Discover effective strategies to avoid common pitfalls in the import process of pickleball products, ensuring smooth regulatory compliance, robust quality control, and optimized logistics management.

In today’s fast-paced global market for sports equipment, importing pickleball products can be both a lucrative and challenging venture. As international trade grows and regulations evolve, import managers, procurement specialists, and company executives need to stay well-informed to avoid costly mistakes. In this article, we detail the common challenges in importing pickleball equipment and provide actionable, practical solutions to manage these issues. Our discussion is supported by industry data, real-world examples, and professional insights—anchored in our deep manufacturing expertise at NEX Pickleball.

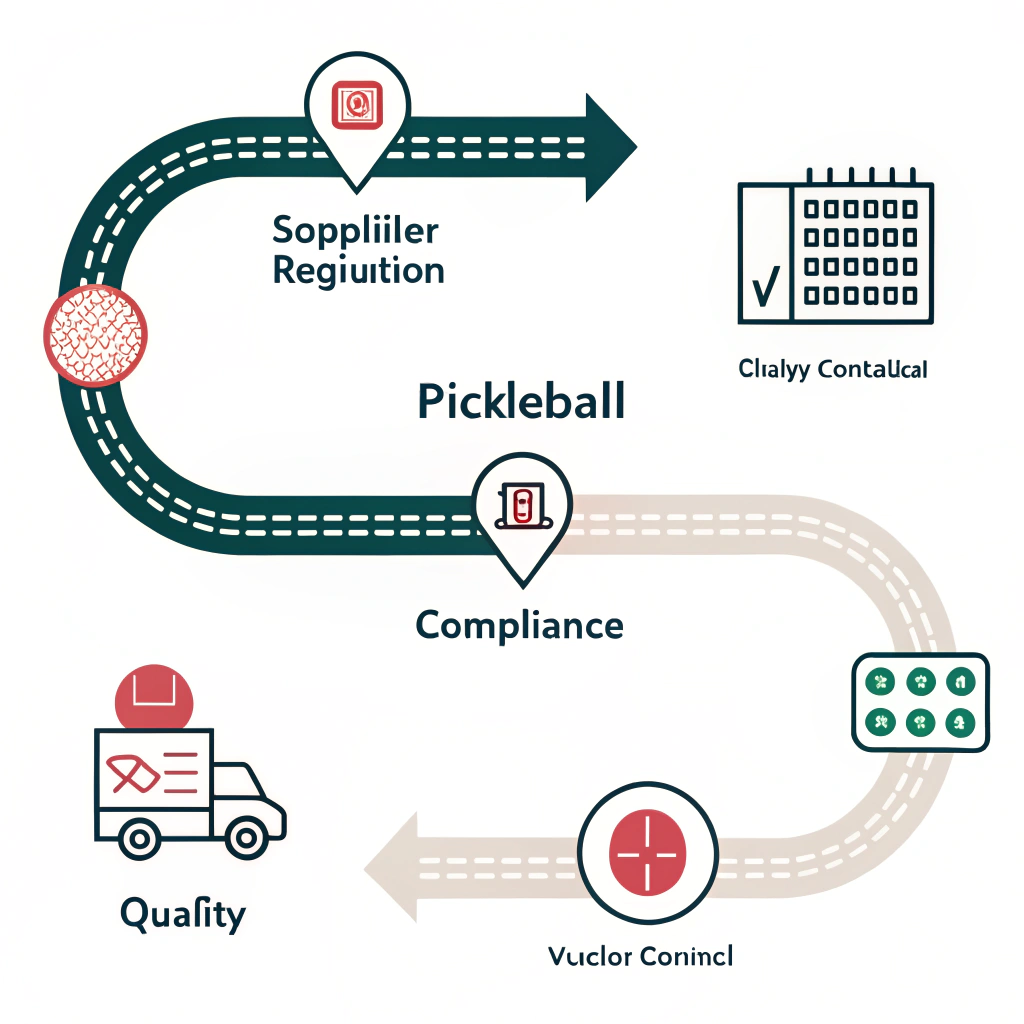

Importing pickleball products involves navigating a complex landscape of regulatory issues, quality assurance demands, and logistical challenges. Many business buyers expect that sourcing high-performance paddles from reputable manufacturers such as NEX Pickleball will be straightforward. However, slight oversights or misinterpretations of international trade norms can lead to:

• Unanticipated regulatory setbacks

• Costly delays due to shipping or customs clearance issues

• Inconsistent quality control between manufacturing batches

• Documentation or compliance errors that result in increased duty fees or penalties

The initial step to mitigating these risks involves a deep understanding of the underlying causes and aligning your procurement strategy accordingly.

Several factors contribute to the import pitfalls associated with pickleball products. They are interdependent and require a multi-faceted approach to resolve:

-

- International trade regulations vary by country, and there are often intricate requirements for product certification, labeling, and customs clearance.

- Changes in trade policies or tariff structures can impact cost estimates and timelines.

-

Supplier Vetting and Quality Assurance:

- Ensuring that your supplier maintains high quality standards is critical. Not all manufacturers adhere to strict quality control processes.

- Variations in production processes—such as hot pressing, cold pressing, and thermoforming2—may affect the consistency and durability of the paddle products.

-

Logistics and Documentation Challenges:

- Shipping delays are common when clear protocols for documentation and compliance are not rigorously followed.

- Inadequate planning around packaging, warehousing, and transportation can cause damage to the products during transit, affecting their performance upon arrival.

Understanding these issues at the ground level is essential for developing a robust strategy that not only minimizes risks but also strengthens the overall import process.

Step 1: Supplier Vetting3 and Production Oversight

-

Conduct Rigorous Supplier Audits:

Evaluate the supplier’s production processes. For example, assess the use of 3K Carbon Fiber4, 12K Carbon Fiber, or T300 Carbon Fiber, and how these materials affect paddle performance. -

Establish Quality Control Protocols:

Confirm that the manufacturer’s quality control measures, including in-process checks during hot pressing, cold pressing, and thermoforming, are robust and meet international standards. -

Request Product Samples and Certifications:

Before finalizing contracts, review samples that undergo rigorous testing for durability, vibration reduction, and overall performance. Certifications from recognized authorities further validate product quality.

-

Understand International Trade Regulations:

Work with customs brokers or trade consultants who are well-versed in trade regulations for sporting goods. This ensures all documentation is in order for seamless customs clearance. -

Regularly Update Compliance Knowledge:

International standards and certification requirements can change rapidly. Keeping abreast of these changes minimizes risks associated with non-compliance. -

Standardize Documentation:

Implement a checklist for all necessary documents—commercial invoices, packing lists, certificates of origin, and product safety certificates help avoid unnecessary delays.

-

Plan for Shipping and Handling:

Develop a clear logistics plan that accounts for the unique shipping requirements of pickleball paddles, particularly sensitive materials that may be impacted by temperature or humidity changes. -

Choose Reliable Shipping Partners:

Evaluate shipping carriers and freight forwarders with proven track records in handling sporting goods. Their expertise in international shipping can mitigate risks of damage and delays. -

Consider Insurance and Contingency Plans:

Protect your shipment against unforeseen issues such as delays or damage. Insurance coverage provides an added layer of security and peace of mind.

-

Develop a Risk Management Plan5:

Identify potential issues before shipment and create contingency actions. This could include setting aside extra budget for unexpected duties or reserving alternate shipping routes. -

Establish Communication Channels:

Maintain transparent and constant communication with your supplier and logistic partners. Real-time updates can help avoid last-minute surprises during the import process.

| Aspect | Risk/Challenge | Effective Strategy | Outcome Expected |

|---|---|---|---|

| Supplier Vetting | Variable quality standards | Conduct thorough supplier audits; review sample products | Consistent high-quality products |

| Quality Control | Inconsistent production processes | Implement strict quality checkpoints during each production stage | Improved consistency and durability |

| Regulatory Compliance | International certification discrepancies | Work with trade experts; ensure complete documentation and certifications | Streamlined customs clearance |

| Logistics Management | Shipping delays and damage | Develop logistics plans; select experienced shipping partners | Timely and safe product delivery |

| Risk Management | Unpredictable additional costs | Create contingency plans and reserve extra budget | Minimized financial risks |

Consider a scenario where a procurement specialist from a European distribution company decided to source pickleball paddles from a new supplier. Initially, they encountered problems with delayed shipments due to unclear documentation. Additionally, product inconsistency emerged because the supplier had recently switched production processes without updating quality control protocols. By following the steps mentioned earlier—conducting a detailed supplier audit, updating documentation standards, and partnering with a seasoned freight forwarder—the company quickly remedied these issues.

Another compelling example comes from NEX Pickleball’s own experience. When a bulk order was scheduled for shipment overseas, our logistics manager identified potential delays due to new tariff regulations introduced mid-production. By preemptively verifying current customs guidelines and liaising with a trusted broker, we adjusted our shipping schedule and avoided costly delays. Such real-world cases reinforce the importance of proactive risk management and continuous monitoring of regulatory changes.

Furthermore, a survey among import managers in the sporting goods industry revealed that nearly 65% had experienced at least one instance of delayed delivery or non-compliance within the last two years. Key factors contributing to these issues included evolving trade policies and insufficient supplier audits. This data underscores the need for a strategic approach based on the solid principles outlined in this article.

Based on the analysis and solutions presented, here are recommendations that every business buyer should consider:

-

Prioritize Supplier Due Diligence:

Make detailed supplier audits standard practice. Validate not only the quality of finished products but also the consistency of production processes. -

Invest in Regulatory Research:

Regularly consult with trade professionals and use specialized software tools to track changes in international trade policies and tariffs. -

Enhance Communication and Coordination:

Establish clear channels between procurement, quality assurance, and logistics teams. This ensures rapid dissemination of information regarding any change in regulatory guidelines or unexpected shipment issues. -

Implement a Robust Logistics Strategy:

Develop a logistics plan that is both flexible and comprehensive. Consider options such as expedited shipping when necessary, and always have contingency logistics providers on standby. -

Leverage Technology for Quality Assurance:

Use data analytics and quality control software to track product performance from sample testing through to final shipment. Technologies like blockchain can also be considered for transparent tracking of the supply chain. -

Plan Financially for Unforeseen Costs:

Always include an allowance for additional charges like increased tariffs or expedited shipping fees. This risk management practice can prevent unforeseen financial burdens.

Success in importing pickleball products hinges on meticulous planning, proactive risk management, and rigorous quality control. By understanding the regulatory intricacies, evaluating supplier capabilities, and optimizing logistics, business buyers can maintain a smooth and cost-effective import process. At NEX Pickleball, we exemplify these principles through our commitment to advanced production techniques and strict quality standards.

Importers who embrace these best practices are better positioned to navigate the inherent challenges of international trade and secure a competitive edge in the sports equipment market. Our experiences and industry insights clearly demonstrate that an investment in due diligence and continuous improvement is an investment in long-term success.

It is crucial for procurement professionals to take a proactive approach—engaging in detailed research and strategic planning—to mitigate risks before they escalate into significant obstacles. With changing market conditions and regulatory landscapes, constant vigilance, and adaptability will ensure that your import operations remain both profitable and resilient.

• What are the main pitfalls when importing pickleball products?

Importing pickleball products can face challenges such as inconsistent quality control, complex regulatory requirements, and logistics delays. These issues often arise from inadequate supplier vetting, changing trade policies, and poor shipping documentation practices.

• How can importers ensure compliance with international regulations?

To ensure compliance, importers should work closely with trade experts, maintain updated documentation for certifications and invoices, and leverage professional customs brokers. Regular audits and a proactive approach to reviewing regulations also play a critical role in avoiding non-compliance penalties.

• What strategies help mitigate logistic challenges in international trade?

Effective strategies include developing a detailed logistics plan, partnering with reliable shipping and freight forwarders, and ensuring that all product documentation is complete. Additionally, planning for potential delays with contingency measures, such as insurance and alternate shipping plans, can significantly reduce risks in international trade.

-

Regulatory Complexity: Click to learn how intricate layers of international trade rules and certification requirements influence cost estimates, timelines, and overall risk in global product imports. ↩ ↩

-

Thermoforming: Click to explore the manufacturing process of thermoforming, its impact on product durability, and why it is key to maintaining consistent quality in production. ↩ ↩

-

Supplier Vetting: Click to delve into supplier vetting best practices, including audit protocols and criteria for evaluating production processes to ensure reliable quality and consistency. ↩ ↩

-

3K Carbon Fiber: Click to understand the characteristics of 3K Carbon Fiber, its applications in high-performance sporting goods, and how it compares to other carbon fiber variants. ↩ ↩

-

Risk Management Plan: Click to read about effective risk management strategies in international trade, including contingency planning, budgeting for unforeseen costs, and methods to mitigate potential disruptions. ↩ ↩