Quick Answer: High-performance carbon fiber pickleball paddles, engineered with materials like 3K, 12K, and T300 Carbon Fiber1, deliver superior spin, power, and durability compared to alternatives. Their precise manufacturing processes—hot pressing, cold pressing, and thermoforming—ensure optimal weight distribution, structural integrity, and customization potential, making them ideal for competitive and recreational markets.

In today’s competitive sports equipment market, choosing the right materials and manufacturing process is critical for delivering paddles that not only perform at a high level but also meet stringent durability and customization requirements. Manufacturers like NEX Pickleball leverage advanced carbon fiber technologies to produce paddles that offer a unique combination of strength, responsiveness, and precision. This article examines why carbon fiber is a preferred choice over alternatives such as fiberglass and composites, how various types of carbon fibers contribute to paddle performance, and the manufacturing processes that enhance these benefits.

B2B procurement managers and product development specialists often face a key decision: how to balance performance improvements with cost-effectiveness when sourcing high-performance pickleball paddles. The challenge lies in:

• Delivering superior spin and control for competitive edge

• Ensuring long-term durability under intensive play

• Balancing material performance with production costs

• Customizing paddle design to meet varied market demands

High-performance paddles require surface materials that offer rigidity for power and flexibility for control. While traditional materials such as fiberglass and composite blends have their merits, carbon fiber is increasingly recognized for its unparalleled performance attributes in paddle applications.

Understanding the material properties is essential for making informed decisions over sourcing. Here, we analyze the characteristics of different carbon fiber types and compare them with other paddle materials.

-

3K Carbon Fiber

- Known for its great strength and flexibility

- Provides excellent durability while reducing vibration

- Ideal for paddles requiring a high rebound force

-

12K Carbon Fiber

- Features a denser thread arrangement

- Delivers a smoother surface and enhanced hardness

- Offers improved impact resistance, optimal for competitive play

-

**T300 Carbon Fiber

- Recognized for outstanding tensile strength

- Balances lightweight design with the need for strength

- Excellent for paddles that demand both power and agility

While fiberglass and composite materials offer benefits such as a wider sweet spot and increased flexibility, they often fall short in overall stiffness and rebound capabilities compared to carbon fiber. Fiberglass might yield a comfortable feeling but may not provide the rigid response required for high-level spin and power. Composite materials, while innovative, can introduce complexities in ensuring uniformity and long-term durability.

Below is a comparison table that summarizes the key differences:

| Material Type | Strength & Durability | Flexibility | Rebound Force | Impact Resistance | Customization Potential |

|---|---|---|---|---|---|

| 3K Carbon Fiber | High | Moderate | High | High | High |

| 12K Carbon Fiber | Very High | Moderate | Very High | Very High | High |

| T300 Carbon Fiber | High | Low | High | Excellent | High |

| Fiberglass | Moderate | High | Moderate | Moderate | Moderate |

| Carbon-Fiberglass Composite | High | Moderate | High | High | High |

The table above illustrates the essential trade-offs that decision-makers must consider. For applications demanding extreme performance metrics—like enhanced spin and power—the superior mechanical properties of carbon fiber derivatives make them the material of choice.

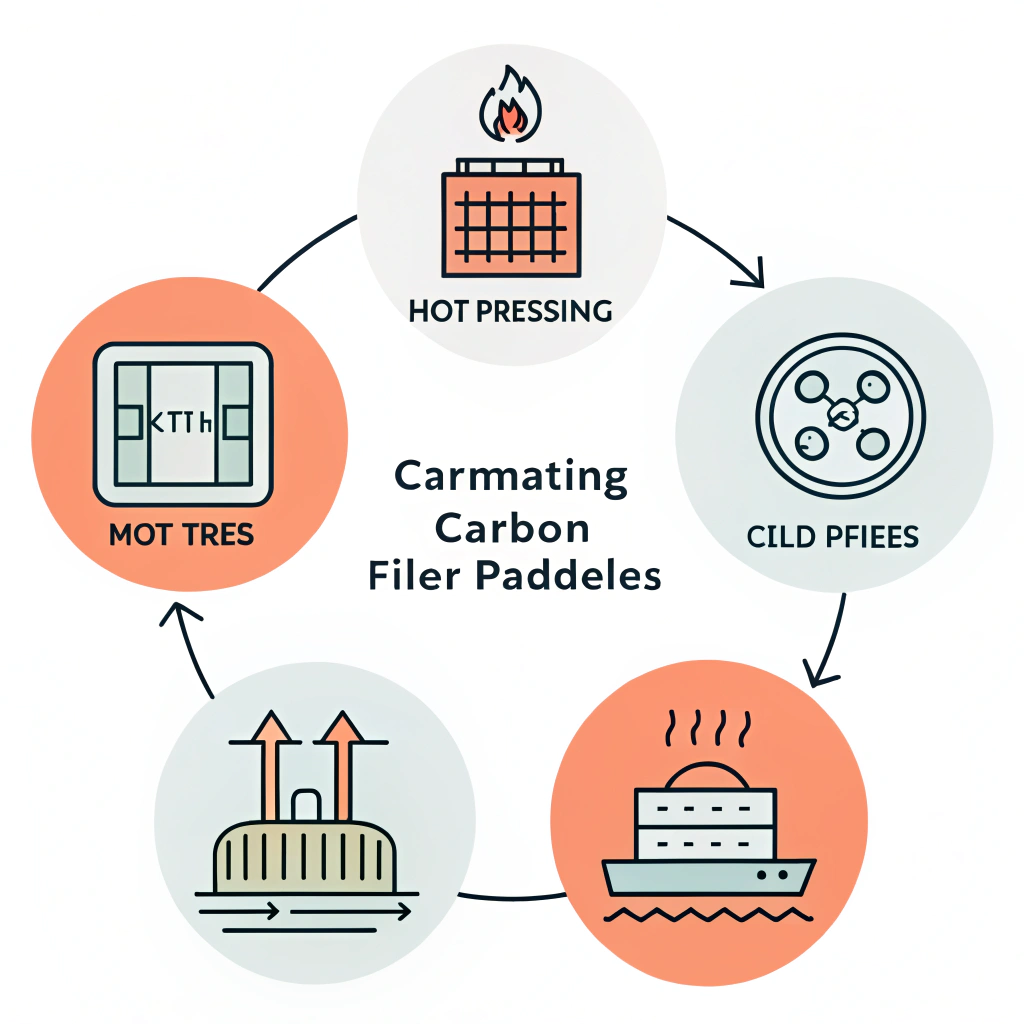

The performance and durability of carbon fiber paddles are not solely determined by the material properties. The production process plays a crucial role in ensuring that the intrinsic benefits of carbon fiber are fully leveraged. NEX Pickleball employs three primary manufacturing methods:

- Description: Involves heating the carbon fiber layers and applying pressure to fuse them together.

- Advantages:

• High production efficiency suited for large-scale manufacturing.

• Yields paddles with excellent impact resistance.

• Provides robust structural integrity ideal for high-performance play. - Disadvantages:

• Potential slight alteration in material feel.

• Requires significant upfront investment in machinery.

- Description: Applies mechanical pressure at room temperature, preserving the material’s native properties.

- Advantages:

• Offers precise control over paddle thickness and overall structure.

• Maintains optimal ball feel and responsiveness.

• Better suited for paddles where tactile feedback is a significant performance factor. - Disadvantages:

• Production cycle may be comparatively longer.

• Demands highly precise and controlled equipment settings.

- Description: This involves heating the material until it becomes pliable, then forming it into the desired shape using molds.

- Advantages:

• Ideal for creating paddles with complex designs and varying thickness profiles.

• Ensures uniform material distribution for optimal balance.

• Suitable for premium and custom-ordered paddles. - Disadvantages:

• Longer production time and higher associated costs.

• Best reserved for products with a higher price point due to customization.

Each method has its own set of benefits and trade-offs. The choice of process depends on the final product's intended use, desired performance characteristics, and production volume requirements.

Imagine a scenario where a specialty retailer is seeking paddles that deliver both excellent spin and minimal vibration. Using 12K Carbon Fiber for the face provides a smooth, hard texture directly contributing to ball control and spin. Meanwhile, pairing the carbon fiber with a Nomex Honeycomb Core5 supports maximum shock absorption, ensuring the paddle remains responsive without compromising on durability.

In practice, the choice of the right manufacturing process further refines the paddle's performance:

• A hot pressing approach might be preferred in a high-volume order where the durability and impact resistance of the paddle are paramount.

• Conversely, cold pressing is recommended when surface feel and precision in ball response are the top priorities.

• Thermoforming is ideal for custom orders where unconventional design elements are incorporated to meet specific branding or ergonomic needs.

This case study underlines why having a flexible production capability is vital for businesses looking to capture both recreational users and competitive athletes in a competitive market.

When evaluating a potential partner for pickup equipment manufacturing, consider the following aspects:

- Material Expertise: A deep understanding of material properties (like the differences among 3K, 12K, and T300 carbon fibers) is essential to ensure product superiority.

- Production Versatility: The ability to offer multiple manufacturing processes (hot pressing, cold pressing, thermoforming) allows for tailored solutions that meet diverse market requirements.

- Customization: With custom paddle options, clients can specify design features such as weight, grip size, balance, and aesthetics. This flexibility enables differentiation in a crowded marketplace.

- Quality Assurance: Rigorous testing protocols ensure that every paddle meets high standards of durability, performance, and longevity.

For instance, at NEX Pickleball, our dedication to innovation and precision manufacturing means that each paddle is designed with a focus on optimizing performance while mitigating common issues like vibration and inconsistent ball response. Utilizing advanced production techniques enables us to deliver OEM services that not only meet industry standards but often exceed them.

Based on the detailed examination above, here are the key action recommendations for procurement managers and product development specialists:

- Evaluate Material Properties: When selecting pickleball paddles, weigh the benefits of different carbon fiber types against alternatives like fiberglass. Prioritize options that elevate spin, control, and durability.

- Consider Production Processes: Understand how manufacturing methods such as hot pressing, cold pressing, and thermoforming can impact paddle performance. Align the choice with your target market’s performance expectations.

- Custom Solutions: Look for manufacturing partners that offer customizable options. Tailoring paddle characteristics can help differentiate your product line in a competitive market.

- Quality and Testing: Ensure that partners maintain rigorous quality control practices. Consistency in production translates to reliable product performance.

- Partnership Evaluation: Choose a partner who not only delivers competitive pricing but also provides technical expertise and support in R&D analytics. This will help secure your market position in both recreational and competitive segments.

Ultimately, leveraging advanced carbon fiber technologies through understanding and comparing material attributes—and aligning them with innovative production techniques—empowers your business to make data-driven, competitive purchasing decisions.

• What is the best carbon fiber pickleball paddle for spin?

Answer: The best carbon fiber pickleball paddle for spin is one that balances power, spin, and control. High-performance models engineered with materials such as 12K and T300 carbon fiber are particularly effective because their design maximizes rigidity and rebound force, providing enhanced spin control and overall playability.

• Are carbon paddles worth it?

Answer: Yes, carbon paddles are worth it because they offer superior stiffness and responsiveness. Their construction maximizes stroke efficiency while reducing the strain on players’ arms, especially during prolonged use, making them an excellent choice for competitive and recreational play.

-

T300 Carbon Fiber: Click to read an in-depth article on T300 Carbon Fiber technology, exploring its tensile strength, lightweight properties, and how it enhances product agility and durability. ↩

-

Hot Pressing: Click to understand the hot pressing manufacturing process, its efficiency in mass production, and how it impacts the structural integrity and impact resistance of composite products. ↩

-

Cold Pressing: Click to explore the cold pressing technique, detailing how it preserves material properties and improves tactile feedback and overall product precision. ↩

-

Thermoforming: Click to read about thermoforming methods, including its suitability for complex designs, uniform material distribution, and the trade-offs in production time and costs. ↩

-

Nomex Honeycomb Core: Click to learn about Nomex Honeycomb Core, including its structure, shock absorption capabilities, and benefits in high-performance composite designs. ↩