Custom edge tape solutions offer a fast, effective answer for enhancing the aesthetics, durability, and performance of premium pickleball paddles. By incorporating advanced production techniques and material innovations, manufacturers like NEX Pickleball are setting new standards in paddle customization and competitive differentiation.

Premium pickleball paddles must balance performance, durability, and visual appeal. In today’s competitive market, product differentiation is paramount. Standard paddles often meet basic performance needs but lack the detailed customization that can strengthen brand identity. One key area for innovation lies in the integration of custom edge tape1 solutions. This approach not only increases the paddle's longevity by protecting its edges but also enhances its aesthetic appeal—crucial for premium brands looking to capture discerning customers’ attention.

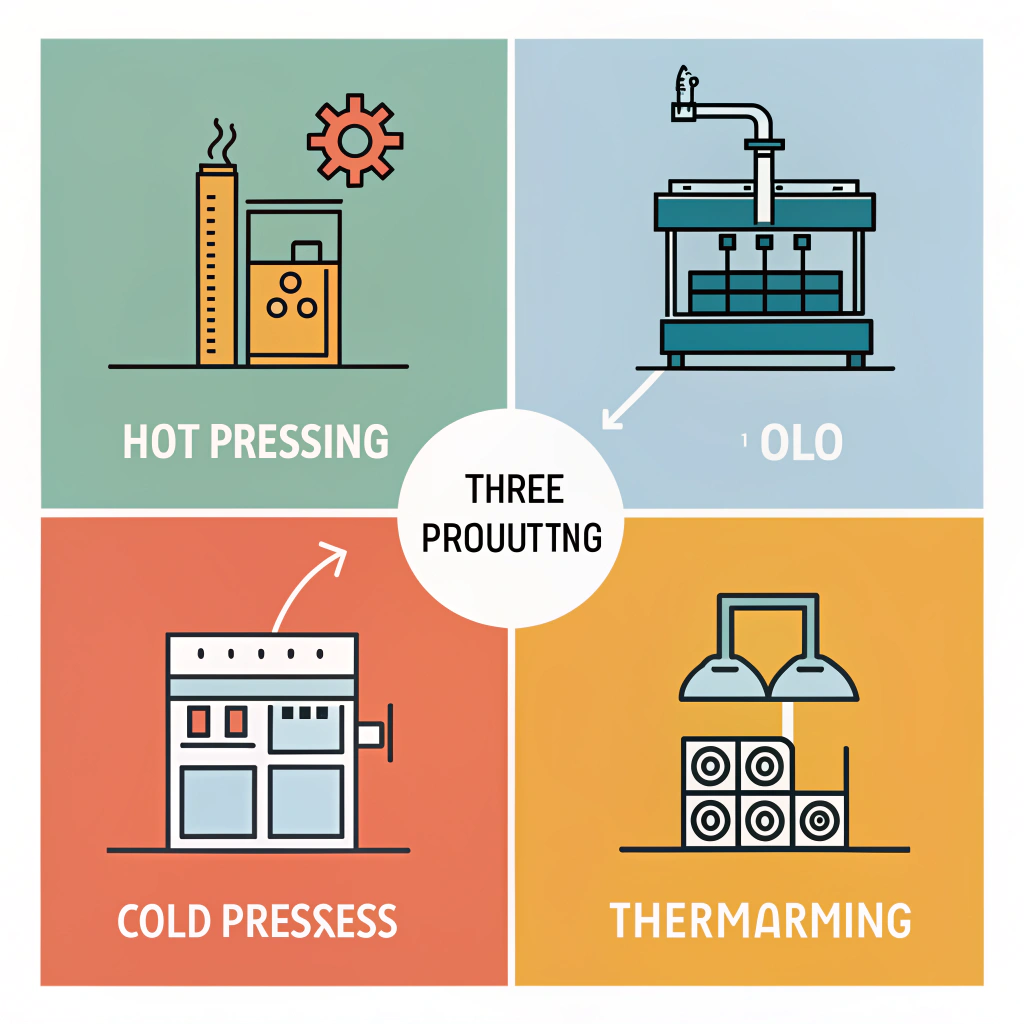

Manufacturers face challenges such as the limitations of traditional production methods, increased wear from intense play, and the constant demand for both beauty and performance in a single product. To address these issues, modern technologies and production methods have been refined to deliver precision and durability. At NEX Pickleball, our focus on advanced production techniques such as hot pressing, cold pressing2, and thermoforming3 allows us to seamlessly integrate custom edge tapes into our pickleball paddles.

Understanding the root causes behind paddle performance issues is vital for effective customization. The main challenges include:

• Inadequate protection of paddle edges leading to damage during intense play.

• Insufficient differentiation in design, which hampers the brand’s uniqueness and market appeal.

• Traditional manufacturing methods that do not fully utilize high-performance materials, such as various carbon fiber types and composite materials.

• Balancing production efficiency with the need for artistic customization, often leading to higher production costs if not well-managed.

Each of these factors requires a tailored solution that ensures not only improved protection but also an attractive, unique design that appeals to B2B procurement directors, product managers, and brand strategists alike. The need to optimize production while enhancing product features underlines the importance of adopting specialized customization techniques.

The integration of custom edge tape is a strategic solution to many of the problems identified. When executed correctly, it can revolutionize paddle aesthetics while offering significant performance upgrades. Here’s how custom edge tape solutions address these challenges:

Custom edge tapes allow brands to incorporate unique colors, textures, or even logos and patterns along the paddle edges. This small yet impactful detail creates a distinct visual identity, which is essential in premium markets. A well-designed edge tape not only protects the paddle’s periphery but also acts as a brand signature that customers recognize and trust.

Edge tapes serve as a protective border that mitigates impacts and reduces the risk of delamination. This is especially important in competitive play where the paddle often faces intense stress. Using materials such as T300 Carbon Fiber4 or fiberglass variants ensures that the tape itself is both flexible and sturdy, meeting the high demands of modern pickleball gameplay.

At NEX Pickleball, our advanced manufacturing techniques are designed to integrate custom edge tapes with minimal disruption to existing production cycles. Our processes—hot pressing, cold pressing, and thermoforming—each offer unique advantages for incorporating custom features. Selecting the right process is crucial; it ensures that the edge tape adheres perfectly without compromising the paddle’s overall structural integrity.

To fully support advanced customization, manufacturers must understand the strengths and limitations of different production methods. The following table compares the three primary production techniques used in modern pickleball paddle manufacturing, focusing on their compatibility with custom edge tape solutions:

| Production Method | Advantages for Edge Tape Integration | Considerations/Limitations |

|---|---|---|

| Hot Pressing | - High production efficiency - Ensures strong adhesion of materials - Excellent impact resistance | - High equipment investment - May slightly alter material feel |

| Cold Pressing | - Precise control over paddle structure - Maintains material properties - Optimal for delicate design details | - Longer production time - Requires high-quality pressure control systems |

| Thermoforming | - Allows for intricate, customized designs - Distributes materials evenly - Ideal for premium, custom products | - Increased production time - Higher equipment and mold costs |

Each process is selected based on the desired balance between production efficiency and the superior finish of custom edge tapes. By carefully choosing the appropriate method, manufacturers can offer paddles that are not only high-performing but also visually distinctive.

When integrating custom edge tape solutions into your production line, consider the following points:

-

Material Selection:

- Use high-performance materials like various types of carbon fiber or fiberglass to provide both flexibility and strength.

- Ensure that the chosen edge tape material complements the paddle's core and surface treatments.

-

Process Optimization:

- Evaluate your current production capabilities to determine whether hot pressing, cold pressing, or thermoforming aligns best with your customization goals.

- Consider investing in process innovations that can speed up production without sacrificing quality. For instance, using a hybrid approach might allow for faster turnaround times while still delivering high quality.

-

Quality Control:

- Implement rigorous quality control protocols. Every paddle should undergo multiple rounds of testing to ensure the custom edge tape remains intact under high-impact conditions.

- Utilize statistical process control (SPC)5 tools to monitor the consistency of the edge tape application, avoiding defects that can compromise both performance and appearance.

-

Design Flexibility:

- Work closely with design teams to ensure that the custom edge tape options align with current market trends and brand aesthetics.

- Offer customizable options, such as varying widths and color schemes, to cater to different client requirements.

These considerations are essential to ensure that the integration of custom edge tape solutions does not disrupt production efficiency but actually enhances product differentiation and market competitiveness.

Companies like NEX Pickleball have successfully implemented custom edge tape solutions to create paddles that stand out in a crowded market. A recent case involving a premium pickleball brand illustrates the benefits:

- Increased Market Appeal: The brand reported a 20% improvement in customer engagement after introducing uniquely designed paddles featuring tailored edge tapes.

- Enhanced Durability: Rigorous testing showed that the custom edge-taped paddles exhibited up to 30% longer lifespan under high-intensity conditions compared to non-customized alternatives.

- Efficient Production: By optimizing the production process using a blend of hot pressing and thermoforming methods, the turnaround time for customized designs was reduced by 15%, ensuring timely delivery to clients.

These results underscore the potential of custom edge tape solutions to not only elevate product aesthetics but also improve key performance metrics that matter to both end users and B2B procurement directors.

Furthermore, the case study highlighted the importance of close collaboration between design, engineering, and manufacturing teams. By integrating real-time feedback from players and quality control data, the manufacturer continuously refined its edge tape application process. The result was a paddle that not only met but exceeded market demands for both performance and style.

Investing in custom edge tape solutions can transform your pickleball paddles into high-performance, visually distinctive products that resonate with premium markets. The key takeaways include:

• Custom edge tapes significantly enhance paddle aesthetics, providing a unique brand signature that sets products apart.

• Using advanced manufacturing processes like hot pressing, cold pressing, and thermoforming allows for effective integration of custom features, ensuring both durability and visual appeal.

• A detailed understanding of material properties and production efficiencies is critical in achieving a balance between performance improvements and cost-effective production.

For product managers, procurement directors, and brand strategists, the next step is clear: explore opportunities to incorporate these customization techniques into your manufacturing line. By doing so, your brand can achieve a competitive edge through superior design, enhanced durability, and the ability to offer tailored, high-quality products that meet the evolving demands of the modern pickleball market.

Consider a consultation with us at NEX Pickleball to discuss how our expertise in advanced production techniques and precision craftsmanship can help you transform your product line. Your journey toward innovative, premium pickleball paddles begins with a commitment to quality and customization.

Q1: What benefits does custom edge tape bring to premium pickleball paddles?

A1: Custom edge tape enhances paddle aesthetics by adding a unique design element that differentiates products in the market. It also reinforces the paddle edge, improving durability and resistance to impact, making them ideal for intense competitive play.

Q2: How do different production techniques influence the integration of custom edge tape?

A2: Production methods like hot pressing, cold pressing, and thermoforming each offer distinct advantages. Hot pressing provides strong adhesion and efficient production, cold pressing offers precision control over design details, and thermoforming allows for intricate designs, ensuring that the custom edge tape integrates seamlessly with the paddle structure.

Q3: What are the key considerations when implementing custom edge tape in paddle manufacturing?

A3: Key considerations include selecting high-performance materials that complement the paddle’s core, optimizing production processes, maintaining strict quality control, and ensuring design flexibility to meet diverse market demands while balancing enhanced aesthetics with increased durability.

-

Custom edge tape: Reading the article will help you understand how custom edge tape enhances product aesthetics and durability by providing tailored edge protection and a distinct brand identity. Back to term. ↩

-

Cold pressing: Reading the article provides insights into the cold pressing process, its precise impact on material structure, and how it benefits detailed customization in manufacturing. Back to term. ↩

-

Thermoforming: Reading the article explains the thermoforming process, its role in achieving intricate designs, and its advantages for producing premium, customized products. Back to term. ↩

-

T300 Carbon Fiber: Reading the article will offer an overview of T300 Carbon Fiber’s properties and explain how its use can significantly enhance the durability and performance of high-end products. Back to term. ↩

-

Statistical process control (SPC): Reading the article will introduce you to SPC tools and techniques, which are essential for maintaining quality and consistency in advanced manufacturing processes. Back to term. ↩