China Pickleball Paddles are manufactured in China using advanced production techniques1 and premium materials, making them a competitive choice for OEM partnerships2 and distributors seeking high performance, durability, and customization options.

In today’s competitive sports equipment market, many procurement managers and OEM partners search for reliable, cost-efficient, and technically advanced manufacturers. China pickleball paddles have emerged as a top choice due to their innovative production processes and the use of premium materials. In this article, we will explore the various production methods, material benefits, and real-world performance data that underline why China remains a leading global supplier. Our focus is on the key aspects that B2B buyers must consider when selecting a manufacturing partner for high-performance pickleball paddles.

Manufacturing a high-quality pickleball paddle requires understanding the unique balance between performance, durability, and cost-efficiency. Decision makers need to address common challenges such as:

- Ensuring consistent quality across large production runs.

- Maintaining high production efficiency while keeping cost levels competitive.

- Integrating state-of-the-art material technologies, such as multiple types of carbon fiber3 and innovative core materials.

- Offering customization options for various player needs and market segments.

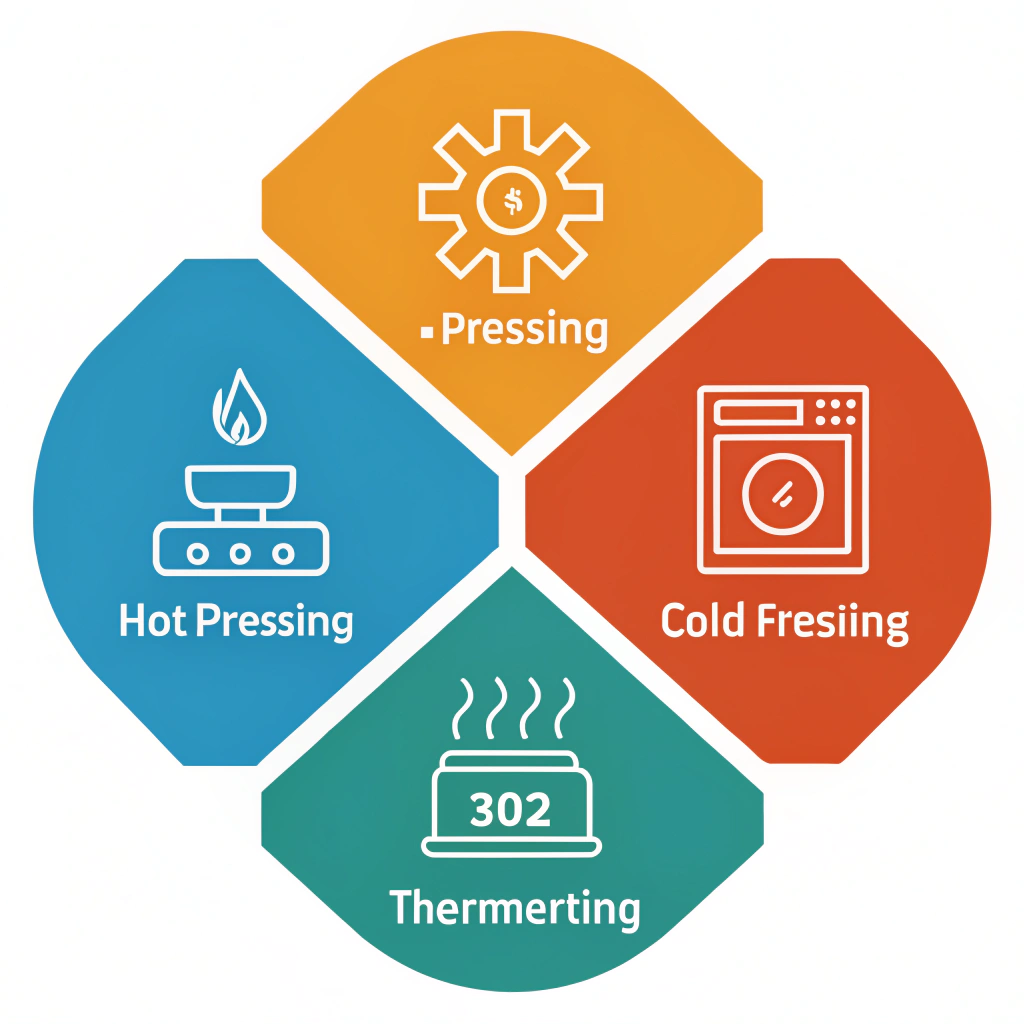

Addressing these challenges requires production processes that can deliver precision and durability. For instance, advanced methods like hot pressing, cold pressing, and thermoforming4 allow manufacturers to tailor the paddle’s structure and performance characteristics to meet client expectations.

The choice of production process significantly influences the final product's attributes. Here we dive into the three primary manufacturing processes used in China’s pickleball paddle production:

This process involves heating and applying uniform pressure to materials, forming a durable and robust structure.

Advantages:

• High production efficiency – ideal for large-scale manufacturing.

• Excellent impact resistance and structural strength.

• Consistent quality, making paddles suitable for competitive play.

Disadvantages:

• Possibility of altering some material properties, which may affect the paddle’s "feel".

• Requires significant investment in specialized equipment.

The cold pressing process shapes the paddle at room temperature, allowing for greater control over material properties.

Advantages:

• Maintains the original material characteristics for superior ball control and responsiveness.

• Precise regulation of thickness and density, which enhances the tactile experience.

Disadvantages:

• Longer production cycles when compared to hot pressing.

• High-quality equipment is necessary to ensure precise pressure regulation.

Thermoforming involves heating the materials to a soft state and using specialized molds to obtain complex paddle shapes.

Advantages:

• Ability to create innovative designs with intricate material distribution.

• Maintains paddle stability, enhancing both control and performance.

Disadvantages:

• Higher equipment investments and longer production times make it best suited for premium or custom products.

Below is a comparison table summarizing these production processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance; consistent quality | May affect material feel; high equipment costs |

| Cold Pressing | Superior ball control; precise thickness control; preserves material properties | Longer cycle times; precision equipment required |

| Thermoforming | Enables complex designs; maintains stability; ideal for premium products | Higher production time; increased equipment investment |

Each process has its role depending on the specific requirements of the final product. For instance, OEM partners needing bulk production with reliable performance may lean towards hot pressing, while those prioritizing custom designs and detailed control might choose thermoforming.

China manufacturers excel not only in production processes but also in the application of a wide range of high-performance materials. These include various types of carbon fiber, different grades of fiberglass, and composite materials – each contributing unique benefits:

-

3K Carbon Fiber

- Offers high strength and flexibility.

- Excellent durability with a reduced vibration profile, leading to improved player comfort.

-

12K Carbon Fiber

- Provides a smoother surface and higher thread density.

- Known for superior hardness and extreme strength, suitable for competitive-level performance.

-

T300 Carbon Fiber

- Balances tensile strength with lightweight properties.

- Frequently used in paddles requiring agile performance without compromising power.

- Fiberglass paddles are celebrated for their enhanced ball control and wider sweet spot, making them an excellent choice for recreational players.

- Composite options, such as the combination of carbon fiber and fiberglass, provide a remarkable balance between strength and flexibility.

- Bamboo Core Composite and Honeycomb Core structures further optimize paddle weight distribution and shock absorption, ensuring longevity and a superior hitting feel.

The strategic use of these materials is a testament to the evolving technology in OEM pickleball manufacturing – ensuring each paddle meets the high standards demanded by competitive play.

The core of any pickleball paddle is critical in defining its playing characteristics. Various core materials used include:

-

Nomex Honeycomb Core

- Offers excellent shock absorption.

- Ensures durability and consistency for high-impact gameplay.

-

Aluminum Honeycomb Core

- Provides balanced weight distribution, blending power and precision.

- Ideal for players who require both strength and controlled performance.

-

- Emphasizes elasticity and minimizes vibration.

- Frequently preferred by recreational players due to its comfort-focused design.

These core innovations are especially important for buyers looking to supply paddles suited for diverse competitive levels, from casual play to high-stakes tournaments.

Several factors set Chinese manufacturers apart in the global marketplace:

• Extensive expertise in using high-precision equipment for production processes.

• A deep understanding of material science that drives continuous improvements in product performance.

• Flexible production capabilities that allow for customized orders, from paddle design to specific material formulations.

• Competitive pricing structures, thanks to scaled manufacturing and efficient processes.

Our company, NEX Pickleball, has embraced these advanced techniques to become a trusted OEM partner for internationally renowned brands such as Joola and Selkirk. By investing in innovative production processes like hot pressing, cold pressing, and thermoforming, we ensure that every paddle meets stringent quality control standards.

These advantages enable B2B partners to not only optimize their supply chains but also cater to a market that increasingly demands precision, durability, and tailored product options.

Several OEM clients have experienced significant benefits by partnering with Chinese manufacturers for their pickleball paddle needs. Some key insights include:

-

Enhanced Production Efficiency:

Clients have noted a marked improvement in their supply chain timelines, as high production efficiency directly correlates to faster order fulfillment and reduced lead times. This speed is critical when meeting market demand for high-performance sports equipment. -

Superior Customization Capabilities:

OEM partners appreciate the ability to customize paddle designs, including material selection and core structures. This flexibility ensures that each product variant is tailored to specific market segments – from high-end competitive play to more affordable recreational options. -

Quality and Performance Consistency:

Rigorous quality control protocols are implemented during every stage of production. Regular testing of paddle attributes such as impact resistance, vibration reduction, and ergonomic design has resulted in improved player comfort and durability, directly influencing customer satisfaction and return business.

A case study from an established sports distributor highlighted a 30% improvement in product durability and a significant reduction in production defects after shifting to a Chinese OEM partner proficient in advanced thermoforming techniques. Such outcomes reinforce the tangible benefits of choosing a manufacturer that is highly experienced in modern pickleball paddle technology.

For procurement managers and OEM partners evaluating suppliers, here are a few critical tips for making an informed decision:

-

Analyze Production Processes:

Compare the technical advantages of hot pressing, cold pressing, and thermoforming relative to your product needs. A detailed comparison table can clarify the trade-offs in efficiency, quality, and cost. -

Assess Material Quality:

Ensure that the manufacturer has a rigorous material sourcing strategy. Look for the use of advanced carbon fibers, reliable fiberglass, and innovative composites that guarantee enhanced performance. -

Inspect Customization Capabilities:

Evaluate whether the supplier can deliver custom paddle designs tailored to different market segments. This flexibility is essential for maintaining competitive advantage and meeting diverse consumer demands. -

Review Quality Control Procedures:

Inquire about the manufacturer’s testing protocols and quality assurance measures. Consistent testing helps in achieving long-term product reliability and customer satisfaction. -

Consider Cost Efficiency:

While quality is paramount, overall cost efficiency also matters. A balanced approach that factors in production efficiency, material costs, and customization ability will guide you to a supplier that maximizes your ROI.

By following these guidelines, you can confidently choose a manufacturing partner that not only meets your technical specifications but also provides a competitive edge in a crowded market.

China remains a dominant force in the manufacturing of high-performance pickleball paddles. The integration of advanced production techniques and superior material innovations has elevated the quality and performance of these products, making them an excellent option for OEM partners and distributors worldwide.

For B2B buyers, the process of selecting a manufacturing partner involves careful analysis of production methods, material choice, and customization capabilities. The ability to tailor designs through processes like hot pressing, cold pressing, and thermoforming provides significant benefits, including enhanced durability, improved player experience, and efficient production cycles.

Our comprehensive analysis underscores that Chinese manufacture does not imply compromise on quality. Instead, it highlights a commitment to precision engineering and innovation. As a trusted OEM partner, NEX Pickleball leverages these advantages to deliver products that resonate with the demands of recreational and competitive players alike. The result is a strategic collaboration that benefits distributors, sports equipment retailers, and ultimately the players who enjoy a truly enhanced game experience.

We encourage procurement managers and OEM partners to evaluate these factors closely and consider the tangible value offered by Chinese manufacturers. Whether you require large-scale production, custom design capabilities, or specialized material expertise, aligning with a partner that understands the nuances of pickleball paddle technology can significantly elevate your offerings in the highly competitive sports equipment market.

Are Paddletek paddles made in China?

Most high-performance paddle manufacturers source materials and assemble products in China, but brands like Paddletek use USA-sourced carbon fiber and produce their own cores in the USA. The distinction lies in the manufacturing model and the sourcing strategy.

Which pickleball paddles are not made in China?

Some pickleball paddles, including the Gamma 405 Graphite Pickleball Paddle (Pennsylvania), PROLITE Stealth GS2 Carbon Fiber Pickleball Paddle (Wisconsin), and Paddletek Bantam Carbon Fiber Pickleball Paddles (Michigan), are manufactured in the USA. These brands emphasize local production and sourcing, which distinguishes them from Chinese-made alternatives.

-

advanced production techniques: Reading this article will help you understand how modern manufacturing technologies streamline production and improve product quality, offering significant competitive benefits. ↩

-

OEM partnerships: Explore insights into how collaborating with Original Equipment Manufacturers can provide streamlined supply chains, improved product consistency, and scalability. ↩

-

carbon fiber: Learn more about carbon fiber, including its properties and benefits in enhancing performance and durability in high-tech sporting equipment. ↩

-

thermoforming: Discover the thermoforming process, its advantages in creating complex shapes, and how it contributes to producing high-performance, custom-designed products. ↩

-

Polymer Honeycomb Core: This article explains the engineering behind Polymer Honeycomb Cores, focusing on their role in reducing vibration and improving product comfort and performance. ↩