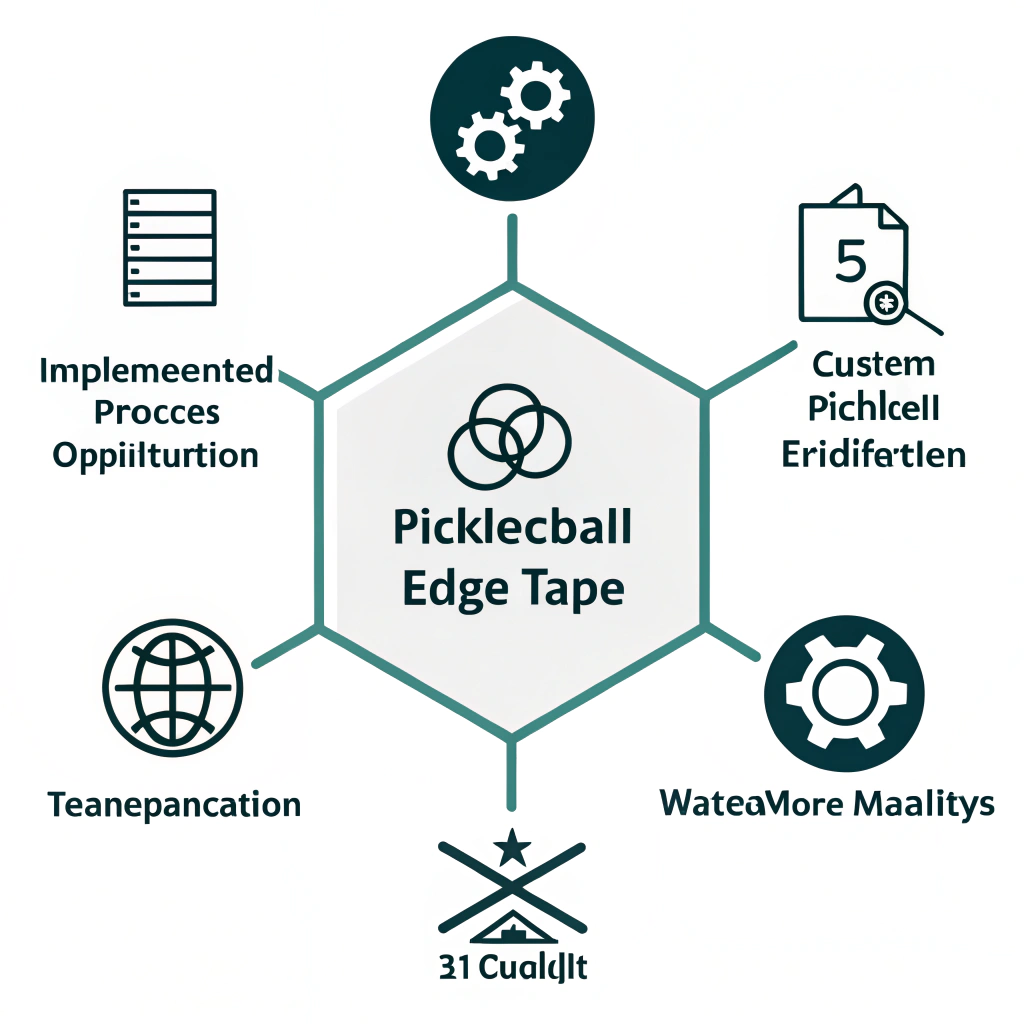

Custom Pickleball Edge Tape provides premium edge protection while offering opportunities for custom branding. In short, it enhances paddle durability, improves adhesive performance1, and allows sports distributors to differentiate their products through tailored design options.

In the competitive world of pickleball, every component of a paddle matters. When it comes to edge protection, even seemingly minor details can affect performance and longevity. Custom pickleball edge tape is designed to guard the paddle edges against wear and tear, prevent delamination, and provide an attractive surface for branding. However, selecting the correct tape isn’t as straightforward as choosing any off-the-shelf option. Decision-makers must evaluate material engineering2, adhesive properties, UV resistance3, and design adaptability to maintain performance and capture brand identity.

Manufacturers and distributors face several common challenges when it comes to edge tape for pickleball paddles:

- Material Degradation: Over time, exposure to sunlight, moisture, and rigorous play can degrade standard tapes, reducing their adhesive quality and physical integrity.

- Suboptimal Adhesion: Tape that loses its stick or fails to adhere properly results in peeling, increasing the risk of damage to the paddle.

- Limited Customization: Reusable or pre-cut tapes often limit branding possibilities, a critical factor for clubs and distributors seeking a unique product identity.

- Cost-Efficiency vs. Performance: Balancing production cost while maintaining high-quality standards is a challenge that demands engineering innovation.

These issues underscore the need for a tailored approach when selecting and manufacturing custom pickleball edge tape.

For sports equipment distributors and pickleball clubs, the choice of edge tape must include a blend of performance and adaptability. An ideal custom edge tape should incorporate the following technical characteristics:

-

Adhesive Performance:

- High-tack adhesives ensure that the tape remains securely in place under high impact and variable temperature conditions.

- Optimal release properties during application, ensuring a smooth installation process.

-

UV Resistance:

- UV-stable materials that resist discoloration and degradation, maintaining performance and aesthetic appeal over time.

-

Durability and Flexibility:

- Materials engineered to resist fraying and wear while offering enough flexibility to conform to paddle curves without compromising strength.

- The use of adhesive formulations that balance performance and long-term durability under repetitive impacts.

-

Customization Capabilities:

- Ability to incorporate on-demand printing, ensuring that custom logos, sponsor names, or vibrant patterns can be integrated seamlessly.

- Design variability that supports a range of thickness options and color customizations to meet specific performance and branding needs.

A detailed technical specification comparison of common tape materials is provided in the table below:

| Key Feature | Standard Edge Tape | Custom High-Performance Tape | Notes |

|---|---|---|---|

| Adhesive Quality | Moderate adhesion | Premium high-tack adhesive | Ensures optimal grip during play |

| UV Resistance | Often low protection | UV-stable and colorfast materials | Critical for outdoor usage |

| Durability | Prone to wear over time | Engineered for long lifecycle | Enhanced resilience through new polymers |

| Custom Branding | Limited customization | Fully customizable with on-demand printing | Allows integration of logos and designs |

| Flexibility | Basic flexibility | Optimized for paddle curves | Improves installation and performance |

Production Processes and Quality Control4

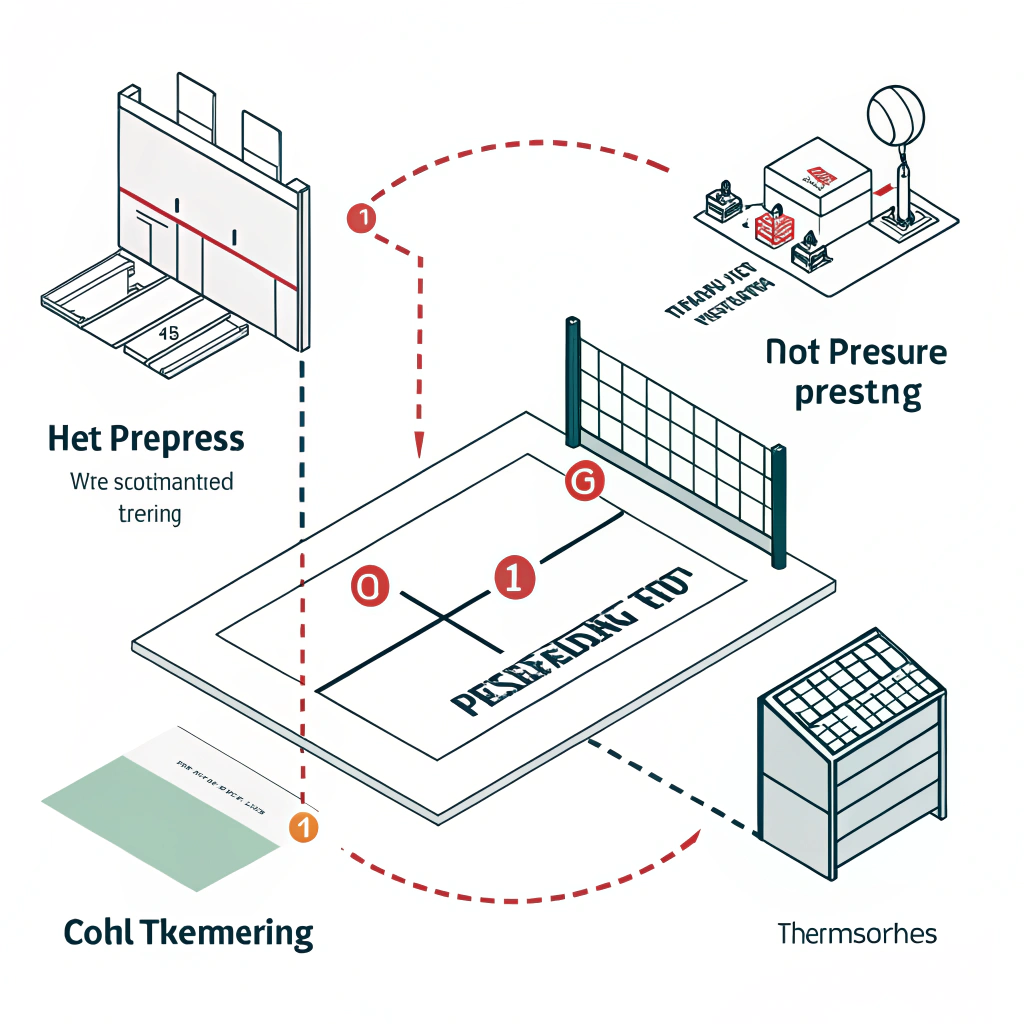

Choosing the right edge tape involves understanding the production processes and quality control methods used during manufacturing. At NEX Pickleball, our advanced production techniques ensure that every tape meets stringent quality standards. Below are the key processes involved:

- Process: Heat and pressure are applied to bond tape material layers.

- Advantages:

- High production efficiency.

- Strong and durable bond suitable for high-impact scenarios.

- Disadvantages:

- May impact some material properties.

- Requires significant equipment investment.

- Process: Material is shaped at room temperature, ensuring that inherent material properties are maintained.

- Advantages:

- Precise control over tape thickness and alignment.

- Maintains the original flexibility and adhesive quality.

- Disadvantages:

- Longer production cycle decreases overall efficiency.

- Necessitates high-quality mechanical pressure systems.

- Process: Materials are heated to create pliable structures, which are then molded into shape.

- Advantages:

- Enables complex tape designs that perfectly follow the paddle edge contour.

- Offers improved stability and enhanced performance in premium products.

- Disadvantages:

- Requires extended production times.

- Includes higher equipment costs.

These methods ensure that the custom pickleball edge tape not only delivers superior performance protection but also adheres to the high standards demanded by competitive play. Implementing robust quality control measures such as periodic adhesion testing, UV exposure trials, and flexibility tests ensures that each batch of tape meets our exacting specifications.

A primary advantage of choosing a custom edge tape is the ability to integrate bespoke branding into the design. This is particularly important for sports equipment distributors and pickleball clubs looking to create a unique identity. Key customization options include:

-

On-Demand Printing:

Custom logos, taglines, contact information, and graphics can be printed directly on the tape. This solidifies brand presence and increases consumer recognition. -

Color Options and Material Finishes:

Multiple color options offer versatility in branding, ensuring that the edge tape complements the overall design of the paddle. Matte or glossy finishes may also be selected depending on branding requirements. -

Tailored Dimensions:

The tape can be engineered into various widths and thicknesses to suit different paddle models and performance criteria. This ensures optimal edge protection without compromising the paddle’s balance or ergonomics. -

Adhesive Adjustments:

Customization isn't merely aesthetic; altering adhesive properties to match regional climate conditions or usage patterns provides improved performance consistency.

By offering these tailored solutions, distributors can differentiate their products in competitive markets while meeting the rigorous demands of performance and durability.

Balancing cost efficiency with high-performance standards is critical in competitive B2B sports equipment manufacturing. Custom pickleball edge tape solutions are designed to provide long-term value by reducing frequent replacement needs and avoiding downtime during tournament play. Consider the following strategies:

-

Bulk Production Benefits:

Producing custom tape in bulk lowers individual unit cost while ensuring consistency in quality and performance. -

Long-Term Durability:

Although advanced materials and production processes may initially increase costs slightly, the extended lifecycle and reduced maintenance needs offset these expenses. -

Competitive Pricing Models:

Strategic partnerships and volume discounts enable distributors to offer competitively priced custom edge tape without compromising on quality. -

Integrated Supply Chain:

By refining our production processes and leveraging on-demand printing, we can adapt quickly to market demands and supply chain changes, ensuring timely delivery and reducing logistical overhead.

The following table summarizes cost and performance considerations:

| Factor | Traditional Edge Tape | Custom Premium Edge Tape | Impact |

|---|---|---|---|

| Unit Cost | Lower initial cost | Slightly higher upfront | Custom tape offers better long-term cost efficiency |

| Durability | Moderate lifespan | Extended lifecycle | Fewer replacements and less downtime |

| Performance Reliability | Varies by application | Consistent high-performance | Improved player experience |

| Branding Flexibility | Limited customization | Fully customizable | Enhanced market differentiation |

| Production Efficiency | Standard methods | Integrated advanced processes | Faster turnaround for bulk orders |

For optimal integration of custom edge tape into your product lineup or sports equipment inventory, consider the following best practices:

-

Evaluation of Material Specifications:

Assess the specific requirements of your target market, such as environmental conditions (e.g., UV exposure, moisture levels) and usage frequency, to choose the most appropriate tape with tailored adhesive and durability properties. -

Prototype Testing and Iterative Improvements:

Before full-scale production, prototype batches should be subjected to rigorous testing under simulated play conditions. This allows for iterative improvements based on real-world feedback, ensuring the final product meets both technical and branding specifications. -

Collaboration with Manufacturing Partners:

Work closely with a partner that possesses advanced manufacturing capabilities—like the hot and cold pressing and thermoforming techniques used at NEX Pickleball—to ensure that production scales smoothly and consistently. This collaboration also supports on-demand customization, aligning production with brand-led initiatives. -

Quality Assurance and Performance Reporting:

Establish a quality control framework that includes regular performance reporting and testing cycles. Use feedback from field tests to refine material properties and adhesive formulations, ensuring that each roll of custom edge tape delivers reliable performance. -

Marketing and Co-Branding Initiatives:

Leverage the customization aspect by integrating co-branding initiatives in your marketing strategy. This can involve promotional offers, limited edition designs, or partnerships with local clubs and tournaments to enhance brand loyalty and recognition.

Following these best practices ensures that your investment in custom pickleball edge tape not only meets technical standards but also aligns with strategic branding and cost efficiency goals.

In summary, custom pickleball edge tape is more than just a protective accessory—it’s a critical performance component that can be fully customized to support branding, improve durability, and optimize game performance. By carefully analyzing material properties, production processes, and cost-performance indicators, sports equipment distributors and clubs can make informed procurement decisions that boost both product quality and market differentiation.

Key action points include:

- Conduct detailed evaluations of adhesive performance, UV resistance, and durability.

- Collaborate with experienced manufacturers offering advanced production processes.

- Leverage on-demand printing and customization options to create unique, market-leading products.

- Implement rigorous quality control and continuous improvement protocols.

By taking these steps, decision-makers can ensure that their custom edge tape not only meets performance requirements but also elevates their brand’s presence in the competitive pickleball market.

People Also Ask

Q: What is the best edge tape for pickleball paddles?

A: The best edge tape for pickleball paddles is one that combines premium adhesive performance, UV resistance, and durability with customization options. For example, advanced options like those offered by Paddlesshop Premium Paddle Edge and No-Brand Edge Tape A (Pre-Cut Designs) are excellent, as they enhance paddle lifespan and gameplay experience.

Q: What is the difference between a pickleball overgrip and grip?

A: A pickleball overgrip is designed to provide enhanced moisture-wicking and “stickiness” for improved feel, whereas a replacement grip focuses on restoring basic grip integrity without offering the same variety of textures or additional performance benefits.

-

Adhesive Performance: Click to read an in-depth explanation on the properties of high-tack adhesives and how they enhance the reliability and durability of sports equipment. ↩

-

Material Engineering: Click to learn about the engineering principles behind material selection and design optimization that ensure optimal performance under varying conditions. ↩

-

UV Resistance: Click to understand the importance of UV-stable materials in preventing degradation and maintaining the aesthetic appeal and performance of sports equipment. ↩

-

Quality Control: Click to discover how rigorous quality control measures and testing protocols ensure consistent product performance and reliability. ↩

-

Thermoforming: Click to explore the thermoforming process and its role in creating complex, durable designs that conform to specific product contours. ↩