Fast Answer: For high-performance pickleball paddles, carbon fiber1 outperforms graphite in terms of durability and stiffness, providing lasting quality without sacrificing light weight—making it a preferred choice for OEM partnerships2.

For procurement managers at sports goods distributors, choosing between advanced composite materials3 is a critical decision. With our expertise at NEX Pickleball, we offer a detailed comparison of carbon fiber and graphite paddles, based on technical performance data, manufacturing techniques, and real-world use cases. This article reviews the material specifications, production processes, and design differences that play a crucial role in meeting strict performance and durability criteria for pickleball paddles.

As markets evolve, B2B buyers are confronted with crucial material decisions when sourcing new products. Procurement managers must balance factors such as:

- Performance enhancements

- Durability of the materials under competitive game conditions

- Production efficiency and manufacturing costs

- Technical specifications tailored to different player levels

In our analysis, we compare two prominent materials—carbon fiber and graphite—to determine which is a better match for producing state-of-the-art pickleball paddles.

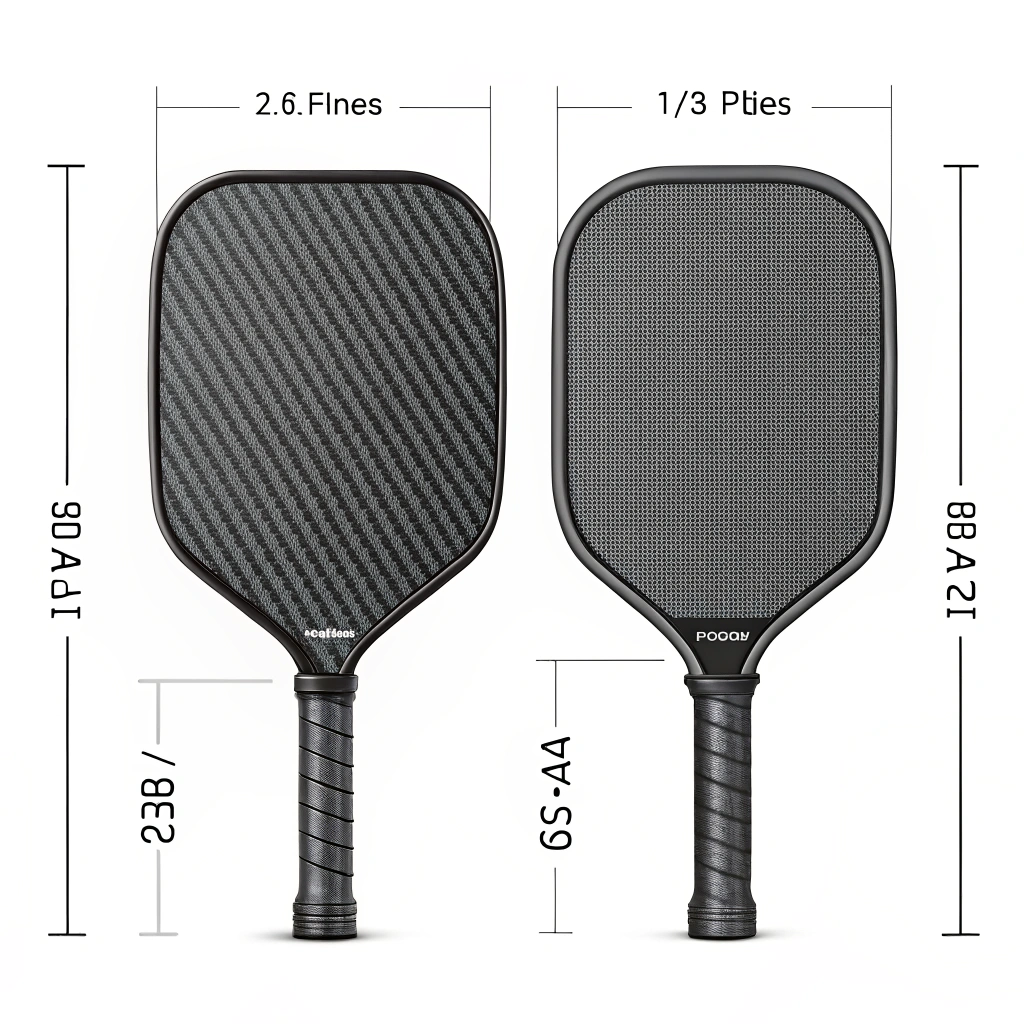

Both carbon fiber and graphite are lightweight and stiff, but they differ in strength, durability, and how they respond to repeated impacts during gameplay. Below is a succinct comparison of the two materials:

| Feature | Carbon Fiber | Graphite |

|---|---|---|

| Strength & Durability | Higher durability; excellent impact resistance | Relatively lighter; less durable than carbon fiber |

| Stiffness | Superior stiffness for consistent control | Adequate stiffness for moderate play |

| Weight | Maintains light weight without compromise | Slight weight advantage in less robust builds |

| Manufacturing Flexibility | Supports advanced techniques like hot pressing4 and thermoforming5 | Typically requires simplified processing methods |

| Cost | Slightly higher initial cost but cost-effective long term | Lower upfront cost but may incur higher maintenance |

| Vibration Dampening | Lower vibration, reducing player fatigue | May transfer more shock impacting playability |

This table highlights that while graphite offers a viable alternative, carbon fiber excels in delivering long-term value through enhanced performance characteristics—a key factor when committing to large-scale manufacturing and OEM partnerships.

Carbon fiber paddles are renowned for their toughness and responsiveness. At NEX Pickleball, we primarily utilize three variants of carbon fiber:

- 3K Carbon Fiber: Offers high rebound force while minimizing vibration. Ideal for paddles needing a perfect balance between power and control.

- 12K Carbon Fiber: Characterized by higher thread density, ensuring a smoother surface and extreme strength. This type is typically reserved for competitive play where durability is non-negotiable.

- T300 Carbon Fiber: Known for its optimal tensile strength-to-weight ratio, resulting in paddles that are lightweight but maintain excellent performance levels.

Carbon fiber’s advantages extend to production methods. Our techniques such as hot pressing and thermoforming maximize the inherent benefits of carbon fiber, leading to paddles that boast excellent impact resistance and precise weight distribution. Although the initial costs for carbon-based materials can be higher, their longevity and consistent performance deliver substantial long-term value.

Graphite, comparable in appearance and basic performance to carbon fiber, brings some strengths to the table. Its key benefits include:

- Lower upfront manufacturing costs

- Ease of processing for simpler designs

- Adequate stiffness that meets basic competitive play requirements

However, in high-performance settings, graphite may fall short. The material is generally less durable than carbon fiber and might show signs of wear earlier under aggressive play conditions. This nuance makes graphite a more sensible choice for recreational products or entry-level competition rather than for top-tier competitive performance.

At NEX Pickleball, our production process is integral to achieving the superior quality expected by our B2B partners. The following sections detail our advanced manufacturing technologies and how they benefit both carbon fiber and graphite paddle production.

-

Hot Pressing: In this process, heat and pressure are applied to the paddle materials. Hot pressing is favored for its efficiency in large-scale production and the ability to produce components with enhanced impact resistance. It is particularly effective for high-strength carbon fiber paddles.

-

Cold Pressing: This method allows for precise control over the paddle’s structure. Maintaining the material’s original properties, cold pressing results in a paddle that offers superior ball feel and precision control. Though slower in production, it is ideal for specialized paddle designs where nuance is important.

-

Thermoforming: Thermoforming involves heating until the material softens, then molding it into the desired shape. This process is especially useful for creating paddles with intricate designs and optimized material distribution for both carbon fiber and composite materials.

Each process carries its own pros and cons, which can affect production timelines and final paddle properties. For instance:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; strong paddles with high-impact resistance | May alter some inherent material properties |

| Cold Pressing | Precise control; maintains material integrity | Longer production times; higher precision equipment cost |

| Thermoforming | Enables complex shapes; precise material distribution | Extended production times; increased equipment investment |

Such production techniques are essential when weighing the long-term cost versus performance benefits—a vital consideration for procurement managers making decisions for quality-sensitive sports equipment.

When deciding between carbon fiber and graphite, consider these pivotal factors:

-

Performance and Game Dynamics

Carbon fiber paddles offer superior stiffness and energy transfer, which is especially beneficial in high-speed, competitive games. Their lower vibration dampening also means less player fatigue during prolonged matches. -

Durability and Maintenance

Long-term durability is a significant factor, particularly for B2B buyers who are focused on longevity and consistent performance. Carbon fiber's resistance to wear and impact makes it a reliable choice for both casual players and professionals. -

Cost and Production Efficiency

While graphite may appeal with lower initial costs, carbon fiber's higher resilience and performance quality can prove more cost-effective over the product's lifecycle. When integrated with our efficient production processes, the slight increase in raw material costs is largely offset by reduced maintenance and replacement frequencies. -

Technological Advancements

Our manufacturing methods such as hot pressing, cold pressing, and thermoforming are tailored to maximize each material’s strengths. For example, carbon fiber paddles manufactured using thermoforming offer enhanced design flexibility and stability for advanced play. -

Customization and Market Adaptability

Both materials support customization. Carbon fiber paddles, however, offer a broader range of options when it comes to advanced composites, benefiting from innovations that improve performance metrics like impact resistance, control, and balance. This aligns well with the custom order capabilities we provide, ensuring each paddle meets specific client requirements.

For high-level competitive play, carbon fiber paddles are recommended due to their strength, minimal vibration, and longevity under intense usage. Carbon fiber paddles are designed to withstand high impact and provide consistent performance even over continuous use, making them the ideal choice for professional and semi-professional players.

While graphite is a viable alternative for recreational play, where the intensity of play is moderate, its ease of processing and lighter initial cost can be appealing for lower-end markets. However, if you plan to scale or upgrade performance standards in the near future, transitioning to carbon fiber can ensure a smoother upgrade path without compromising quality.

For companies engaged in OEM manufacturing, the ability to customize both carbon fiber and graphite paddles is crucial. Our advanced production techniques allow for the tailoring of paddle weight, balance, and grip size to exactly match client specifications. Here, carbon fiber—thanks to its adaptable nature—offers a competitive edge particularly when designing products for high-demand markets. Collaborating with an experienced manufacturer like NEX Pickleball ensures that you receive paddles with consistent quality control, precise material distribution, and superior performance attributes.

For procurement managers considering large-scale orders, the following steps are recommended:

- Evaluate your market needs and player skill levels. Consider if your market trends lean toward competitive, high-performance solutions or recreational, cost-effective options.

- Assess long-term cost efficiency. While graphite may appear less expensive initially, factor in durability and replacement costs to determine overall value.

- Request samples from OEM manufacturers like NEX Pickleball, and run field tests to see how materials perform under real-life conditions.

- Utilize our detailed technical specifications and production process insights to align your product specifications with market demands.

- Schedule a consultation with our technical team to discuss customization options tailored to your specific clientele.

In conclusion, while both carbon fiber and graphite have their places in the production of pickleball paddles, carbon fiber provides significant advantages in terms of durability, high-performance output, and precision manufacturing. This makes it especially well-suited for high-demand markets and competitive use cases. Our extensive use of advanced production processes like hot pressing, cold pressing, and thermoforming only reinforces carbon fiber’s edge, ensuring that every paddle delivers outstanding performance and longevity.

For B2B buyers, aligning your procurement strategy with these insights means you can confidently source paddles that meet the exacting standards of competitive play while also offering superior value over their lifecycle. With NEX Pickleball’s commitment to quality, customization, and technical excellence, we invite you to explore our offerings and discover why carbon fiber paddles are the optimal choice for forward-thinking sports retail and distribution networks.

Which is better for pickleball paddle graphite or carbon fiber?

Carbon fiber is generally preferred over graphite because it provides superior durability and stiffness, leading to a more consistent, high-performance paddle. Its ability to reduce vibration and withstand high impact makes it ideal for competitive play.

What is the best carbon fiber pickleball paddle?

Among top-rated options, products like the Six Zero Double Black Diamond Control and Vatic Pro PRISM Flash are noted for their exceptional all-court performance. These products are recognized for delivering a balanced mix of power, control, and durability essential for advanced play.

Are carbon fiber paddles worth it?

Yes, investing in carbon fiber paddles proves beneficial due to their high durability, excellent impact resistance, and reduced vibration during extended play, ultimately enhancing game performance while reducing energy fatigue.

-

carbon fiber: Reading this article will help you understand the production, properties, and performance benefits of carbon fiber in high-performance sports equipment. ↩

-

OEM partnerships: Reading this article will provide insights into original equipment manufacturer relationships, including integration strategies and benefits for large-scale production. ↩

-

advanced composite materials: Reading this article will expand your knowledge on composite materials, exploring their composition, performance advantages, and role in modern manufacturing. ↩

-

hot pressing: Reading this article will explain the hot pressing process, its impact on material properties, and why it is a preferred production method for durable sports equipment. ↩

-

thermoforming: Reading this article will help you understand thermoforming, a process used to shape materials with heat for complex designs and optimized material performance. ↩