In this article, we quickly answer the evolution of pickleball paddle manufacturing: starting from the traditional wooden paddles to advanced carbon fiber1 and composite2 designs, manufacturers have continuously improved paddle performance through innovative production techniques such as hot pressing3, cold pressing4, and thermoforming5. Today’s paddles offer superior power, control, and durability—a testament to decades of engineering evolution and quality control advancements.

Drawing inspiration from industries such as aerospace and automotive, where precision, quality, and innovation are driving forces, the sports equipment sector has embraced similar methodologies. These external industries have successfully integrated advanced materials and production processes over time, and the pickleball equipment market is no exception. This article bridges those external industrial experiences with the internal evolution of pickleball paddle manufacturing, highlighting historical milestones, production techniques, and quality control measures that have shaped our manufacturing journey.

The earliest pickleball paddles were crafted primarily from wood. During the Wood Era, manufacturers faced significant limitations:

- Paddles were heavy and stiff.

- They possessed minimal technological enhancements.

- Lack of standardized quality control methods led to inconsistent performance across products.

This era laid the foundation for stringently testing methods later adopted by modern manufacturers. Companies, facing high levels of variability and limited design flexibility, recognized that innovation was necessary to meet the demands of competitive play.

As pickleball grew in popularity, the demand for better performance drove the first innovation leap: the introduction of basic honeycomb paddles. Key characteristics of this phase included:

- Adoption of polymer honeycomb cores to reduce weight while improving strength.

- Improved ball control and durability through a more consistent core structure.

- Introduction to cost-effective production methods that began to move away from traditional handcrafted methods.

This innovation marked a paradigm shift in manufacturing, as it allowed suppliers to reduce weight and enhance overall paddle performance. Manufacturers began exploring newer techniques and materials, setting the stage for more sophisticated production methods.

Building on the earlier innovation, the next generation of pickleball paddles embraced thermoforming. This process allowed manufacturers to mold paddles with complex shapes and thicknesses while adding foam edge walls and unibody carbon fiber designs. The significant advantages included:

- Enhanced ball control and rebound force.

- Increased durability and impact resistance.

- A greater range of design flexibility, which allowed customization in terms of weight distribution and grip ergonomics.

These advancements not only improved the competitive performance on the court but also showed the industry's commitment to quality and consistency. The adoption of thermoforming paralleled trends in other high-performance manufacturing sectors, further cementing its place in modern production methods.

The incorporation of advanced materials has allowed modern pickleball paddles to reach unprecedented performance levels. Below is an overview of the advanced materials and the corresponding production methods deployed:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Offers excellent strength and flexibility, ideal for paddles requiring a high rebound force.

- 12K Carbon Fiber: Features higher thread density for a smoother surface and greater hardness, suitable for competitive play that demands extreme strength and impact resistance.

- T300 Carbon Fiber: Known for its outstanding tensile strength, providing a balance between strength and lightweight design.

-

Fiberglass:

- E-Glass Fiberglass is used to deliver enhanced ball control and a wider sweet spot due to its flexibility and elasticity.

-

Composite Materials:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both, offering an efficient blend of strength, lightness, and flexibility.

- Bamboo Core Composite: Known for its lightweight and high impact-resistance properties, ensuring durability and a clear hitting feel.

- Honeycomb Core: Incorporates high-density polymers to provide superior shock absorption.

-

Core Materials:

- Nomex Honeycomb Core: Provides excellent shock absorption and stability, which is crucial for high-performance paddles.

- Aluminum Honeycomb Core: Balances weight and strength, catering to players who require both power and control.

- Polymer Honeycomb Core: Offers enhanced elasticity, resulting in reduced vibration and a more comfortable playing experience.

Modern pickleball paddle manufacturing uses three main production processes, each offering distinct advantages. Below is a quick comparison table summarizing these processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency • Strong impact resistance • Excellent structural integrity | • May alter material properties • High equipment investment costs |

| Cold Pressing | • Greater precision in thickness and structure • Keeps material properties intact • Enhanced ball feel | • Longer production cycles • Requires precise pressure control |

| Thermoforming | • Enables intricate designs and precise material distribution • Maintains paddle stability • Suitable for premium, customized products | • Longer production time • Higher equipment costs |

Each of these methods is chosen based on the design requirements, material characteristics, and target market needs. As manufacturing partners, our strategic approach ensures that whether it is hot pressing for robust impact resistance or cold pressing for precise ball control, every paddle meets stringent quality standards.

At the core of our manufacturing philosophy is an uncompromising commitment to quality control. Every paddle undergoes rigorous testing to ensure it meets both performance and durability standards. Our holistic approach focuses on:

- Material Integrity: Using advanced materials such as T300 carbon fiber and high-density polymers ensures each paddle maintains its desired properties over time.

- Production Consistency: Specialized techniques like hot pressing and thermoforming allow us to produce paddles with consistent shape, weight distribution, and surface finish.

- Ergonomic Design: Each paddle’s design considers human factors, such as optimal grip size and balance. This ergonomic focus not only enhances performance but also minimizes player fatigue during extended play.

The evolution from manual craftsmanship to fully automated, precision-based production has improved product consistency and allowed for innovative design tweaks. Our clients can demand custom paddle options where specific design elements—including weight, balance, and grip size—are optimized for individual player needs.

Modern manufacturing has seen tremendous changes, largely driven by technological advancements and a growing demand for high-quality sports equipment. For instance, industries such as aerospace have long benefited from advancements in manufacturing automation and material science. These trends have cascaded into the sports equipment sector, prompting innovations that are applicable to high-performance pickleball paddles.

Our approach at NEX Pickleball seamlessly integrates advanced production techniques with the benefits of modern materials. This results in paddles that are not only designed for performance enhancement but also engineered for long-term durability. Our continuous investment in research and development is a definitive factor in ensuring that our products remain at the forefront of technological advancements.

In today’s competitive market, partnering with a reliable and technologically advanced manufacturer is crucial. Businesses seeking a stable supply chain and consistent quality will find that our manufacturing evolution speaks to decades of accumulated expertise.

Key recommendations for procurement managers include:

- Evaluate the manufacturing history of potential OEM partners.

- Consider the production processes and quality control measures a manufacturer employs.

- Look for technical details, such as the use of advanced materials and precision production methods, that support long-term performance.

By choosing a partner that prioritizes innovation and quality, sports equipment businesses can enhance their competitive edge. Our evolution from the wood era to the modern, high-performance paddle generation reflects our steadfast commitment to improving every element of paddle production. It is this commitment that ensures our paddles deliver superior performance—both on the court and in the marketplace.

-

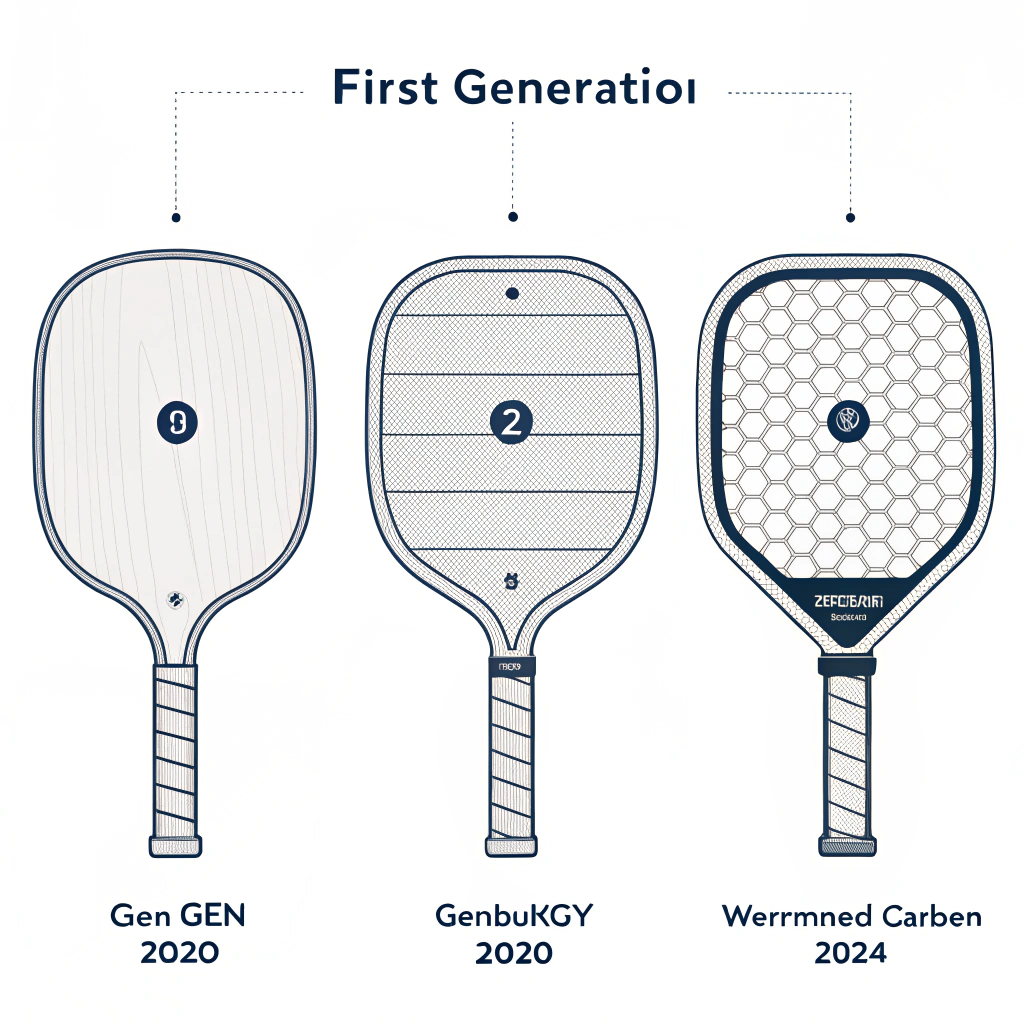

What is the evolution of pickleball paddles?

The evolution of pickleball paddles began with heavy, wooden paddles known as Gen 0. As the sport grew, Gen 1 introduced basic honeycomb cores made of polymer materials, followed by Gen 2 where thermoforming techniques allowed for foam edge walls and integrated carbon fiber designs, significantly enhancing performance and durability. -

What is the average lifespan of a pickleball paddle?

The average lifespan of a pickleball paddle varies by usage: casual players may experience 1 to 3 years of use, while those who play frequently might need a replacement every 6 months to a year. Performance wear and material fatigue are key factors affecting a paddle’s longevity. -

How do you know when it's time for a new pickleball paddle?

Indicators for replacing a paddle include excessive wear or damage to the paddle’s face. When performance issues such as reduced control, diminished rebound force, or noticeable damage occur, these signs suggest it may be time to invest in a new paddle.

-

carbon fiber: Reading this link will provide insights into carbon fiber materials, their properties, manufacturing processes, and applications in high-performance products. ↩ ↩

-

composite: Reading this link will explain composite materials, including their construction, benefits, and usage in advanced manufacturing technologies. ↩ ↩

-

hot pressing: Reading this link explains the hot pressing process, detailing how elevated temperatures and pressure enhance material integrity and product performance. ↩ ↩

-

cold pressing: Reading this link describes the cold pressing process, focusing on its precision benefits and how it preserves material properties for superior product quality. ↩ ↩

-

thermoforming: Reading this link offers an overview of the thermoforming process, its advantages, and its role in shaping high-precision, customized products. ↩ ↩