Quick Answer: Superior control in pickleball paddles is achieved by selecting the right combination of advanced composite materials1 and manufacturing processes—especially cold pressing2 and thermoforming3—which preserve material properties, create a thicker, plush core, and ensure precise weight distribution for optimal ball dwell time and control.

In today’s competitive pickleball market, procurement managers and seasoned B2B buyers demand equipment that not only enhances player performance but also delivers unmatched durability and precision. One of the key performance features players look for is control. In this article, we delve into how various materials and production processes impact paddle control, helping you make an informed, data-backed decision when selecting your bulk order from a trusted manufacturer like NEX Pickleball.

Control in pickleball is largely influenced by the paddle’s composition, including its facing materials, core design, and manufacturing method. Fundamental factors include:

- Material Properties: The use of premium carbon fiber (3K, 12K, and T300 types)4, E-Glass fiberglass5, and innovative composites can directly affect ball feel and vibration damping.

- Core Composition: Whether it is a thicker honeycomb—be it Nomex, aluminum, or polymer—plays a crucial role in how the ball interacts with the paddle surface.

- Production Technique: Methods like cold pressing retain intrinsic material properties for better control, whereas hot pressing might enhance impact resistance but could alter the paddle’s natural feel.

The interplay of these factors determines the paddle’s overall behavior—balancing control, power, and durability. For buyers focused on premium retail and high-performance competitive play, ensuring the ideal balance is essential.

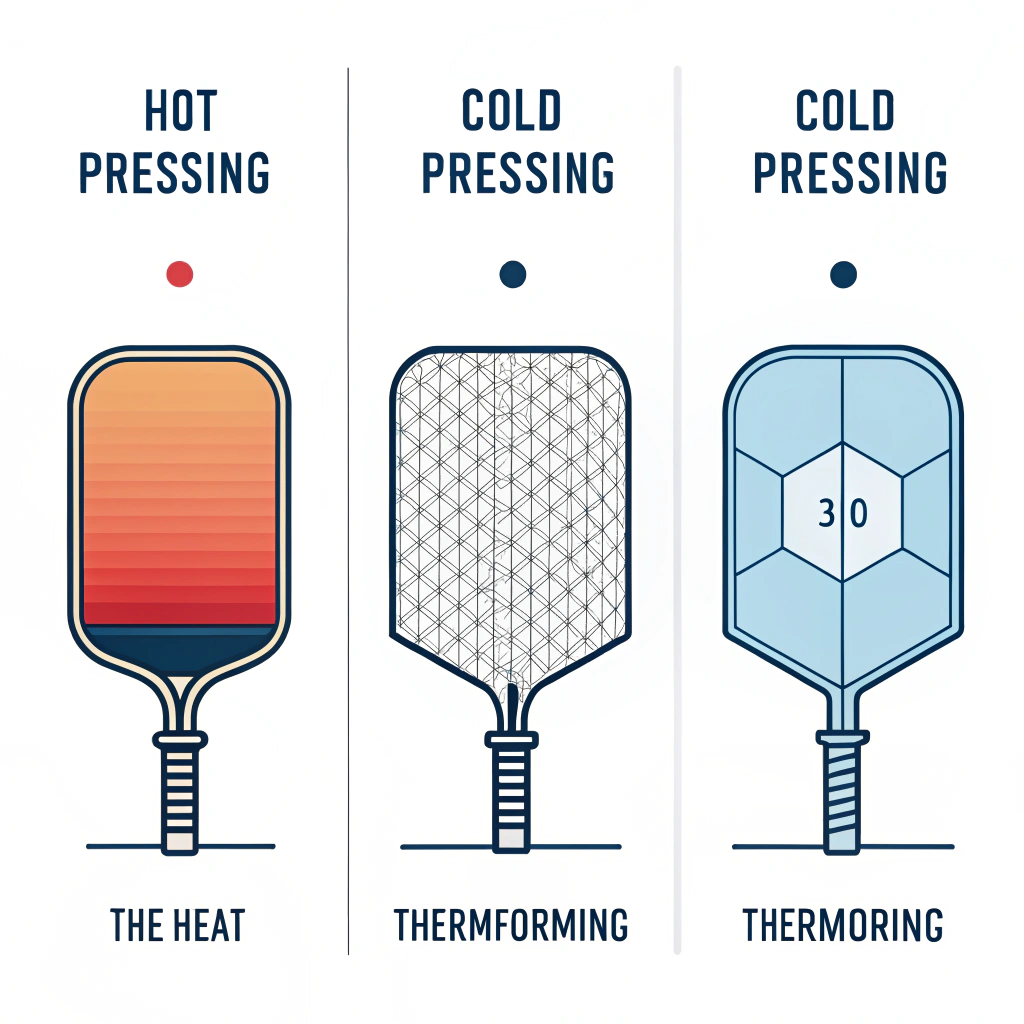

Each manufacturing process used at NEX Pickleball comes with its pros and cons in terms of control and overall performance. Choosing the right technique is key to aligning with your performance and quality needs.

Below is a table summarizing the three primary production methods and their relevance to control optimization:

| Production Process | Key Advantages for Control | Limitations Affecting Control | Ideal Applications |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong structure; excellent impact resistance | May slightly alter material properties, potentially reducing natural ball feel | Mass production of high-strength paddles for competitive play |

| Cold Pressing | Superior thickness control; preserves material’s intrinsic properties; enhanced ball feel and responsiveness | Longer production cycles; requires precise machinery control | Paddles requiring delicate control and a “plush” feel suitable for dinks |

| Thermoforming | Allows for intricate design control; precise material distribution; improved stability and performance | Higher cost and longer production time, limiting scalability | Custom or premium paddles with complex geometry and control optimization |

As shown, cold pressing stands out for creating paddles with a thicker core and improved dwell time on the ball, ideal for maximizing control. However, practical application may require a blend of these techniques to meet desired performance levels while balancing production efficiency.

In addition to production techniques, the materials used in paddle construction greatly affect control. Let’s examine these materials:

- 3K Carbon Fiber: Valued for its strength and flexibility, it provides excellent durability and reduces vibration. This type is optimal for paddles needing a high rebound force without compromising on control.

- 12K Carbon Fiber: With a smoother surface and higher thread density, it offers enhanced hardness and improved impact resistance. It is ideal when a blend of power and control is required in high-speed competitive play.

- T300 Carbon Fiber: Known for its exceptional tensile strength, it delivers a balanced performance, lending both power and lightweight control.

- E-Glass Fiberglass: Its elasticity and tensile strength provide an enhanced ball feel, allowing the paddle to offer a wider sweet spot. This helps players maintain control during both soft dinks and fast-paced volleys.

Combining different fibers can further optimize paddle performance:

- Carbon Fiber and Fiberglass Composite: This hybrid approach leverages both materials' benefits, balancing power with precise control.

- Bamboo Core Composite: Known for its lightweight and superior impact resistance, it ensures a clear hitting sensation while enhancing control.

- Honeycomb Core Options: Using different honeycomb structures (Nomex, Aluminum, and Polymer) can modify the paddle’s response. Specifically, thicker cores tend to provide a “plush” hit, ensuring longer ball dwell time and better control during delicate shots.

When selecting paddles, it is crucial to consider that features like core thickness and material composition directly influence the paddle’s control characteristics. A thicker, well-calibrated core generally offers players ease in controlling dinks, drops, and resets.

At NEX Pickleball, the commitment to quality drives our innovation in paddle manufacturing. Our in-depth understanding of advanced materials and complex production processes allows us to fine-tune every paddle to meet the high standards of professional players and retail distributors.

- Material Selection: The first step is choosing premium materials that match the performance requirement. For paddles emphasizing control, a combination of 12K Carbon Fiber with E-Glass Fiberglass or a hybrid composite often provides the best ball feel.

- Manufacturing Technique Customization: Based on the intended use, production experts select the right manufacturing method. Cold pressing is preferred for control-centric paddles due to its ability to maintain a thicker core and a softer surface.

- Quality Control Protocols: Advanced testing methods ensure that every paddle meets rigorous evaluation criteria. Consistent weight distribution and ergonomic grip design are crucial for providing the desired control.

- Customization Options: For bulk orders and specialized needs, custom paddle options allow procurement managers to specify design parameters such as design shape, weight balance, and grip size. These customizable options further enhance control for end users.

These tailored steps ensure that every paddle not only meets but exceeds the expectations of high-level competitive play. Integrated quality control, advanced production processes, and a rich understanding of materials lead to paddles that offer superior control without sacrificing durability.

For those in the decision phase, comparing key performance indicators is vital. Let’s review a simple decision-making guide that highlights how different production techniques and materials affect paddle control:

| Factor | Impact on Control | Detailed Insight |

|---|---|---|

| Core Thickness | Increased ball dwell time | Thicker cores provide a softer touch, leading to better control on parries and dinks |

| Material Composition | Enhanced vibration damping and rebound | High-quality carbon and fiberglass composites reduce vibration while ensuring crisp contact |

| Production Process (Cold Press) | Maintains natural material properties | Cold pressing preserves material integrity leading to improved control and enhanced feel |

| Production Process (Hot Press) | High strength but slightly stiffer feel | While excellent for power, it might compromise on the subtle control needed for delicate plays |

| Customization Options | Tailored control for specific needs | Customizable paddle designs allow for precise adjustments in weight balance and grip hardness |

This table should guide procurement managers in understanding which aspect is most important when the primary focus is on control. For example, if the objective is to minimize mishits on delicate shots, emphasizing a thicker core achieved via cold pressing and enhanced material combinations is critical.

In practice, high precision in paddle production is indispensable. At NEX Pickleball, we ensure that every paddle goes through robust quality control testing, verifying factors such as:

- Impact Resistance: Ensuring that the paddle withstands repetitive high-speed impacts without degrading its structural integrity.

- Vibration Dampening: Reducing vibrations to ensure that players feel the ball precisely, leading to better control during play.

- Ergonomic Design: Tailored grips and balanced weight distribution minimize fatigue, allowing players to maintain consistent control throughout extended play sessions.

These quality standards demonstrate our commitment to producing paddles that not only meet but exceed the expectations of sophisticated B2B buyers and competitive players alike.

For procurement managers in the sports equipment industry, the journey to selecting the perfect control-enhanced pickleball paddle involves understanding the interplay between advanced materials and precise manufacturing processes.

Key takeaways include:

- Leveraging cold pressing techniques to preserve material properties for a thicker core and improved ball feel.

- Combining premium materials like 12K Carbon Fiber and E-Glass Fiberglass to balance power and control.

- Utilizing comprehensive quality control systems to ensure each paddle meets high performance and durability standards.

- Considering custom paddle options that allow adjustments to design, weight, and grip, providing a tailored solution for various competitive and retail needs.

By focusing on these elements, you can make a strategic bulk purchasing decision that satisfies your requirements for high-end, control-optimized pickleball paddles. This not only meets the needs of elite players but also ensures your product offerings remain competitive in a demanding market.

We invite you to explore our detailed production insights further and consider how a combination of specialized techniques and materials can elevate your equipment portfolio. Contact NEX Pickleball for additional technical support and expert consultation if you require customized manufacturing solutions tailored to specific performance targets.

-

What pickleball paddles have the most control?

Pickleball paddles offering the most control typically feature a thicker, well-calibrated core achieved through cold pressing and advanced material combinations like 12K Carbon Fiber or a hybrid composite. This configuration increases ball dwell time and minimizes vibration, enabling precision control during soft and strategic play. -

What is the best pickleball paddle for advanced players?

For advanced players, paddles that combine a precise core design with premium materials—often seen in models designed for high performance—are ideal. Such paddles typically have an elongated, ergonomic design and feature advanced composites that balance power and control, meeting the demands of both competitive play and refined shot-making. -

Are thicker pickleball paddles better for control?

Yes, thicker pickleball paddles generally offer better control, as they provide a more “plush” feel. This enhanced cushioning allows the ball to dwell on the paddle face longer, making it easier to perform delicate shots like dinks, drops, and resets, which are critical for maintaining precision during play.

-

composite materials: Click to learn more about the science behind composite materials and how they combine multiple constituents to create high-performance, lightweight solutions crucial for modern manufacturing. ↩

-

cold pressing: Click to explore the cold pressing process—its benefits in preserving intrinsic material properties and its role in achieving superior control in sports equipment. ↩

-

thermoforming: Click to discover how thermoforming techniques enable intricate design control and precise material distribution, enhancing overall product stability and performance. ↩

-

carbon fiber (3K, 12K, and T300 types): Click to read about different carbon fiber types, their manufacturing variations, and their unique performance attributes in high-end composite applications. ↩

-

E-Glass fiberglass: Click to understand E-Glass fiberglass technology, its mechanical properties, and why it is incorporated in advanced composites for better vibration damping and control. ↩