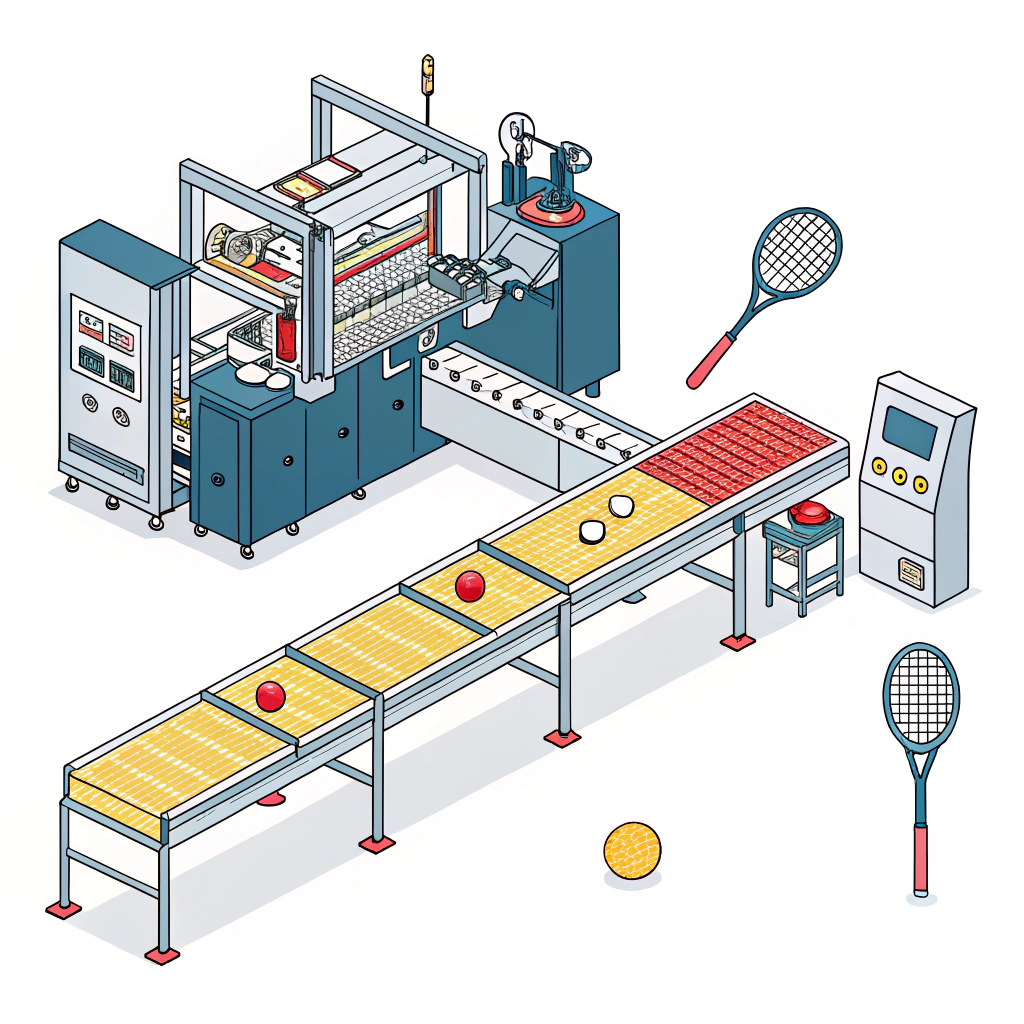

Quick Answer: Chinese pickleball paddles combine advanced manufacturing techniques, premium materials, and custom design options to deliver high-performance equipment for competitive and recreational play. NEX Pickleball leverages processes such as hot pressing, cold pressing1, and thermoforming2 to create durable, precise paddles tailored for today’s dynamic sports market.

In today’s rapidly growing pickleball market, procurement managers and product development specialists demand paddles that deliver not only superior performance but also long-term durability. With rising competition and evolving player needs, understanding the production processes and material qualities inherent in Chinese pickleball paddles is vital for making sound purchasing decisions. In this article, we explore the manufacturing practices behind high-quality paddles, focusing on advanced materials like carbon fiber3, fiberglass4, and various composites.

Problem Description

Procurement teams in sports equipment distribution face several critical challenges when sourcing pickleball paddles:

• Ensuring that the paddles achieve a perfect balance of power, control, and comfort.

• Finding suppliers who adopt advanced production techniques that maintain consistent quality.

• Verifying that different materials such as carbon fiber and composite materials meet specific competitive performance demands.

• Identifying long-term partners that offer customization, on-demand printing, and design flexibility.

For many companies, choosing the right manufacturer means carefully analyzing both the materials and the processes used. Chinese manufacturers, like NEX Pickleball, have made a name in the B2B space by not only meeting but exceeding quality standards through innovative production methods.

Cause Analysis

Understanding the manufacturing processes is central to addressing these challenges. Here are the main reasons why production processes and material choices are critical:

- Material Quality: The paddle’s face and core materials, such as 3K carbon fiber or T300 carbon fiber, directly impact performance. Higher thread densities – as seen with 12K carbon fiber – offer greater hardness and resilience.

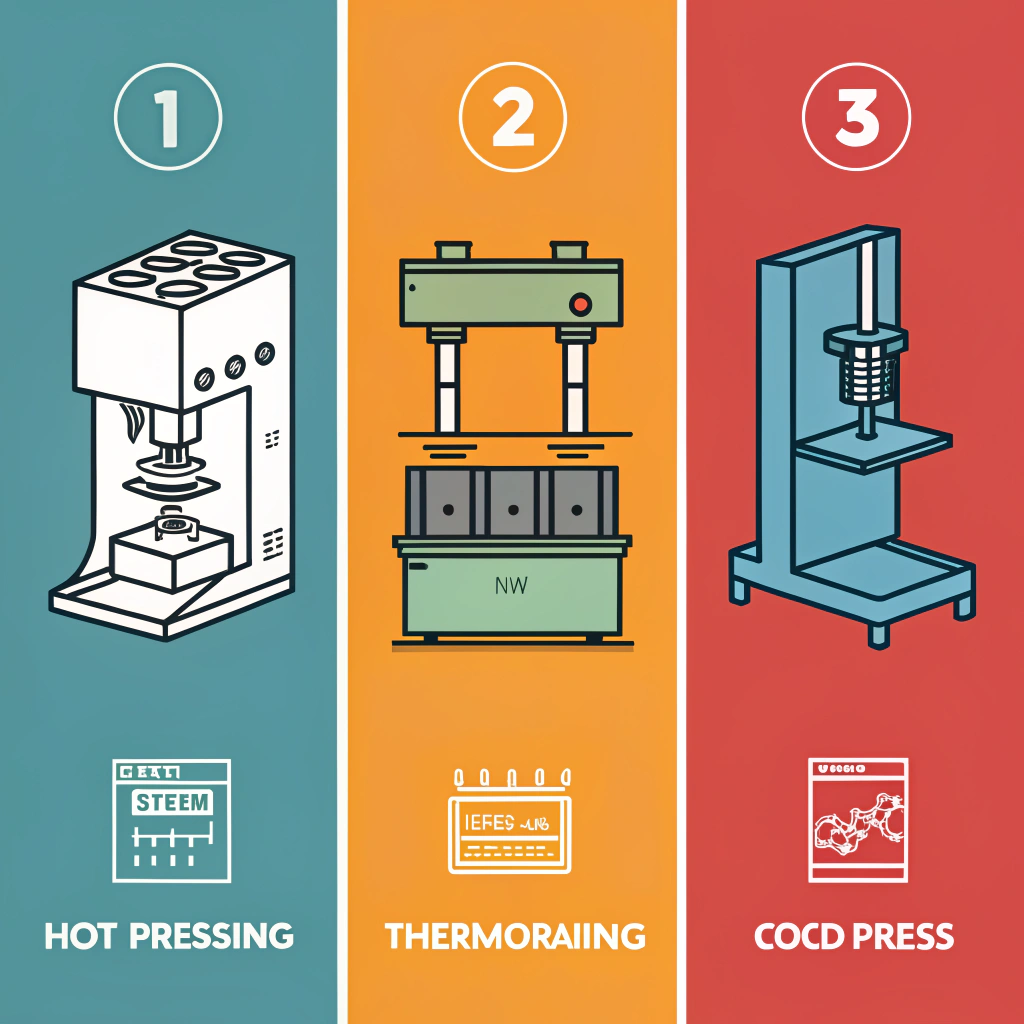

- Production Techniques: Processes like hot pressing, cold pressing, and thermoforming influence the paddle’s structural integrity. Each has distinct advantages and limitations that affect performance, durability, and production efficiency.

- Customization Options: The modern procurement landscape often demands on-demand printing services and bespoke design specifications. Custom paddle design services allow businesses to market unique branded equipment, thereby enhancing customer engagement.

- Quality Control: Consistent quality control using advanced testing ensures that every paddle meets safety and performance benchmarks. Manufacturers like NEX Pickleball undertake rigorous inspection to maintain competitive premium standards.

Solution: Detailed Overview of Manufacturing Processes

Manufacturers, particularly those based in China, have developed sophisticated production processes to meet global demands. Let’s take a closer look at each process and the role they play in crafting high-performance pickleball paddles.

Hot pressing involves heating materials and simultaneously applying high pressure to form a paddle. This process is known for its high production efficiency and strong impact resistance.

Advantages:

• Efficient for large-scale production.

• Yields durable paddles with excellent shock absorption.

• Enhances the overall impact resistance and structural integrity.

Disadvantages:

• Requires significant investment in high-temperature equipment.

• Heat exposure might alter the natural feel of the paddle.

Cold pressing shapes the paddle under mechanical pressure at room temperature. This method is best for designs requiring precise control over thickness and material distribution.

Advantages:

• Maintains the intrinsic properties of each material.

• Provides excellent ball control and a refined hitting feel.

• Allows precise control over paddle weight distribution.

Disadvantages:

• Longer production cycles compared to hot pressing.

• Demands precision equipment to ensure consistent quality.

Thermoforming heats the material to its softening point and molds it into the desired shape using custom-designed molds. This technique is ideal for producing paddles with complex designs and dynamic material distribution.

Advantages:

• Facilitates intricate designs and precise material layout.

• Enhances the stability of the paddle during play.

• Provides flexibility in combining multiple high-performance materials.

Disadvantages:

• Longer production time may increase manufacturing cost.

• Higher investment in specialized molds and heating equipment.

Below is a comparative table of these production processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, strong structure | High equipment cost, potential material alteration |

| Cold Pressing | Precise control, maintains material properties, excellent ball feel | Longer cycle time, precision pressure control needed |

| Thermoforming | Intricate design capabilities, maintains stability, versatile | Longer production time, higher equipment costs |

Material Innovations and Their Impact

The performance of a pickleball paddle is not solely dependent on the production process; the choice of materials plays an equally crucial role. At NEX Pickleball, a variety of premium materials are utilized:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Offers a robust yet flexible structure, ideal for paddles that require high rebound performance. This material helps reduce vibration, ensuring a smoother playing experience.

- 12K Carbon Fiber: With a denser weave, it provides unparalleled hardness and durability. This type is particularly suited for competitive play where extreme impact resistance is necessary.

- T300 Carbon Fiber: Known for exceptional tensile strength and weight balance, T300 is perfect for players looking for a harmonious blend of power and agility.

-

Fiberglass Options:

- E-Glass Fiberglass: Delivers excellent elastic properties and tensile strength. Its natural flexibility enhances ball control, making it highly suited for paddles where precision is paramount.

-

Composite Materials:

- Carbon Fiber and Fiberglass Composite: Combines the strengths of both materials to offer enhanced durability without compromising on speed and control.

- Bamboo Core Composite: Lightweight and impact-resistant, offering a clear ball contact feel ideal for prolonged use.

- Honeycomb Core: Promotes superior shock absorption, reducing vibration and extending paddle lifespan.

-

Core Materials:

- Nomex Honeycomb Core: Excellent for long-lasting durability and exceptional impact absorption.

- Aluminum Honeycomb Core: Balances weight distribution, providing both power and precision.

- Polymer Honeycomb Core5: Provides enhanced elasticity and improved user comfort, particularly beneficial for recreational players.

By leveraging these advanced materials, manufacturers can tailor paddles to meet varying performance needs, ensuring that whether for competitive or recreational use, every paddle delivers exceptional control and power.

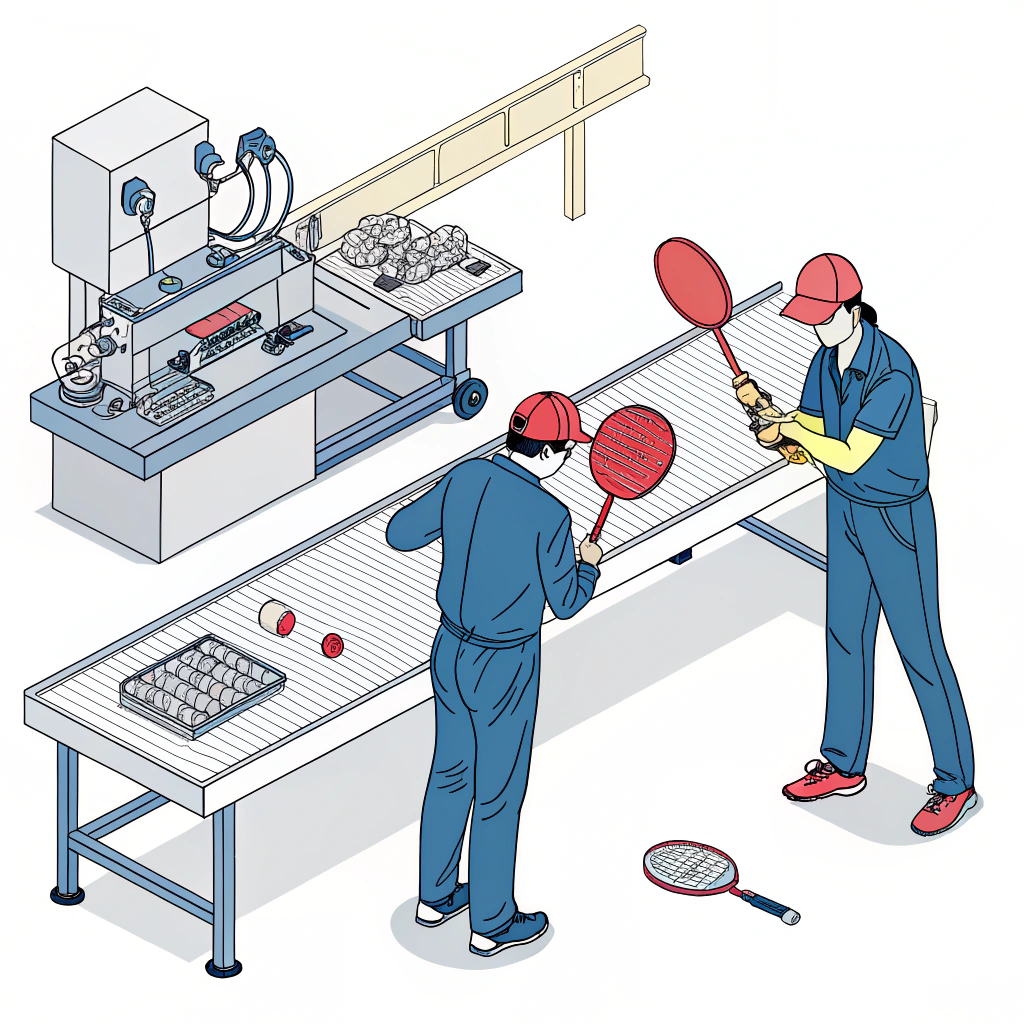

Quality Control and Customization: Ensuring Consistency in Manufacturing

For B2B buyers, consistent quality is non-negotiable. NEX Pickleball implements strict quality control measures, ensuring that each paddle is meticulously tested for performance, strength, and durability. This attention to detail translates into equipment that not only meets regulatory standards but also exceeds end-user expectations.

Key aspects of quality control include:

• Rigorous pre-production material testing to verify material integrity and performance.

• Continuous monitoring throughout the production cycle to detect any deviations early.

• Post-production evaluations, including durability tests and impact resistance assessments.

• Customized finishing options, including on-demand printing and ergonomic grip modifications, which are essential for brand differentiation.

These measures contribute to a transparent production process, giving clients the confidence that every product delivered is built to last and perform under competitive conditions.

Case Study: NEX Pickleball’s Production Excellence

NEX Pickleball stands as a prime example of how these manufacturing processes and material innovations come together to create a top-tier product. By combining advanced production techniques with strict quality control protocols, the company consistently delivers paddles that satisfy even the most demanding B2B clients.

For instance, when a major sports equipment distributor required paddles that could withstand the rigors of professional play while being lightweight enough for rapid response, NEX Pickleball utilized a T300 carbon fiber face paired with a Polymer Honeycomb Core5. The result was a paddle that offered a perfect blend of control, power, and reduced vibration – exactly what the distributor needed to meet the demands of professional training.

Furthermore, customization options allowed the distributor to integrate on-demand printing services, enabling them to offer personalized designs for local teams and league events. This not only strengthened brand loyalty but also expanded the company's reach in the competitive sports equipment market.

Actionable Insights and Recommendations

For procurement managers and product development specialists evaluating suppliers, the following insights can guide your decision:

- Emphasize the importance of production processes as a key indicator of product performance. Understand whether the manufacturer uses hot pressing, cold pressing, or thermoforming and how each process aligns with your product goals.

- Assess the materials used in paddle construction. Key components such as carbon fiber types, fiberglass, and composite cores play a crucial role in determining the final product's durability and performance.

- Look for manufacturers that maintain strict quality control standards throughout the production process. Request documentation or certifications that showcase their testing procedures and quality metrics.

- Consider customization options. On-demand printing and bespoke design capabilities can add significant value, enabling you to differentiate your product in the market.

- Request case studies or client testimonials that demonstrate the manufacturer’s ability to solve specific performance or longevity challenges.

Following these guidelines can help you select a manufacturer with the technical expertise and production capability to meet your precise requirements for a high-quality, competitive product offering.

People Also Ask

PAA1: What is the best Chinese brand pickleball paddle?

Answer: DinkPickleball is often recognized as a leading Chinese brand in pickleball paddles. Their products, known for high-quality materials and precision design, are used by top players globally and boast a strong reputation in competitive use.

PAA2: Are Selkirk pickleball paddles made in China?

Answer: While Selkirk & Selkirk LABS paddles are assembled or manufactured in the USA with careful quality control, it is common that a significant portion of their components originates from China.

PAA3: Are Paddletek paddles made in China?

Answer: Not all pickleball paddle brands are made in China. Paddletek, for instance, uses USA-sourced carbon fiber for their face material and manufactures their core materials domestically, differentiating their supply chain from some other brands.

-

Cold Pressing: Click to read more about how cold pressing preserves material integrity and contributes to precise weight distribution and enhanced ball control in high-performance equipment. ↩ ↩

-

Thermoforming: Click to explore the thermoforming process which involves heating materials to mold complex designs, ensuring stability and versatility in product manufacturing. ↩ ↩

-

Carbon Fiber: Click to learn about carbon fiber’s unique properties, including high strength-to-weight ratio and vibration reduction, which are critical for advanced sports equipment. ↩ ↩

-

Fiberglass: Click to understand the benefits of fiberglass, such as its elastic properties and tensile strength, and how it enhances performance in competitive and recreational equipment. ↩ ↩

-

Polymer Honeycomb Core: Click to discover how Polymer Honeycomb Core technology improves elasticity and user comfort, offering significant performance advantages in sports equipment manufacturing. ↩ ↩ ↩2