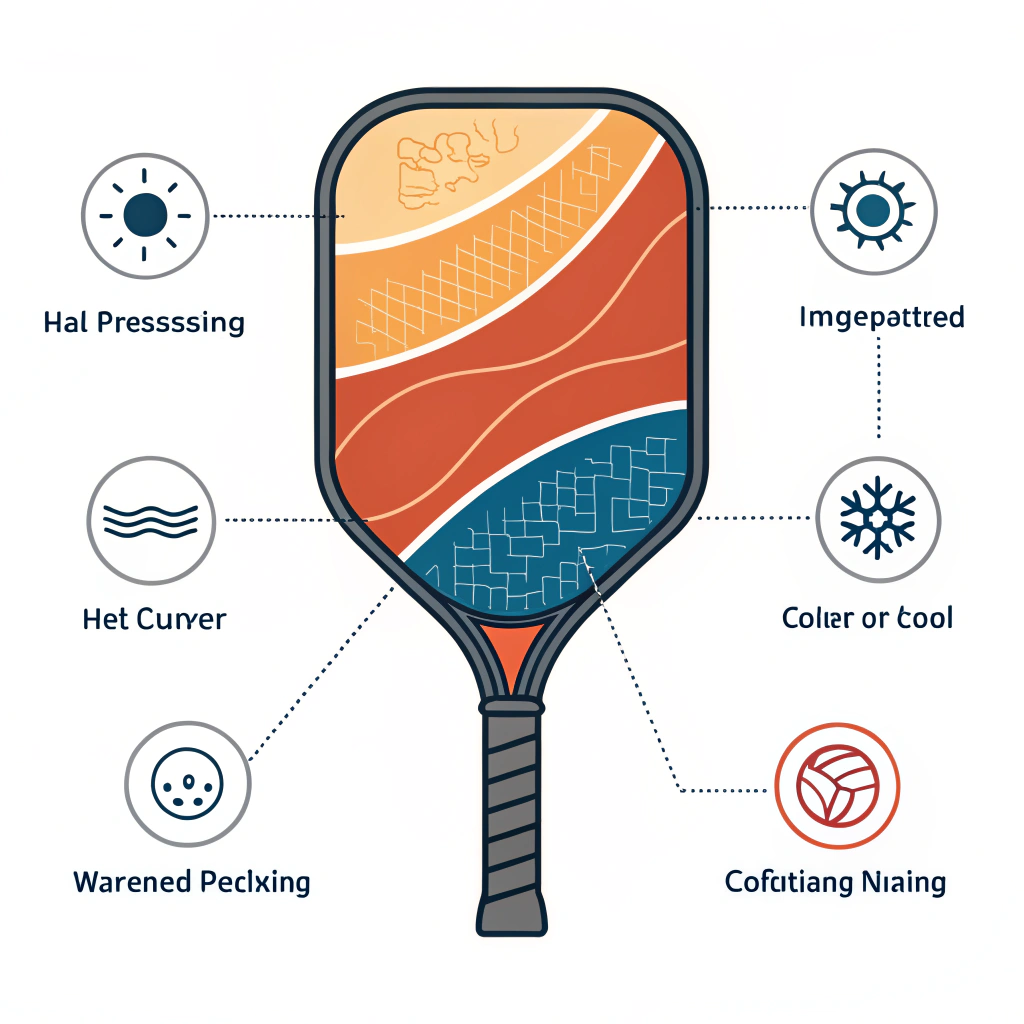

Advanced manufacturing processes—hot pressing1, cold pressing2, and thermoforming3—play a vital role in delivering the right balance of power and control in high-performance pickleball paddles. These processes, paired with advanced material choices like carbon fiber4, fiberglass, and innovative composite cores, are essential for ensuring durability, precision, and consistency in paddle production.

Pickleball paddle production is a complex process involving multiple advanced manufacturing techniques and high-performance materials. For B2B decision makers in sports equipment manufacturing, understanding the engineering behind these paddles is crucial. The selection of materials and production processes determines not only the paddle's performance attributes such as ball control and power transmission but also its durability under rigorous play conditions.

At NEX Pickleball, every paddle is engineered with precision, using high-end materials like carbon fiber variants such as 3K, 12K, and T300, in combination with other materials such as fiberglass and composite cores. Each of these materials influences the final paddle’s weight, balance, and impact resistance, ensuring optimal performance for both recreational and competitive players.

Modern paddle manufacturing must strike a fine balance between production efficiency and delivering a state-of-the-art product. The challenges lie in:

• Achieving consistency in material properties despite variations in production methods.

• Balancing speed of production with high quality and durability.

• Meeting diverse market demands for paddles that offer both power and control simultaneously.

For professionals in production management and quality control, these challenges are not only technical but strategic. In an environment where rapid production cycles and high performance cannot be compromised, evaluating the trade-offs between different manufacturing processes is essential.

The performance of a paddle is highly dependent on how the selected manufacturing process interacts with the chosen materials. The need for reliable process control becomes even more critical when working with advanced materials that have very specific performance attributes.

A detailed evaluation of the three primary manufacturing techniques reveals distinct advantages and challenges associated with each.

Hot pressing involves applying heat and pressure simultaneously to form a secure bonding between layers. This method is widely used for high-volume production due to its efficiency and ability to produce paddles with strong impact resistance.

Key Advantages:

- High production efficiency and consistency.

- Strong bonding of materials, which leads to excellent impact resistance.

- Reliable structural integrity under high-performance conditions.

Disadvantages:

- The combination of heat and pressure can slightly alter the intrinsic properties of some materials.

- High initial capital investment for heating and pressing equipment.

- Less flexibility in adjusting thickness variations compared to other methods.

Cold pressing uses mechanical pressure at room temperature to shape the paddle, allowing for more precise control over dimensions and thickness. This process maintains the natural properties of the materials, preserving their intended performance attributes.

Key Advantages:

- Superior precision in achieving exact thickness and material alignment.

- Preservation of material properties, leading to better ball feel and responsiveness.

- Ideal for custom designs where minute differences in material behavior are critical.

Disadvantages:

- Generally slower production cycles, which can increase lead times.

- Requires high-quality mechanical equipment for precise pressure application.

- May not be suitable for high-volume production without significant process improvements.

Thermoforming involves heating a material to its softening point before shaping it into the desired form using molds, making it especially suitable for complex or custom paddle designs. This method enables the creation of paddles with intricate internal structures and precise weight distribution.

Key Advantages:

- Ability to produce paddles with complex, non-uniform shapes.

- Enhanced control over material distribution, which can improve paddle stability and performance.

- Suitable for producing premium, custom-made paddles.

Disadvantages:

- Longer production times compared to hot pressing.

- Requires high start-up costs due to specialized molds and thermoforming equipment.

- Best suited for niche markets rather than mass production.

| Manufacturing Process | Production Efficiency | Precision Control | Material Impact Preservation | Best Suited For |

|---|---|---|---|---|

| Hot Pressing | High | Moderate | Slight alteration possible | High-volume production, impact resistance |

| Cold Pressing | Moderate/Low | High | Excellent preservation | Custom designs, detailed dimensional control |

| Thermoforming | Moderate | High | Requires careful process control | Complex shape designs, premium products |

Material selection is crucial in paddle design. Each type of material brings unique properties:

- 3K Carbon Fiber: Provides flexibility and high rebound force, reducing paddle vibration.

- 12K Carbon Fiber: Known for its higher thread density, offering a smoother surface and increased impact resistance.

- T300 Carbon Fiber: Balances tensile strength with lightweight properties for optimal performance.

The choice of carbon fiber directly influences how energy is transferred from the paddle to the ball, affecting both power and control in gameplay.

- E-Glass Fiberglass: Delivers excellent elasticity and tensile strength, producing a wider sweet spot and improving ball control.

Fiberglass paddles are often preferred when a softer touch and enhanced control are needed, making them popular among players looking for precision in placement rather than power.

Combining materials often leads to enhanced performance:

- Carbon Fiber and Fiberglass Composite: This blend capitalizes on the strengths of both materials, delivering a well-rounded performance with a mix of power and control.

- Bamboo Core Composites: Known for their lightweight properties and impact resistance, they provide a unique hitting feel.

-

- Honeycomb Cores5: Excellent for shock absorption and vibration reduction, available in Nomex, aluminum, and polymer variants.

| Core Material | Key Attributes | Ideal For |

|---|---|---|

| Nomex Honeycomb | High shock absorption and durability | Long-lasting performance and stability |

| Aluminum Honeycomb | Balanced weight and stiffness | Offering a mix of power and precise control |

| Polymer Honeycomb | Enhanced elasticity, reduced vibration | Providing a softer, more comfortable play feel |

The combination of these materials with advanced manufacturing processes is what sets the foundation for the superior performance of NEX Pickleball paddles.

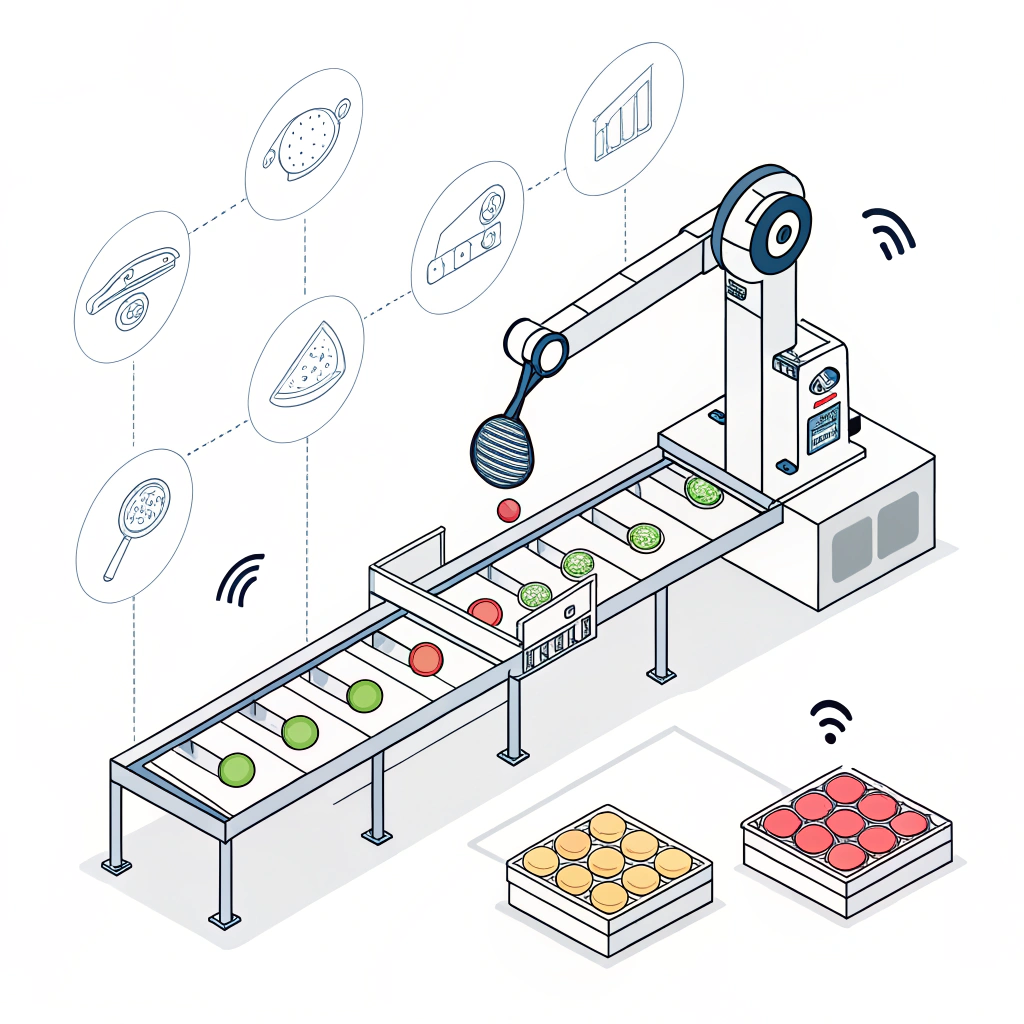

Ensuring product quality is paramount. At NEX Pickleball, rigorous testing and quality control measures are in place:

- Consistent Batch Testing: Each paddle undergoes laboratory testing to ensure properties like impact resistance, vibration damping, and durability meet high standards.

- Customized Ergonomics: An ergonomic grip design is integrated to maximize comfort and reduce the risk of fatigue during prolonged play.

- Precision Weight Distribution: Achieved using a combination of advanced production techniques and material science, ensuring every paddle performs predictably.

This rigorous quality control ensures a consistent playing experience, whether using paddles produced via hot pressing, cold pressing, or thermoforming. A series of internal data comparisons have shown that minor adjustments in production parameters can lead to significant improvements in overall performance metrics. This level of detail is crucial for B2B partners seeking reliable and high-performance products.

The practical implementation of these manufacturing processes can be exemplified through our own experience at NEX Pickleball. As the original contract manufacturer for elite brands such as Joola and Selkirk, we have continuously honed our production methods. Key insights include:

-

Process Flexibility:

By adapting production techniques according to the paddle model and material combinations, we optimize both performance and production speed. For example, using thermoforming for custom high-end models allows us to meet specialized demands while maintaining a high quality standard. -

Technological Integration:

Advanced sensor technology and automated pressure control systems in our cold pressing lines ensure precise control over paddle dimensions, leading to paddles that offer exceptional responsiveness and consistent performance. -

Data-Driven Quality Assurance:

Integrating real-time testing data into the production cycle not only helps in immediate quality corrections but also feeds back into process improvement, significantly reducing batch variability and production defects. -

Customer-Centric Innovations:

We often work directly with sports organizations to develop paddles tailored to specific playing styles or branding requirements. This collaboration leads to continuous innovations in both design and production methodologies.

The iterative learning process in our production lines, supported by detailed analysis and customer feedback, underscores the importance of advanced manufacturing techniques. By carefully choosing between hot pressing, cold pressing, and thermoforming based on performance requirements and production volumes, manufacturers can achieve a balance between cost-effectiveness and product excellence.

For production managers, R&D engineers, and quality control professionals evaluating paddle manufacturing methods, consider the following best practices:

• Align material selection with the intended paddle performance. For high-impact play, 12K carbon fiber combined with a Nomex honeycomb core offers superior durability and power.

• Choose a production method that supports your volume needs. High-volume demands might be best served by hot pressing, while niche, high-performance products benefit from cold pressing or thermoforming.

• Integrate real-time quality testing into your production line. Leverage automated systems to maintain consistency and quickly adapt to any deviations in product specifications.

• Collaborate with manufacturing partners experienced in state-of-the-art techniques. Our process at NEX Pickleball, which combines modern production methods with rigorous quality control, illustrates how strategic partnerships can boost both innovation and market competitiveness.

- Evaluate the trade-offs between processes by running pilot productions—capturing data on performance, efficiency, and defect rates.

- Invest in automation and sensor-based quality control to minimize manual errors and standardize production metrics.

- Continuously update design parameters based on feedback from professional players and field testing to ensure that the product remains competitive in a fast-paced market.

By following these guidelines, B2B partners can not only optimize production efficiency but also enhance the end-user experience, ultimately reducing costs while boosting overall performance.

Q1: How does hot pressing enhance paddle durability?

A1: Hot pressing applies heat and pressure simultaneously, ensuring strong bonding between layers and resulting in paddles with excellent impact resistance and long-lasting structural integrity.

Q2: What are the main benefits of using composite materials in pickleball paddles?

A2: Composite materials, such as those combining carbon fiber with fiberglass or incorporating honeycomb cores, offer a balanced mix of power, control, and shock absorption, resulting in paddles that are both durable and highly responsive.

Q3: How do different production processes affect the balance between power and control in paddle performance?

A3: Each production process—hot pressing for strong, high-volume builds; cold pressing for precise dimensional control and optimal ball feel; and thermoforming for complex, customized designs—directly influences how well a paddle can deliver power and maintain control during play.

-

hot pressing: Click to explore how applying simultaneous heat and pressure creates strong bonds between materials, enhancing production efficiency and structural integrity in high-performance manufacturing. ↩

-

cold pressing: Click to learn about the mechanics of using room-temperature pressure to preserve material properties and achieve precise dimensional control in manufacturing processes. ↩

-

thermoforming: Click to discover how thermoforming leverages heat to shape materials into complex geometries, enabling custom designs and premium product features. ↩

-

carbon fiber: Click to understand the unique properties of carbon fiber, including its lightweight strength and flexibility, which are vital for optimizing sports performance equipment. ↩

-

honeycomb cores: Click to delve into honeycomb core technology, which offers superior shock absorption and vibration reduction for enhanced balance and durability in sports equipment. ↩