NEX Pickleball’s advanced production techniques combine cutting-edge materials with proven processes—hot pressing, cold pressing, and thermoforming—to deliver pickleball paddles that excel in performance, durability, and customization.

In today’s competitive sporting goods market, selecting high-performance pickleball paddles is key to meeting customer expectations and outperforming the competition. As a leading OEM manufacturer1, NEX Pickleball leverages advanced production techniques and premium materials—from various types of carbon fiber2 and fiberglass to innovative composite cores—to craft paddles that offer superior strength, control, and longevity. This article outlines the challenges facing procurement managers, examines the underlying causes of performance variance among paddles, and presents a clear list of production process benefits and challenges. We also provide key insights on materials, quality control, and customization options, giving you the actionable knowledge needed for making informed sourcing decisions.

When evaluating pickleball paddles for bulk purchasing, one of the most common concerns is achieving the right balance between advanced materials, manufacturing precision, and cost efficiency. Some paddles fail to deliver expected levels of power or control because of inadequate material choices or suboptimal production processes. The main challenges include:

• Ensuring consistency in high-performance composite materials3

• Achieving precise weight distribution and ergonomic design

• Balancing production efficiency with quality assurance

• Customizing paddle designs to meet specific client needs without compromising durability

Addressing these challenges requires a deep understanding of both the raw materials and the various manufacturing techniques available today.

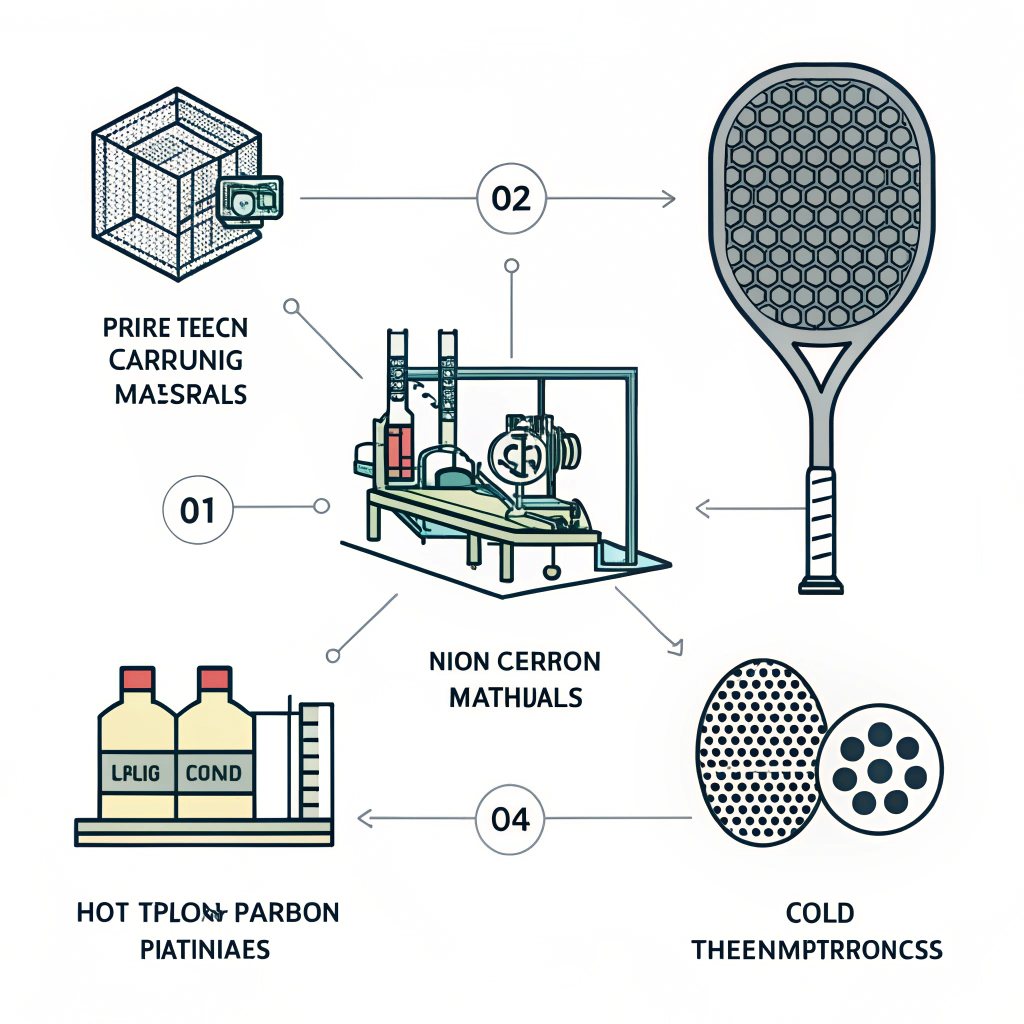

At NEX Pickleball, we use a variety of premium materials that decisively impact paddle performance:

-

Carbon Fiber Variants

- 3K Carbon Fiber offers high strength and flexibility, perfect for paddles requiring high rebound forces.

- 12K Carbon Fiber boasts a higher thread density for smoother surfaces and improved hardness, suitable for competitive play.

- T300 Carbon Fiber ensures an optimal balance between strength and lightweight design.

-

Fiberglass Options

- E-Glass Fiberglass is prized for its elasticity and tensile strength, which enhances power and control, while offering a wider sweet spot.

-

Composite Materials

- Carbon Fiber and Fiberglass Composite: Combining both materials, this composite achieves an optimal balance of power, durability, and control.

- Bamboo Core Composite: Provides lightness and high impact resistance, delivering a distinct and clear hitting feel.

- Honeycomb Core: Known for excellent shock absorption, it reduces vibration and improves paddle longevity.

-

Core Technologies

- Nomex Honeycomb Core delivers unmatched shock absorption and stability.

- Aluminum Honeycomb Core balances weight with power and precision.

- Polymer Honeycomb Core minimizes vibration while offering a comfortable hitting experience.

Different manufacturing techniques are pivotal in defining paddle performance:

-

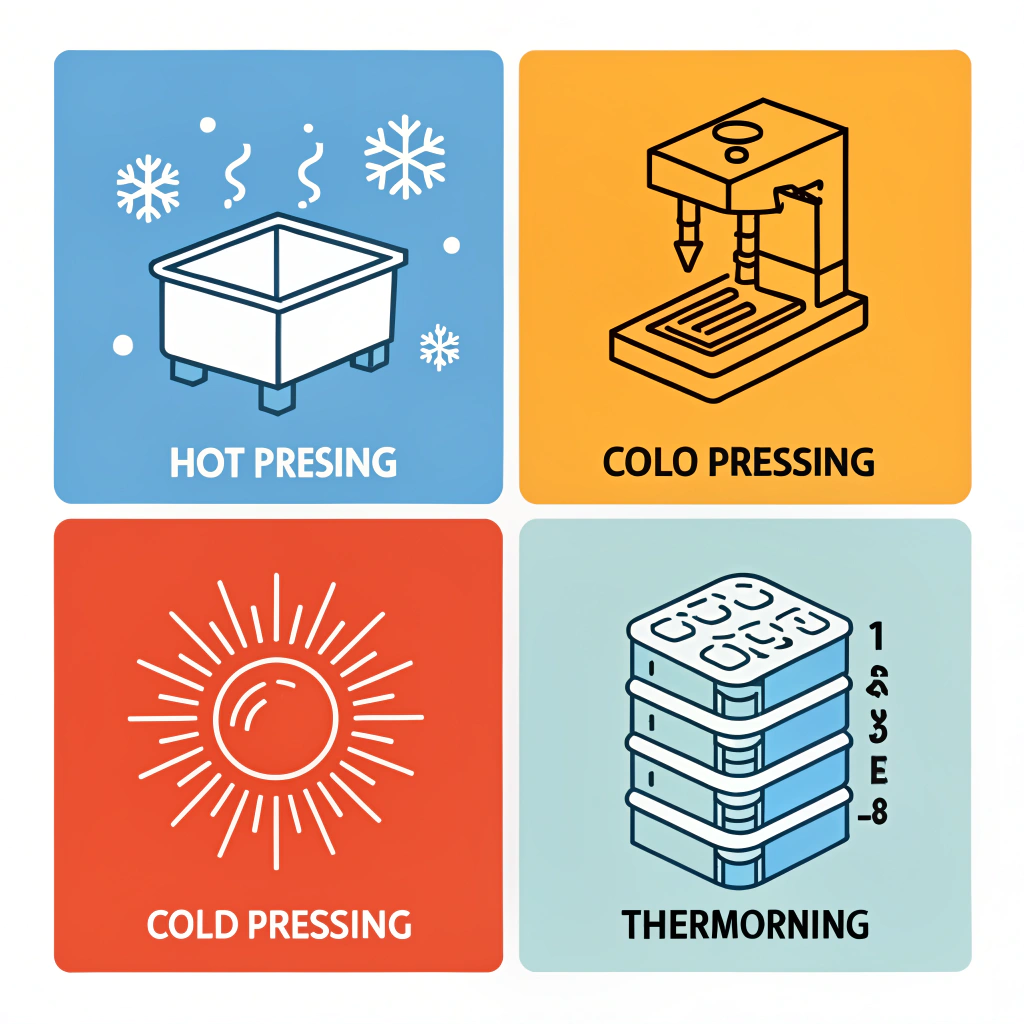

Hot Pressing

- Involves heating and applying pressure to the paddle materials.

- Advantages include high efficiency, robust impact resistance, and strong structural integrity, making it ideal for large-scale production.

- Disadvantages include potential alterations of material properties that may affect the paddle’s feel and the high investment needed for equipment.

-

Cold Pressing

- Shapes the paddle material without high temperatures to maintain material integrity.

- Advantages are enhanced control over paddle thickness, preservation of material properties, and excellent responsiveness.

- Disadvantages include longer production cycles and stringent requirements for pressure control, often requiring high-end equipment.

-

- Softens the material at a controlled heating point before forming it into shape using precise molds.

- Advantages include the ability to produce paddles with intricate designs and stable material distribution, which is critical for premium, custom paddle production.

- Disadvantages lie in the longer production turnaround and increased equipment costs.

Each of these processes has its own set of pros and cons, and the selection depends on the specific performance needs and market positioning of the final product.

To help you make informed decisions, here is a table summarizing the key differences between the three primary production processes:

| Production Process | Key Advantages | Limitations | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency, durable paddles, strong impact resistance | Potential alteration of material properties, high equipment cost | Large-scale, high-strength paddles |

| Cold Pressing | Superior control, maintains material integrity, excellent ball feel | Longer production cycle, precise equipment needed | Paddles requiring precise design and control |

| Thermoforming | Intricate designs, stable material distribution, customizable | Longer production time, higher production costs | Premium products and custom-made paddles |

This comparative analysis helps determine which process aligns best with your performance and cost efficiency goals, ensuring that your product lineup meets the evolving demands of advanced players and recreational enthusiasts alike.

NEX Pickleball’s commitment to quality control5 is evident in every stage of production. Each paddle undergoes rigorous testing to ensure that characteristics like weight distribution, grip ergonomics, and surface texture meet the highest standards. This commitment to quality is essential for maintaining a competitive edge in the marketplace.

• Material Testing: Every batch of carbon fiber, fiberglass, and composite is tested for tensile strength, elasticity, and durability before assembly.

• Precision Manufacturing: Advanced machinery ensures that every paddle fulfills design specifications, from core material distribution to surface treatment for improved grip and spin.

• Performance Trials: Each product series is subjected to real-world performance trials that simulate the high-impact conditions of competitive pickleball play.

These measures not only enhance the on-court performance of paddles but also build confidence among procurement managers who need reliable, long-lasting sporting goods for their clients.

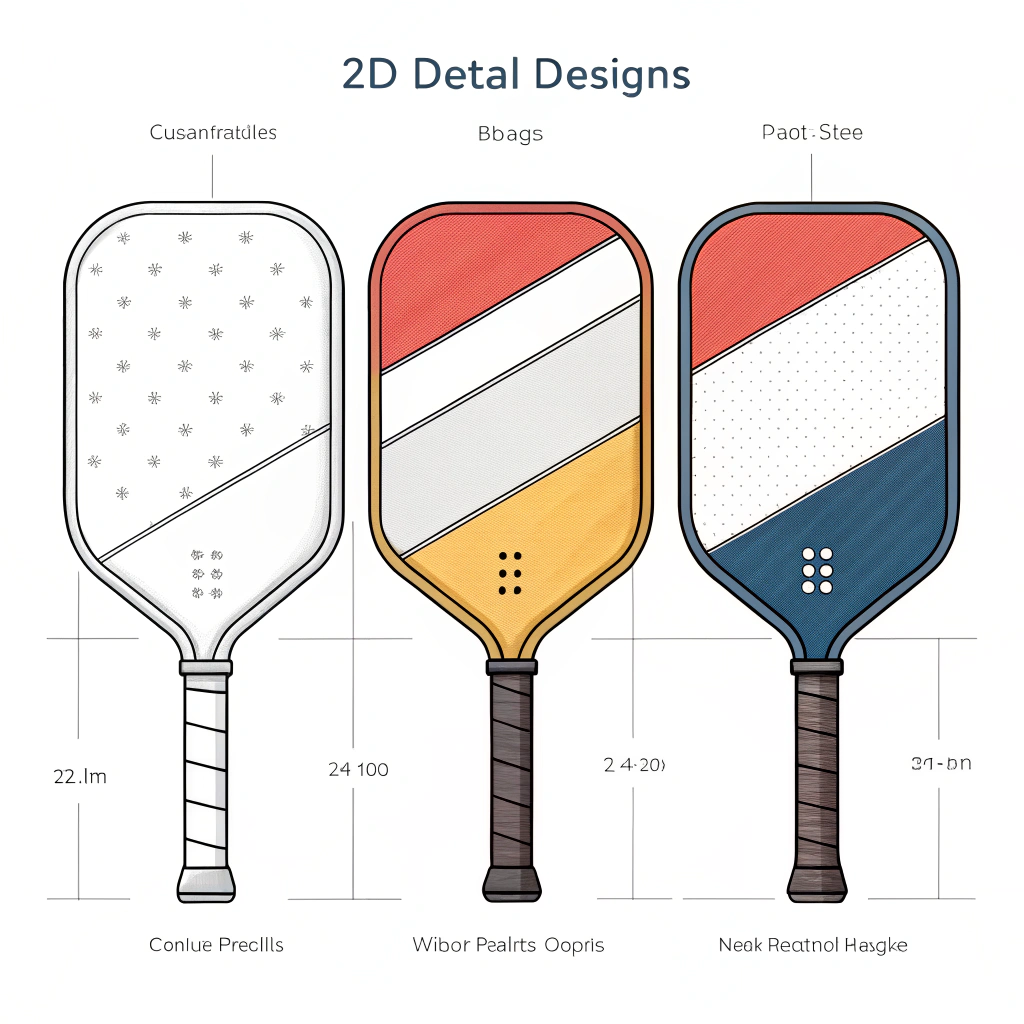

Customization is at the heart of B2B sourcing decisions. NEX Pickleball offers a range of custom paddle options to meet diverse market needs:

- Design Flexibility: Clients can choose from a variety of materials, core types, and surface finishes to meet specific performance requirements.

- Ergonomic Adaptation: Multiple grip sizes ensure that paddles can be tailored to different player profiles, enhancing comfort and reducing the risk of injury during prolonged play.

- Branding Opportunities: Custom prints and color schemes allow retail clients and sports organizations to incorporate their brand identity into every paddle.

These customizable features mean that whether you are a distributor, a retailer, or a team manager, you can acquire paddles that fit perfectly with your market’s demands.

When selecting a manufacturer or supplier, several strategic insights can guide your decision-making process:

-

Production Efficiency vs. Customization:

- High-volume orders may favor hot pressing for its efficiency, whereas niche markets and premium segments might demand the customization capabilities offered by thermoforming.

-

Material Cost vs. Performance Benefits:

- Although high-end materials like 12K and T300 carbon fiber increase initial costs, the performance benefits in terms of durability, control, and power can provide long-term value for competitive markets.

-

Quality Assurance:

- A robust quality control process minimizes defects and inconsistency, which is crucial for maintaining your brand reputation with end customers.

-

Market Differentiation:

- Distinguishing your product offering through advanced manufacturing techniques and exclusive material combinations can create a competitive advantage that is hard to replicate.

By balancing these strategic insights, procurement managers and product development specialists can optimize their sourcing decisions, ensuring that the selected paddles not only meet high-performance standards but also align with broader market trends and customer expectations.

In conclusion, advanced production methods at NEX Pickleball—characterized by methods such as hot pressing, cold pressing, and thermoforming—are essential to producing high-performance pickleball paddles. Our use of premium materials, coupled with rigorous quality control and customization options, provides a compelling case for choosing our paddles as the core offering in your sporting goods portfolio.

For procurement managers seeking to source top-tier equipment, the following actionable steps are recommended:

- Evaluate the specific needs of your market segment and the performance characteristics required by your customers.

- Match production processes with product demands: choose hot pressing for scale, cold pressing for precision, and thermoforming for premium customization.

- Leverage quality control records and real-world performance data to ensure reliability and durability.

- Consider customization features to enhance product differentiation and brand loyalty among end-users.

By following these steps, you'll be better positioned to secure a supplier that not only meets high-quality standards but also offers innovative manufacturing solutions tailored to your business needs.

• Do more expensive pickleball paddles make a difference?

It is true that higher-end paddles often incorporate advanced materials such as carbon fiber, raw carbon, and fiberglass, which can enhance control, power, and spin. However, while these advanced materials offer performance benefits, they are not the sole determinant of success on the court; lower-priced paddles can also perform well if designed and manufactured effectively.

• What is considered an advanced pickleball player?

An advanced pickleball player is generally rated in the range of 4.0 to 5.5+ and is characterized by consistent shot execution, strategic play, and excellent on-court athleticism. These players require equipment that offers enhanced control, power, and precision to match their higher skill level.

• What are the better pickleball paddles?

Better pickleball paddles are those designed with a balance of premium materials, advanced production techniques, and superior quality control. Key features include the use of advanced carbon fiber, well-engineered cores, ergonomic grips, and precise manufacturing processes that optimize power, control, and durability.

-

OEM manufacturer: Reading this article will provide detailed insights into original equipment manufacturing processes, including scale production, quality standards, and customization strategies that differentiate market leaders. ↩ ↩

-

carbon fiber: Reading this article will provide insights into the properties of carbon fiber, including its lightweight strength and role in enhancing performance in high-end sporting equipment. ↩ ↩

-

Composite Materials: Reading this article will elaborate on how combining different materials results in products that balance strength, durability, and performance, essential for innovative product design. ↩ ↩

-

Thermoforming: Reading this article will help you understand how controlled heating and molding are applied to shape materials into complex, high-quality products, offering vital benefits in custom manufacturing. ↩ ↩

-

quality control: Reading this article will explain the rigorous testing processes and quality assurance measures that ensure consistent manufacturing standards and reliable product performance. ↩ ↩