Advanced production techniques in pickleball paddle manufacturing mean that high-performance, durable, and customizable equipment is available to meet your specific OEM1 and private label2 needs. NEX Pickleball leverages processes like hot pressing, cold pressing, and Thermoforming3 combined with diverse high-quality materials such as carbon fiber4 and fiberglass5 to optimize balance, control, and longevity.

In today's competitive sports equipment market, decision-makers must carefully compare manufacturing processes and material choices to deliver products that stand out. As procurement and product development managers, you seek not only competitive pricing but also superior quality that drives consumer satisfaction and brand reputation. With NEX Pickleball’s state-of-the-art production methods and innovative materials, you can confidently offer customized pickleball paddles that meet both performance and strategic branding requirements.

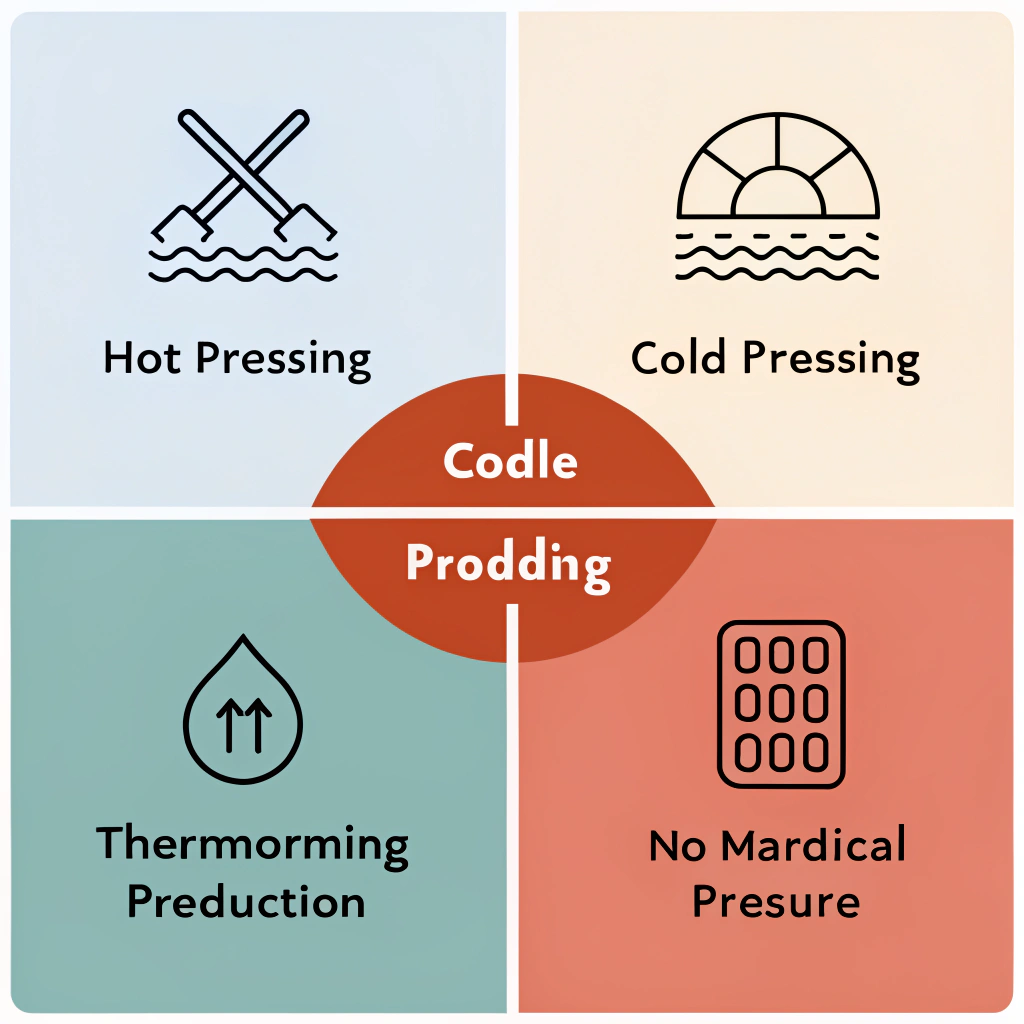

Selecting the right production method is a decisive factor in achieving the ideal combination of durability, playability, and precise control. At NEX Pickleball, we offer three main production techniques:

-

Hot Pressing

This technique uses heat and pressure to meld materials into a cohesive, high-strength structure. The advantages include:- High production efficiency suited for large-scale manufacturing.

- Superior impact resistance ensuring long-lasting performance.

- Structural stability vital for competitive gameplay.

However, hot pressing may slightly modify material properties, which can affect the tactile feel of the paddle.

-

Cold Pressing

This method shapes materials at room temperature using mechanical pressure, preserving the original properties:- Enhanced precision in controlling paddle thickness and overall structure.

- Better maintenance of material integrity results in improved ball feel.

- Offers a delicate balance between flexibility and control, ideal for players demanding quick responses.

The drawback is that cold pressing usually results in longer production cycles and demands high-precision equipment.

-

Thermoforming

Materials are heated to a softening point and then molded into intricate shapes:- Suitable for producing paddles with complex designs and varied thickness.

- Ensures even material distribution, improving overall paddle stability.

- Ideal for premium, custom-made paddles with high-performance demands.

Despite its benefits, thermoforming is associated with higher equipment costs and longer manufacturing times.

Below is a table summarizing the pros and cons of each process:

| Production Process | Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency, strong structure, excellent impact resistance | Potential alteration of material feel, high equipment cost |

| Cold Pressing | Precise control, maintains material properties, excellent ball feel | Longer production cycles, requires precision equipment |

| Thermoforming | Intricate design capability, uniform material distribution, great stability | Higher cost, longer production time |

The materials used in paddle construction are paramount to the paddle’s performance and durability. At NEX Pickleball, we strategically select—and sometimes combine—several premium materials to create paddles that excel under various play conditions.

Carbon fiber4 is a favorite among competitive players due to its high strength-to-weight ratio and resilience. We offer several types:

- 3K Carbon Fiber: Offers excellent flexibility with high rebound force. It is ideal for situations needing strong impact resistance while reducing vibration.

- 12K Carbon Fiber: With a denser thread structure, 12K creates a smoother paddle surface. This variant delivers increased hardness and durability, making it perfect for high-intensity play.

- T300 Carbon Fiber: Highly prized for its tensile strength, T300 enables a balanced mix of lightweight and robustness, ensuring quick maneuverability and precision.

For players who value a balanced relationship between power and control, fiberglass5 offers a wider sweet spot and enhanced durability:

- E-Glass Fiberglass: Provides excellent elasticity and ball control, giving players a good feel during every stroke.

We also blend materials to harness the best of each. For instance:

- Carbon Fiber and Fiberglass Composite: Combines the strength and lightness of carbon fiber with the flexibility of fiberglass, delivering incredible balance and performance.

- Bamboo Core Composite: Uses bamboo’s lightweight yet impact-resistant properties, allowing for a crisp, clear hitting feel.

- Honeycomb Core: Designed from high-density polymers, these cores absorb shocks effectively and minimize vibration, which extends the paddle's durability.

In the competitive sports equipment landscape, customization is essential for differentiating your product. NEX Pickleball not only offers superior base materials and advanced production techniques but also provides extensive design personalization options that cater to specific market and branding needs.

- Design and Weight Balance: Tailor the paddle's weight to ensure optimal balance and maneuverability.

- Ergonomic Grip Design: Choose from a variety of grip sizes to enhance comfort and reduce fatigue during long matches.

- Surface Texture Modifications: Enhance ball control and spin through specially treated surfaces.

- Branding and Color Customizations: Align the paddle design with client branding, which is essential for private label products or team sports merchandise.

These options empower distributors to create products that truly resonate with their end-users, ultimately boosting consumer satisfaction and retention. The flexibility extends from standard production runs to bespoke, on-demand print services tailored for unique project requirements.

Quality assurance in our manufacturing process is non-negotiable. Every paddle, irrespective of the production method or material choice, undergoes stringent testing procedures to meet international performance standards. Our testing covers:

- Durability Testing: To ensure that the paddle consistently handles high-intensity impacts.

- Impact and Shock Absorption: Measuring how well the paddle dissipates force to reduce user strain.

- Balance and Weight Distribution Evaluations: Confirming that each paddle delivers the optimum playing experience.

- Ergonomic Grip Testing: Ensuring that the design is comfortable over prolonged use.

These rigorous quality control measures guarantee that every product delivered not only meets but often exceeds the expectations of professional and recreational players alike.

When comparing OEM and private label solutions, it's essential to understand both the advantages and potential trade-offs:

- Scalability: Higher production volumes, significant for large-scale distribution.

- Consistent Quality: Our advanced production techniques ensure uniform quality across all units.

- Customization Depth: Although customization is available, OEM might lean towards standardization to maintain efficiency.

- Brand Differentiation: Fully customizable to reflect your brand’s unique identity.

- Tailored Designs: Adapt designs to meet specific market requirements and consumer trends.

- Flexibility: Offers a unique selling proposition, particularly in niche markets where brand identity is key.

While both models offer distinct benefits, your final decision should factor in market positioning, target consumer expectations, and production timeline requirements. Below is a quick comparison:

| Attribute | OEM Manufacturing | Private Label Solutions |

|---|---|---|

| Production Volume | High | Moderate to High |

| Customization Flexibility | Standard customization | Full design and branding control |

| Time-to-Market | Faster due to standardization | May require additional design phase |

| Brand Differentiation | Limited | Strong |

This comparison should help you gauge which approach aligns better with your procurement strategy and market goals.

For procurement managers in the sports equipment industry, making the right manufacturing and material decisions is key to competitive differentiation. Here are some action recommendations:

-

Assess Your Brand’s Needs:

Define whether your product requires advanced customization or can benefit from large-scale OEM production. Consider factors like expected market demand and brand identity. -

Compare Quality Metrics:

Review the production process details and material innovations available with NEX Pickleball. Our rigorous testing data and performance benchmarks provide you with transparent insights. -

Schedule a Consultation:

Engage with our technical experts to discuss how our advanced production techniques can align with your strategic needs. Whether you need detailed specifications for carbon fiber variants or insights into ergonomic design adjustments, we are here to help. -

Consider Long-Term Partnerships:

Establishing a partnership with a manufacturer that prioritizes innovation, quality, and customization ensures that your products will consistently meet evolving market demands.

By following these steps, you can ensure that your product offerings stand at the forefront of the sports equipment industry, backed by proven technology and exceptional craftsmanship.

Q1: What are the benefits of using advanced production techniques in pickleball paddle manufacturing?

A1: Advanced production techniques such as hot pressing, cold pressing, and thermoforming allow for superior material bonding, consistent quality control, and the creation of intricate designs. These methods enhance paddle durability, impact resistance, and overall performance—key factors for both OEM and private label products.

Q2: What is the difference between hot pressing and cold pressing processes in paddle production?

A2: Hot pressing involves applying heat and pressure to create a strong, durable bond among materials, making it efficient for mass production. Cold pressing, by contrast, uses mechanical pressure at room temperature to preserve the original material properties, resulting in superior control over paddle thickness and enhanced ball feel.

Q3: How does customization impact product performance in pickleball equipment?

A3: Customization allows for tailored adjustments in design, weight distribution, grip size, and surface treatment, ensuring that the paddle meets specific player requirements. This results in improved ergonomics, better control, and a more distinctive market identity, especially for private label and branded products.

-

OEM: Reading the article will provide insights into the original equipment manufacturer model, which streamlines production and ensures consistent quality for large-scale distribution. ↩ ↩

-

private label: Click here to learn how private label production offers full customization to reflect your brand’s unique identity and capture niche market opportunities. ↩ ↩

-

Thermoforming: Learn how thermoforming, a heat-based molding process, enables intricate design capabilities and uniform material distribution for premium paddle production. ↩ ↩

-

carbon fiber: Discover more about carbon fiber, a high-strength, lightweight material that enhances performance and durability in high-end sports equipment. ↩ ↩ ↩2

-

fiberglass: Explore the benefits of fiberglass, noted for its durability and flexibility, which helps in delivering balanced performance in paddle construction. ↩ ↩ ↩2