Quick Answer: Pickleball Paddle Pricing1 is influenced by material costs, manufacturing processes, quality control, and bulk order discount structures. By understanding the differences between production methods like Hot Pressing2, Cold Pressing3, and Thermoforming4—and comparing materials such as various types of carbon fiber5 and composite cores—you can make an informed decision on which supplier, including NEX Pickleball, provides the best value for bulk orders.

In today's competitive sports equipment market, finding the right balance between cost and quality is essential for procurement managers and sourcing specialists. This article dives deep into the factors that affect pickleball paddle pricing, breaking down the underlying cost drivers and comparing different manufacturing processes. Through data-driven analysis and direct comparisons, we aim to help you identify the supplier that offers the best value for your bulk purchase requirements. Whether you are looking for performance-enhancing materials or cost-efficient manufacturing, understanding these key elements is crucial for a successful sourcing decision.

The first major factor influencing paddle pricing is the selection of materials. Premium materials offer performance benefits but tend to raise costs:

- Carbon Fiber5: Available in various types such as 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber, each type brings unique advantages. For example, 3K is known for its strength and flexibility, while 12K offers a smoother surface and higher impact resistance ideal for competitive play.

- Fiberglass: Known for its balance between power and control with a wider sweet spot. E-Glass Fiberglass, with its excellent elasticity, is a common choice for manufacturers seeking enhanced ball control.

- Composite Materials: These combine carbon fiber and fiberglass, or integrate a Bamboo Core or Honeycomb Core, to provide a balance of power, lightness, and durability.

Additionally, the core material of the paddle plays a significant role in cost and performance:

- Nomex Honeycomb Core: Provides excellent shock absorption and durability.

- Aluminum Honeycomb Core: Balances weight and offers impressive power and control.

- Polymer Honeycomb Core: Reduces vibration and offers a comfortable hitting experience more suited for beginners.

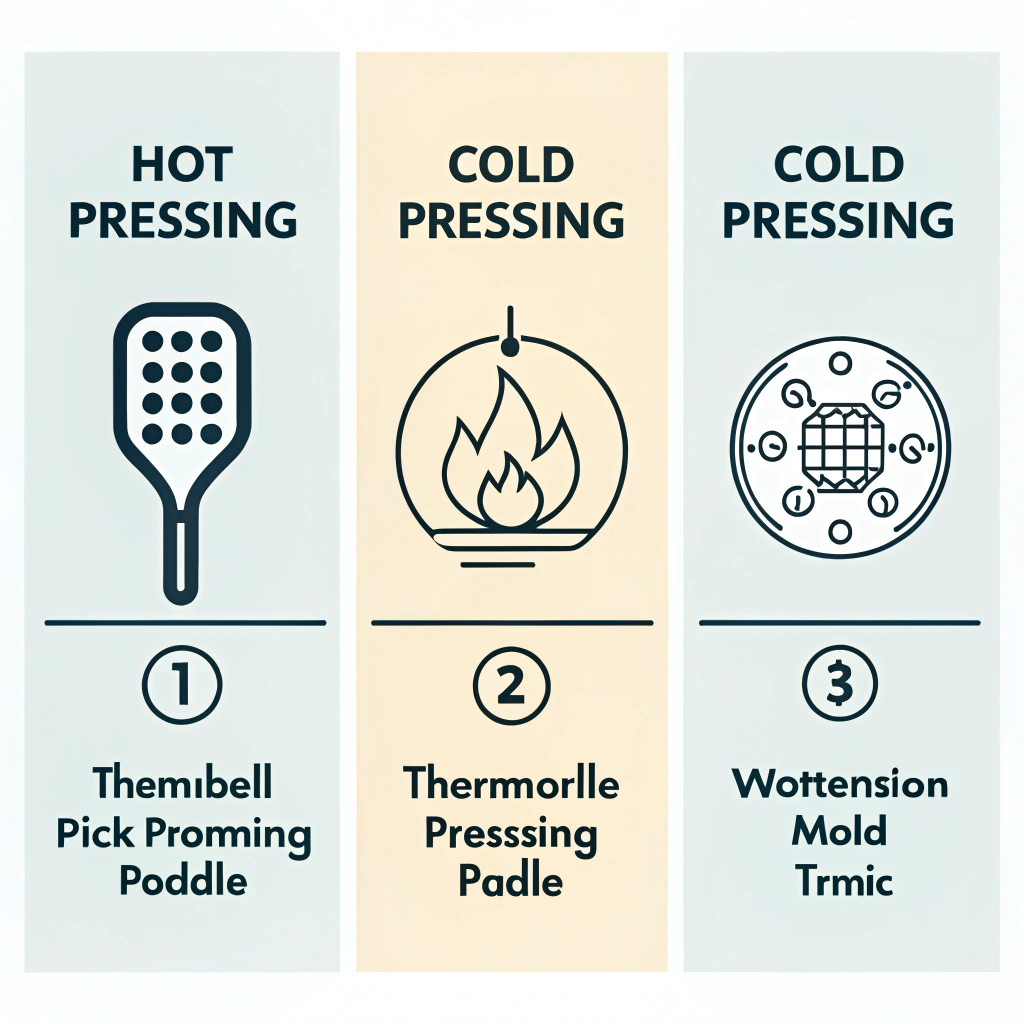

Different production techniques not only affect the physical properties of a paddle but also influence the overall production cost:

-

- Advantages: High efficiency, strong paddle construction with excellent impact resistance, and the ability to scale production for bulk orders.

- Disadvantages: Potential changes to material feel, higher capital investment in production equipment.

-

- Advantages: Greater precision in controlling paddle thickness, better retention of material properties leading to improved ball feel.

- Disadvantages: Longer production cycles, requiring superior pressure control and high-quality machinery.

-

- Advantages: Enables the creation of complex designs, ensures precise material distribution and stability.

- Disadvantages: Higher production time and equipment costs, making it ideal for premium or custom-made paddles.

In B2B settings, production efficiency and economies of scale play a crucial role. Suppliers who invest in advanced production technologies can achieve:

- Faster turnaround times

- Consistent product quality

- Reduced labor and operational costs

These factors directly impact the unit price offered to bulk purchasers. Suppliers who can optimize production processes are more likely to offer appealing bulk discounts, making them highly competitive. When comparing suppliers, consider:

- Equipment efficiency and technological investments

- Experience in quality control and process optimization

- History of timely production and delivery

When evaluating suppliers, procurement managers must compare multiple dimensions. The following table summarizes key aspects to consider when selecting a pickleball paddle manufacturer:

| Parameter | Material Quality | Manufacturing Process | Production Efficiency | Customization Options | Bulk Discount Potential |

|---|---|---|---|---|---|

| Supplier A (Generic) | Standard fiberglass and basic composites | Hot pressing; limited precision | High, but may compromise paddle feel | Limited customization | Moderate |

| Supplier B (Premium) | High-grade carbon fiber, composite materials | Cold pressing; improved control | Moderate; longer cycle times | High customization | Low due to premium pricing |

| NEX Pickleball | Wide range including 3K, 12K, and T300 carbon fiber, along with diverse composite and core options | Hot pressing, cold pressing, thermoforming | High efficiency with strict quality control | Extensive customization options, including on-demand print services | Exceptional bulk order discounts combined with competitive pricing |

The table above highlights that while some suppliers might lower prices by using more standard materials or less precise production techniques, NEX Pickleball ensures premium quality while optimizing production to offer competitive pricing—a balance that is critical for bulk orders without sacrificing quality.

The cost of carbon fiber and other premium materials can fluctuate based on global supply chain dynamics. Manufacturers involved in direct sourcing or long-term contracts often secure better pricing, which can then be passed on as savings in bulk orders. For example, NEX Pickleball continuously monitors material costs while ensuring a consistent supply of high-quality carbon fiber variants, reducing price volatility and ensuring that bulk buyers receive reliable pricing.

Investments in advanced technology—such as precision cold pressing machinery or thermoforming molds—represent significant upfront costs. However, these investments lead to:

- Reduced reject rates

- Superior product consistency

- Enhanced durability and performance performance over the product life cycle

Quality control processes in NEX Pickleball's production are among the strictest in the industry. Rigorous testing and continuous process monitoring guarantee that every paddle meets the high standards required by professional players. For procurement managers, this translates into lower long-term returns on investment, given the reduced chance of product failures and the enhanced performance delivered to end users.

Bulk purchasing significantly lowers unit cost. Suppliers like NEX Pickleball can offer volume-based discounts because high production efficiency lowers total cost per unit. This factor is crucial when evaluating supplier quotes—especially when comparing with manufacturers less equipped to handle high production volumes efficiently.

An optimized production line with multiple processes caters to varied market segments:

- Hot pressing for high-volume, durable paddles suited for competitive play at a lower unit cost.

- Cold pressing for paddles where precision is key, even if the production cycle is longer.

- Thermoforming for specialty or custom orders where design intricacies are critical.

Having access to all three methods provides a versatile edge, allowing the manufacturer to offer a wide range of products that can meet differing client needs without sacrificing cost-effectiveness.

NEX Pickleball distinguishes itself from other manufacturers by combining several key advantages:

Our use of multiple types of carbon fiber—including 3K, 12K, and T300—ensures that you get a product that is not only durable but also optimized for different performance requirements. This flexibility in material selection allows for a wide range of pricing options, ensuring that whether your focus is on cost or performance, we can meet your specific requirements.

By leveraging hot pressing, cold pressing, and thermoforming, NEX Pickleball is able to tailor production processes to match specific product demands. This multi-faceted approach means that we can produce paddles that suit different market segments—from entry-level to professional-grade—at pricing structures that reflect the quality and performance of each variant.

With increasing demand for differentiation in the sports equipment market, customization has become a key factor in purchasing decisions. NEX Pickleball offers on-demand print services and the ability to fine-tune paddle characteristics such as weight, balance, and grip size, giving you the flexibility to tailor your order to your market’s unique needs. This level of customization not only adds value to the end product but also enhances your brand's appeal to your customers.

A strong reputation in B2B trade is built on reliability and consistency. Our rigorous testing phases ensure that every paddle that leaves our facility has been made to the highest quality standards. By reducing the rate of defects and improving overall product performance, we offer long-term benefits that justify a more efficient procurement process.

Timely delivery and transparent communication are cornerstones of successful B2B relationships. With a well-established supply chain and streamlined production protocol, NEX Pickleball can guarantee both rapid turnaround times and consistent product availability. This predictability in supply is essential for managing large orders and ensuring that your retail or distribution operations run smoothly.

Understanding the factors that drive pickleball paddle pricing is essential for making informed purchasing decisions in a competitive B2B landscape. With material quality, production processes, and supplier efficiencies playing pivotal roles, procurement managers must evaluate not only the price tag but also the long-term performance and reliability of the products.

NEX Pickleball leverages advanced production techniques combined with high-quality material sourcing to provide products that are both competitively priced and superior in performance. When evaluating suppliers, consider the following recommendations:

• Analyze the material types used and ensure they meet your performance needs.

• Compare the manufacturing processes in use, focusing on production efficiency and quality control.

• Inquire about bulk order discount structures and customization options to maximize your ROI.

• Evaluate the supplier’s track record in supply chain management and timely delivery.

By thoroughly assessing these criteria and understanding the cost dynamics in paddle production, you can secure a partnership that maximizes performance quality while adhering to budget constraints. NEX Pickleball is committed to delivering products that not only meet but exceed market expectations, making us a reliable partner in your sourcing strategy.

Q: What is the best value pickleball paddle for the money?

A: The best value pickleball paddle strikes a balance between performance-enhancing materials and pricing efficiency. While budget options exist, models incorporating premium features such as multi-grade carbon fibers, and advanced manufacturing processes like cold pressing or thermoforming, often offer superior durability and performance. Evaluating suppliers who focus on quality control and offer bulk discounts will help secure the best overall value.

Q: How much should a good pickleball paddle cost?

A: A well-made pickleball paddle typically costs between $30 and $100. Paddles at the lower end of the price range are often suited for beginners, whereas premium paddles designed with high-performance materials and advanced production methods tend to be priced higher. It is essential to balance price with performance to meet the needs of your target market.

Q: What is the best pickleball paddle manufacturer?

A: The best pickleball paddle manufacturer combines superior material quality, efficient production processes, and consistent quality control. Leading brands, including those that produce high-performance paddles with advanced carbon fibers and offer wide customization, set industry standards. It is important to compare manufacturers based on capability, reliability, and overall value—attributes that suppliers like NEX Pickleball have consistently demonstrated.

-

Pickleball Paddle Pricing: Click to explore a comprehensive guide on the factors and cost drivers influencing pickleball paddle pricing, helping optimize procurement decisions. ^Return ↩

-

Hot Pressing: Click to learn about hot pressing technology, its efficiency benefits in mass production, and its impact on product durability and cost. ^Return ↩ ↩2

-

Cold Pressing: Click to understand the cold pressing process, its role in preserving material properties, and how it contributes to precise product quality. ^Return ↩ ↩2

-

Thermoforming: Click to read about thermoforming techniques, their advantages in creating complex designs, and their applications in custom manufacturing. ^Return ↩ ↩2

-

Carbon Fiber: Click to read an in-depth article on the properties, grading, and applications of carbon fiber in high-performance manufacturing. ^Return ↩ ↩2