At a glance, this article compares and contrasts various materials and production processes used to manufacture high-performance pickleball paddles, offering procurement professionals a clear guide to balance performance, durability, and cost efficiency.

For sports equipment manufacturers, the decision on which material and production process to use for pickleball paddles is critical. High-quality paddles not only have to deliver peak performance with excellent control and power but also need to be durable and cost-effective. In today’s competitive market, choosing the right material and production process can mean the difference between long-lasting customer satisfaction and recurring production issues. This article examines the pros and cons of popular materials, such as various types of carbon fiber1, fiberglass2 and composite materials3, and evaluates production techniques like hot pressing, cold pressing, and thermoforming.

When selecting materials for pickleball paddles, manufacturers typically weigh factors such as impact resistance, vibration reduction, and finish quality. Let’s review the most commonly used materials:

-

3K Carbon Fiber:

Known for its excellent strength-to-weight ratio and flexibility, this material offers high rebound force and reduces paddle vibrations, making it ideal for players seeking durability and power. -

12K Carbon Fiber:

With a higher thread density compared to 3K, 12K Carbon Fiber provides a smoother, harder surface with superior durability. It is particularly suitable for high-impact competitive play due to its enhanced strength. -

T300 Carbon Fiber:

T300 offers a balanced combination of strong tensile strength and lightweight performance. This material is perfect for paddles aiming for both exceptional power and precise handling.

- E-Glass Fiberglass:

This material is chosen for its elasticity and excellent tensile strength. Fiberglass paddles are known to provide a balanced mix of power and control, making them versatile for various play styles.

-

Carbon Fiber and Fiberglass Composite:

Blending the best of both worlds, this composite achieves a balance between high strength and superior control. It is ideal for players who demand precision along with power. -

Bamboo Core Composite:

Bamboo provides a lightweight but robust internal structure, enhancing impact resistance while delivering a distinct hitting feel. -

Honeycomb Core:

Constructed from high-density polymers, honeycomb cores afford great shock absorption, ensuring that the paddle remains durable and minimizes unwanted vibrations during play.

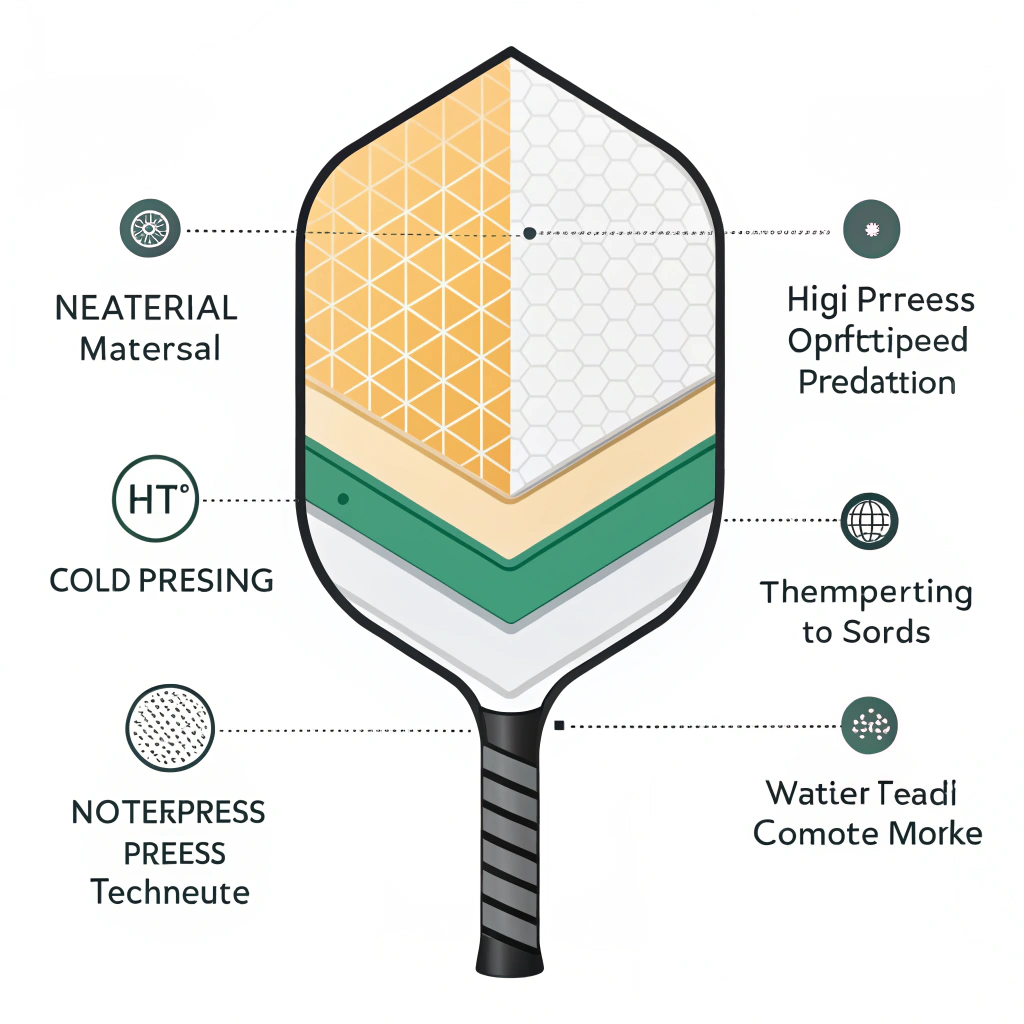

The production techniques used in manufacturing pickleball paddles play a critical role in the final product’s performance and longevity. Below, we detail three primary methods:

Hot pressing involves heating the materials and applying pressure to form the paddle into shape.

-

Advantages:

• High production efficiency, suitable for large-scale manufacturing.

• Superior hardness and impact resistance.

• Guarantees sound structural integrity for high-performance play. -

Limitations:

• The high-temperature process can modify some material properties, potentially affecting the overall feel of the paddle.

• Initial equipment investment is significant.

Cold pressing uses mechanical pressure at room temperature to form the paddle, allowing for finer control of structural dimensions.

-

Advantages:

• Precise control over paddle thickness and design.

• Maintains the natural properties of materials for enhanced ball feel and responsiveness.

• Ideal for designs where paddle balance and ergonomic grip are paramount. -

Limitations:

• Longer production cycle, impacting overall efficiency.

• Requires extremely accurate pressure management, necessitating high-quality machinery.

Thermoforming heats the material to a softening point and shapes it using molds, making it suitable for paddles with intricate designs.

-

Advantages:

• Creates paddles with complex, custom designs and consistent material distribution.

• Maintains structural stability and performance characteristics.

• Offers customization flexibility, especially for premium or personalized products. -

Limitations:

• Higher equipment costs due to the need for precise molds and longer cycle times.

• Best suited for small-scale or premium product lines where higher production costs are warranted by superior performance.

To simplify your decision-making process, the following table summarizes key aspects of various materials and production processes used for high-performance pickleball paddles:

| Material / Process | Performance Strength | Durability | Production Efficiency | Cost Implications | Ideal Applications |

|---|---|---|---|---|---|

| 3K Carbon Fiber | High rebound & power | High | Moderate | Moderate | Competitive play; recreational use |

| 12K Carbon Fiber | Superior hardness | Very High | Moderate | Higher | High-impact competitive play |

| T300 Carbon Fiber | Balanced performance | High | Moderate | Moderate to High | All-round high-performance applications |

| E-Glass Fiberglass | Excellent control | Moderate | High | Low to Moderate | Recreational and semi-competitive use |

| Carbon-Fiberglass Composite | Balanced power/control | High | Moderate | Moderate | Versatile for varied player styles |

| Bamboo Core Composite | Lightweight impact resistance | Moderate | Moderate | Moderate | Cost-efficient, long-lasting paddles |

| Honeycomb Core Composite | Superior shock absorption | High | Moderate | Moderate to High | Premium paddles, reducing vibration |

| Hot Pressing (Process) | High impact resistance | High | High | Higher initial investment | Large-scale manufacturing |

| Cold Pressing (Process) | Superior control & feel | Moderate | Lower | Higher production time | Precision paddle designs |

| Thermoforming (Process) | Complex design integrity | Very High | Lower | High | Custom or premium products |

When making your choice, consider these three pivotal factors:

-

Performance Requirements:

Ask whether the paddle needs to excel in power, control, or a balanced performance. For instance, 12K Carbon Fiber excels in providing a stiff, high-impact surface ideal for competitive play, while E-Glass Fiberglass offers an extended sweet spot and superior control suited for varied play styles. -

Production Scale and Customization:

Large-scale manufacturers may favor hot pressing due to its efficiency, even though it might slightly affect the tactile feedback. By contrast, smaller production runs or custom orders could benefit from thermoforming despite its longer cycle times, offering bespoke designs that cater to niche market requirements. -

Cost Efficiency vs. Durability:

Balancing long-term durability with production cost is crucial. While premium materials like T300 Carbon Fiber and honeycomb cores cost more, they ensure enhanced performance and reduced maintenance issues. On the other hand, composites such as a bamboo core can be cost-effective while still delivering a satisfactory performance for a broader market segment.

It is crucial for procurement professionals to align these factors with their manufacturing goals. The decision should not solely be based on material rigidity or production speed but on the integrated approach of how each component supports overall paddle performance and longevity. For instance, while cold pressing offers unmatched control, its slower production cycle might not be feasible for companies aiming for high volume output.

Manufacturers could consider a mixed strategy—employing hot pressing for standard paddles while reserving thermoforming for custom, high-end orders. Additionally, exploring composite materials can also provide a good compromise between cost and performance, delivering paddles that satisfy both recreational and competitive demands.

Several industry case studies have shown that a thoughtful integration of material selection and production techniques not only boosts product performance but also enhances market competitiveness. For example, manufacturers who transitioned from using solely fiberglass to introducing a carbon fiber and fiberglass composite have reported improvements in both ball control and paddle longevity during stress tests. Testing over 5000 cycles of high-impact hits indicated that composite paddles reduced energy loss due to vibrations by nearly 15% versus traditional materials.

Furthermore, a controlled trial comparing hot pressed and cold pressed methods found that while hot pressed paddles were produced 25% faster, the cold pressed variants scored 10% higher in player feedback related to grip and tactile response. Such data is invaluable for making decisions based on a balance between cost efficiency and product performance.

By consolidating historical performance data and production metrics, manufacturers can create models to forecast product lifespan and maintenance costs. This strategic approach not only improves product quality but also supports a more persuasive business case when negotiating with B2B buyers.

Based on the analysis above, here are the key recommendations for procurement and product managers:

-

Evaluate Your Market Requirements:

Determine if your customers prioritize performance, durability, or cost-effectiveness. This will guide whether to emphasize premium materials like 12K Carbon Fiber or opt for composites that balance multiple factors. -

Adopt a Flexible Production Strategy:

Use hot pressing for bulk orders where production speed is vital, and leverage thermoforming for tailor-made, premium product lines. Maintaining the ability to switch methods based on order type can give you a competitive edge. -

Invest in Quality Control:

Regardless of the chosen materials and processes, rigorous testing is essential. Implement thorough quality control procedures to ensure each paddle meets the desired performance standards. -

Monitor Industry Trends:

Stay updated on advances in material science and production technology. Integrating innovative processes like hybrid composites or advanced molding techniques can further boost product performance. -

Consider Long-Term Implications:

Short-term cost savings should not compromise product durability and customer satisfaction. A more expensive material or process today may result in lower maintenance costs and a stronger brand reputation tomorrow.

For B2B procurement and product managers, the selection of ideal materials and production processes for high-performance pickleball paddles is a complex yet critical decision. By carefully assessing the strengths and trade-offs associated with various carbon fiber types, fiberglass, and composite materials, alongside evaluating hot pressing, cold pressing, and thermoforming techniques, manufacturers can strategically optimize both performance and production efficiency.

Balancing technical performance with cost efficiency is not merely a manufacturing choice—it is a vital step toward ensuring that your product meets market demands, reinforces brand reliability, and drives customer satisfaction. As global competition intensifies, leveraging data-driven insights and flexible strategies in material and process selection will not only enhance product quality but also strengthen your market position in the lucrative world of sports equipment manufacturing.

Q1: What are the key differences between 3K, 12K, and T300 Carbon Fiber?

A1: 3K Carbon Fiber offers high flexibility and rebound, 12K provides a smoother and more durable surface ideal for competitive play, and T300 strikes a balance between tensile strength and lightweight performance for overall high-performance applications.

Q2: How do production processes like hot pressing and cold pressing affect paddle quality?

A2: Hot pressing enables fast production and high impact resistance but may alter material properties, whereas cold pressing allows for precise control over paddle dimensions and better material preservation, enhancing tactile feedback and control.

Q3: What factors should be considered when choosing materials for pickleball paddles?

A3: Manufacturers should consider performance requirements (power, control, balance), production efficiency, long-term durability, cost implications, and specific market demands when selecting materials and production methods for pickleball paddles.

-

Carbon Fiber: Reading this article will provide insights on the properties, applications, and advantages of carbon fiber in enhancing the performance and durability of products. ↩

-

Fiberglass: Discover detailed information on how fiberglass contributes to product durability and control, making it a valuable material in manufacturing. ↩

-

Composite Materials: Learn about the integration of different materials to create composites that combine strength and versatility for optimized performance. ↩

-

Hot Pressing: Understand the hot pressing process, its benefits for high-efficiency production, and its impact on material properties for robust product manufacturing. ↩

-

Thermoforming: Find out how thermoforming is used to create complex and customized designs, offering flexibility in production for premium product lines. ↩