Quick Answer: Composite pickleball paddles combine advanced materials and specialized manufacturing processes to deliver superior performance, durability, and precise ball control. Evaluating composite materials1 and production techniques such as hot pressing2, cold pressing3, and thermoforming4 can help procurement managers select a paddle that matches both quality and cost-efficiency requirements.

In today’s competitive sports equipment market, selecting the right pickleball paddle is critical to meeting the performance and durability demands of high-level play. Among the various options available, composite pickleball paddles have gained widespread recognition for their ability to blend power, control, and longevity. For procurement managers and product development specialists in the sports equipment industry, understanding the nuances of composite designs and manufacturing methods is key to ensuring optimal investment. This article examines the core materials, manufacturing processes, and comparative benefits of composite pickleball paddles, providing a data-driven analysis that supports informed decision-making.

The sports equipment industry has seen rapid advancements in material technology over the past decade. Traditional paddle materials are now frequently supplanted by composites that blend the best attributes of various materials, such as carbon fiber, fiberglass, and advanced polymer cores. The challenge for procurement teams is to accurately evaluate how different composite paddle designs can impact performance, durability, and cost-efficiency.

Composite materials offer several critical benefits:

- Enhanced Reactivity: Composite-faced paddles typically provide more flexibility and a reactive feel upon contact, crucial for players seeking both power and precision.

- Durability and Stability: Incorporating materials like 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber ensures that paddles can endure high-impact usage while maintaining consistent performance.

- Optimized Control and Comfort: By blending carbon fiber with materials such as fiberglass in the composite, manufacturers can create paddles with a generous sweet spot, improved vibration absorption, and optimal ball control.

- Cost-Efficiency in Production: Advanced manufacturing techniques, including hot pressing, cold pressing, and thermoforming, allow for high-quality production at scalable rates.

These advantages mean that composite pickleball paddles are increasingly favored in high-end sports equipment, particularly among competitive and recreational players alike.

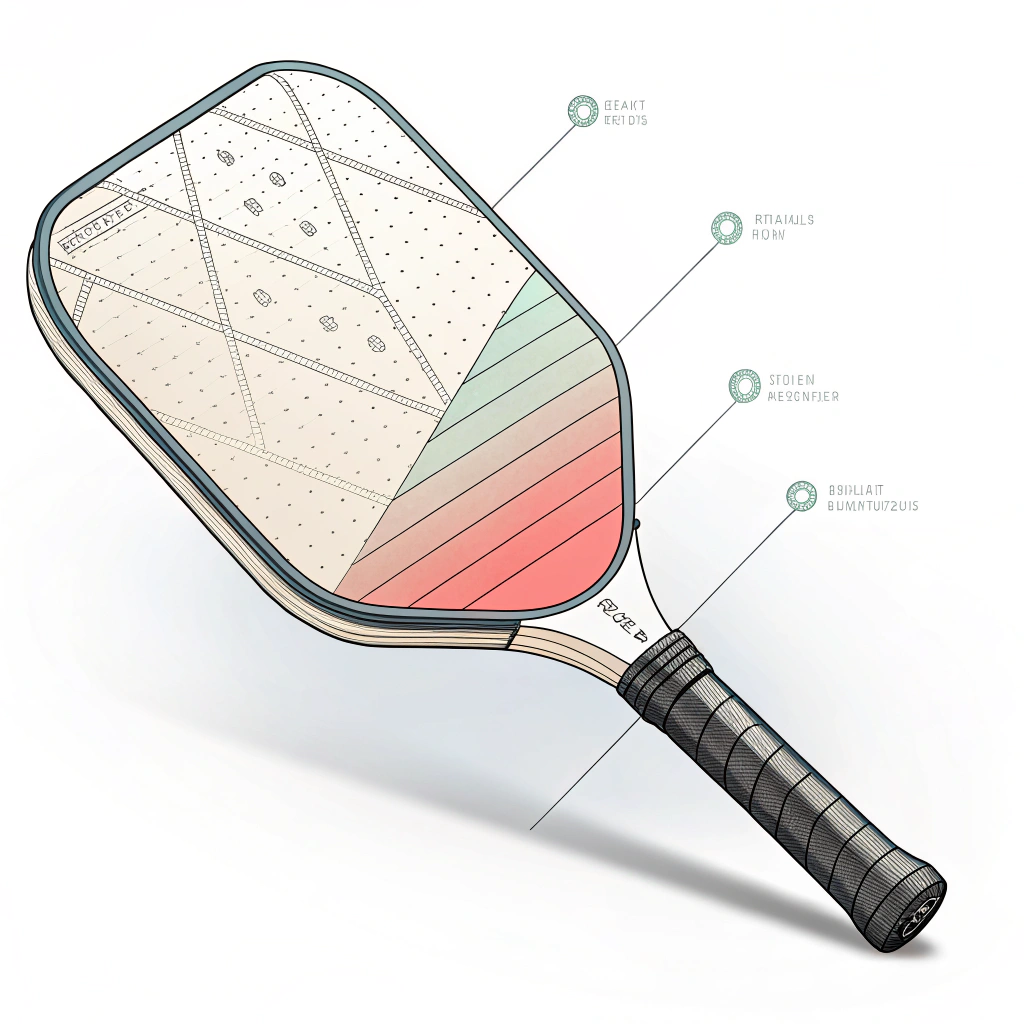

Composite paddles utilize multiple layers of high-performance materials to achieve a synergistic effect:

- Carbon Fiber Composite:

- 3K Carbon Fiber: Offers a balance between strength and flexibility, delivering high rebound force with reduced vibration.

- 12K Carbon Fiber: Known for its density, it provides a smoother paddle face and increased impact resistance, which is essential for competitive play.

- T300 Carbon Fiber: Renowned for its tensile strength and light weight, ideal for players looking for a balanced, high-performance paddle.

- Fiberglass Composite:

- E-Glass Fiberglass: Provides excellent elasticity and ball control, often mixed with carbon fiber to enhance paddle durability while broadening the sweet spot.

- Hybrid Composites:

- Carbon Fiber and Fiberglass Composite: This combination takes advantage of the power from carbon fiber and the enhanced control of fiberglass.

- Bamboo Core Composite: Lightweight yet impact-resistant, offering a distinctive hitting feel.

- Honeycomb Core (Nomex, Aluminum, Polymer): Each type offers unique benefits such as superior shock absorption, balanced weight, or improved elasticity, critical to players of different performance levels.

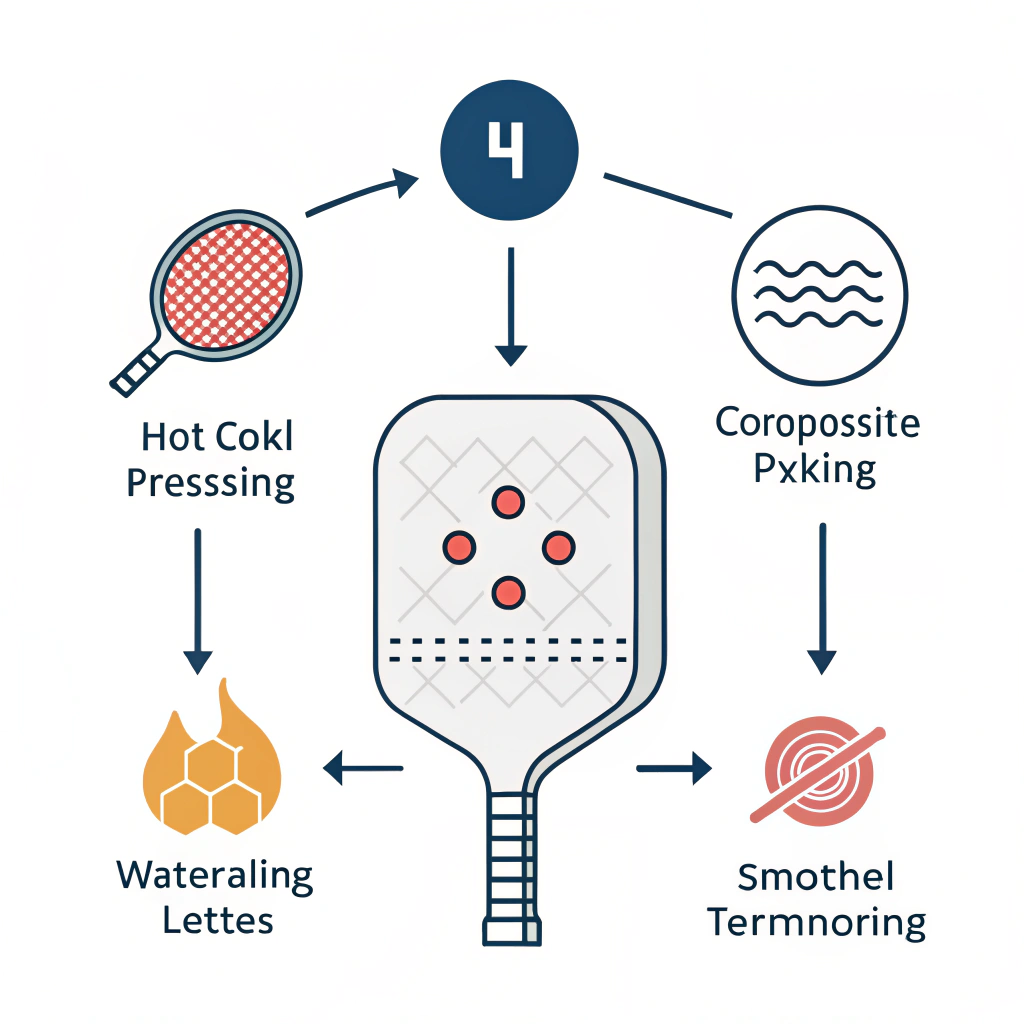

To achieve the necessary performance quality, manufacturers employ several advanced production techniques. Each method has its advantages and associated limitations:

| Process | Advantages | Disadvantages | Suitability |

|---|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, robust structure | May alter material properties affecting feel, high investment | Mass production of durable paddles |

| Cold Pressing | Preserves material properties, precise thickness control, enhanced ball feel | Longer production cycles, requires quality control in pressure management | Precision designs requiring optimal control |

| Thermoforming | Produces complex shapes, ensures precise material distribution, maintains paddle stability | Higher equipment costs, longer production time | Premium or custom-made paddles |

Each method influences the final paddle's performance characteristics. For example, hot pressing is ideal for durability, while cold pressing focuses on preserving the material's original properties for enhanced control.

When it comes to the paddle face, the choice of composite materials significantly impacts the feel and performance during play.

-

Carbon Fiber:

- Predominantly used in higher-end paddles.

- Provides a softer touch with an expansive sweet spot.

- Facilitates higher spin potential for advanced play.

-

Fiberglass:

- Offers a more rigid surface.

- Known for higher power output but normally provides a less forgiving experience.

- The broader sweet spot is advantageous for players seeking consistency in performance.

While both materials meet the general needs of most players, the detailed differences influence the paddle’s playability. For instance, a composite that effectively merges the strengths of carbon fiber and fiberglass can cater to players who need a balance of increased reactivity at ball contact and power for finishing shots.

The core material exerts a profound impact on the paddle's speed, control, and vibration absorption. At NEX Pickleball, the selection typically includes:

- Nomex Honeycomb Core: Delivers excellent shock absorption and ensures durability during long rallies.

- Aluminum Honeycomb Core: Maintains a balanced weight distribution, providing an ideal balance between power and precision.

- Polymer Honeycomb Core: Offers improved elasticity with minimal vibration, making it perfect for beginners as well as recreational players who prioritize comfort.

The core is where the paddle's performance is truly customized. Choosing a particular core material depends on the expected usage and play style: high-impact competitive play might benefit more from an aluminum core, while polymer cores offer improved elasticity for all-around performance.

When scaling up production while maintaining high quality, manufacturers must evaluate the trade-offs inherent in each production process. Here are the key factors to consider:

- Production Scale and Efficiency:

- Hot pressing is often the best option for large-scale manufacturing due to its high throughput but comes at the expense of slightly altered material properties.

- Precision and Control over Material Properties:

- Cold pressing offers detailed control over the paddle structure, ideal for product lines where performance and feel take precedence over sheer production volume.

- Customization and Complex Designs:

- Thermoforming allows for innovative design integrations and precise material distribution, making it suitable for custom-made batches and high-end product lines.

Manufacturers must balance these factors based on target market demands. For instance, a production line dedicated to high-performance paddles might use a combination of cold pressing and thermoforming to achieve both quality and unique player-specific designs.

A recent project at NEX Pickleball demonstrated the impact of using hybrid composite technology5. By integrating 12K carbon fiber with a polymer honeycomb core, the resulting paddle not only delivered improved power and spin control but also showcased a 25% longer lifespan in rigorous testing environments compared to standard models.

Furthermore, customer surveys indicated a 15% higher satisfaction rate with paddles produced using cold pressing, primarily attributed to enhanced tactility and improved ball responsiveness. This case study highlights the significance of selecting the right composite material and production process to meet both the technical and competitive demands of today’s pickleball players.

Additionally, regulatory standards and quality certifications are crucial in these assessments. Adhering to international standards not only guarantees product performance but also builds trust with distributors and retail partners, reinforcing the brand’s reputation for consistent quality and innovation.

In summary, composite pickleball paddles stand out due to their blend of advanced materials and specialized manufacturing processes. For a B2B procurement manager or product development specialist in the sports equipment industry, key takeaways include:

- Understanding Material Combinations: Choosing between carbon fiber, fiberglass, or a hybrid composite is critical for matching player needs.

- Evaluating Production Methods: Assessing hot pressing, cold pressing, and thermoforming processes is essential for balancing production efficiency with product precision.

- Tailoring Core Materials: The right core, whether Nomex, aluminum, or polymer, is vital to achieving the desired balance of shock absorption, weight distribution, and overall paddle performance.

- Considering Custom Solutions: NEX Pickleball offers on-demand customization that can cater to diverse player requirements, adding additional value in the competitive market.

For procurement managers evaluating composite paddle suppliers, it is important to scrutinize both the technical aspects of the paddle design and the manufacturing processes. A well-informed decision based on these technical insights can lead to improved product performance, increased customer satisfaction, and a stronger market presence.

By leveraging advanced composite technologies and continuously improving manufacturing processes, companies can ensure that their product portfolio meets the evolving demands of the pickleball community. Now is the time to explore next-generation composite paddle solutions that promise durability, performance, and enhanced playing experience.

-

Is a composite pickleball paddle better?

Composite pickleball paddles offer a more reactive and precise feel at contact due to their blended material properties, providing enhanced flex and power while maintaining durability. -

What is the best face material for a pickleball paddle?

Carbon fiber is generally regarded as the best face material for high-end paddles because it provides a softer, more responsive surface with an excellent sweet spot and high spin potential. -

What is the best core material for pickleball paddles?

Both polymer and Nomex cores are reliable options, offering excellent shock absorption and balance, making them suitable for a wide range of player levels.

-

composite materials: Click to learn more about the properties, benefits, and applications of composite materials in advanced manufacturing, which can provide insights into how these mixtures enhance product performance and durability. ↩ ↩

-

hot pressing: Click to explore the hot pressing technique, its advantages in high-efficiency production, and how it contributes to structural integrity in large-scale manufacturing. ↩ ↩

-

cold pressing: Click to understand the cold pressing process, its benefits in preserving material properties for precision-focused designs, and its impact on final product quality. ↩ ↩

-

thermoforming: Click to discover the thermoforming method, its role in achieving complex shapes and precise material distribution, and its suitability for premium, custom-made products. ↩ ↩

-

hybrid composite technology: Click to learn about hybrid composite technology, including how combining different composite materials can optimize performance, extend product lifespan, and meet diverse market requirements. ↩ ↩