The high-level answer is that partnering with a reliable Chinese manufacturer like NEX Pickleball – with advanced production techniques, rigorous quality control, and proven export expertise – ensures high-performance, durable pickleball paddles that meet the demanding standards of global markets.

Procurement managers and sourcing agents in the sports equipment industry face multiple challenges when selecting a manufacturing partner. They must evaluate production capabilities, technological processes, material quality, and export track records. In the demanding domain of pickleball paddles, small differences in production methods and material specifications can significantly affect performance on the court. For instance, a paddle's responsiveness, durability, and overall feel hinge on the choice of core materials and the precision of production processes.

At NEX Pickleball, we understand that technical precision and compliance with international trade guidelines are non-negotiable. Clients often struggle with issues like inconsistent quality between production batches, lack of transparency in production processes, and inadequate customization. Our advanced manufacturing techniques and commitment to quality control provide a clear solution for procurement managers who need a dependable partner.

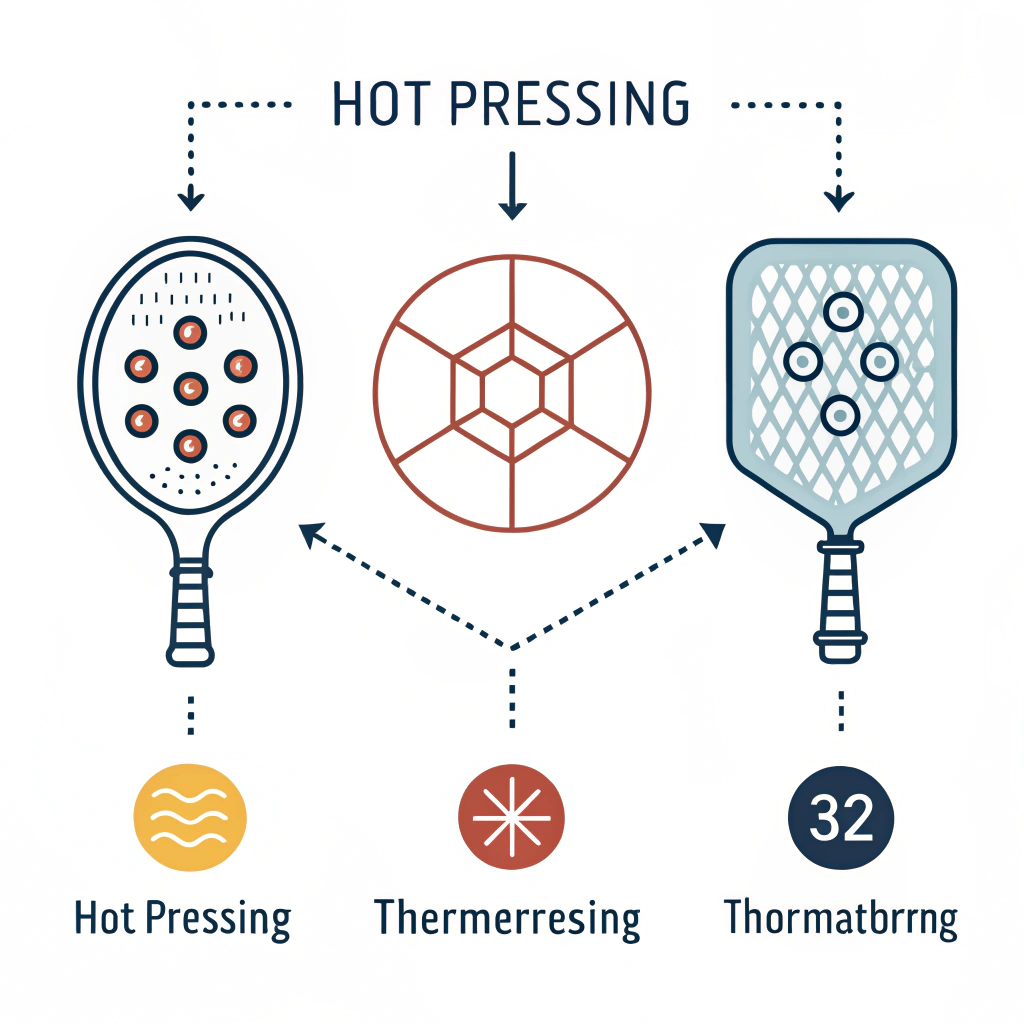

One of the core factors in paddle performance is the production process. Different techniques such as hot pressing, cold pressing1 and thermoforming2 each come with their unique advantages and limitations.

| Process | Advantages | Limitations | Suitable For |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; durable | May alter material feel; high equipment investment | High-strength paddles |

| Cold Pressing | Precise control over thickness; retains original material properties; excellent ball feel | Longer production cycles; demands precise pressure control | Paddles requiring fine control |

| Thermoforming | Intricate design; uniform material distribution; enhanced stability | Longer production time; higher equipment costs | Premium or custom designs |

Each of these production methods plays a crucial role in the final performance and consistency of our pickleball paddles. For instance, hot pressing is ideal when high production volume is required without compromising on strength. In contrast, cold pressing is chosen for paddles that emphasize feel and precision. For premium, custom designs – where intricate paddle shapes are important – thermoforming enables the creation of unique, high-performance products.

The choice of materials is another significant factor in manufacturing high-performance pickleball paddles. NEX Pickleball leverages a variety of premium materials to meet diverse performance needs:

-

Carbon Fiber:

• 3K Carbon Fiber offers high rebound force and excellent durability by reducing vibration.

• 12K Carbon Fiber provides a smoother surface and superior impact resistance, making it ideal for competitive play.

• T300 Carbon Fiber balances strength and weight for agile performance on the court. -

Fiberglass:

Fiberglass paddles, such as those using E-Glass Fiberglass3, deliver a harmonious balance between power and control. The larger sweet spot ensures optimum ball control, even for rapid gameplay. -

Composite Materials:

Combining carbon fiber with fiberglass yields paddles that successfully merge the benefits of both materials. Additionally, a Bamboo Core Composite or Honeycomb Core enhances vibration absorption and energy distribution. This leads to paddles with a clear hitting feel and longer playability. -

Core Materials:

The choice of the core significantly influences durability and playability.

• Nomex Honeycomb4 cores provide superior shock absorption for sustained play.

• Aluminum Honeycomb cores are balanced for power and precision.

• Polymer Honeycomb cores reduce vibration, ensuring a comfortable feeling during extended play.

Using advanced materials and combining them innovatively has enabled our partners to offer a range of paddles that cater to both recreational players and high-level competitors.

When dealing with high-performance sports equipment, quality control is everything. For procurement professionals, consistent quality means reliable end products and trust in your manufacturing partners. NEX Pickleball employs stringent quality control measures through:

-

Rigorous Testing:

Every paddle undergoes multiple testing phases where performance, durability, and material integrity are evaluated. This means that any deviations in production are immediately identified and rectified. -

Modern Techniques:

The integration of technology in our production processes—be it hot pressing, cold pressing, or thermoforming—is continuously updated to reflect industry advancements. This dedication minimizes chances of defects and ensures high-performance, repeatable product results. -

Customization Capabilities:

With on-demand printing and specific design tailoring, every order can be customized, ensuring that sports organizations and retailers receive products that match their exact requirements. This flexibility adds significant value in a competitive sourcing landscape. -

Compliance and Export Readiness:

Our adherence to international trade standards and export compliance5 protocols is thoroughly managed. Clients can be assured that every product meets global market requirements, reducing the risk of regulatory issues.

Procurement managers value a partner that not only delivers quality products but also emphasizes technological innovation and regulatory compliance. By using a combination of detailed inspection protocols and state-of-the-art production methods, NEX Pickleball builds products that align with the highest international standards in the sports equipment industry.

Consider a scenario where a major sports retailer sought to introduce a premium line of pickleball paddles. The retailer needed a manufacturing partner capable of offering both high performance and consistent quality. They were particularly concerned with ensuring that paddle designs provided exceptional balance, durability, and enhanced player comfort.

The solution involved selecting NEX Pickleball as their manufacturing partner. Through a careful consultation, we identified the appropriate combination of materials – opting for 12K Carbon Fiber for its superior strength, combined with a Nomex Honeycomb Core that offered excellent shock absorption. Our process engineers recommended using a blend of thermoforming for custom shape precision and cold pressing for maintaining the intimate material feel.

The result was a paddle that not only met but exceeded market performance expectations. Customer feedback highlighted an increase in ball control and overall game consistency. This case study reinforces the importance of selecting a partner with advanced production expertise capable of adapting to client specifications, thereby securing a competitive edge in a crowded market.

For sourcing agents and procurement managers evaluating manufacturers in the sports equipment sector, especially for pickleball paddles, consider the following steps:

-

Assess Production Techniques:

Evaluate whether the supplier uses modern production methods such as hot pressing, cold pressing, or thermoforming. Ensure that their technical capabilities align with your quality and volume requirements. -

Examine Material Composition:

Request detailed information on the types of materials used. A bank of premium materials – including various carbon fiber types, fiberglass, and composite solutions – is a significant indicator of advanced capabilities and product quality. -

Check Quality Assurance Protocols:

Inquire about testing procedures and certifications. A manufacturer with robust quality control measures will minimize risks and ensure consistent product performance across batches. -

Evaluate Customization Options:

Customization often leads to a competitive market advantage. Ensure that the manufacturer offers customization in material composition, design, and even on-demand printing services to meet your unique brand or market requirements. -

Review Export and Compliance Records:

A proven track record in handling international trade, including adherence to global compliance standards, is essential. This experience reduces the likelihood of delays or regulatory issues post-manufacture.

A table summarizing these checkpoints:

| Checklist Item | Key Questions to Ask | What It Indicates |

|---|---|---|

| Production Techniques | What processes are used? | Advanced methods ensure consistent quality. |

| Material Quality | Which materials and composites are utilized? | Premium materials equate to better performance. |

| Quality Assurance | What testing standards and certifications are in place? | Lower risk of defects and non-compliance. |

| Customization Capabilities | How flexible is the manufacturer regarding custom orders? | Adaptability to your specific market needs. |

| Export Compliance | What is the track record with international standards? | Reliability and smoother global market entry. |

Remember, the right manufacturing partner not only produces high-quality products but also shares your commitment to innovation and continuous improvement.

Partnering with an experienced Chinese manufacturer like NEX Pickleball offers you a competitive edge through advanced production techniques, high-quality material selection, and strict quality control. Our comprehensive approach—from sourcing premium materials like carbon fiber and fiberglass to innovatively employing hot pressing, cold pressing, and thermoforming—is designed to deliver paddles that meet the rigorous demands of today’s competitive sports industry.

For procurement managers looking to make informed decisions, our solution-driven methodology addresses common industry challenges effectively. By assessing production methods, material superiority, rigorous quality checks, and adherence to international export standards, you can confidently select a partner that supports your business growth and satisfies your customer’s needs.

Taking the next step involves evaluating your sourcing requirements against a detailed framework. With data-backed insights and a history of successful client partnerships, NEX Pickleball stands ready to help you achieve high performance in the global sports market.

People Also Ask

Q1: What are the benefits of using advanced production processes in pickleball paddle manufacturing?

A1: Advanced production techniques, such as hot pressing, cold pressing, and thermoforming, ensure superior material consistency, improved impact resistance, and precise paddle design, leading to high-performance and durable products suitable for both competitive and recreational play.

Q2: How does NEX Pickleball maintain quality control throughout its production stages?

A2: NEX Pickleball utilizes rigorous testing protocols at every stage of production, leveraging modern equipment and standardized quality control measures. This approach minimizes defects, ensures compliance with international standards, and guarantees that every paddle meets high-performance criteria.

Q3: Why should procurement managers choose NEX Pickleball as their manufacturing partner for pickleball paddles?

A3: Procurement managers benefit from NEX Pickleball’s advanced production techniques, use of premium materials, flexible customization options, and robust export compliance. These factors combine to ensure a reliable supply of high-quality, durable pickleball paddles that satisfy both market and regulatory standards.

-

Cold Pressing: Click here to learn about this manufacturing process that retains original material properties and enables precise control for improved product feel. ↩ ↩

-

Thermoforming: Click here to explore how thermoforming creates intricate designs and ensures a uniform material distribution for premium custom products. ↩ ↩

-

E-Glass Fiberglass: Click here for insights into E-Glass Fiberglass, a composite material that balances power and control in high-performance sporting equipment. ↩ ↩

-

Nomex Honeycomb: Click here to understand the benefits of Nomex Honeycomb cores in providing superior shock absorption and durability in sports equipment manufacturing. ↩ ↩

-

Export Compliance: Click here to review the importance of export compliance protocols in ensuring adherence to international trade standards and smooth global market entry. ↩ ↩