Custom branded pickleball paddle sets offer an effective solution for companies seeking unique promotional sports merchandise. They provide superior quality, high-performance features, and customizable branding options that enhance both marketing efforts and corporate gifting initiatives.

In today’s competitive market, businesses are increasingly turning to high-quality sports equipment as a way to solidify brand identity and impress clients. Custom branded pickleball sets not only capture attention but also deliver performance on the court. At NEX Pickleball, we understand the challenges of sourcing products that meet both aesthetic and functional requirements, and we have streamlined our manufacturing processes to ensure that every paddle stands up to rigorous corporate standards.

Many companies face similar hurdles when considering custom sports equipment for branding purposes. The key challenges include:

• Ensuring product quality and consistent manufacturing processes

• Balancing performance with aesthetic appeal

• Meeting tight production timelines for bulk orders

• Customizing each element from grip size to surface texture for optimum player experience

These aspects significantly influence purchasing decisions, especially in the B2B sector where brand integrity and supply chain efficiency are paramount.

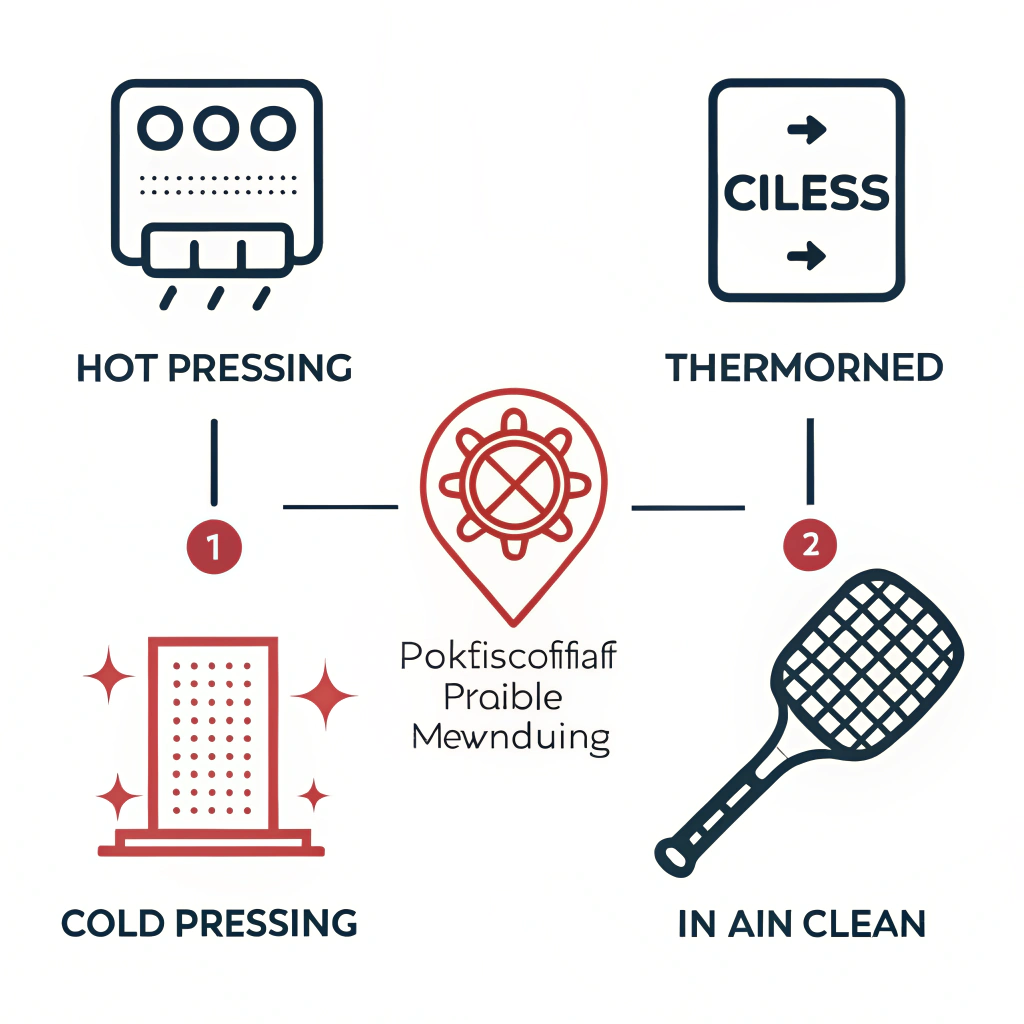

At NEX Pickleball, we utilize three main production processes—each tailored to different product requirements—to ensure that every paddle meets high standards. Below is a comparative table that outlines the advantages and limitations of each method:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; produces durable paddles with excellent impact resistance; ensures strong structural integrity | Can alter some material properties; requires high investment in specialized equipment |

| Cold Pressing | Offers precise control over paddle thickness and structure; preserves material properties for better control and flexibility; enhances ball feel and responsiveness | Longer production cycles; demands precise pressure control, increasing equipment costs |

| Thermoforming1 | Ideal for creating intricate designs and ensuring precise material distribution; maintains paddle stability; perfect for premium products or custom orders | Longer production times; higher equipment costs; best suited for high-end products |

This table clearly shows that each process has its merits. Choosing the right technique depends on the paddle’s intended use—whether for high-impact competitive play or for promotional corporate events.

For purchasing managers and marketing executives, the ability to imprint logos, taglines, and custom designs on sports equipment is crucial. Our Custom Logo Pickleball Set offers extensive options such as:

• Custom Printed Paddles: Utilize on-demand printing2 capabilities to incorporate vibrant, detailed logos or slogans that stand out.

• Branded Paddle Set: Perfect for corporate gifting, these paddle sets turn everyday sporting equipment into moving advertisements for your brand.

• Promotional Sports Merchandise: Combine quality with artistry—each paddle is engineered for superior performance while representing your unique brand identity.

The process involves close collaboration with our clients to understand their specific branding needs. We then tailor the paddle's design elements, ensuring that every detail from grip size to finishing touches aligns perfectly with your corporate image.

Understanding the material composition of a pickleball paddle is essential for ensuring both performance and durability. Our selection of premium materials includes:

• Carbon Fiber Options:

- 3K Carbon Fiber3: Known for its strength and flexibility, it minimizes vibration and offers high rebound force.

- 12K Carbon Fiber: Provides a smoother surface with outstanding hardness and impact resistance, ideal for competitive play.

- T300 Carbon Fiber: Balances outstanding tensile strength with light weight, ensuring athletes receive both power and control.

• Fiberglass:

- E-Glass Fiberglass4: Offers versatility with excellent elasticity and tensile strength, leading to a broader sweet spot and enhanced ball control.

• Composite Materials:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials for a balanced performance.

- Bamboo Core Composite: Offers a lightweight impact resistance along with a natural and appealing aesthetic.

- Honeycomb Core: Provides superior shock absorption and stability, reducing vibration and extending paddle life.

Each of these materials is chosen based on specific performance needs and production objectives, ensuring that our paddles remain reliable whether used for corporate events or competitive sports.

Quality control lies at the heart of our manufacturing process. At NEX Pickleball, each paddle undergoes rigorous testing to verify:

- Structural Integrity: Ensuring all paddles can withstand high-impact scenarios while retaining their form.

- Precision in Design: Confirming that the paddle maintains precise weight distribution and optimized surface texture for improved playability.

- Branding Accuracy: Ensuring that custom logo placements and printed designs meet client specifications down to the finest detail.

By adhering strictly to these quality protocols, we guarantee that every custom branded paddle that leaves our factory upholds the highest standards. This level of attention is especially important when fulfilling bulk orders where consistency and reliability are absolutely crucial.

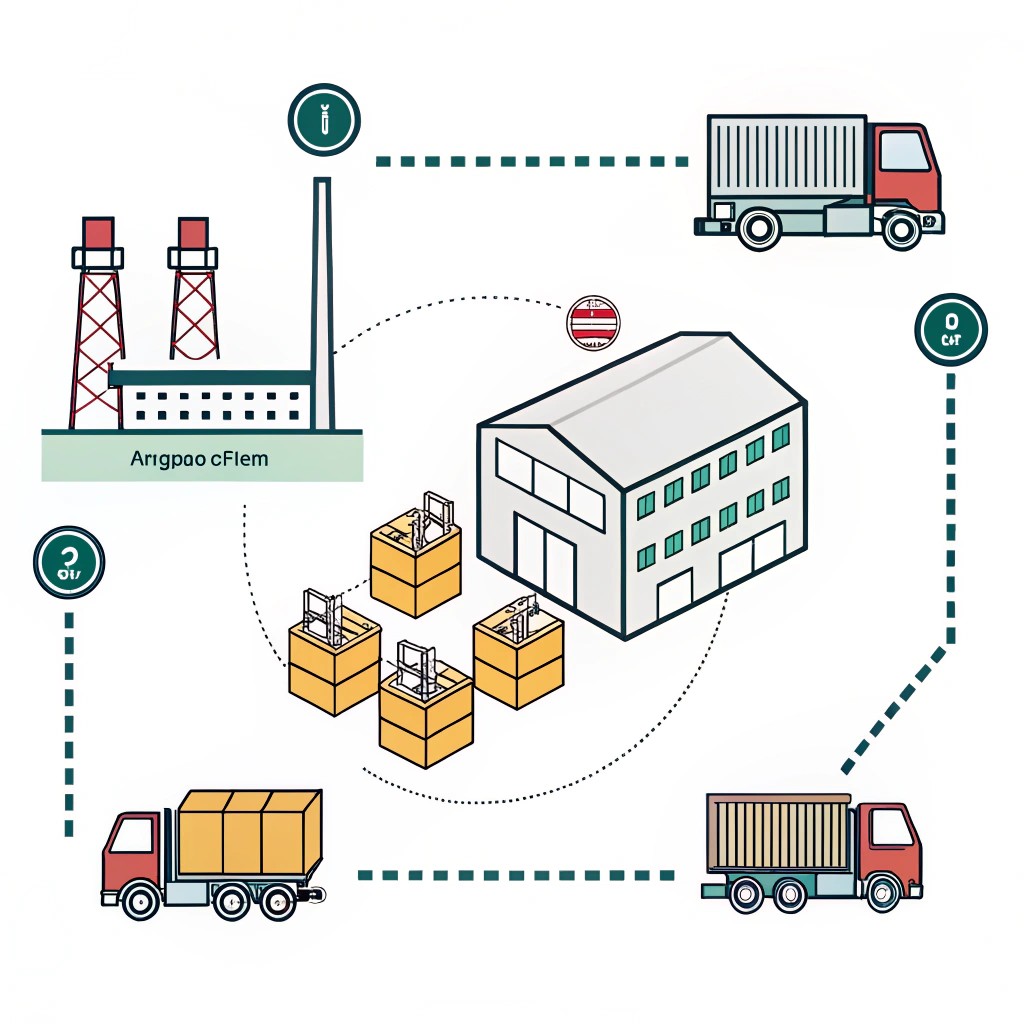

For B2B procurement, time is money. NEX Pickleball’s streamlined production process is designed to support:

• Bulk Order Processing5: Efficient production cycles that handle large orders without compromising quality.

• On-Demand Printing: Flexibility to cater to custom designs and smaller scale customization needs with rapid turnaround times.

• Efficient Shipping and Delivery: A robust logistics system ensures timely deliveries, making us a dependable partner for corporate clients.

Our robust supply chain management system integrates production scheduling, quality checks, and inventory management to foster a hassle-free experience for our clients. This system is especially advantageous for marketing executives and purchasing managers who require reliability and speed from their suppliers.

When procuring custom branded pickleball equipment, consider the following best practices:

| Key Factor | Best Practice |

|---|---|

| Customization Options | Confirm that the supplier offers extensive options for logo placement, color selection, and finishing details. |

| Material Quality | Verify that premium materials like high-grade carbon fiber, fiberglass, and composites are used for durability and performance. |

| Production Process Transparency | Ensure that the supplier provides detailed insights into their production processes and quality control measures. |

| Bulk Order Efficiency | Look for manufacturing partners with streamlined operations and proven track records in fulfilling large orders timely. |

| Post-Production Quality Checks | Confirm that each batch undergoes rigorous testing to maintain consistent quality and performance. |

Adopting these best practices not only ensures a high-quality final product but also builds a long-term, mutually beneficial partnership with your supplier.

Custom branded pickleball sets are more than just sports equipment—they are a powerful marketing tool that brings performance, style, and brand recognition together. By choosing a supplier like NEX Pickleball, your company gains access to the latest in manufacturing technology, a wide range of premium materials, and an unwavering commitment to quality.

If you are in the process of evaluating suppliers for custom sports equipment, consider the following action points:

• Discuss your branding needs and customization details with the supplier to ensure perfect alignment with your corporate identity.

• Review the manufacturing processes and quality assurance protocols to guarantee that every paddle meets your standards.

• Consider initiating a pilot order to evaluate the product's performance, production timelines, and branding fidelity before scaling up your procurement.

Taking these steps can secure a reliable supplier that not only meets the technical and quality requirements but also effectively supports your promotional and corporate gifting strategies.

Investing in custom branded pickleball sets brings immediate brand recognition and long-term customer loyalty, making it a strategic move for high-impact marketing campaigns.

People Also Ask

Q1: What are the benefits of custom branded pickleball paddles?

A1: Custom branded pickleball paddles enhance brand visibility, offer high-performance sports equipment, and serve as effective promotional merchandise or corporate gifts. They combine quality manufacturing with the ability to feature detailed custom designs.

Q2: How does NEX Pickleball ensure quality control in its production process?

A2: NEX Pickleball implements rigorous quality control measures including structural testing, precise design verification, and strict inspection of custom branding details to ensure each paddle meets high-performance and durability standards.

Q3: What production processes are used in manufacturing high-performance pickleball paddles?

A3: The paddles are manufactured using hot pressing, cold pressing, and Thermoforming1. Each method is chosen based on the specific performance, design, and quality requirements, ensuring robust performance and customizability.

-

Thermoforming: Read this article to understand how thermoforming techniques optimize intricate design manufacturing and material distribution. ↩ ↩2

-

on-demand printing: Discover the advantages of on-demand printing in customizing sports merchandise, improving turnaround times, and reducing inventory overheads. ↩

-

3K Carbon Fiber: Explore this resource to learn about 3K carbon fiber properties, its impact on durability, flexibility, and overall performance in high-grade sports equipment. ↩

-

E-Glass Fiberglass: Click to understand the characteristics and benefits of E-Glass fiberglass, including its elasticity and tensile strength in sports equipment manufacturing. ↩

-

Bulk Order Processing: Learn how efficient bulk order processing can streamline large-scale production, ensuring quality control and timely fulfillment. ↩