Thermoformed pickleball paddles offer a one-piece construction that ensures exceptional power, durability, and consistent performance. This guide explains how thermoformed1 works, compares it with other production methods, and provides practical insights for manufacturing professionals looking to optimize their paddle production.

In today’s competitive sporting goods sector, production techniques are a critical factor in determining product performance and manufacturing efficiency. For manufacturers of pickleball paddles, production processes such as hot pressing, cold pressing, and thermoforming have unique benefits and challenges. Factory managers, production engineers, and R&D professionals must understand these methods to select the process that best meets both performance standards and production scale requirements.

Many modern manufacturing operations are shifting towards advanced technology processes to address quality standards and market demands. Thermoforming, in particular, is gaining momentum due to its ability to produce paddles with a seamless, one-piece structure. This process not only offers improved material distribution but also enhances the paddle’s durability and playing performance.

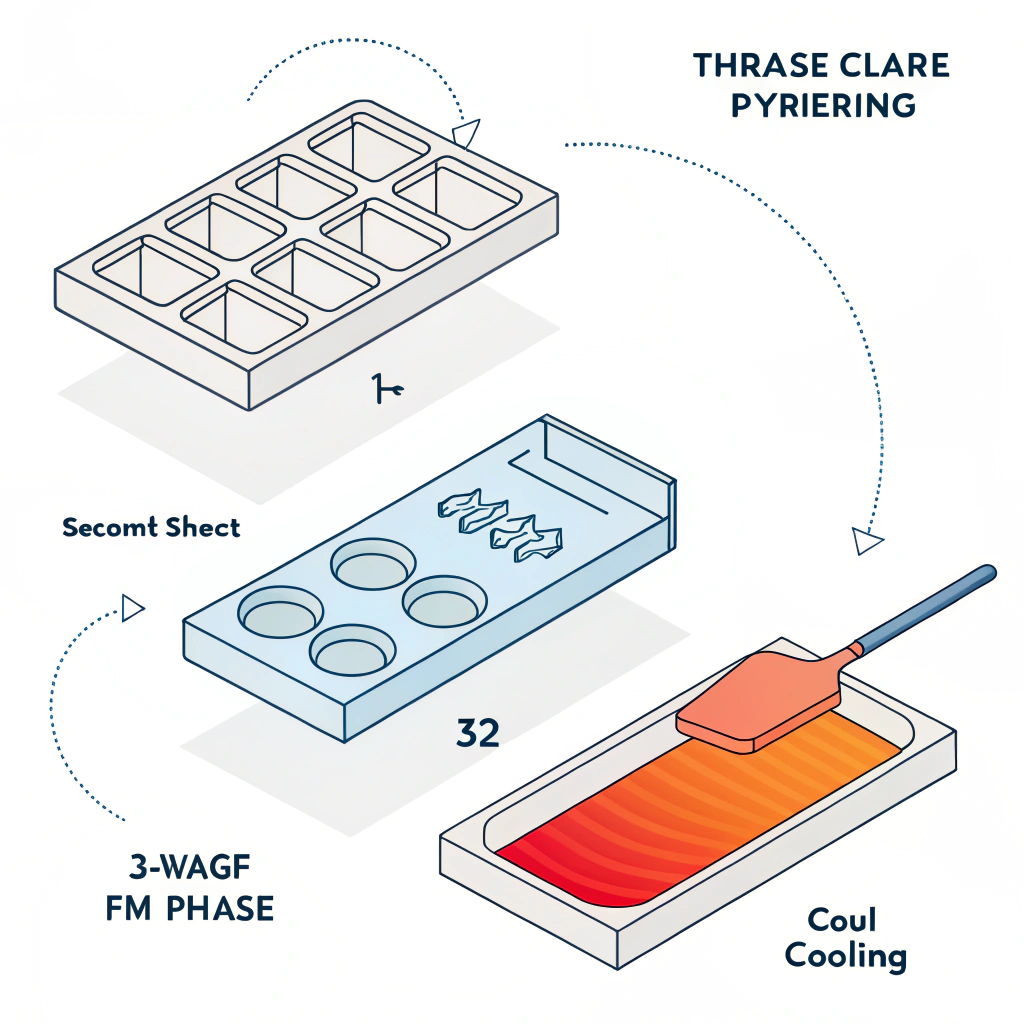

Thermoforming is a manufacturing technique where a polymer sheet is heated to a pliable temperature, formed into the desired paddle shape using molds, and then cooled down to retain that shape. The process results in paddles that combine lightweight properties with high impact resistance. Key production phases in thermoforming include:

• Heating: The polymer sheet is uniformly heated until it reaches a flexible state.

• Molding: The softened sheet is then pressed into a mold that defines the paddle’s final shape and structural features.

• Cooling: The paddle is cooled rapidly to lock in the design details and maintain material integrity.

This method is highly valued in OEM manufacturing2 environments because it supports complex designs and customizations without compromising overall performance.

When deciding between production techniques, comparing thermoforming with alternatives such as hot pressing and cold pressing is crucial. The table below outlines the key differences in terms of production efficiency, material impact, and quality outcomes.

| Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High production efficiency; excellent impact resistance | May alter material properties; high equipment investment | Large-scale production and high-strength paddles |

| Cold Pressing | Precise control over material thickness; better ball feel | Longer production cycles; requires highly specialized equipment | Designs needing extreme precision and control |

| Thermoforming | Complex shape capabilities; uniform material distribution; improved durability | Longer production time; higher equipment and mold costs compared to hot pressing | High-performance paddles with custom designs |

In this comparison, thermoforming stands out as a process that can deliver a superior touch and function to paddles, particularly when intricate design details and consistent material performance are required.

The thermoforming process is not without its own set of challenges, but its benefits can outweigh these when implemented correctly. Let’s break down the core advantages and potential limitations:

• One-Piece Construction: With thermoforming, the entire paddle is molded in one step, ensuring structural integrity and a consistent design without seams that could compromise durability.

• Enhanced Material Distribution: The heating and molding process ensures even distribution of advanced polymer materials3. This is critical when using high-performance composites such as T300 or 12K carbon fiber.

• Custom Design Capabilities: Thermoforming supports the creation of paddles with custom ergonomic grips, varied weight distribution, and complex geometric shapes, allowing manufacturers to tailor products to specific market needs.

• Improved Durability: By optimizing the process parameters, manufacturers can achieve paddles with better impact resistance and longevity, essential for high-stress competitive play.

• Higher Production Costs: The initial investment for molds and specialized equipment is higher compared to some other processes like hot pressing.

• Longer Cycle Time: The heating and cooling phases extend the production cycle, which may affect overall throughput in high-volume manufacturing.

• Process Complexity: Maintaining precise temperature and pressure conditions demands rigorous monitoring and control systems during production.

Manufacturers must weigh these factors relative to their production objectives and market demands. When durability, design flexibility, and high performance are top priorities, the benefits of thermoforming make it a worthwhile investment.

Implementing thermoforming in a production line requires attention to equipment calibration and quality management standards. The following points highlight critical considerations:

- Precision Molding Equipment: High-quality molds designed to exact specifications are essential. These molds must be capable of maintaining consistent pressure and temperature throughout the forming cycle.

- Temperature Control Systems: Accurate heating systems ensure that the polymer sheet reaches the optimal pliable state. Consistent heating is key to preventing defects in the finished product.

- Quality Assurance Protocols: Rigorous testing protocols help identify any deviations in material strength, balance, and durability. Every paddle must pass through several quality checkpoints before final approval.

- Process Training: Skilled operators and engineers are required to monitor and adjust the production parameters. Proper training can reduce errors and ensure high productivity over long production runs.

Integrating advanced monitoring solutions and automation can greatly enhance production efficiency, ensuring that every thermoformed paddle meets the targeted performance standards.

At NEX Pickleball, the transition to advanced thermoforming techniques has led to significant improvements in paddle performance. As a leading manufacturer, the company leverages cutting-edge production processes to create paddles that combine power, control, and durability.

• Custom Mold Design: NEX Pickleball invests in state-of-the-art mold design. The designs are tailored to specific paddle geometries to maximize weight distribution and ergonomic support.

• Material Choices: The company uses a combination of advanced polymers and composite materials, such as T300 Carbon Fiber4 and Nomex Honeycomb Core5, which are optimized during the thermoforming process to deliver a uniform material structure.

• Rigorous Testing: Quality control is undertaken at multiple stages of production. Devices are calibrated to ensure that each paddle meets the extreme performance metrics demanded by today’s competitive players.

• Feedback Integration: Continuous feedback from production engineers and players guides incremental process improvements, which not only enhance performance but also lower defect rates and material wastage.

By adopting thermoforming, NEX Pickleball has been able to craft paddles that meet stringent international standards while keeping pace with technological innovations. The company's results illustrate how a commitment to advanced production techniques can lead to better manufacturing outcomes and a competitive edge in the marketplace.

For production managers and R&D professionals looking to incorporate thermoforming into their manufacturing processes, the following steps are recommended:

- Conduct a thorough cost-benefit analysis comparing current production methods with thermoforming. Consider both the initial investment and the long-term benefits in terms of quality and performance consistency.

- Invest in robust quality control systems and automation tools that can monitor and adjust process parameters in real time.

- Explore pilot projects to validate the process adaptations before full-scale implementation. This allows for data collection and process optimization with minimal risk.

- Engage with experienced mold designers and material engineers to ensure that the molds and materials used are of the highest standard. Customization is key to achieving particular performance metrics.

- Regularly review production data and gather field feedback to adjust process parameters and maintain a continuous improvement cycle.

Taking these steps will help manufacturers optimize production quality, reduce operational risks, and deliver high-performance pickleball paddles that satisfy even the most rigorous quality standards.

Thermoforming is proving to be an effective manufacturing process for producing high-performance pickleball paddles. While it comes with higher upfront costs and a longer cycle time, its advantages—such as uniform material distribution, enhanced durability, and the capability for custom designs—make it an excellent choice for markets demanding premium performance.

By comparing thermoforming with traditional processes like hot pressing and cold pressing, manufacturers gain valuable insights into how each method affects paddle properties. NEX Pickleball’s success story is a testament to the potential of thermoforming in achieving superior product quality and performance. Production managers and engineers are encouraged to evaluate their current processes, consider advanced thermoforming techniques, and take steps toward incorporating these innovations to remain competitive in the evolving sporting goods market.

Implementing these changes can lead to sustainable improvements in product performance and manufacturing efficiency, ensuring that the company not only meets but exceeds the expectations of competitive and recreational pickleball players globally.

• Are thermoformed pickleball paddles better?

Thermoformed pickleball paddles are known for their one-piece construction, which offers improved power, uniform strength, and exceptional durability. The thermoforming process allows for advanced polymer materials to be used, resulting in paddles that offer both enhanced performance and extended longevity in competitive play.

• What is the process of thermoforming pickleball paddles?

The process of thermoforming involves heating a polymer sheet until it becomes pliable, then molding it into the desired paddle shape using custom-designed molds. After the material cools, the paddle retains its precise and uniform form. This process yields paddles that are both lightweight and sturdy, capable of delivering excellent control and power during play.

• Are all pickleball paddles made in the same factory?

While most pickleball paddles are manufactured in China due to established industrial capabilities and cost efficiencies, several premium brands take pride in localized production. The manufacturing location often depends on a company's quality control preferences and brand positioning, with some notable brands opting for domestic production to emphasize craftsmanship and quality standards.

-

thermoformed: Click to read more about the thermoforming process, its benefits for one-piece construction, and how it enhances product durability and consistency in manufacturing. ↩ ↩

-

OEM manufacturing: Click to learn about OEM manufacturing, its role in supporting advanced production techniques, and its significance in establishing efficient production environments. ↩ ↩

-

advanced polymer materials: Click to explore how advanced polymer materials contribute to improved performance and durability in high-performance manufacturing processes. ↩ ↩

-

T300 Carbon Fiber: Click to read more about T300 Carbon Fiber, its properties, applications in composite manufacturing, and its impact on enhancing product strength and longevity. ↩ ↩

-

Nomex Honeycomb Core: Click to discover the benefits of Nomex Honeycomb Core, including its structural stability and contribution to superior product performance in manufacturing. ↩ ↩