with Advanced Materials:

UV printing does not compromise the paddle’s performance. The process is compatible with advanced carbon fiber4, fiberglass, and composite materials, ensuring that the paddle maintains its structural integrity and performance characteristics.

The flexibility of UV printing means businesses can offer both standard and fully-customized designs. This capability allows distributors to meet a wide range of client demands, from limited-edition series to long-term branded merchandising alliances.

Another innovative trend in paddle manufacturing is the edgeless design. This design minimizes the traditional borders of a paddle, delivering several key advantages:

-

Increased Maneuverability:

Edgeless paddles often provide a more refined and balanced playing surface. The absence of a pronounced edge can lead to better shot variety, as it allows for smoother transitions and adjustments during play. -

Enhanced Visual Appeal:

A continuous surface without clear-cut edges offers a sleek, modern look that appeals to both amateur and professional players. It embodies a high level of craftsmanship and design ingenuity. -

Custom Banding Options:

When paired with custom UV printing, edgeless designs offer limitless potential for unique branding. Companies can integrate logos and patterns seamlessly across the surface, enhancing overall aesthetics and market differentiation. -

Considerations for Advanced Players:

While edgeless designs can benefit most, advanced players may prefer the protective qualities and sweet spot enhancements offered by edged paddles. Thus, the choice between edgeless and edged designs should align with player preference and game style.

This design innovation combines function with advanced aesthetics. It signals that a product isn’t just about performance—it’s about the overall experience and brand story conveyed through its design.

The selection of materials is critical in achieving both durability and performance. At NEX Pickleball, we focus on a broad range of materials, each offering unique benefits:

- 3K Carbon Fiber:

Offers excellent flexibility and strength, ideal for paddles that need high rebound force with reduced vibration. - 12K Carbon Fiber:

Provides a smoother finish, greater hardness, and superior durability—favored in competitive environments. - T300 Carbon Fiber:

Balances strength and light weight, making it perfect for players seeking a highly responsive paddle.

Each carbon fiber type ensures that paddles deliver optimal performance tailored to different styles of play and player experience levels.

- E-Glass Fiberglass:

Known for its elasticity and extensive sweet spot, it combines power with control seamlessly. - Composite Materials:

Often involve combining carbon fiber with fiberglass for enhanced balance between strength and flexibility. Materials like Bamboo Core Composite5 or Honeycomb Core (made from high-density polymer) are used to further reduce vibration while delivering a crisp hitting experience.

Below is a simplified table summarizing the core components and their advantages:

| Material Type | Key Features | Benefits | Ideal For |

|---|---|---|---|

| 3K Carbon Fiber | Strength, flexibility, vibration reduction | Enhanced rebound force | Competitive play with quick reflexes |

| 12K Carbon Fiber | Smoother surface, hardness, durability | Superior impact resistance | High-impact competitive play |

| T300 Carbon Fiber | Balanced performance, light weight | Quick maneuverability | All-round performance |

| E-Glass Fiberglass | Elasticity, wider sweet spot | Improved ball control | Versatile players |

| Composite Materials | Combination of carbon fiber and fiberglass | Best of both worlds | Customized brand-specific paddles |

| Bamboo/Honeycomb Core | Impact absorption, lightweight structure | Reduced vibration, crisp feel | Long-lasting durability |

For procurement specialists evaluating manufacturing partners, it is vital to consider both the technical performance and the branding potential of the final product. NEX Pickleball excels in offering:

-

Tech-Forward Manufacturing:

Incorporating hot pressing, cold pressing, and thermoforming allows us to tailor the paddle production to meet specific functional and aesthetic requirements. -

State-of-the-Art Customization:

Our collaboration with renowned brands like Joola and Selkirk proves our capability to serve high-end markets. Combined with custom UV printing, we deliver paddles that are not only high performing but also visually striking. -

On-Demand Printing Services:

The ability to integrate on-demand printing services ensures that brand logos and designs are applied accurately and consistently. This flexibility supports small batch orders or fully customized series, crucial in today’s fast-paced market where trends can shift rapidly. -

Quality Control and Consistency:

Rigorous testing regimes and proven production processes help maintain the highest quality standards. From precise weight distribution to ergonomic grip design and tailored surface treatment, every paddle is engineered for optimal performance. -

Customization at Scale:

Whether it’s for a local sports club or a national retailer, our manufacturing process is designed to scale while keeping cost-effectiveness at the forefront. This balance makes our paddles a compelling option for B2B partners looking to differentiate their product portfolios with technical innovation and branding excellence.

Based on our extensive experience, here are a few actionable recommendations for distributors and procurement specialists:

-

Identify Your Target Market:

Ensure that your paddle offerings align with the skill levels and preferences of your end-users. For instance, consider edgeless designs for brands emphasizing modern aesthetics, while edged paddles might be preferred for traditional performance enhancement. -

Leverage Customization:

Use custom UV printing to incorporate branding elements that resonate with your clientele. This can include everything from unique color schemes to detailed graphics that emphasize exclusivity. -

Prioritize Material Integrity:

Assess the key performance metrics of the materials used, such as carbon fiber variants or composite cores. The right selection can considerably enhance the paddle performance, giving your brand a competitive edge in quality and durability. -

Evaluate Production Techniques:

Work with manufacturers who offer a blend of technological innovations. Understanding whether hot pressing, cold pressing, or thermoforming best aligns with your design needs is crucial in achieving the optimal balance between aesthetics and functionality. -

Ensure Robust Quality Control:

Partnering with manufacturers who employ rigorous testing and consistent quality standards will reduce risk and ensure that every paddle meets the premium standards expected by your distributors and end-users.

Each recommendation aims to provide a comprehensive strategy that spans technical engineering to market positioning. By integrating advanced manufacturing methods with robust customization capabilities, B2B buyers can secure premium products that translate into long-term customer satisfaction and brand loyalty.

Advanced manufacturing techniques, such as custom UV printing and innovative edgeless designs, are turning the tide in the premium pickleball paddle market. At NEX Pickleball, we harness the best in material science and production processes—whether hot pressing, cold pressing, or thermoforming—to create paddles that do not compromise on performance or aesthetics. Our approach offers a versatile, high-quality solution tailored to the specific needs of both competitive players and brand-enhancing distributors. As a procurement specialist or product manager, selecting a partner with robust technical expertise and customizable options is crucial to meeting market demands. Embrace these innovations to deliver products that not only excel in performance but also enhance your brand’s market appeal.

Q: Is an edgeless pickleball paddle better?

A: Edgeless paddles offer improved maneuverability and a refined playing surface that can enhance shot variety. However, while they provide a sleek design and modern aesthetics, edged paddles may offer extra protection and a larger sweet spot. The choice depends on player preference and performance needs.

Q: Who makes the best quality pickleball paddles?

A: Leading brands such as Joola, Selkirk, CRBN, and Gearbox are known for their superior quality paddles. These companies offer a range of innovative designs and materials. However, manufacturers like NEX Pickleball, with advanced processes and custom UV printing, also deliver premium performance for competitive markets.

Q: Does an expensive pickleball paddle make a difference?

A: Higher-end paddles often utilize advanced materials like carbon fiber, raw carbon, and fiberglass, which can enhance control, power, and spin. While the cost can correlate with advanced technology and durability, it is important to select a paddle that best meets the specific performance needs rather than simply opting for the most expensive option.

-

custom UV printing: Click to understand how this printing technology enables high-resolution, durable prints that enhance branding and product customization in manufacturing. ↩

-

edgeless paddle designs: Click to learn more about edgeless designs, which offer modern aesthetics and improved maneuverability by minimizing traditional paddle borders. ↩

-

Thermoforming: Click to explore thermoforming processes, a method used to mold materials into complex shapes for innovative product designs. ↩

-

advanced carbon fiber: Click for insights into advanced carbon fiber materials, explaining their strength, flexibility, and role in high-performance sports equipment. ↩

-

Bamboo Core Composite: Click to discover the benefits of Bamboo Core Composite materials, which help reduce vibration and enhance the durability of premium sports equipment. ↩