Advanced manufacturing techniques and premium materials are revolutionizing pickleball paddle production by ensuring superior performance, durability, and consistency in quality. Manufacturers like NEX Pickleball leverage processes such as hot pressing, cold pressing1, and thermoforming2, combined with advanced composite materials3 to meet the rigorous demands of competitive play and high-volume production.

In today’s competitive sports equipment industry, maintaining a balance between quality and mass production poses significant challenges. B2B procurement managers and operations directors in the sports equipment sector seek production partners who can not only deliver advanced manufacturing capabilities but also ensure that every paddle meets precise performance standards. The core challenges include material selection, process precision, and consistent quality control. Modern pickleball paddle manufacturers are turning to cutting-edge techniques to address these issues, which is why understanding the manufacturing process becomes crucial in selecting a reliable partner.

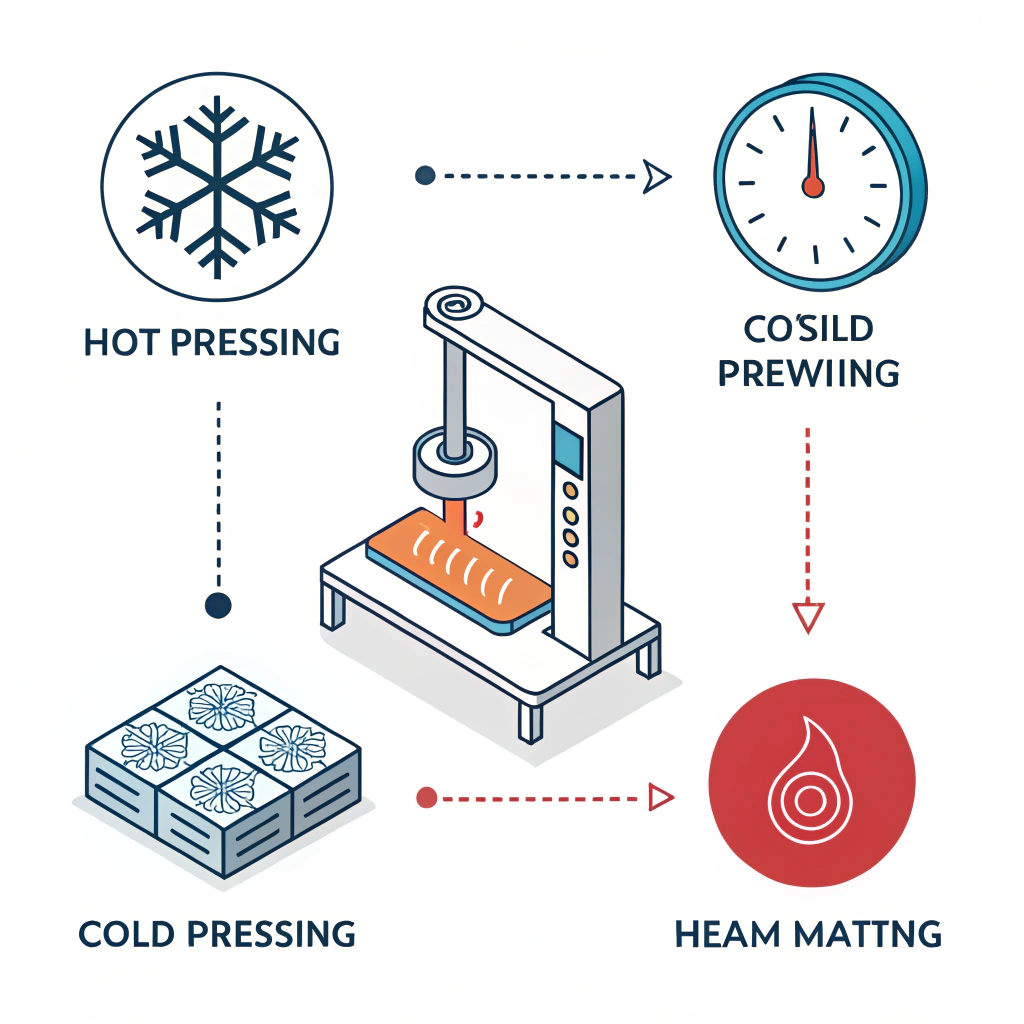

Manufacturing processes such as hot pressing, cold pressing, and thermoforming play an essential role in paddle production. Each process offers unique benefits as well as specific constraints that impact the paddle’s final performance characteristics.

• Hot Pressing:

This technique involves applying heat and high pressure to the paddle materials, resulting in a strong and durable product that can handle high-impact collisions during fast-paced games. However, this process may slightly alter the inherent material properties, affecting the tactile feel of the paddle. Its effectiveness in achieving high production efficiency makes it the go-to method for large-scale manufacturing.

• Cold Pressing:

Cold pressing allows manufacturers to shape materials at room temperature, maintaining the original qualities of the composite. This results in paddles that offer superior control, better ball feel, and consistent thickness. The downside is that production cycles tend to be longer, requiring more precise equipment and quality assurance measures.

• Thermoforming:

Thermoforming utilizes heating the material to form it via molds for complex paddle designs. This process enhances the stability and distribution of materials throughout the paddle, allowing for innovative shapes and superior performance characteristics. While ideal for premium or custom-made paddles, it comes with higher equipment costs and longer production time.

A comprehensive comparison of these processes can be summarized in the table below:

| Manufacturing Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High efficiency • Excellent impact resistance | • May alter material feel • High equipment cost |

| Cold Pressing | • Preserves material integrity • Superior control | • Longer cycle times • Requires precise control |

| Thermoforming | • Supports complex designs • Uniform material distribution | • High cost • Extended production time |

This table provides B2B professionals with a clear view of how each method aligns with performance expectations and production needs, aiding in making informed sourcing decisions.

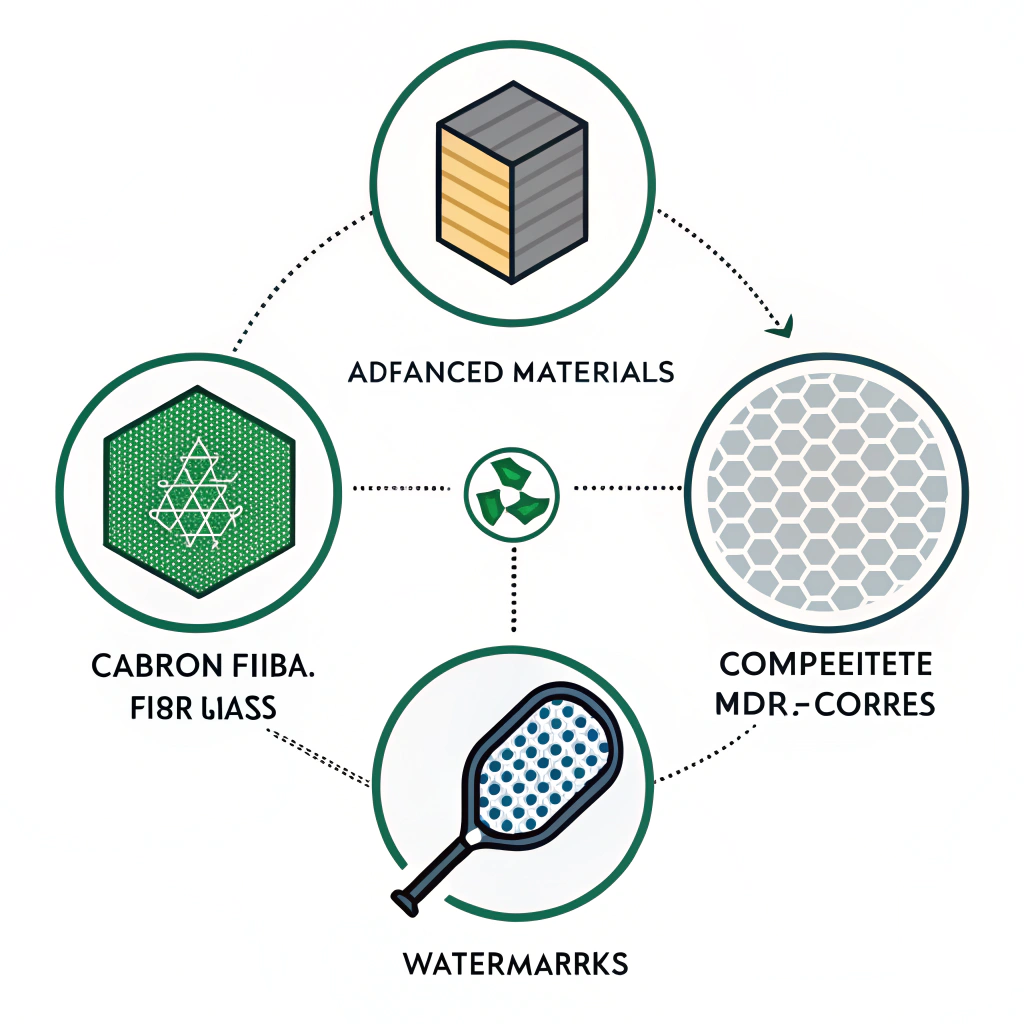

Beyond production processes, the choice of materials is equally critical. High-performance pickleball paddles are crafted from a range of premium polymers and composites, including various types of carbon fiber, fiberglass, and other composite materials. Each material offers unique advantages:

• Carbon Fiber Types:

- 3K Carbon Fiber is prized for its strength and flexibility, making it ideal for paddles with high rebound force requirements.

- 12K Carbon Fiber features a higher thread density, creating a smoother surface with improved hardness and durability suitable for competitive play.

- T300 Carbon Fiber4 is recognized for its exceptional tensile strength, ensuring lightweight paddles that do not compromise on performance.

• Fiberglass:

Fiberglass paddles balance power and control with a wider sweet spot. Its elasticity and tensile strength, particularly with the E-Glass Fiberglass variety, ensure that players enjoy a superior ball feel and precise control over their shots.

• Composite Materials:

Advanced composites, such as a blend of carbon fiber and fiberglass, combine the benefits of both, offering balanced performance attributes like extra power and refined control. Additionally, innovative materials like Bamboo Core Composite and Honeycomb Core Composite provide benefits including lightweight construction, enhanced impact resistance, and superior shock absorption.

• Core Materials:

The internal core significantly influences the paddle’s overall feel and performance.

- Nomex Honeycomb Core5 is celebrated for excellent shock absorption and durability, lending consistency to high-impact play.

- Aluminum Honeycomb Core delivers a balanced weight distribution offering both power and precision.

- Polymer Honeycomb Core is favored by recreational players for its elasticity and reduced vibration, ensuring a comfortable playing experience.

In high-performance paddle manufacturing, the integration of these advanced materials with sophisticated processes results in products that excel in performance, resilience, and ergonomic design.

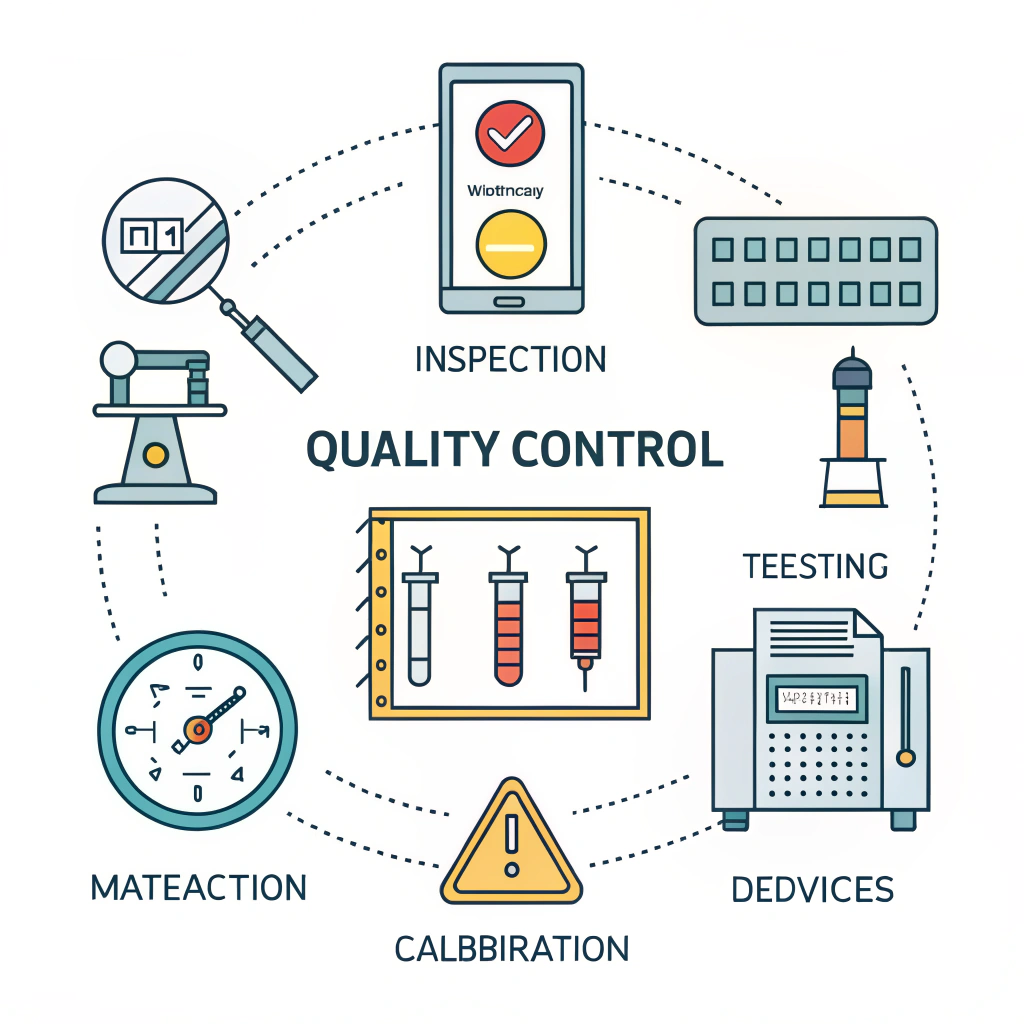

Quality control is a cornerstone of advanced manufacturing in the sports equipment industry. At companies like NEX Pickleball, every paddle is subject to rigorous testing regimes to ensure optimal performance. This comprehensive quality control strategy includes:

- Material Verification: Each component, from carbon fibers to composite cores, is tested for mechanical properties and consistency.

- Process Calibration: Equipment such as hot presses, cold presses, and thermoforming molds are regularly calibrated to maintain precision and uniformity in production.

- Performance Testing: Final paddles undergo impact testing, vibration analysis, and balance assessments to ensure they meet performance standards.

- Customization and Feedback: Clients can order custom paddle designs, with modifications like tailored grip sizes and weight distribution. Continuous feedback from professional players and B2B partners feeds into iterative improvements.

This robust quality assurance process minimizes defects, ensures durability, and boosts user confidence in the product. Such practices are essential for B2B procurement managers who value long-term reliability in equipment.

To further illustrate the practical benefits of these advanced manufacturing techniques, consider a case study: A leading sports retailer approached NEX Pickleball to develop a new line of high-performance paddles. The client was particularly interested in achieving a balance between power and control while ensuring that every paddle provided consistent playability across large production volumes.

Challenge: The retailer had to overcome production variability, ensuring that advanced materials such as T300 carbon fiber and Nomex honeycomb cores delivered consistent performance for competitive play.

Solution: By leveraging a combination of cold pressing and thermoforming techniques, the production team was able to retain the superior material properties while also incorporating complex ergonomic designs. Rigorous quality control measures were instituted at every production phase, ensuring that the paddles not only met but exceeded performance expectations.

Outcome: The resulting paddles featured excellent power, control, and durability, winning critical acclaim in competitive sports events and driving significant order volumes. This collaboration underscored the impact of advanced production technologies on product quality and reinforced the reputation of manufacturers like NEX Pickleball as reliable partners in sports equipment innovation.

In summary, advanced manufacturing processes and the integration of premium materials are at the heart of modern pickleball paddle production. For B2B procurement managers, this means partnering with manufacturers who offer not only high-volume efficiency but also uncompromising performance and quality control. A deep understanding of processes like hot pressing, cold pressing, and thermoforming, combined with expert material selection, enables companies like NEX Pickleball to deliver paddles that are robust, precise, and tailored to the needs of serious players.

Decision-makers looking for long-term strategic sourcing solutions should consider the total value proposition—combining manufacturing expertise, material quality, and rigorous testing protocols—to achieve superior product performance. Moving forward, embracing these advanced production techniques is crucial to staying competitive in the rapidly evolving sports equipment market. Manufacturers are encouraged to invest in research and develop even more precise, sustainable, and innovative production processes to meet future demands.

Adopting best practices in materials and production will not only enhance product performance but also build enduring partnerships within the industry. The insights provided here should serve as a comprehensive guide to understanding the technical and operational considerations behind high-performance pickleball paddle manufacturing.

People Also Ask

Q1: What advanced manufacturing processes are used in pickleball paddle production?

A1: Manufacturers employ techniques such as hot pressing, cold pressing, and thermoforming. Each method contributes to different performance attributes—hot pressing for structural strength and efficiency, cold pressing for precise control and material integrity, and thermoforming for complex, custom designs.

Q2: How do different materials like carbon fiber and fiberglass impact paddle performance?

A2: Carbon fiber types (3K, 12K, T300) bring high strength, reduced vibration, and improved rebound force, while fiberglass offers a wider sweet spot and superior control. The choice of material, along with composite combinations, directly influences paddle weight, durability, and overall playability.

Q3: Why is rigorous quality control important in the manufacturing of high-performance pickleball paddles?

A3: Rigorous quality control ensures that every paddle meets strict performance standards, providing consistency in playability and durability. Regular material tests, equipment calibration, and performance assessments are critical to guarantee that the manufacturing process delivers reliable and high-quality products for competitive use.

-

cold pressing provides insights into a production process that shapes materials at room temperature, preserving their original properties and ensuring superior control and consistency in manufacturing. ↩

-

thermoforming explains the process of heating and molding materials to achieve complex designs, enhancing product performance while balancing production costs and cycle times. ↩

-

advanced composite materials details the use of materials that combine two or more constituents to achieve enhanced strength, durability, and performance in high-demand environments. ↩

-

T300 Carbon Fiber offers an in-depth look at a high-performance material known for its exceptional tensile strength and lightweight properties, vital for competitive sports equipment. ↩

-

Nomex Honeycomb Core discusses the specialized use of Nomex in manufacturing to provide excellent shock absorption, durability, and consistent performance under high-impact conditions. ↩