When evaluating pickleball paddles for bulk procurement1, the optimal choice hinges on a careful comparison of materials, manufacturing techniques, and performance characteristics. In this article, we break down the key factors—including carbon fiber grades, fiberglass alternatives, and advanced manufacturing processes—to help you confidently align your purchasing strategy with your business objectives.

B2B procurement managers and sports equipment distributors face a challenging selection process when sourcing paddles. The main concerns include:

• Ensuring durability and high-performance standards

• Balancing power and spin features

• Aligning manufacturing quality with your retail or facility requirements

A wide range of technologies such as hot pressing, cold pressing2, and thermoforming directly influence the final product’s quality. This comprehensive comparison provides data-driven insights into selecting paddles that have been rigorously engineered for both competitive play and long-lasting reliability.

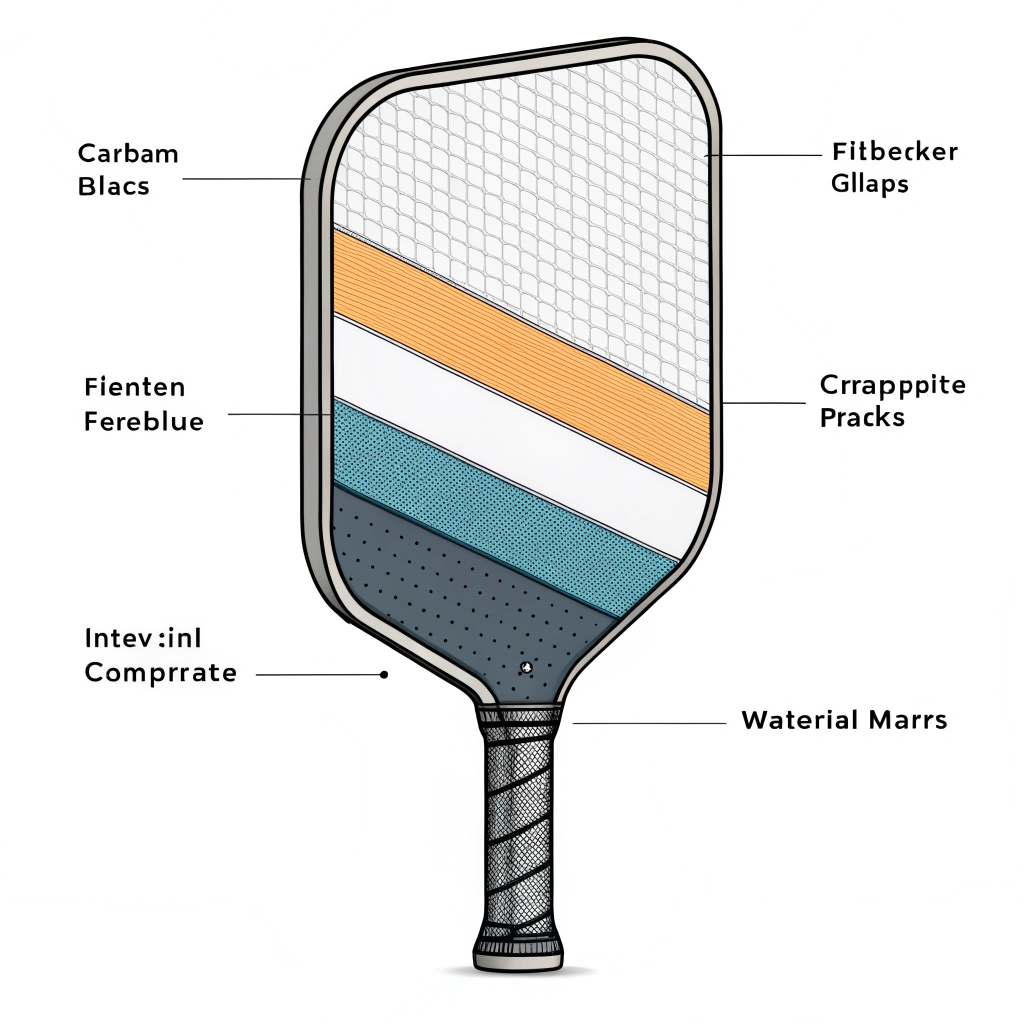

In today’s competitive market, the materials used in paddle production play a significant role. Let’s review the leading options:

The use of carbon fiber is crucial for paddles that prioritize power and responsiveness. Manufacturers employ different types of carbon fiber to cater to diverse playing styles:

- 3K Carbon Fiber: Valued for its strength and flexibility, it delivers high rebound force and excellent durability while reducing vibrations during play.

- 12K Carbon Fiber: With a higher thread density, it offers a smoother surface, enhanced hardness, and durability. It is optimal for high-impact scenarios and competitive use.

- T300 Carbon Fiber: Known for its outstanding tensile strength, this fiber strikes a balance between strength and low weight, offering a superior playing experience.

Fiberglass paddles contribute to greater ball control and provide a wider sweet spot. They are typically more flexible and deliver a responsive feel, making them popular among players who prioritize touch and control.

Composite Materials3: The Best of Both Worlds

By combining materials, companies now offer paddles with composite constructions that maximize multiple performance factors:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of power from carbon fiber with the soft touch of fiberglass, providing a balance of strength and flexibility.

- Bamboo Core Composite: This structure delivers a lightweight yet highly impact-resistant solution, ensuring a crisp hitting feel for long-lasting play.

- Honeycomb Core (Polymer based): Known for superior shock absorption, honeycomb cores reduce vibrations while enhancing durability through high-density materials.

A clear material comparison helps you decide which feature is most critical for your market segment.

Below is a summary table comparing the key characteristics of the materials used in high-performance paddles:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| 3K Carbon Fiber | High rebound, excellent durability, reduced vibration | Competitive play and high-impact |

| 12K Carbon Fiber | Smoother surface, great hardness, high impact resistance | Extreme strength & precision |

| T300 Carbon Fiber | Balanced strength and weight, superior tensile strength | Players seeking lightweight power |

| Fiberglass | Wide sweet spot, excellent ball control, increased flexibility | Recreational and control-focused |

| Composite (Carbon Fiber/Fiberglass) | Combines flexibility and strength, balanced performance | Mixed performance needs |

| Bamboo Core Composite | Lightweight, impact resistant, clear hitting feel | Long-lasting play, unique feel |

| Honeycomb Core (Polymer) | Superior shock absorption, vibration reduction | Comfortable hitting experience |

This comparison table provides a quick reference for material selection based on performance impacts.

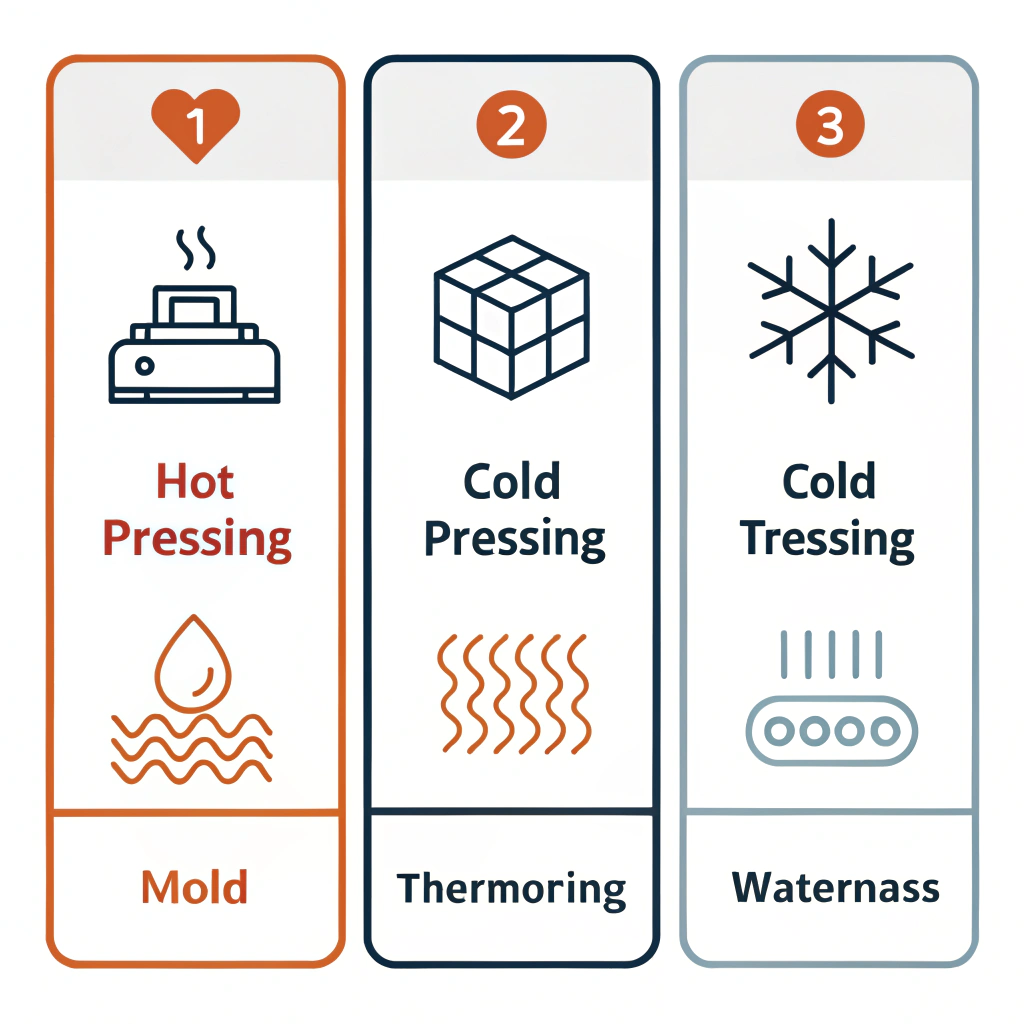

The production process is another critical factor that influences a paddle’s performance characteristics. At NEX Pickleball, three main manufacturing techniques are used, each with distinct advantages and compromises:

Hot pressing involves applying high temperatures and pressure to mold the paddle materials.

- Advantages:

- High production efficiency, essential for large-scale orders.

- Results in a strong paddle with excellent impact resistance.

- Maintains structural integrity for high-performance outcomes.

- Disadvantages:

- High initial investment in production equipment.

- Some material properties might be altered, potentially affecting the paddle feel.

Cold pressing shapes paddle materials at room temperature by mechanically applying pressure.

- Advantages:

- Enables precise control over paddle thickness and texture.

- Maintains the inherent properties of materials for better control and flexibility.

- Offers superior ball feel and responsiveness.

- Disadvantages:

- Longer production cycles may reduce overall efficiency.

- Demands high-quality equipment for precise pressure control.

Thermoforming involves heating materials to a soft state and then molding them into shape using specialized molds.

- Advantages:

- Permits complex designs and exact material distribution.

- Ensures paddle stability, enhancing overall performance.

- Suitable for both premium and custom-made products.

- Disadvantages:

- Longer production times increase manufacturing costs.

- Requires a significant investment in advanced equipment.

Below is a table summarizing the strengths and limitations of these production processes:

| Process | Strengths | Limitations |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | High equipment cost, altered feel |

| Cold Pressing | Precise control, excellent responsiveness | Longer cycles, precise equipment needed |

| Thermoforming | Complex designs, precise material distribution | Increased production time, higher costs |

This insight aids procurement managers in understanding how the production process can affect product quality and pricing, which is crucial for aligning bulk purchase decisions with your business needs.

The selection of core materials further refines paddle performance. Different core types affect the paddle’s stiffness, vibration dampening, and overall playability:

- Features: Made from durable polymers, this core offers outstanding shock absorption.

- Application: Perfect for players prioritizing longevity and stability.

- Features: Provides a balanced weight distribution geared towards both power and control.

- Application: Ideal when a synergistic mix of precision and impact force is required.

- Features: Known for better elasticity and minimized vibrations.

- Application: Especially suited for players who prefer sensitive touch and long-duration comfort.

The decision between these cores should depend on the intended end-user profile and playing style. For instance, competitive facilities may lean towards Nomex or Aluminum cores for performance consistency, while recreational centers could prefer the softer touch provided by Polymer cores.

Understanding how material and manufacturing choices translate into functional performance helps in selecting the right paddle for each market scenario. Below is a detailed breakdown of how these elements relate to specific performance metrics:

- Carbon Fiber Paddles: Particularly those using 12K and T300 variants, are engineered to deliver maximum power. The superior tensile strength of these materials allows players to hit with force while maintaining control.

- Hot Pressed Designs: Typically produce paddles with greater robustness ideal for high-rebound impacts, contributing to power efficiency.

- Composite Materials: Especially those combining carbon fiber with fiberglass, optimize the sweet spot for controlled spin.

- Cold Pressed Paddles: Tend to retain a material’s inherent flexibility, which can enhance spin dynamics by offering a better-quality ball feel.

- Lightweight Constructions: Both carbon fiber and fiberglass options tend to produce lightweight paddles. This design offers easier maneuverability and precise control, which is beneficial for seniors who favor accuracy over sheer force.

- Vibration Dampening Features: Technologies like honeycomb polymer cores provide enhanced shock absorption, reducing strain and increasing playability for older players.

Investing in paddles that are specifically aligned with the intended use—whether competitive power play, spin optimization, or user comfort—ensures that your bulk procurement choice matches market demand.

For quick reference, the following table juxtaposes performance attributes with the underlying material and manufacturing characteristics:

| Performance Metric | Key Material/Process | Resulting Benefit | Ideal Target User |

|---|---|---|---|

| Power | 12K/T300 Carbon Fiber, Hot Pressing | High rebound force, longevity | Competitive athletes |

| Spin | Composite (Carbon Fiber/Fiberglass), Cold Pressing | Enhanced ball control and sweet spot | Players seeking spin control |

| Comfort | Fiberglass, Polymer Core | Lightweight, reduced vibration | Senior players, beginners |

This table can serve as a decision aid when discussing specifications with team members or suppliers, ensuring that each buyer understands how each feature translates into on-court performance.

The in-depth comparison of materials, production techniques, and core structures clearly reveals that the right pickleball paddle must balance high-performance metrics with durability, usability, and cost-effectiveness. Here are several action points for B2B buyers:

• Clearly define your target market: Consider whether your clientele prioritizes power, spin, or user-friendly design for seniors.

• Evaluate suppliers on their production methods: Understand the trade-offs inherent in hot pressing, cold pressing, and thermoforming, and ensure that the chosen method aligns with your quality and throughput needs.

• Use comparative tables and performance metrics: These tools not only streamline decision-making but also empower you to negotiate better terms based on proven product characteristics.

• Consider customization options: With on-demand customization available, you can tailor the paddle design—grip size, weight, balance—to meet specific customer demands, ensuring brand differentiation in your retail offerings.

By integrating these considerations into your decision-making process, you are better positioned to procure pickleball paddles that not only meet stringent performance standards but also generate a competitive advantage in the sports equipment market.

• Which pickleball paddle gives you the most power?

Answer: The most powerful pickleball paddles typically feature high-density carbon fiber materials—such as 12K or T300 variants—and are manufactured using processes like hot pressing to secure structural strength and high rebound force.

• Which pickleball paddle generates the most spin?

Answer: Paddles optimized for spin often employ composite designs that blend carbon fiber and fiberglass. The resulting flexibility enhances the sweet spot and ball control, allowing players to create significant spin on their shots.

• What is the best pickleball paddle for seniors?

Answer: For seniors, lightweight paddles made from materials like fiberglass or specific carbon fiber versions are ideal. Their reduced weight and improved vibration dampening offer better control and precision, which are critical for players prioritizing comfort over raw power.

-

bulk procurement: Read this article to learn strategies for purchasing large quantities effectively, including cost-saving techniques and supply chain optimization tailored for B2B buyers. ↩ ↩

-

cold pressing: Click to explore how cold pressing preserves material properties during manufacturing, offering benefits in product consistency and tactile performance. ↩ ↩ ↩2

-

Composite Materials: Learn about the benefits of composite materials in manufacturing, including how combining different fibers can enhance product performance and durability. ↩ ↩

-

thermoforming: Discover the process of thermoforming, its advantages for complex designs, and how it contributes to the structural integrity of high-performance sports equipment. ↩ ↩

-

Nomex Honeycomb Core: This explanation covers honeycomb core technology, detailing its shock absorption capabilities and role in improving the longevity and playability of sports equipment. ↩ ↩