Pickleball paddle face materials like carbon fiber, fiberglass, and composites1 are crucial in determining spin performance, control, and durability. This article quickly explores how these materials differ and offers practical guidance for procurement managers and product developers seeking high-performance, cost-effective solutions.

In the competitive sports market, especially in pickleball, the paddle face material significantly influences player performance. Buyers need materials that can optimize spin, provide durability under repeated impacts, and suit both recreational and high-intensity competitive play. With materials such as carbon fiber, fiberglass, and composite blends available, understanding their differences is essential to make informed purchasing decisions.

Procurement managers and product development specialists are often challenged by:

• Balancing superior performance with cost efficiency.

• Matching material properties to player needs and market segments.

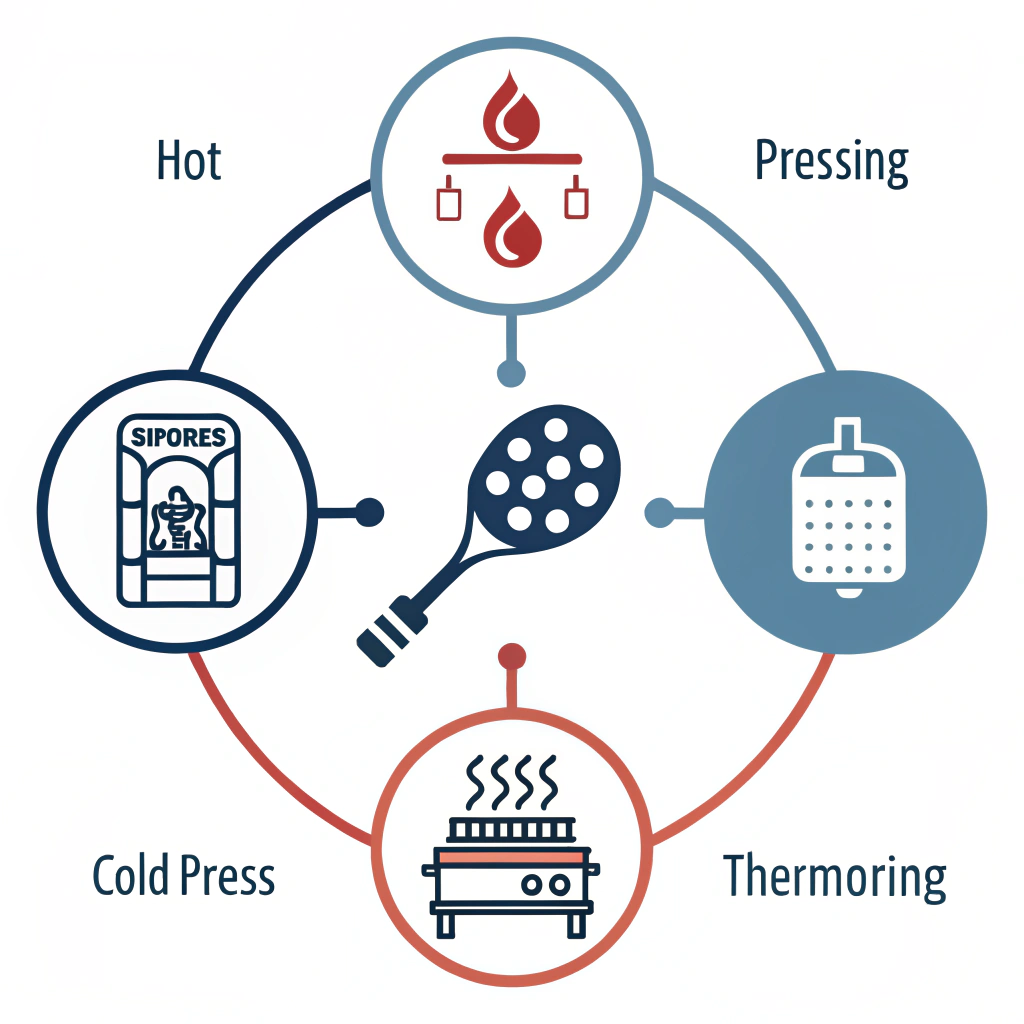

• Understanding advanced manufacturing processes like hot pressing, cold pressing, and thermoforming that affect the paddle's performance.

These challenges call for a clear, comparative analysis of the materials and processes used in pickleball paddle production.

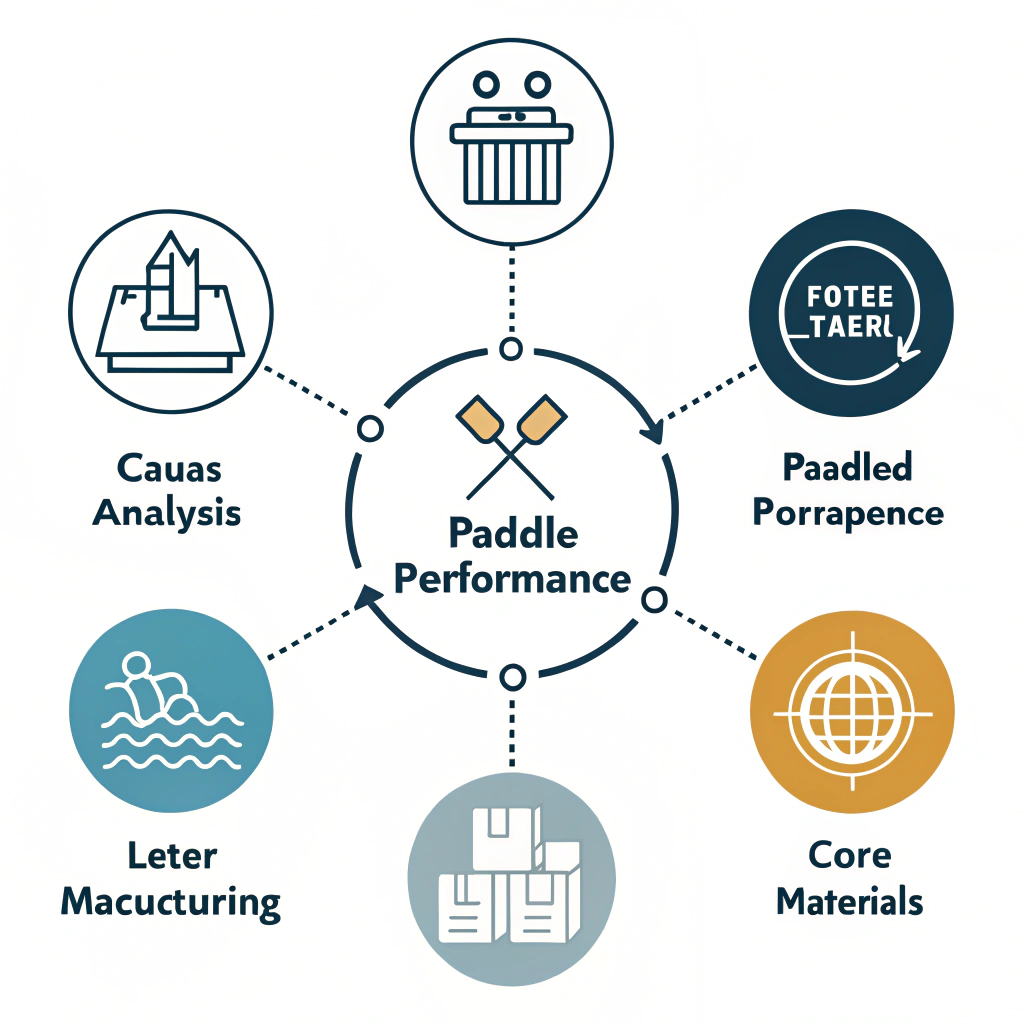

The spin performance and overall paddle behavior depend on several factors:

-

Material Composition:

- Carbon Fiber: Known for its lightness and rigidity, offers excellent power and minimal vibrations.

- Fiberglass: Provides more flexibility and control, suitable for players focusing on ball placement and a balanced feel.

- Composite Materials: Combine carbon fiber and fiberglass, or integrate unique cores like bamboo or honeycomb, to strike a balance between control and power.

-

Manufacturing Processes:

- Hot Pressing2: Ensures strong bonding and overall structural strength but might slightly affect the paddle's feel.

- Cold Pressing3: Maintains the inherent properties of the materials, offering enhanced control and a smoother ball feel.

- Thermoforming4: Ideal for intricate designs that require precise material distribution and stability, although it may increase production time.

-

Core Materials:

Even when focusing on face materials, the core plays a role in dampening vibration and influencing the overall paddle response. Options include Nomex, aluminum, and polymer cores, with polymer variants like polypropylene5 known for their soft-touch and controlled performance.

Understanding the interplay between these factors is critical when evaluating how effectively a paddle face material enhances spin performance. In many cases, using cutting-edge production processes can amplify the inherent benefits of the selected material.

To assist in making a well-informed decision, consider the following table which details key attributes of the most common paddle face materials:

| Material Type | Key Properties | Advantages | Suitable For |

|---|---|---|---|

| Carbon Fiber (3K/12K/T300) | Extremely stiff, lightweight, high rebound | High performance, excellent power delivery, reduced vibration | Intermediate to advanced players needing precision and power |

| Fiberglass (E-Glass) | Flexible, resilient, wider sweet spot | Superior control, ideal ball feel, durable | Beginners and players focusing on control and spin |

| Composite Materials | Hybrid properties from combined materials | Balanced performance, enhanced design flexibility | Players seeking a blend of power and control |

| Polymer/Polypropylene Core Options | Soft, flexible impact absorption | Quieter, better control with a soft touch | Recreational players and those requiring maximum comfort |

This table summarizes the core strengths and typical applications, helping procurement managers align product features with market requirements.

Carbon fiber paddles are favored for their excellent weight-to-strength ratio. Variants like 3K and 12K offer players options based on required stiffness and surface smoothness. Carbon fiber paddles often demonstrate:

- High rebound force: Maximizes power during play.

- Reduced vibration: Enhances the overall playing experience.

- Structural durability: Ideal for competitive environments.

These properties make carbon fiber a staple for intermediate to advanced players who demand a high level of performance and responsiveness.

Fiberglass paddles bring a different set of benefits. Their flexibility and inherent softness provide:

- Wider sweet spot: Greater margin for error.

- Enhanced control and spin potential: Perfect for players who rely on spin tactics rather than brute force.

- Durability in repeated play: A practical choice for training and recreational use.

Fiberglass is often recommended for entry-level players or those who are still mastering their techniques, ensuring that the paddle adapts comfortably to varied playing styles.

Composite paddle faces combine the strengths of both carbon fiber and fiberglass, offering a balanced mix of power and control. These materials are engineered to:

- Provide enhanced performance through sheer innovation in material science.

- Deliver improved responsiveness through an optimal blend of stiffness and flexibility.

- Offer customization opportunities for performance metrics that can be fine-tuned to specific market needs.

In many cases, composite options are a response to evolving demands where a single material fails to cover all aspects of performance.

While the focus is on face materials, the choice of core materials plays a supportive role. A polymer or polypropylene core, for example, is designed to offer:

- Optimal shock absorption: Enhancing durability and reducing fatigue during long matches.

- A soft, yet responsive hit: Ensuring controlled ball behavior that complements the paddle face.

- Noise reduction: Providing a quiet playing experience that is often appreciated in community leagues and training sessions.

Selecting a paddle is thus not only about the face but also about how well the core and face work together to optimize spin and control.

The production processes used in manufacturing also play an essential role in optimizing paddle performance. Consider how each process affects the final product:

- Advantages:

- High production efficiency and consistent quality across large batches.

- Enhances the material’s structural integrity, making the paddle robust.

- Challenges:

- High initial equipment investment.

- Potentially altered material properties, affecting the tactile feel.

- Advantages:

- Maintains the natural properties of materials, leading to superior control and ball feel.

- Greater precision in shaping, crucial for achieving optimal thickness and weight distribution.

- Challenges:

- Longer production cycles, which may impact output for large orders.

- The need for highly controlled environments to ensure consistency.

- Advantages:

- Allows for intricate design details and precise material distribution.

- Ideal for custom and premium paddle production.

- Challenges:

- Longer production time and higher equipment costs.

- Typically reserved for high-end products or specialized designs.

Each manufacturing process interacts with the chosen materials to determine the paddle's final performance attributes. For procurement managers, understanding these nuances ensures that production strategies align with market expectations and product performance goals.

Leading manufacturers such as NEX Pickleball integrate advanced production techniques to deliver paddles with optimal performance. Here are some best practices and industry trends:

-

Rigorous Testing:

- Each paddle undergoes extensive durability and performance tests to ensure it meets high-quality standards, ensuring that the selected material and process deliver on their performance promises.

-

Customization Capabilities:

- Offering custom paddle options allows suppliers to cater to varied client needs, from team branding to specific performance adjustments (balance, weight, grip size).

-

Market-Driven Material Selection:

- Data-driven decisions guide material selection: for instance, carbon fiber might be prioritized when targeting competitive athletes, while fiberglass could be chosen for broader recreational use.

-

Sustainability in Materials:

- As the market becomes increasingly eco-conscious, manufacturers are also considering the sustainability of materials. Innovations in composite design include the use of recycled fibers and greener production practices.

-

Performance Data Integration:

- Using feedback from professional players and controlled testing environments helps in refining paddle designs continuously. This data validates whether the enhanced spin capability and control through specific face materials translate well in real-world scenarios.

An alliance between technology innovation and market insight has led to a rich variety of products that cater to the multifaceted requirements of the modern pickleball player.

In summary, the choice of pickleball paddle face material is pivotal in delivering high spin performance, control, and durability. Carbon fiber offers power and lightness suitable for competitive play, whereas fiberglass provides enhanced control ideal for beginners and players focusing on technique. Composite materials blend these benefits, often presenting an attractive compromise for diverse player needs. Additionally, the manufacturing process—whether hot pressing, cold pressing, or thermoforming—further influences the final performance and cost-effectiveness of the paddle.

For procurement managers and product developers, the recommended action steps include:

- Evaluate market segments and player performance levels to select the appropriate paddle face material.

- Compare the inherent benefits of carbon fiber versus fiberglass and composite materials based on performance data.

- Consider the manufacturing process and corresponding cost implications to ensure a balanced procurement strategy.

- Collaborate with manufacturers like NEX Pickleball, who have extensive expertise in advanced technologies, ensuring that your requirements for spin, control, and durability are met with high-quality, rigorously tested products.

By strategically aligning material properties, manufacturing techniques, and market needs, B2B buyers can make efficient, confident decisions that optimize both product performance and overall market competitiveness.

Q: What is the best material for a pickleball paddle face?

A: Carbon fiber is frequently recognized as the best choice due to its exceptional weight-to-strength ratio, offering high power and responsiveness. Its structural properties reduce vibration and ensure long-lasting durability, making it ideal for competitive play.

Q: Is carbon fiber or fiberglass better for pickleball?

A: Carbon fiber tends to excel in power and stiffness, making it suitable for intermediate to advanced players, whereas fiberglass offers more flexibility and control, often favored by beginners who need a richer ball feel and enhanced spin control.

Q: What is a polypropylene core for pickleball?

A: A polypropylene core is designed as a soft, flexible structure within the paddle. It uses a honeycomb configuration to provide excellent shock absorption and a soft touch while maintaining precise control during gameplay.

-

composites: Click to learn how composite materials combine different fibers and cores to optimize the balance between power and control in sports equipment. ↩ ↩

-

Hot Pressing: Click to explore the hot pressing manufacturing process, its benefits in enhancing structural integrity, and its role in achieving consistent production quality. ↩ ↩ ↩2

-

Cold Pressing: Click to understand how cold pressing preserves material properties for improved control and ball feel, critical for precision in sports manufacturing. ↩ ↩ ↩2

-

Thermoforming: Click to read about thermoforming techniques, their application in creating intricate designs, and the trade-offs in production timing and cost. ↩ ↩ ↩2

-

polypropylene: Click to examine polypropylene’s characteristics as a core material, including its shock absorption capabilities and impact on paddle performance. ↩ ↩