Surface defects in pickleball paddles are often caused by inconsistencies in production processes such as hot pressing, cold pressing, or thermoforming1. Identifying these issues early and applying targeted quality control interventions is key to ensuring high performance and durability in your final products.

In today's high-performance sporting equipment market, ensuring the quality of pickleball paddles is a top priority for quality control managers, product developers, and procurement specialists. Surface defects—ranging from delamination2 to dead spots—can affect not only the playability of the paddle but also the brand’s reputation in competitive sports. Let’s delve deep into the common challenges encountered during production, analyze their root causes, and provide actionable solutions tailored to manufacturing high-standard pickleball paddles.

Surface defects during the manufacturing process can manifest in various ways. Common issues include:

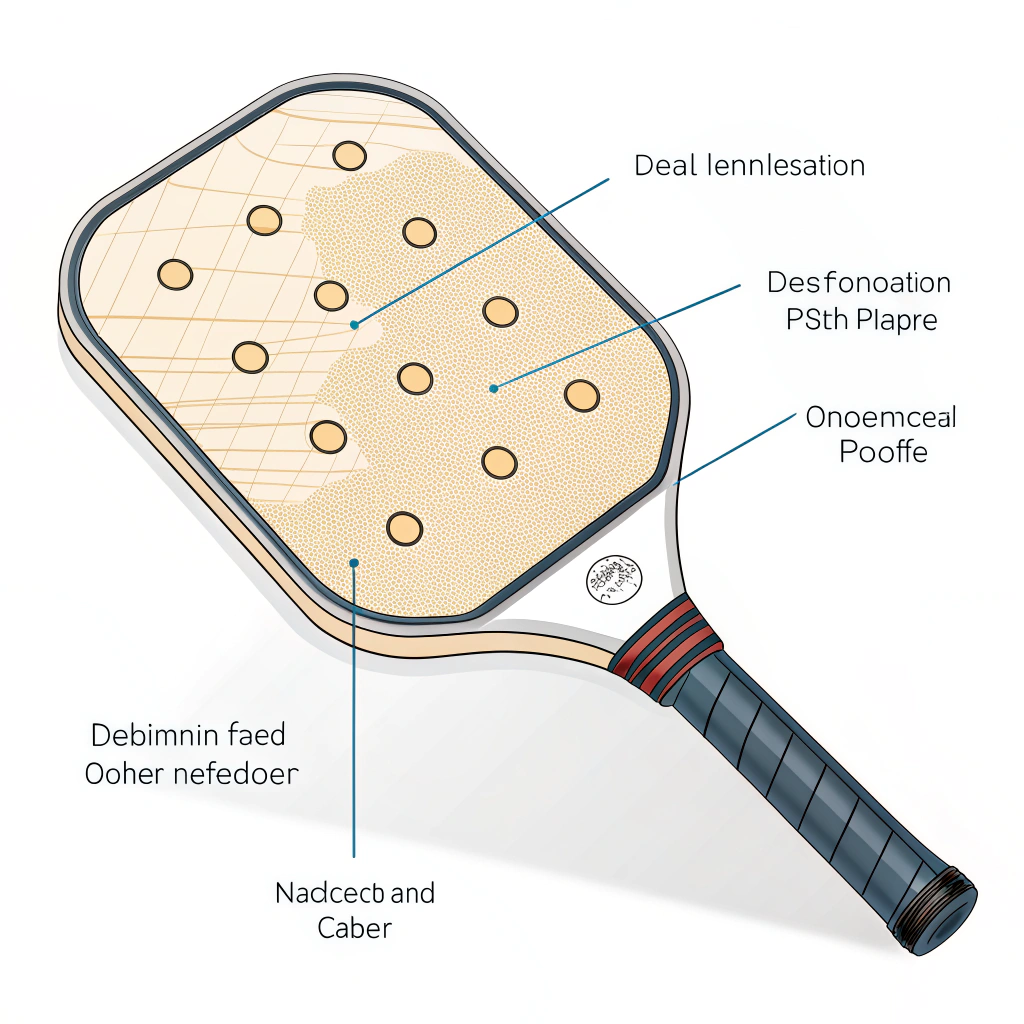

- Delamination2: Bubbling, peeling, or soft spots on the paddle’s surface.

- Dead Spots: Areas where the paddle has diminished responsiveness or where impacts consistently damage the surface.

- Uneven Texture: Inconsistent surface finishes caused by improper material distribution or pressure application.

- Material Imperfections: Visible flaws in the carbon fiber, fiberglass, or composite layers that result in reduced structural integrity.

These defects are not only unsightly but can significantly affect performance factors such as rebound, ball control, and overall player comfort. When even minor discrepancies exist, the overall durability and longevity of the paddle are at risk.

Several key factors contribute to the development of surface defects in pickleball paddles:

-

Material Quality and Handling:

The use of diverse premium materials like 3K, 12K, or T300 carbon fiber3 alongside fiberglass and composite materials can introduce inconsistencies if not handled properly. For example, any contamination or improper layering may result in delamination or weak spots. -

Inadequate Pressing Processes:

Each manufacturing process—namely, hot pressing, cold pressing, and thermoforming—has its inherent challenges.- In hot pressing, extreme heat coupled with high pressure, while effective for enhancing durability, may sometimes alter material properties if not perfectly controlled.

- Cold pressing requires precise pressure regulation over longer cycles, and any deviation might lead to uneven surface textures.

- Thermoforming1, though excellent for complex shapes, demands precise temperature control; slight variations can result in material softening beyond optimal levels, leading to defects.

-

Tooling and Equipment Limitations:

High-performance production techniques require advanced machinery. Outdated or improperly calibrated equipment can disrupt the uniformity of pressure, temperature, or mold conformity, hence creating imperfections. -

Inconsistent Production Parameters:

Variability in setting the processing parameters such as temperature, pressure, and cycle duration is a common culprit. Even minor fluctuations can change the behavior of composite materials, leading to areas with insufficient bonding or variable hardness. -

Quality Control Gaps:

Without regular inspection and immediate feedback loops within the production line, early signs of surface defects can be overlooked. This delay in identifying issues can cascade into larger production lots with compromised quality.

To address and prevent these surface defect issues, here is a detailed set of solutions:

- Strict Material Inspection: Implement a rigorous incoming material inspection process emphasizing the integrity of carbon fiber, fiberglass, and composite layers.

- Controlled Environment: Maintain controlled humidity and temperature conditions in storage areas to prevent material degradation before processing.

A comparative analysis of production processes can help identify critical control points:

| Process | Advantages | Disadvantages | Key Considerations |

|---|---|---|---|

| Hot Pressing | High efficiency; strong, durable paddles | May alter material properties; high equipment cost | Ensure precise control of temperature and pressure |

| Cold Pressing | Maintains material properties; better for precise control | Longer cycle durations; requires high-quality equipment | Use calibrated machines for consistent pressure |

| Thermoforming | Allows for intricate designs; optimal for premium materials | Extended production times; higher cost | Monitor temperature uniformity and mold specifications |

- Process Calibration: Regularly calibrate equipment and monitor key parameters closely. Automated sensors and digital data logging can help maintain consistency.

- Process Standardization: Develop and adhere to strict Standard Operating Procedures (SOPs) for each pressing process. Document any changes and continuously train operators on best practices.

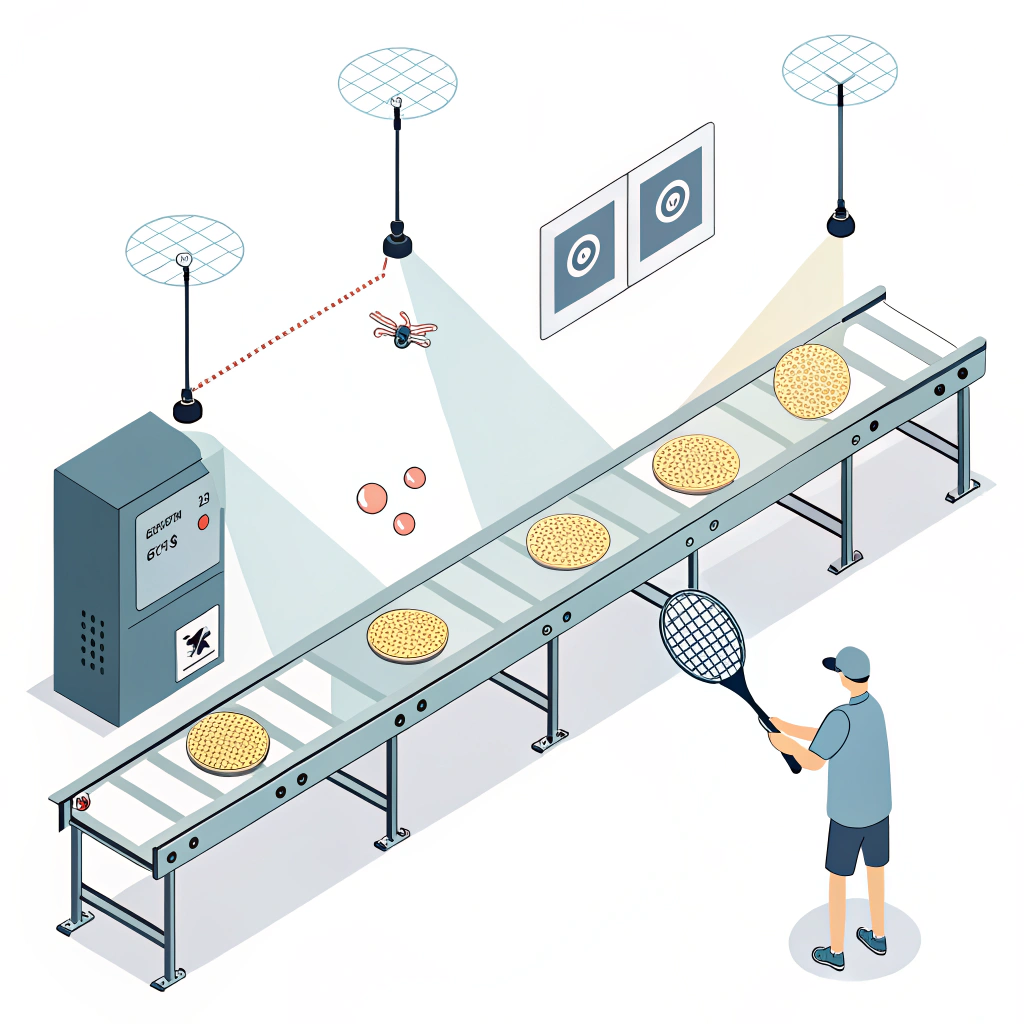

- In-line Inspection Systems4: Introduce high-resolution cameras or sensor-based systems with real-time feedback to detect early signs of delamination, dead spots, or uneven textures.

- Regular Audits and Reviews: Conduct periodic quality audits at each production stage. Track defect rates and analyze trends to feed back into process improvements.

- Operator Training: Ensure that production staff are well-trained in both the technical aspects of machinery operation and the visual cues of potential surface defects.

- Statistical Process Control (SPC)5: Apply SPC methods to monitor process variability and maintain tighter control over production parameters. Use control charts to identify when a process drifts from acceptable ranges.

- Immediate Corrective Actions: When a defect is identified, halt production for a mini-assessment and immediately address the anomaly. This might include adjusting the temperature, pressure, or conducting a recalibration run.

- Share Insights: Build a platform or regular review sessions where teams across quality control, production, and product development can share insights on recurring issues and effective solutions.

- Partner with Experts: Consider engaging with external experts or consultants to audit your process and suggest further refinements. Collaboration with upstream suppliers can also provide better raw material quality assurances.

A leading manufacturer in the sports equipment sector recently faced issues with delamination. Their initial root cause analysis revealed a combination of inconsistent hot pressing and material pre-conditioning problems. By recalibrating the pressing equipment, instituting a stricter material handling protocol, and introducing real-time monitoring systems, they were able to reduce surface defect rates by over 30% within six months.

Key data points from their process improvement included:

- A 25% drop in material handling-related defects.

- A 15% increase in production efficiency due to fewer reactor stoppages.

- Improved product performance based on extensive client feedback in competitive play.

This case reinforces the value of integrating technology, standardized processes, and continuous quality feedback to improve overall product durability and performance.

While implementing these strategies, it is essential to remain mindful of the following:

- Investment in Technology: Upgrading to advanced QC systems and automated machinery requires significant investment. However, the long-term benefits in product quality and production efficiency often offset the initial costs.

- Adaptation to Different Materials: Each material type—whether carbon fiber, fiberglass, or composite—behaves differently. Tailoring the process parameters for different materials is essential for optimal results.

- Balance Between Speed and Precision: Increasing production speed can sometimes compromise quality. Striving for a balance between efficiency and precision is crucial.

- Interdepartmental Communication: Ensuring that all stakeholders, from procurement to quality control, are on the same page is vital for the successful implementation of these improvements.

In summary, tackling surface defects in pickleball paddles requires a comprehensive and systematic approach:

- Begin with understanding the root causes of defects such as delamination, dead spots, and material inconsistencies.

- Optimize each production process (hot pressing, cold pressing, thermoforming) with stringent controls and regular calibration.

- Enhance quality control through real-time inspection systems and effective feedback loops.

- Collaborate across departments and with industry experts to share insights and drive continuous improvement.

For quality control managers and production teams, the actionable next steps are:

- Audit your current production processes to identify any inconsistencies or calibration issues.

- Invest in technology and staff training to implement robust real-time quality control measures.

- Standardize operating procedures across all production lines and monitor key performance indicators regularly.

- Consider partnering with external experts to benchmark your processes against industry best practices.

Implementing these changes will not only reduce surface defects but also improve the overall performance and longevity of your paddles, thereby enhancing customer satisfaction and competitive advantage.

What does a delaminated pickleball paddle look like?

A delaminated pickleball paddle often exhibits bubbling or peeling on its surface along with uneven textures. When you run your hand over the face, you might notice soft spots that differ from the rest of the paddle, signaling that the layers have separated.

What are the dead spots on pickleball paddles?

Dead spots are areas on the paddle—commonly at the top corners, above the handle, or at the center of the sweet spot—where the paddle's responsiveness is reduced. These occur due to repeated impacts or due to the paddle absorbing too much shock in a localized area.

What is the life expectancy of a pickleball paddle?

The life expectancy of a pickleball paddle varies. Casual players might expect 1 to 3 years of use, while frequent players may need to replace their paddle every 6 months to a year, depending on the level of use and care provided.

-

thermoforming: Reading this article will provide insights into the thermoforming process, its challenges, benefits, and the importance of precise temperature control in producing complex shapes with optimal material properties. ↩ ↩ ↩2

-

delamination: Discover how delamination occurs during production, why it degrades product performance, and methods to detect and prevent this common defect. ↩ ↩ ↩2

-

3K, 12K, or T300 carbon fiber: Learn about the differences between 3K, 12K, and T300 carbon fibers, including their structural characteristics and implications for material strength in high-performance applications. ↩ ↩

-

In-line Inspection Systems: Understand the role of in-line inspection systems in real-time quality assurance, including how sensor- and camera-based technologies can identify defects early in the manufacturing process. ↩ ↩

-

Statistical Process Control (SPC): Explore how SPC techniques help monitor production variability, enabling tighter quality control and early detection of process deviations. ↩ ↩