Quick Answer: In 2025, choosing the best lightweight pickleball paddle requires a careful comparison of advanced materials, precision manufacturing processes, and the resulting performance benefits. By examining technologies such as 3K, 12K, and T300 carbon fiber1, along with innovations in composite cores and production techniques like hot pressing, cold pressing, and thermoforming, procurement managers can confidently select high-performance paddles that offer an optimal balance of weight, durability, and control.

The market for high-performance, lightweight pickleball paddles has evolved significantly, with technological advancements driving improvements in material quality and production precision. As procurement and product managers evaluate options for their distribution portfolios, it is essential to make an informed decision based on detailed specifications, innovative manufacturing processes, and relevant performance metrics. In this article, we compare various production techniques and materials used in lightweight paddles, helping you identify the product that best meets your supply needs while promising enhanced end-user performance.

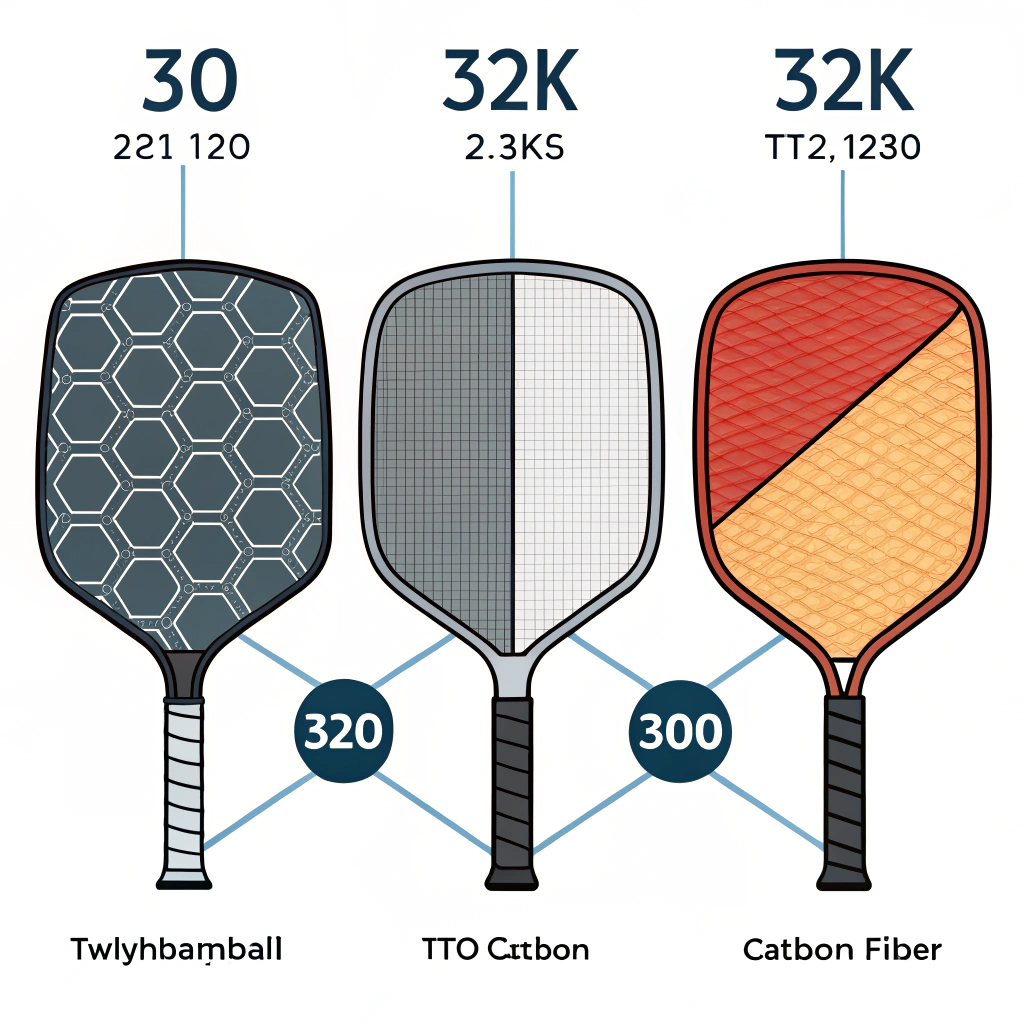

When evaluating lightweight pickleball paddles, the choice of materials is critical. Manufacturers use different types of carbon fiber and composite materials to achieve the desired balance of strength, flexibility, and weight reduction. Below, we break down the main materials:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Renowned for its strength and flexibility, this material is ideal for paddles that require high rebound force and reduced vibration, ensuring a dynamic playing experience.

- 12K Carbon Fiber: This variant offers a higher thread density. Paddles made from 12K have smoother surfaces, improved hardness, and robust impact resistance, making them suitable for competitive play.

- T300 carbon fiber1 has outstanding tensile strength, striking the perfect balance between light weight and power, ideal for those looking to boost both speed and control.

-

Fiberglass:

Fiberglass paddles provide a balance between power and precision. The E-Glass Fiberglass in particular is chosen for its elasticity and superior ball control, offering a wider sweet spot without sacrificing durability. -

Composite Materials2:

Combining different materials, such as carbon fiber and fiberglass, or incorporating unique core options, can enhance a paddle’s performance:- Carbon Fiber and Fiberglass Composite: Merging the resilient properties of carbon fiber with the responsive nature of fiberglass offers paddles with balanced strength, lightness, and control.

- Bamboo Core Composite: Utilizing bamboo cores not only reduces weight but also increases the impact resistance, providing a crisp hitting feel.

- Honeycomb Core Options3: These are engineered for superior shock absorption and reduced vibration. Options include Nomex, aluminum, and polymer honeycomb cores, each offering different levels of durability and comfort.

Understanding these materials and their benefits helps inform your decision when comparing products and ensuring that the chosen paddle meets the demands of both end users and market trends.

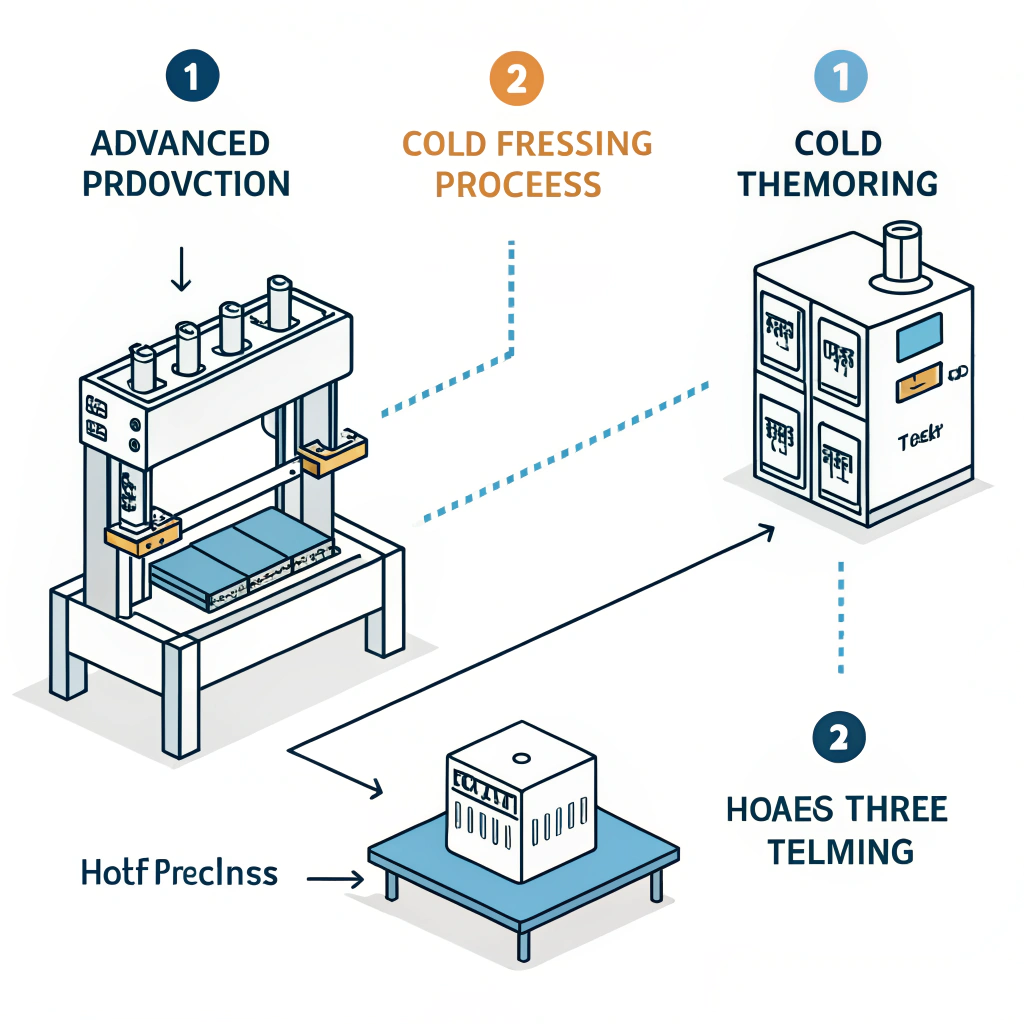

Beyond materials, production techniques play a vital role in determining the performance attributes of pickleball paddles. There are three primary production processes that manufacturers use:

Hot pressing involves heating materials and applying high pressure simultaneously to shape the paddle. It is widely used for high-performance paddles because of:

- Advantages:

• High production efficiency suitable for large-scale manufacturing.

• Enhanced impact resistance and structural integrity. - Disadvantages:

• Potential alteration of material properties, which may affect the paddle's feel.

• Requires significant investment in specialized equipment.

This process shapes the paddle material at room temperature through mechanical pressure, yielding paddles with precise control over thickness and design:

- Advantages:

• Maintains the natural properties of the material, resulting in improved control and varied flexibility.

• Provides a superior ball feel, essential for players seeking refined touch and responsiveness. - Disadvantages:

• Generally results in longer production cycles.

• Demands highly precise pressure control, necessitating quality manufacturing equipment.

Thermoforming involves heating the composite material until it becomes pliable and then using molds to create complex shapes:

- Advantages:

• Enables the creation of intricate paddle designs with precise material distribution.

• Enhances stability and material integrity, vital for high-performance products. - Disadvantages:

• Requires increased production time and higher equipment costs, making it better suited for premium or custom solutions.

Below is a summary table comparing the three production techniques:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance; structural integrity | Potentially alters material feel; high equipment cost |

| Cold Pressing | Precise control over thickness; preserves material properties; superior ball feel | Longer production cycles; requires precision equipment |

| Thermoforming | Creates intricate designs; maintains material distribution; ensures stability | Longer production time; higher production costs |

These manufacturing processes directly influence the paddle's final performance. Selecting the right production process can optimize the paddle’s quality, ensuring that the final product meets high standards. For example, a paddle using thermoforming may provide an intricate design with superior control, perfect for advanced players and competitive markets, while hot pressing may deliver a more robust paddle suited for extensive, high-impact play.

For procurement decisions, it is crucial to consider various core parameters that influence a paddle's performance:

- Weight: Lightweight paddles allow for faster movements and reduce fatigue during long play sessions. In 2025, we see a notable shift towards materials that minimize weight without compromising strength.

- Material Balance: The integration of carbon fiber or composite materials ensures that while the paddle remains light, it still maintains structural integrity and durability.

- Grip and Ergonomics: An effective paddle must offer an ergonomic design with multiple grip sizes available. Enhancements like textured surfaces help improve ball control and prevent slippage even during intense play.

- Vibration Dampening: A well-designed core, such as a polymer or honeycomb structure, helps minimize vibrations, offering a smoother and more comfortable playing experience.

Below is an example of technical specifications for a premium lightweight paddle:

| Specification | Detail |

|---|---|

| Weight | 7.5 – 8.5 ounces |

| Core Material | Polymer Honeycomb or Nomex Honeycomb |

| Surface Material | 12K Carbon Fiber / Composite Blend |

| Grip Sizes | Multiple (custom options available) |

| Manufacturing Process | Typically Thermoforming for premium design |

| Vibration Dampening | Advanced polymer layering techniques |

By comparing these technical details, procurement managers can better understand which product aligns with their supply portfolio’s specific requirements.

As we move towards 2025, the demand for technologically advanced yet lightweight pickleball paddles continues to rise. B2B buyers are especially interested in paddles that combine innovative material science with precise manufacturing techniques. Here are some strategic points for procurement:

- Emphasize Advanced Materials: Paddles that feature 12K carbon fiber or blends of carbon fiber and fiberglass offer enhanced durability and performance. The incorporation of premium materials not only boosts competitive play but also promises long-term reliability.

- Consider Production Efficiency and Customization: Utilizing processes such as Cold Pressing4 and Thermoforming5 allows manufacturers to produce paddles that meet exacting performance standards. Customization options, including adjustable grip sizes and tailored surface treatments, provide additional value for special orders and branded retail products.

- Cost versus Performance Analysis: While top-of-the-line paddles may involve a higher initial investment, their advanced production processes and material quality make them a cost-effective choice over time. Evaluating the long-term benefits such as increased player satisfaction and reduced warranty claims, supports a higher upfront cost for premium products.

- Supplier Reliability and Quality Control: Partnering with manufacturers like NEX Pickleball, who are known for strict quality control and innovative engineering, ensures consistent production quality across large orders. The rigorous testing procedures, including strength, flexibility, and vibration assessments, further safeguard your investments.

For distributors, these trends indicate that offering lightweight, high-performance paddles not only meets the increasing demands of competitive players but also positions your portfolio as ahead of market expectations. As performance specifications evolve, embracing technologies that maintain a balance between weight and durability is pivotal.

In summary, the choice among lightweight pickleball paddles hinges upon a thorough comparison of materials, production techniques, and technical specifications. The market in 2025 is set to feature paddles that use high-grade carbon fiber, combined with innovative core designs, to deliver exceptional playability and durability.

Procurement professionals should:

• Evaluate the material benefits (such as 3K, 12K, and T300 carbon fiber1) against the manufacturing processes (hot pressing, Cold Pressing4, Thermoforming5).

• Consider technical metrics like weight, grip ergonomics, and vibration dampening performance.

• Balance initial costs against long-term benefits in durability and customer satisfaction.

By following these action points and leveraging manufacturers with a proven track record in production excellence such as NEX Pickleball, you are well-positioned to enhance your product line with paddles that appeal to both competitive and recreational players. This thoughtful approach will not only optimize your portfolio but also deliver a meaningful competitive edge in the sports equipment market.

People Also Ask

Q1: What is the best light weight pickleball paddle?

A1: The best lightweight pickleball paddles balance minimal weight with optimal strength and control. While some models like the Gruvn Muvn 13S and the Ethos Dunamis excel in lightness, paddles such as the Paddletek ESQ or ALW offer a mix of performance and lightweight qualities, ensuring excellent rebound and vibration dampening for competitive play.

Q2: What are the best pickleball paddles in 2025?

A2: In 2025, the trend leans towards technologically advanced paddles built with premium materials. Top picks include high-end models like the JOOLA Perseus Pro IV, which, although expensive, deliver unmatched performance. For those seeking quality at a slightly lower price point, paddles such as the 11SIX24 or Vatic Pro offer advanced features suitable for competitive as well as recreational play.

Q3: What is the #1 rated pickleball paddle?

A3: Ratings can vary based on specific performance criteria and consumer needs. However, top-rated paddles in current market rankings include models from JOOLA and Paddletek. Notable mentions are the JOOLA Ben Johns series and other highly acclaimed models that rank among the Top 10 paddles, reflecting excellent design, durability, and user satisfaction.

-

T300 carbon fiber: Reading this article will help you understand the unique mechanical properties and performance benefits of T300 carbon fiber, which offers an optimal balance between light weight and strength for advanced paddle designs. ↩ ↩ ↩2 ↩3

-

Composite Materials: This article explains how composite materials combine different fibers to achieve enhanced durability and performance, crucial for understanding modern paddle construction. ↩ ↩

-

Honeycomb Core Options: Learn about honeycomb core options, including Nomex, aluminum, and polymer variants, which are engineered to provide superior shock absorption and vibration reduction for enhanced playability. ↩ ↩

-

Cold Pressing: Discover the technical advantages and challenges associated with cold pressing, a process that preserves the natural properties of materials for precision paddle manufacturing. ↩ ↩ ↩2 ↩3

-

Thermoforming: Explore how thermoforming allows for intricate paddle designs by heating and molding composite materials, providing stability and detailed structural control in high-performance products. ↩ ↩ ↩2 ↩3