Cold pressing offers precise control over material thickness and retains ideal material properties, while thermoforming1 enables the creation of more complex and refined paddle designs. This article provides a detailed technical comparison between these two advanced production processes for high-performance pickleball paddles, guiding B2B procurement managers and manufacturing engineers through the decision-making process.

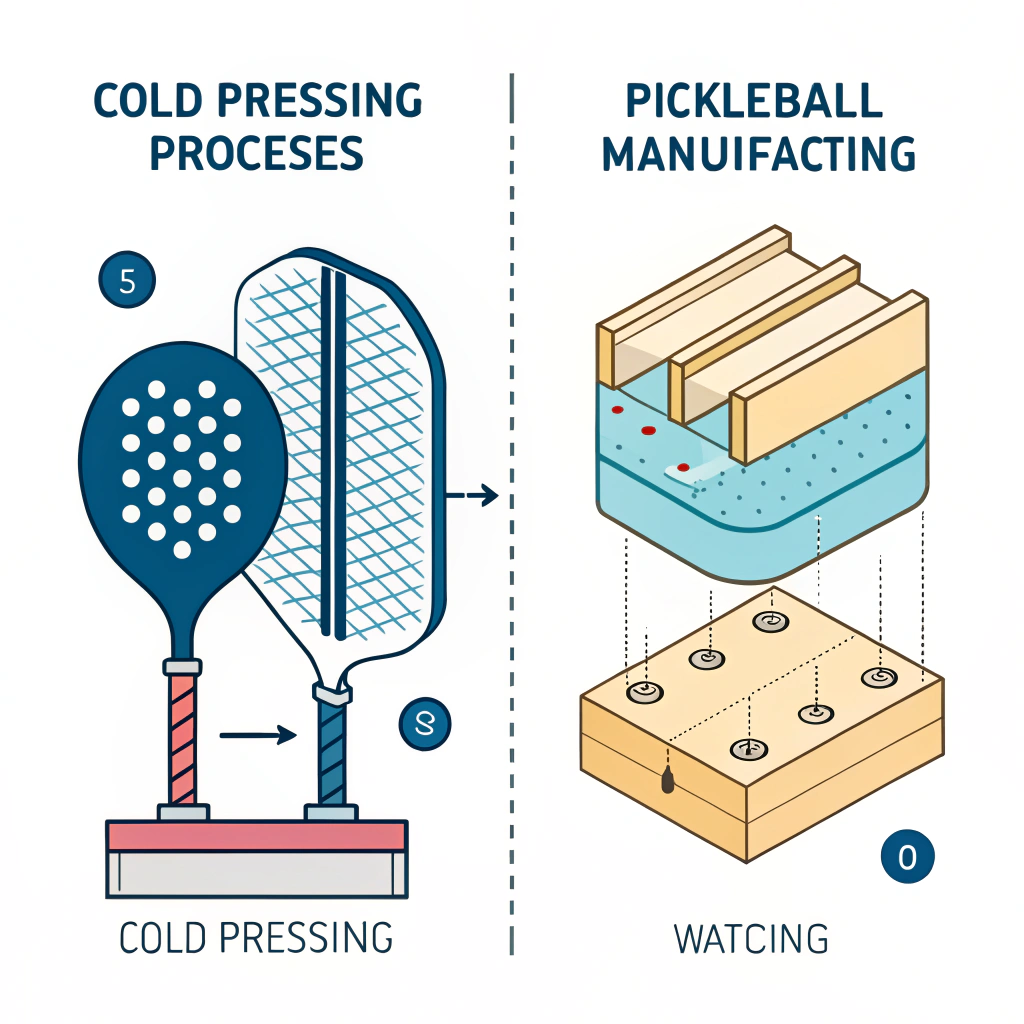

Modern pickleball paddles rely on advanced production techniques to deliver the best balance of durability, performance, and cost efficiency. Two popular manufacturing methods are cold pressing2 and thermoforming. Both processes have unique benefits and trade-offs, making them suitable for different production goals:

• Cold Pressing: This process shapes paddle materials at room temperature under controlled mechanical pressure. It preserves the intrinsic properties of each material, providing high precision in thickness and structure. It is ideal when product uniformity and ball feel are paramount.

• Thermoforming: This method is based on heating the material until it softens and then using molds to shape it. It is highly effective in producing paddles with intricate designs, ensuring excellent material distribution and structural stability. Thermoforming is often chosen for premium product lines that demand high aesthetic quality and complex designs.

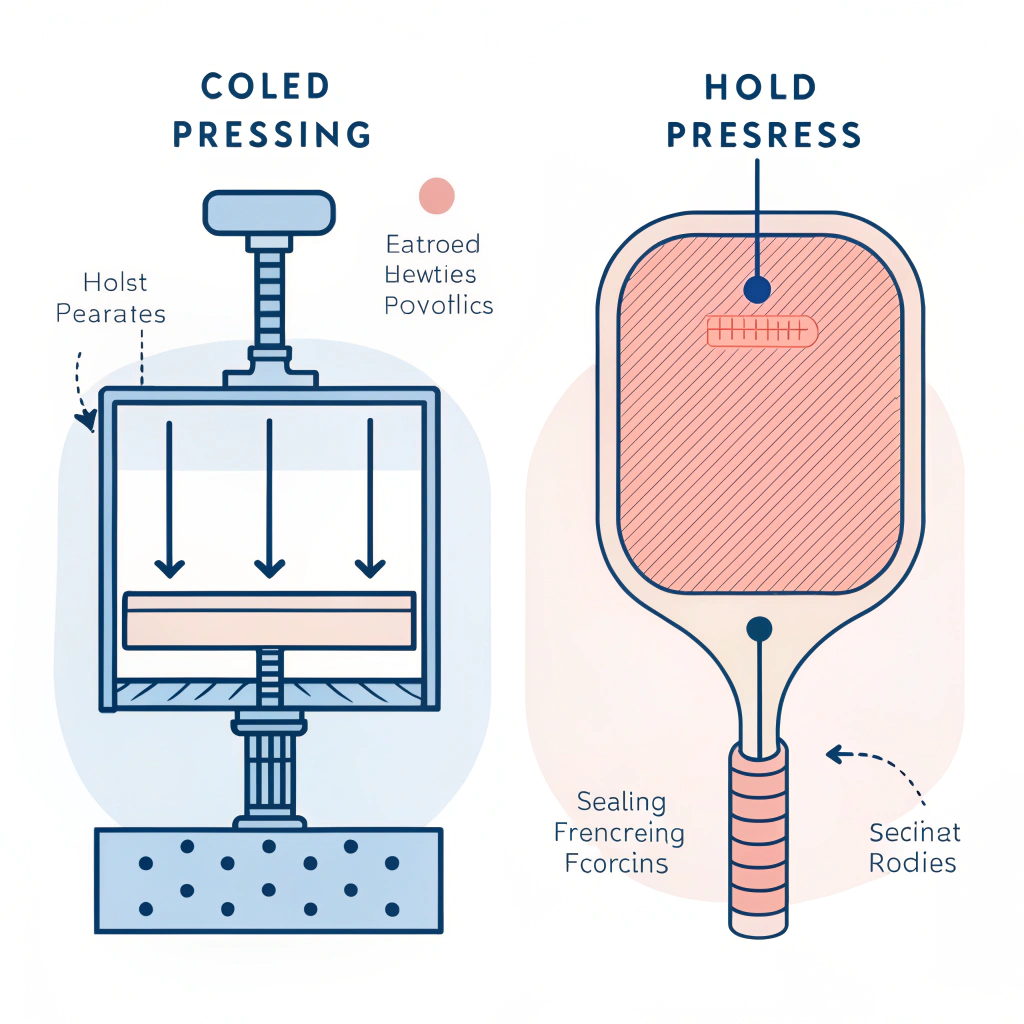

When using the cold pressing process, manufacturers benefit from a technique that emphasizes consistency and control over the fundamental properties of the paddle.

Advantages:

• Precision Control: Cold pressing allows fine-tuning of the paddle’s thickness and structural integrity without altering the inherent material properties. This results in a highly consistent product.

• Enhanced Ball Feel: Since the process is performed at room temperature, the tactile feedback remains intact. This control leads to superior ball control and responsiveness during play.

• Material Integrity: The cold press process minimizes the risk of material degradation, ensuring the paddle maintains its designed flexibility and shock absorption properties.

Disadvantages:

• Longer Production Cycle: Due to the need for controlled pressure and precision calibration, the production cycle can be slower compared to thermoforming.

• Investment in Precise Equipment: Achieving high-quality outcomes requires advanced machinery that maintains consistent pressure control, which might result in higher initial investment.

Thermoforming involves heating materials to a softening point followed by using molds to form the paddle shape. This process is particularly advantageous for designs that require intricate geometries and specialized material distribution.

Advantages:

• Design Flexibility: Thermoforming enables the creation of paddles with complex shapes and optimized surface treatments. This process can also integrate unique ergonomic features to improve player comfort.

• Uniform Material Distribution: When performed correctly, thermoforming can ensure that the polymer or composite material is evenly distributed, which enhances paddle stability and power.

• Stability and Durability: The controlled heating and molding process can significantly improve the structural integrity of the paddle, making it more resistant to physical stresses such as impacts and abrasions.

Disadvantages:

• Longer Production Time: The heating and cooling cycles extend the overall production time, which might reduce throughput in a large-scale manufacturing environment.

• Higher Equipment Costs: Specialized heating molds and precise temperature control systems are required, making the process capital intensive.

| Criteria | Cold Pressing | Thermoforming |

|---|---|---|

| Control & Precision | High precision and consistent material properties; ideal for maintaining tactile ball feel. | Allows for intricate designs but may slightly alter material properties due to heat. |

| Production Efficiency | Slower production cycle; demands high-quality pressure control systems. | Generally faster in creating complex shapes; longer cycle time overall due to heating/cooling. |

| Cost Implications | Requires precise machinery; higher labor intensity means moderate equipment investment. | Involves high initial investment in molds and temperature control systems; cost-effective for premium product lines. |

| Durability & Stability | Excellent control over material integrity may result in optimized durability. | Superior structural integrity and aesthetic finish, making them highly durable against impacts. |

| Customization | Ideal for custom paddle specifications with unique ball feel. | Best for paddles with complex design requirements and ergonomic enhancements. |

Manufacturers must evaluate the balance between efficiency and quality control when selecting a production process. Cold pressing ensures a high degree of uniformity in paddle structure. This method is preferred when the emphasis is on replicable quality and ease of quality control. In contrast, thermoforming excels in high-volume production where appealing aesthetics and design variations are also critical factors.

• For batch production where consistent thickness and material properties yield optimal performance, cold pressing remains favorable.

• When the design and surface complexity are key differentiators, the additional time and investment in thermoforming may result in a product that attracts a premium segment.

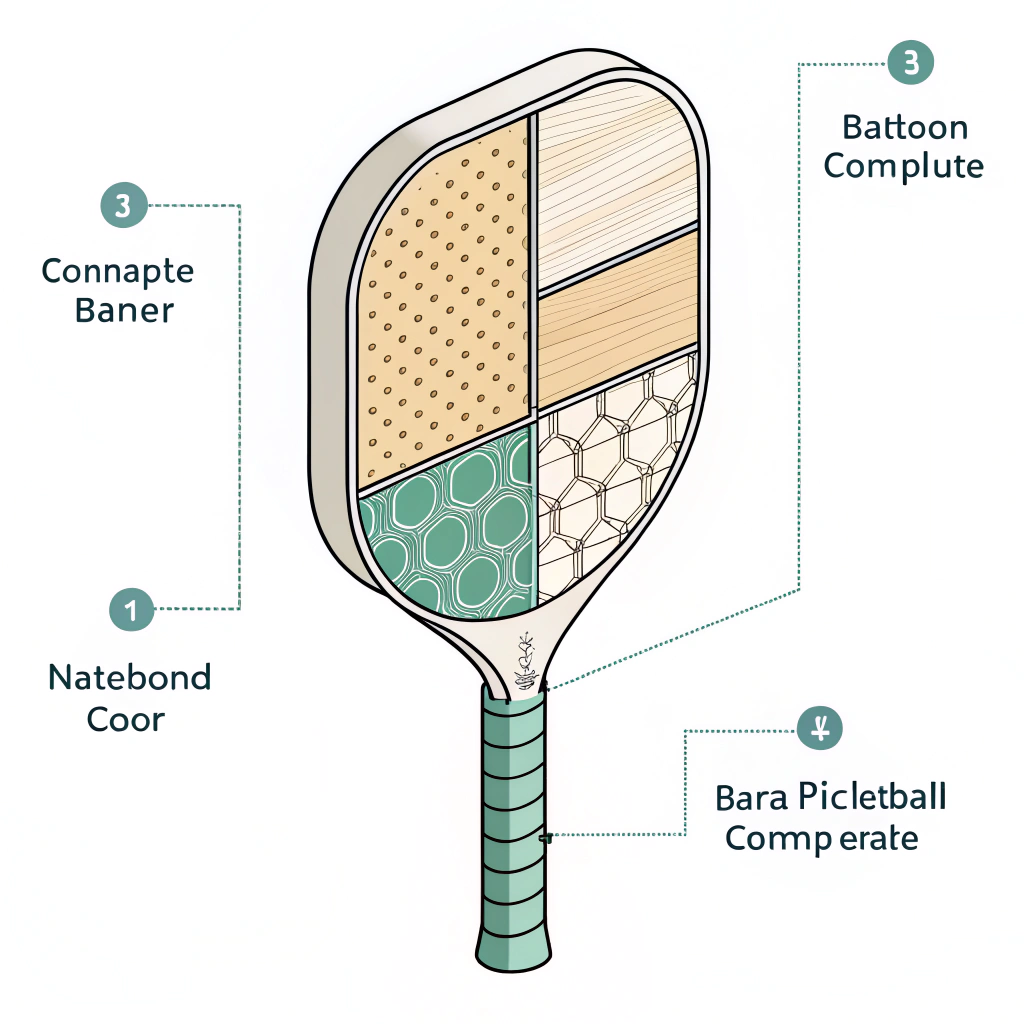

The paddle’s performance is heavily influenced by how well its materials are processed. With cold pressing, the low-temperature environment protects sensitive materials such as carbon fibers3 and fiberglass from potential degradation that heating could cause. This process ensures that the paddle retains the engineered balance needed for optimal ball response.

Thermoforming, by contrast, leverages high temperature to mold the paddle into a highly consistent and durable finish. The process is particularly effective when working with composite materials4 that combine benefits such as enhanced impact resistance and lightweight durability. For instance, paddles constructed with a bamboo core composite or honeycomb core significantly benefit from the molding process that thermoforming affords.

Cost considerations play a vital role in manufacturing decisions. Manufacturers must compare not only the immediate production costs but also the long-term benefits regarding durability, performance, and market positioning.

Cold Pressing Cost Factors:

• Direct labor and time investment are relatively high due to the need for precision control.

• Equipment costs involve advanced pressure monitoring devices which can be moderate to high depending on production scale.

• Lower energy consumption because the process is conducted at room temperature.

Thermoforming Cost Factors:

• Higher equipment costs are associated with heating systems and custom molds.

• Energy consumption is higher due to the need for heating and controlled cooling cycles.

• However, the ability to produce premium designs may justify the investment through higher market prices and differentiated products.

Manufacturers often balance these factors by segmenting production lines: using cold pressing for cost-sensitive, performance-focused lines and thermoforming for high-end, feature-rich paddle offerings.

When determining which manufacturing method to adopt, consider the following real-world factors:

-

Target Market and Product Positioning:

If the goal is to supply high-volume, competitively priced paddles with consistent qualities, cold pressing is very attractive. On the other hand, if targeting a premium market where aesthetics and unique design features add extra value, thermoforming may be the better option. -

Material Choices and Design Requirements:

Manufacturers using sensitive materials need to consider the effect of heat on material properties. For example, T300 Carbon Fiber5 retains its performance characteristics best under the controlled conditions of a cold press. Meanwhile, composite materials that benefit from a uniform finish might be best processed through thermoforming. -

Equipment and Production Scale:

Scaling production efficiently involves consideration of capital expenditure. Cold pressing can be more time-consuming but may incur lower running costs. Thermoforming, with its higher initial investment, is ideal for operations that can absorb the cost and benefit from a faster response to complex design demands. -

Quality Assurance and Durability:

Both processes offer their strengths in terms of durability. Cold pressing ensures that material properties remain intact while thermoforming guarantees a smooth, uniform structure that enhances impact resistance. The choice depends on whether you prioritize tactile performance or a robust finish that can better resist dings and dents. -

Application and End-Use Scenarios:

For paddles intended for high-performance competitive play, the excellent ball feel and precision from cold pressing may give players a competitive edge. In contrast, recreational or custom-branded paddles that require an eye-catching design, and therefore a high aesthetic value, are better served by thermoforming.

Manufacturers might also consider a hybrid approach—applying cold pressing for the structural core while using thermoforming for the outer design layers. This fusion can balance both performance and design attributes and represents an emerging trend in paddle manufacturing.

Recommendations for Decision Makers:

• Conduct product testing to understand how each manufacturing process impacts performance metrics such as rebound force, impact resistance, and vibration dampening.

• Evaluate long-term production costs against potential market price points to determine which process affords greater profitability.

• Consider customer feedback and market trends—especially the rising demand for custom, premium-designed paddles—to future-proof production investments.

In summary, each manufacturing process—cold pressing and thermoforming—has distinct advantages in the production of high-performance pickleball paddles. Cold pressing excels in delivering a consistent, precise paddle with an unparalleled ball feel, while thermoforming provides the design flexibility and enhanced aesthetic appeal that can command a premium in the market. B2B procurement managers and manufacturing engineers should carefully evaluate production volumes, material requirements, and market positioning to make an informed trade-off decision.

Ultimately, the choice between cold pressing and thermoforming depends on your specific production goals, resource availability, and long-term strategic objectives. By considering the detailed comparisons discussed above, you can optimize your manufacturing process to deliver high-quality paddles that meet both performance standards and market expectations.

Q: Do thermoformed paddles last longer?

A: Thermoformed paddles generally exhibit exceptional durability due to the use of high-quality polymer materials that are resistant to dings, dents, and surface wear. The thermoforming process also ensures a uniformly distributed structure that enhances overall longevity.

Q: Is hot press or cold press pickleball paddles better?

A: The choice depends on the desired performance characteristics. Hot press paddles offer consistent performance and enhanced durability, while cold press paddles provide a unique feel and superior control. Both methods have their advantages depending on the target market and production requirements.

-

thermoforming: Click here to learn about the thermoforming process, its applications in manufacturing complex designs, and its role in producing aesthetically refined products. ↩ ↩

-

cold pressing: Read the article to understand the principles and benefits of cold pressing, including how it preserves material integrity and ensures precise product specifications. ↩ ↩

-

carbon fibers: Explore this resource for insights into carbon fibers, their properties, and why they are critical in maintaining high performance and material durability during manufacturing. ↩ ↩

-

composite materials: Discover how composite materials combine different substances to offer strength and light weight, and how they are optimized in advanced manufacturing processes. ↩ ↩

-

T300 Carbon Fiber: Read more about T300 Carbon Fiber, a high-performance material used in manufacturing for its superior strength-to-weight ratio and consistency under varying temperatures. ↩ ↩