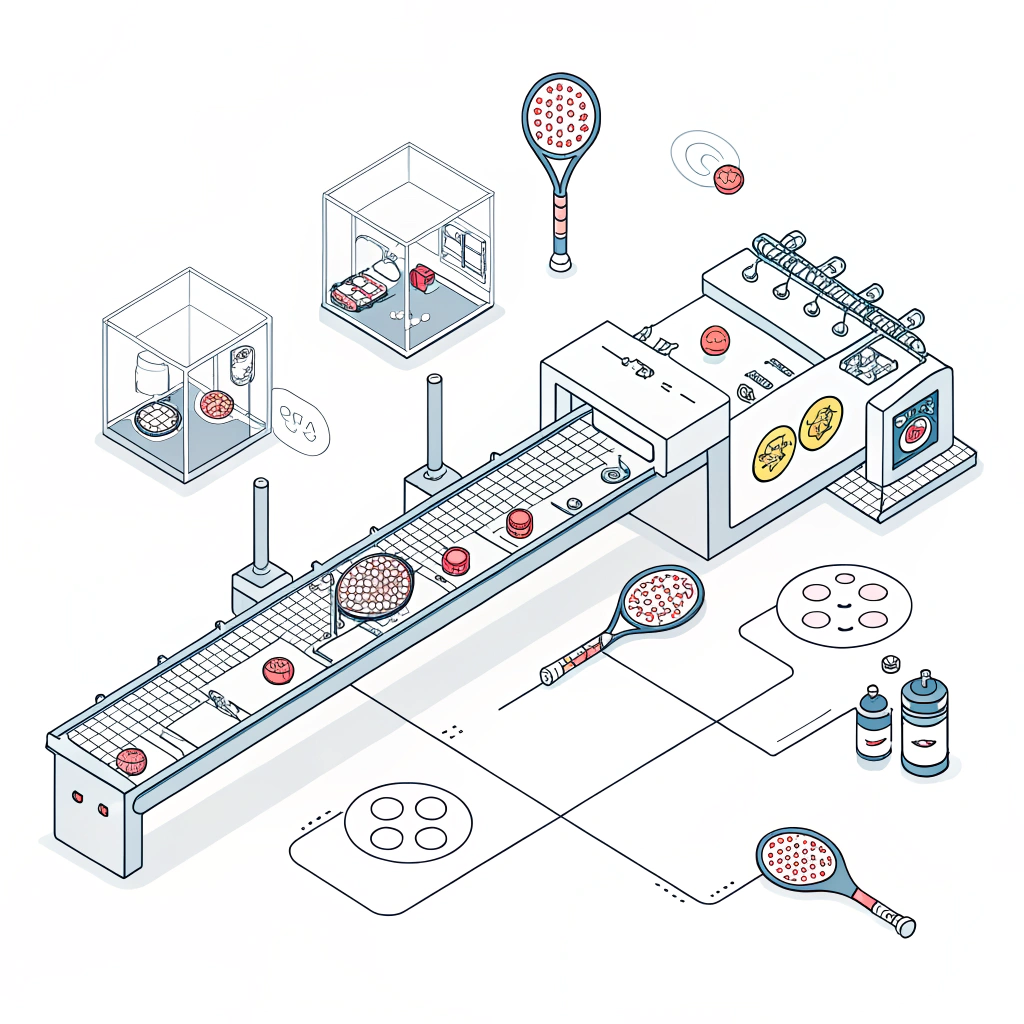

Manufacturing consistent, high-performance pickleball paddles means rigorous quality control and precision production processes are essential to build supplier trust and ensure product excellence.

In today’s competitive sporting goods market, quality assurance1 plays a crucial role in establishing long-term partnerships between manufacturers and distributors. For companies such as NEX Pickleball, dedicated to producing high-performance paddles, ensuring precision production across different processes is the key to meeting the high standards demanded by B2B procurement managers and sports equipment distributors.

Quality issues in paddle manufacturing can arise from several factors. Variations in raw material2 quality, inconsistent production processes, and fluctuations in equipment performance can lead to paddles that do not meet the desired durability or performance standards. For instance, using carbon fiber3 variants like 3K, 12K, and T300 carbon fiber requires tailored production techniques that are sensitive to changes in temperature and pressure. Similarly, composite materials4 and diverse core options—such as Nomex, aluminum, or polymer honeycomb cores—pose challenges that require precise control during production.

Ensuring that every paddle produced consistently meets quality benchmarks is not only essential for competing in the market but also crucial for reducing returns, building brand trust, and reinforcing a robust supply chain.

Several reasons contribute to quality issues in the manufacturing of pickleball paddles:

• Material Variability: The performance of paddles significantly depends on the inherent properties of the raw materials. For example, different types of carbon fiber exhibit varying degrees of strength, flexibility, and durability.

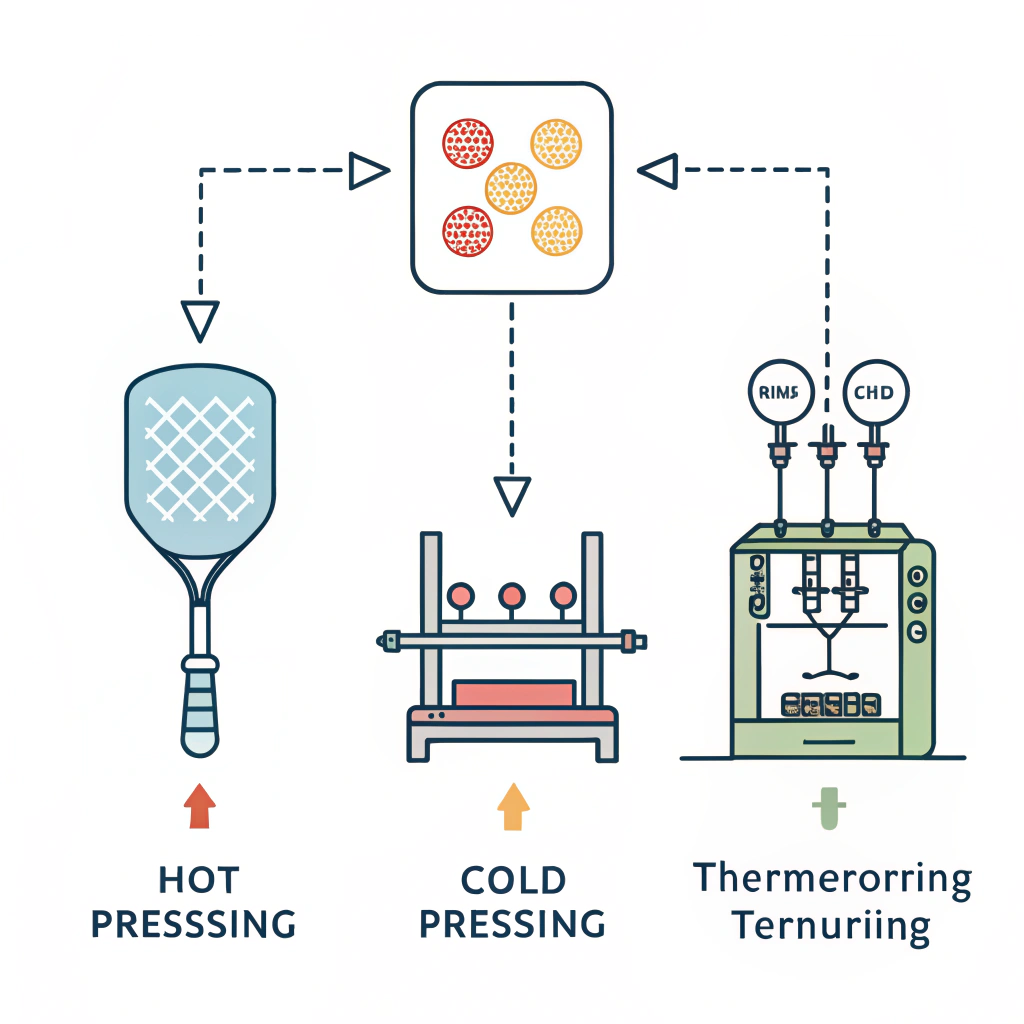

• Process Sensitivity: Production processes such as hot pressing, cold pressing, and thermoforming5 each have unique advantages and limitations. Small deviations in temperature, pressure, or timing can alter material properties and impact the paddle’s final quality.

• Equipment Calibration: High-end equipment like hot presses and thermoforming machines require regular calibration to maintain consistent output. Any misalignment or lack of preventive maintenance can lead to production inefficiencies.

Each of these factors requires careful monitoring and systematic quality controls to ensure that every product meets the industry’s rigorous standards.

Overcoming these challenges starts with a clear, structured approach that involves comprehensive quality assurance protocols, robust production techniques, and continuous process improvements. Below is a detailed breakdown of how to achieve this:

NEX Pickleball employs three key production processes—hot pressing, cold pressing, and thermoforming—to manufacture our high-quality paddles. Each method has its unique benefits and constraints that must be balanced against the specific performance requirements of the paddle.

Below is a comparative table outlining the pros and cons of these processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; maintains structural integrity | Possible alteration of material feel; high investment in equipment |

| Cold Pressing | Precise control over paddle thickness; preserves material properties; excellent ball feel | Longer production cycle; requires precise pressure control |

| Thermoforming | Facilitates complex designs; ensures even material distribution; maintains paddle stability | Longer production time; higher equipment costs |

Understanding these processes and aligning them with performance needs is fundamental to consistently achieving the desired outcome for every paddle manufactured.

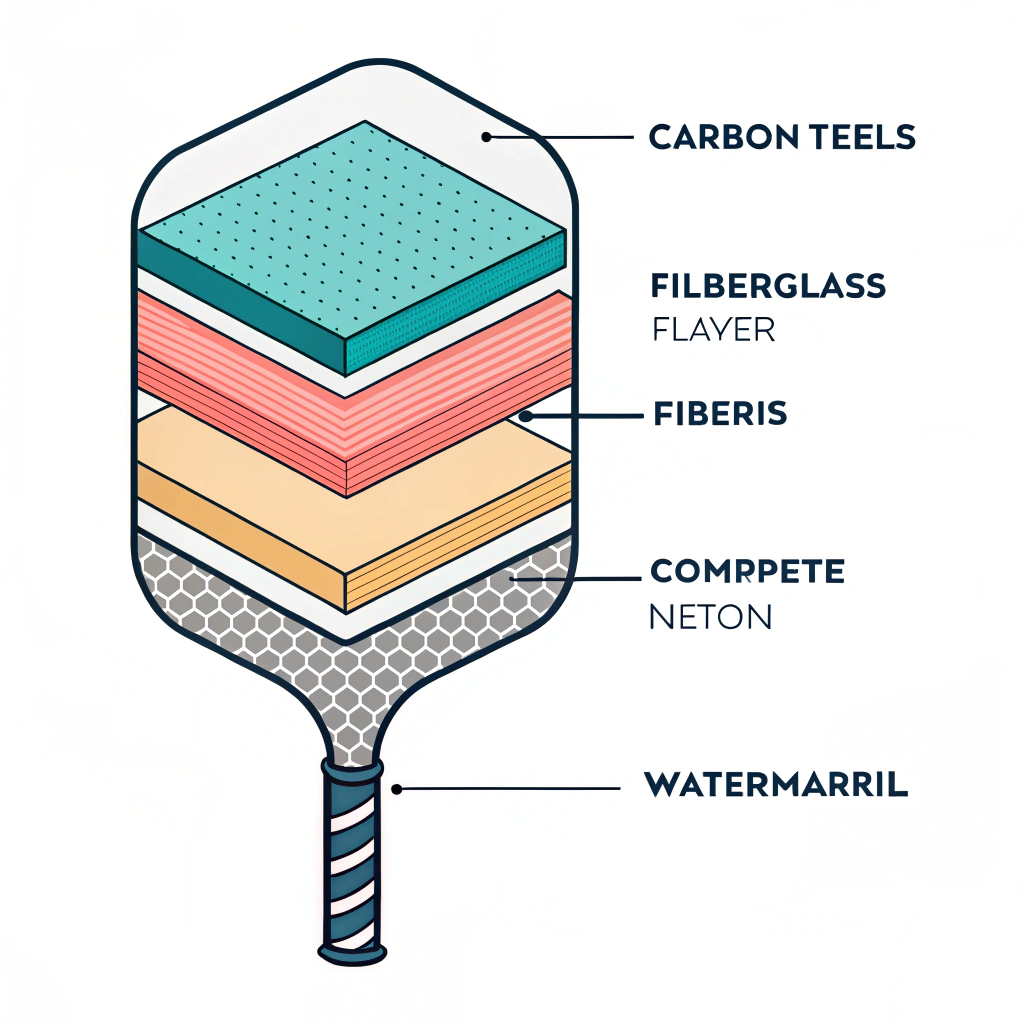

Selecting premium materials is the cornerstone of paddle performance. At NEX Pickleball, combinations of carbon fiber, fiberglass, and innovative composite materials are used to enhance both power and control.

• Carbon Fiber Variants:

- 3K Carbon Fiber: Offers excellent strength and flexibility, making it ideal for paddles that require remarkable rebound force.

- 12K Carbon Fiber: Provides a smoother surface and increased durability through higher thread density, thus improving overall performance.

- T300 Carbon Fiber: Known for its outstanding tensile strength, delivering a balanced combination of strength and lightweight performance for competitive play.

• Composite mixes, such as carbon fiber combined with fiberglass, yield paddles that balance the benefits of both materials to maximize power and control. Custom paddle designs further allow procurement managers to specify factors like design, weight distribution, balance, and grip size, ensuring that the product meets exact market requirements.

This careful integration of materials and production techniques results in paddles that are not only high-performing but also highly reliable—a critical factor for distributors and retailers seeking consistency in supply.

Quality assurance in manufacturing is maintained through a series of well-defined testing protocols. Each paddle undergoes rigorous testing to verify that it meets specific criteria for strength, durability, and playability. Key quality checkpoints include:

• Material Inspection: Assessing the quality and consistency of raw materials such as different carbon fiber types.

• In-Process Monitoring: Regular measurements of pressure and temperature ensure controlled conditions are maintained during production.

• Final Product Testing: Each finished paddle is tested for balance, rebound, and vibration control to simulate real-game conditions.

These multi-level tests ensure that only paddles that meet our strict quality standards are shipped to customers, reinforcing trust and supply chain transparency.

For B2B procurement managers evaluating potential manufacturing partners, the following action items are crucial:

• Request detailed documentation on the quality control processes and testing protocols.

• Compare technical specifications of materials and production methods used by different manufacturers.

• Evaluate case studies or testimonials that highlight the manufacturer’s commitment to consistent output and long-term production performance.

• Consider the investment in high-end equipment and the manufacturer’s adaptability to evolving production techniques.

By focusing on these strategies, procurement managers can make informed decisions based on both technical data and operational excellence. These insights also help in establishing long-term partnerships with suppliers who demonstrate superior quality assurance and innovation.

Industry data shows that manufacturers who invest in advanced production processes and maintain rigorous testing protocols consistently outperform competitors in terms of product durability and customer satisfaction. For example, adopters of thermoforming methods for premium paddle lines have reported enhanced product longevity and reduced vibration, crucial for competitive play.

Moreover, the use of high-quality carbon fiber variants and composite materials correlates directly with improved performance metrics. Distributors and sports equipment retailers note that paddles designed with precisely controlled weight distribution and ergonomic grip design yield greater market acceptance and repeat business.

In many cases, manufacturers like NEX Pickleball who implement these stringent quality controls not only achieve operational efficiency but also build a strong reputation for durability and performance in the market. This reputation is often supported by data from product testing, customer feedback, and industry benchmarks that spotlight a commitment to excellence.

To build trust with B2B partners and maintain a reputation for excellence in the competitive sports equipment market, manufacturers must implement a robust quality assurance framework. At NEX Pickleball, we integrate advanced material science, optimized production processes, and comprehensive testing protocols to ensure every paddle meets high performance and durability standards.

For procurement managers, working with a manufacturing partner that can demonstrate consistency, transparency, and technical innovation in production is essential. By reviewing documented quality controls, production consistency, and material performance history, you can confidently select suppliers who align with your market demands and long-term business objectives.

We invite you to explore how our customized production and quality assurance processes can meet your needs. Contact us today for more technical insights, product samples, and detailed documentation on our production methods that continue to set benchmarks in the pickleball equipment industry.

People Also Ask

Q: What is the marketing strategy of pickleball?

A: Effective pickleball marketing leverages digital channels such as Google Ads for search and display campaigns, as well as social media platforms like Facebook, Instagram, and YouTube to reach enthusiasts and drive high-intent engagement.

Q: How to build confidence in pickleball?

A: Confidence in pickleball is built by consistent practice, focusing on technique improvement, and learning from experienced players. Analyzing match performance and engaging in structured training sessions can significantly enhance a player's self-assurance.

Q: What is the code of ethics for pickleball?

A: The pickleball code of ethics emphasizes respect for others, fairness in competition, integrity in conduct, adherence to official associations’ policies, and personal responsibility, all of which contribute to fostering a respectful and trustworthy playing environment.

-

quality assurance: Read the article to understand how systematic checking and standardized procedures enhance production reliability and foster long-term supplier partnerships. ↩ ↩

-

raw material: Read the article to learn how variations in raw material quality can affect manufacturing outcomes and product performance in industrial production. ↩ ↩

-

carbon fiber: Read the article to explore the properties, applications, and benefits of carbon fiber in high-performance manufacturing settings. ↩ ↩

-

composite materials: Read the article to discover how composite materials combine different properties for enhanced durability and performance in product design. ↩ ↩

-

thermoforming: Read the article to understand thermoforming techniques, their advantages, and practical considerations in precision manufacturing. ↩ ↩