Quick Answer: Advanced production techniques such as hot pressing1, cold pressing2, and thermoforming3 are the keys to manufacturing high-performance composite pickleball paddles4 that maximize durability, power, and control for competitive play.

In today’s competitive sports equipment market, procurement managers and product development heads face the challenge of choosing manufacturing methods that optimize paddle performance without compromising on durability or customization. With the rising demand for composite pickleball paddles, manufacturers like NEX Pickleball have turned to cutting-edge processes to produce paddles that meet the highest standards. This article explores the advanced production techniques, compares their performance benefits, and explains how to choose the right method for your product needs.

Manufacturers and distributors are under constant pressure to enhance product offerings with innovative, high-performance equipment. In the case of composite pickleball paddles, features such as impact resistance, optimal weight distribution, and consistent quality are non-negotiable. However, achieving these features starts at the production process. The decision between methods like hot pressing, cold pressing, and thermoforming carries significant implications in terms of production efficiency, material integrity, and overall paddle performance.

Procurement managers must evaluate:

• How each process affects material properties

• The trade-offs between production time, equipment investment, and resulting paddle quality

• Customization potential and alignment with market demands

Understanding each technique’s advantages and limitations is essential for making an informed decision, especially when your product offerings hinge on performance and longevity.

Manufacturing high-performance composite pickleball paddles involves several advanced techniques. Here, we break down the primary methods: hot pressing, cold pressing, and thermoforming.

Hot pressing involves applying heat and pressure to composite materials to form the paddle. This process is well-suited for producing paddles that require significant strength and impact resistance.

Advantages of Hot Pressing:

• Rapid production efficiency suitable for large volumes

• Enhanced structural integrity, ensuring paddles withstand high-impact shots

• Results in a strong paddle with excellent impact resistance

Disadvantages of Hot Pressing:

• Potential alteration of material properties which may affect the tactile feel

• High initial investment in specialized equipment

Manufacturers often choose hot pressing when the primary goal is to create a durable paddle that maintains performance under aggressive play conditions.

In contrast, cold pressing shapes the paddle material at room temperature using mechanical pressure. This technique preserves the material’s natural properties, making it a preferred choice when precision and control are critical.

Advantages of Cold Pressing:

• Greater control over paddle thickness and structural details

• Maintains inherent material characteristics for a precise ball feel

• Ideal for creating paddles that prioritize control over raw power

Disadvantages of Cold Pressing:

• Longer production cycles, which can reduce overall efficiency

• Requires high-precision pressure control, often demanding more sophisticated systems

For distributors who cater to players seeking nuanced control and comfort in their playing gear, cold pressing delivers a distinct advantage.

Thermoforming involves heating composite materials until they soften, then molding them using custom-designed molds. This process is particularly beneficial for paddles with complex designs or when optimal material distribution is critical.

Advantages of Thermoforming:

• Ability to produce intricately designed paddles with precise material distribution

• Maintains paddle stability and enhances performance through controlled shaping

• Ideal for premium products and custom-made paddles

Disadvantages of Thermoforming:

• Typically requires a longer production time

• Higher equipment costs that may affect pricing for large-scale production

Thermoforming empowers manufacturers to experiment with innovative designs and tailor paddle characteristics to specific player needs. This customization can be a game-changer in a competitive sports market.

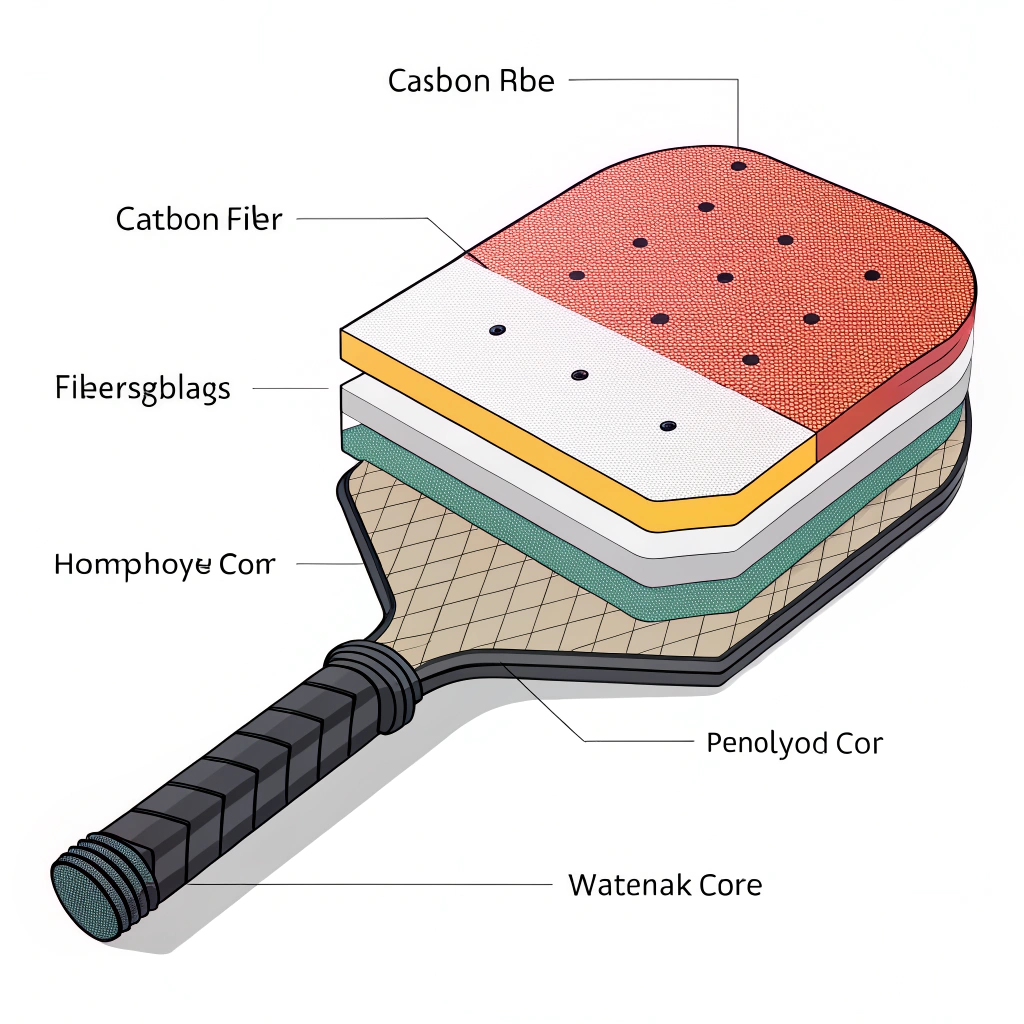

The raw materials used in composite pickleball paddles are as critical as the production process itself. Manufacturers combine different materials such as carbon fiber5, fiberglass, and various core materials to achieve a balance between power, control, and durability.

• 3K Carbon Fiber: Offers flexibility and strength, reducing vibration for a more comfortable hitting experience.

• 12K Carbon Fiber: Provides a smoother surface with enhanced durability and hardness, suitable for competitive play.

• T300 Carbon Fiber: Known for outstanding tensile strength, offering the right mix of strength and light weight.

Fiberglass paddles are recognized for their balance of power and control. They typically offer a wider sweet spot and enhance ball control. Additionally, manufacturers blend carbon fiber with fiberglass or even incorporate bamboo core composites to create paddles that cater to both recreational and advanced players.

Critical to the paddle’s performance is the core material used, which affects impact absorption and overall playability. Options include:

• Nomex Honeycomb Core: Known for excellent shock absorption and long-lasting durability.

• Aluminum Honeycomb Core: Delivers balanced weight for power and precise control.

• Polymer Honeycomb Core: Preferred by recreational players for elasticity and reduced vibration.

Manufacturers integrate these materials through the production processes to create slices of technology that support both high performance and customization.

For a holistic view, the following table outlines the benefits and limitations of each production technique:

| Production Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High production efficiency, strong impact resistance, excellent structural integrity | Altered material texture, high equipment investment | High-volume manufacturing with a focus on durability |

| Cold Pressing | Precise control over thickness and structure, preserves natural material properties, enhanced ball feel | Longer production cycle, higher precision control required | Customized paddles focusing on control and comfort |

| Thermoforming | Complex design capability, precise material distribution, maintains stability | Longer production time, higher costs | Premium or custom-made paddles where design intricacy is key |

This table helps procurement managers and product development teams to quickly grasp the trade-offs associated with each technique. It serves as a decision-making aid when weighing performance attributes against production constraints.

When selecting a production process, several factors should guide your decision:

-

Performance Demands:

- If your market primarily seeks paddles that can withstand aggressive, high-impact play, hot pressing might be the optimal choice.

- For a product positioned towards precision and control, cold pressing provides the necessary material integrity.

-

Production Volume and Efficiency:

- For large-scale manufacturing, hot pressing offers speed and efficiency.

- If customization is a priority and scale is manageable, thermoforming might justify its longer cycle with superior design versatility.

-

Material Integrity and Customization:

- Cold pressing helps maintain the intrinsic properties of advanced materials like carbon fiber, which is crucial for achieving the desired balance in paddle performance.

- Thermoforming allows for unique shapes and customizations that can differentiate your product in the market.

-

Cost Implications:

- The initial investment in equipment might be higher for thermoforming, but the improved product quality and ability to offer custom solutions could justify the cost.

- Hot pressing, while cost-effective for bulk production, may introduce changes to the material feel that are less desirable for paddle enthusiasts seeking premium performance.

By carefully evaluating these factors, procurement managers can align production techniques with strategic product goals, ensuring that each paddle meets the precise demands of competitive play. The choice of manufacturing process directly influences the paddle’s performance metrics, durability, and even its market positioning.

At NEX Pickleball, quality control is not simply a step in the production process—it is a commitment. Each composite paddle undergoes rigorous testing to ensure consistency in weight distribution, grip ergonomics, and surface texture. High-performance products require careful monitoring from the start:

• Rigorous Testing: Every paddle is inspected and tested for impact resistance, vibration reduction, and performance consistency.

• Customization Options: Clients can choose design elements such as paddle weight, balance, grip size, and even surface finishes to tailor the paddle according to game style and player preference.

• Adaption of Advanced Techniques: Whether using hot pressing for high-volume orders or thermoforming for uniquely designed paddles, each product meets stringent standards that align with industry benchmarks.

Manufacturers who emphasize both quality control and customization not only ensure a superior product but also cultivate a strong market reputation, ensuring customer loyalty and repeat business.

Recent industry data underscores the importance of selecting advanced production methods. In a comparative study of composite paddle performance:

• Paddles manufactured with hot pressing consistently recorded higher impact resistance values, ideal for forceful play.

• Those produced via cold pressing exhibited superior control characteristics, as evidenced by improved ball feel during technical gameplay.

• Thermoformed paddles, although produced at a slower rate, demonstrated unique design flexibility that allowed for niche market positioning, appealing to professional courts and custom sports teams.

These case findings support the view that the production method directly correlates with paddle performance and market success. For procurement managers evaluating potential suppliers, presented data enables a more objective selection process that aligns with both technical and business goals.

In summary, the choice of production process for composite pickleball paddles is driven by multiple factors:

• If you need high-volume, durable paddles for aggressive play, hot pressing provides the necessary strength and efficiency.

• For paddles where precise control and material integrity are paramount, cold pressing is the optimal choice despite longer production cycles.

• For innovative, customizable paddle designs aimed at the premium segment, thermoforming offers unmatched versatility and design integrity.

Procurement managers should weigh these factors against their strategic product goals. Our advanced production processes at NEX Pickleball are tailored to meet these diverse needs. By choosing a supplier with robust quality control, precise manufacturing techniques, and customization capabilities, your next product line could significantly enhance performance and market appeal.

Take a proactive step in elevating your product portfolio. Consider these advanced manufacturing techniques as a pathway to distinguish your offerings in a competitive market. Contact NEX Pickleball for more detailed insights and to discuss tailored production solutions for your ideal composite pickleball paddles.

People Also Ask

Q: Is a composite pickleball paddle better?

A: Composite pickleball paddles offer a more reactive, precise feel on contact compared to other materials. They provide additional flex and power while maintaining excellent control, making them ideal for players seeking both performance and durability.

-

hot pressing: Click to discover how heat and pressure are applied to composite materials to enhance structural integrity and impact resistance. ↩ ↩

-

cold pressing: Click to learn about the mechanical pressure technique at room temperature that preserves material properties for precise control. ↩ ↩

-

thermoforming: Click to explore the process of heating and molding composites into complex shapes, ideal for custom designs. ↩ ↩

-

composite pickleball paddles: Click to read more about the advanced composite materials and construction techniques that enhance durability, power, and control for competitive play. ↩ ↩

-

carbon fiber: Click to understand why this high-strength, lightweight material is crucial for performance and durability in sports equipment. ↩ ↩