Our quick answer: For pickleball paddle faces, carbon fiber variants1—especially 3K, 12K, and T300—are widely recognized for their superior balance of strength, rebound performance, and durability, making them the preferred choice for high-performance paddles.

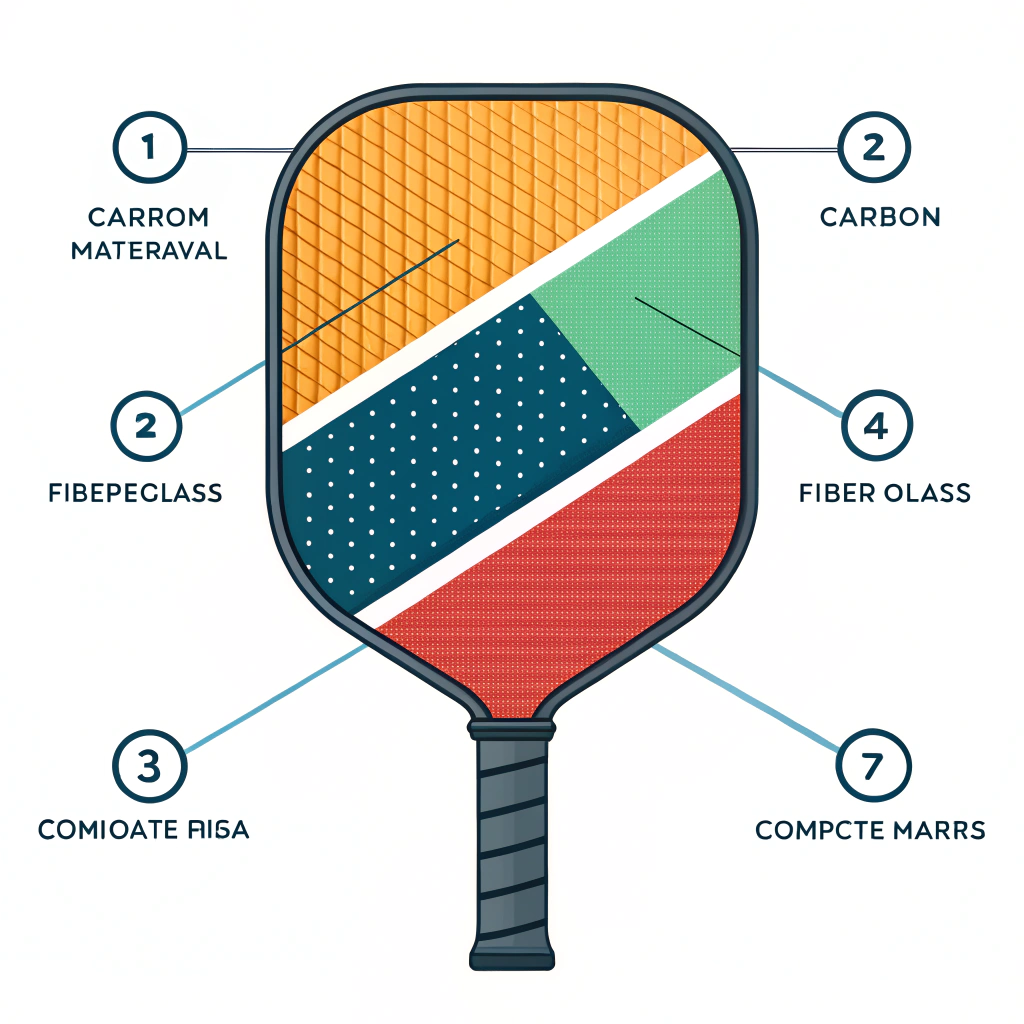

In today’s competitive sports equipment market, selecting the right paddle face material is crucial. Paddle manufacturers and distributors must ensure that the materials used deliver not only high-performance gameplay but also long-lasting durability. This article dives into the technical specifics of various paddle face materials—such as Carbon Fiber, Fiberglass2 and composite structures3—to help purchasing managers and product development specialists make informed decisions.

Modern pickleball paddles face intense pressure to combine lightweight design with exceptional impact resistance and precision control. The primary challenges include:

• Maintaining structural integrity under high impact

• Minimizing vibration for better control and comfort

• Balancing material strength without sacrificing responsiveness during play

These challenges are further complicated by evolving production processes and the need to cater to both recreational and high-level competitive players. As such, our focus will be on evaluating the advantages and trade-offs of various paddle face materials, aligning technical specifications with real-world performance metrics.

To address the performance demands, manufacturers have developed multiple material options. Let’s break down the most common types:

Carbon Fiber is a standout in the sports equipment industry. With several variations available, each type presents unique benefits:

• 3K Carbon Fiber: Known for its strength and flexibility. It provides excellent durability and reduces vibrations, making it ideal for paddles that require high rebound force.

• 12K Carbon Fiber: Offers greater thread density, resulting in a smoother surface finish. Its hardness and impact resistance make it perfect for competitive play.

• T300 Carbon Fiber: Emphasized for its superior tensile strength and balanced performance between light weight and durability.

These carbon variants are highly favored in high-performance scenarios, particularly where players require both power and control.

Fiberglass2 is another popular choice owing to its balance between power and control. Key highlights include:

• E-Glass Fiberglass: Known for its elasticity and tensile strength, it provides an excellent ball feel with enhanced control.

• It features a wider sweet spot, ensuring consistent performance even during challenging gameplay conditions.

Composite materials combine the strengths of different components and have become increasingly popular. Two noteworthy examples include:

• Carbon Fiber and Fiberglass Composite: This blend offers an optimal mix of strength, light weight, and flexibility, serving players looking for both power and precision.

• Bamboo Core Composite: Bamboo is naturally lightweight and highly impact-resistant. This composite is well-known for delivering an authentic hitting feel and enduring performance.

The core of the paddle plays a pivotal role in its overall performance. Some of the widely used core materials include:

• Nomex Honeycomb Core: Made from durable polymers, it offers superior shock absorption and stability during forceful impacts.

• Aluminum Honeycomb Core: Balances weight and power, providing good control for precision play.

• Polymer Honeycomb Core: Renowned for its elasticity and vibration reduction, it yields a comfortable impact experience, particularly valued by recreational players and beginners.

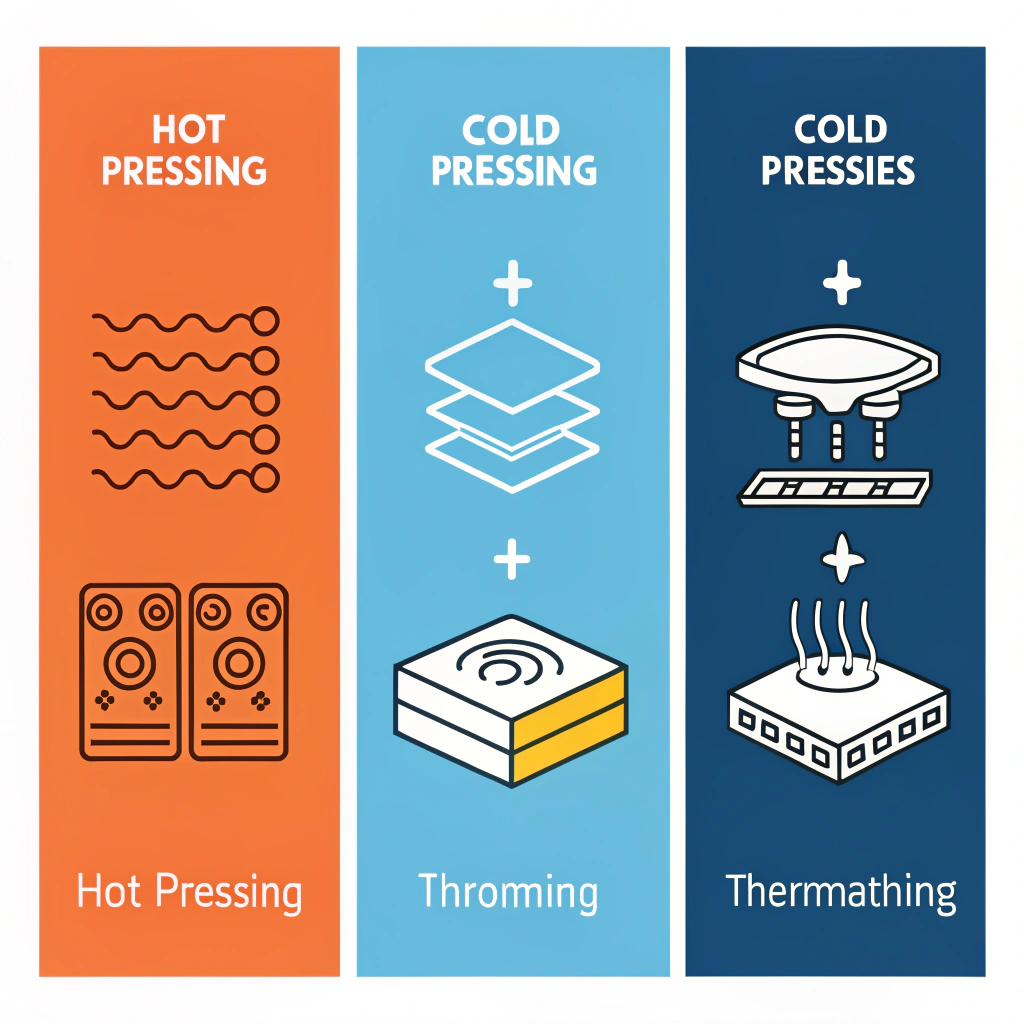

Understanding the manufacturing process is essential for evaluating the final product performance. NEX Pickleball utilizes three main production techniques, each influencing material properties differently:

This process involves heating and pressure application to form the paddle.

- Advantages:

• High production efficiency, ideal for large-scale manufacturing.

• Generates a structurally robust paddle with excellent impact resistance. - Disadvantages:

• High equipment investment is required.

• Potential modification of material properties may alter the paddle feel.

Cold pressing shapes the paddle at room temperature using mechanical pressure.

- Advantages:

• Precision in controlling paddle thickness and structure is remarkable.

• Maintains the intrinsic characteristics of the base material, ensuring optimal ball feel and responsiveness. - Disadvantages:

• Longer production cycles can reduce overall efficiency.

• Demands precise pressure regulation, which may require specialized equipment.

Thermoforming heats materials to softening points before forming them under molded conditions.

- Advantages:

• Ideal for creating paddles with complex designs and precise material distributions.

• Enhances paddle stability and performance. - Disadvantages:

• Involves longer production times and higher equipment costs, making it more suited for premium or custom orders.

A clear understanding of the trade-offs between materials is key to informed decision making. Below is a comparison table summarizing the primary features of each material option:

| Material | Strength & Impact Resistance | Vibration Reduction | Production Efficiency | Suitable For |

|---|---|---|---|---|

| 3K Carbon Fiber | High | Good | High (with hot pressing) | Competitive and high rebound use |

| 12K Carbon Fiber | Very High | Moderate | Moderate | High-performance play and durability |

| T300 Carbon Fiber | Balanced High | Excellent | High/Moderate | Players seeking balanced performance |

| E-Glass Fiberglass | Moderate | Excellent | High (with cold pressing) | Recreational players and accurate control |

| Carbon-Fiberglass Composite | High | Good | Moderate | Versatile, power-focused design |

| Bamboo Core Composite | High | Excellent | Moderate | Durable and long-lasting play |

| Nomex Honeycomb Core | High | Excellent | High | Professional-level stability |

| Aluminum Honeycomb Core | Moderate | Good | High | Balanced power and control requirements |

| Polymer Honeycomb Core | Moderate | Excellent | High | Recreational and comfort-focused use |

This table serves as a fast reference for comparing material characteristics and helps align technical features with the specific needs of different market segments.

Several leading paddle manufacturers have demonstrated significant performance variances based on chosen materials. For instance, paddles utilizing T300 Carbon Fiber have shown a higher rebound percentage in lab tests, making them well-suited for rapid, high-intensity exchanges. On the other hand, paddles with E-Glass Fiberglass excel in controlled environments, providing a larger sweet spot and ensuring excellent precision, which is particularly advantageous for new players or those who prioritize control over raw power.

Field tests with various core materials also reveal that Nomex Honeycomb Cores ensure minimal deformation under stress. Data from these tests indicate that reduced vibration levels directly correlate with improved player accuracy and reduced hand fatigue—a critical metric for both competitive and recreational users.

6. Integration with Custom Design and OEM manufacturing5

For procurement specialists engaged in OEM manufacturing5, the flexibility in design is a major advantage. NEX Pickleball offers custom paddle designs that allow clients to tailor various aspects such as weight distribution, grip size, and face material. This capacity for customization is especially important when considering:

• Market differentiation through unique paddle designs that reflect a brand’s identity.

• Tailoring material composition based on the target player’s skill level and play style.

• Incorporating advanced manufacturing processes to ensure consistent quality control.

For instance, clients can choose from the full range of carbon fiber and composite materials to accommodate specific performance needs, while also leveraging high-efficiency production techniques that ensure cost-effectiveness without compromising quality.

Based on the technical analysis provided:

- Prioritize Carbon Fiber Variants: For high-performance paddles, choose from 3K, 12K, or T300 carbon fibers based on the balance required between strength and weight. High rebound and excellent durability make carbon fiber the foremost choice for competitive play.

- Consider Fiberglass Options: If the target market values control and a larger sweet spot, E-Glass fiberglass offers an excellent alternative. Its balance of elasticity and durability is ideal for broader audiences.

- Leverage Composite Materials for Versatility: Integrate composites to combine multiple performance attributes, particularly for clients who desire a balance of power and control.

- Match Production Process to Material: Align the production process with the selected material. For example, hot pressing enhances impact resistance in carbon fiber paddles, while cold pressing is better suited for precision-based materials like fiberglass.

- Evaluate Customization Potential: Utilize OEM services to tailor paddle features, ensuring the final product meets the needs of specific market segments. Consider factors like grip size and weight balance for a custom player experience.

The technical performance of pickleball paddles hinges on selecting the optimal face material aligned with production capabilities and user expectations. Carbon fiber variants remain the top choice for many high-performance applications due to their excellent strength, reduced vibration, and durability. However, other materials like fiberglass and composites offer unique advantages for specialized player needs. By understanding the production processes—hot pressing, cold pressing, and Thermoforming4—and their influence on material performance, B2B buyers can make informed decisions that align with their market strategy.

This comprehensive technical guide aims to serve as an essential resource for purchasing managers and product developers at sports equipment distribution companies. With detailed insights supported by data and industry-tested practices, companies are better equipped to choose materials that bolster the overall performance of their pickleball paddles and differentiate their product offerings in the competitive market.

• What is the best material for a pickleball paddle face?

Our experts agree that carbon fiber—particularly in its 3K, 12K, or T300 forms—stands out as the top material. It delivers superior strength, excellent rebound performance, reduced vibration, and durability essential for high-performance paddles.

• What is the best core material for pickleball paddles?

Both Polymer and Nomex Honeycomb Cores offer distinct advantages; Polymer provides better elasticity and vibration reduction for enhanced comfort, while Nomex ensures high shock absorption and long-lasting stability, making them suitable for various levels of play.

-

carbon fiber variants: Click to explore detailed insights into different types of carbon fibers, their manufacturing processes, and how they influence performance metrics for high-end sports equipment. ↩ ↩

-

Fiberglass: Click to learn about fiberglass properties, benefits in sports equipment, and its role in providing optimal control and durability in high-performance products. ↩ ↩ ↩2

-

composite structures: Click to understand the science behind composite structures, including material blending techniques and performance enhancements in technologically advanced products. ↩ ↩

-

Thermoforming: Click to discover the thermoforming process, its advantages in manufacturing complex designs, and how it improves material distribution and product performance. ↩ ↩ ↩2

-

OEM manufacturing: Click to explore the benefits of OEM manufacturing, including customization options, streamlined production, and strategic advantages for businesses in niche markets. ↩ ↩ ↩2