Quick Answer: NEX Pickleball’s robust manufacturing capabilities, combining advanced hot pressing1, cold pressing2, and thermoforming3 technologies, ensure efficient handling of large orders while maintaining precision, quality control, and optimal performance for each paddle.

In today’s competitive sports equipment market, procurement professionals require a manufacturing partner who can consistently deliver high-performance products at scale. A 10,000 paddle order is not merely a volume challenge but an intricate balancing act involving production scalability, material performance, and quality control. Here, we explore how NEX Pickleball meets these demands with rigor and precision.

Large bulk orders present unique obstacles:

- Ensuring production capacity keeps pace with high-volume demands.

- Integrating advanced manufacturing processes while maintaining strict quality standards.

- Utilizing premium materials without sacrificing performance.

- Handling logistical challenges and operational scalability.

For procurement managers, understanding each production element is crucial to evaluating a supplier’s ability to meet bulk order requirements.

When managing a significant 10,000-paddle order, several factors need consideration:

- Production Process Differentiation: Whether using hot pressing1 (as mentioned previously), cold pressing, or thermoforming, each method has its strengths and limitations. The choice affects production speed, paddle strength, and overall performance.

- Material Quality and Selection: The use of various materials such as 3K Carbon Fiber4, 12K Carbon Fiber, fiberglass, and composite materials ensures that paddles can meet different performance expectations ranging from control to power.

- Quality Control and Testing: Rigorously testing every paddle ensures compliance with international sports equipment standards. Attention to detail in weight distribution, ergonomic design, and vibration dampening is crucial.

- Flexibility in Customization: Offering customized options—like specific grip sizes, design, weight balance, and graphic printing—demands an agile production process, which is a challenge during high-volume manufacturing.

- Technological Integration: Advanced production technologies allow for consistent quality. However, significant investments and precise calibration are required to maintain uniformity across large orders.

NEX Pickleball employs several interconnected strategies to address these challenges effectively:

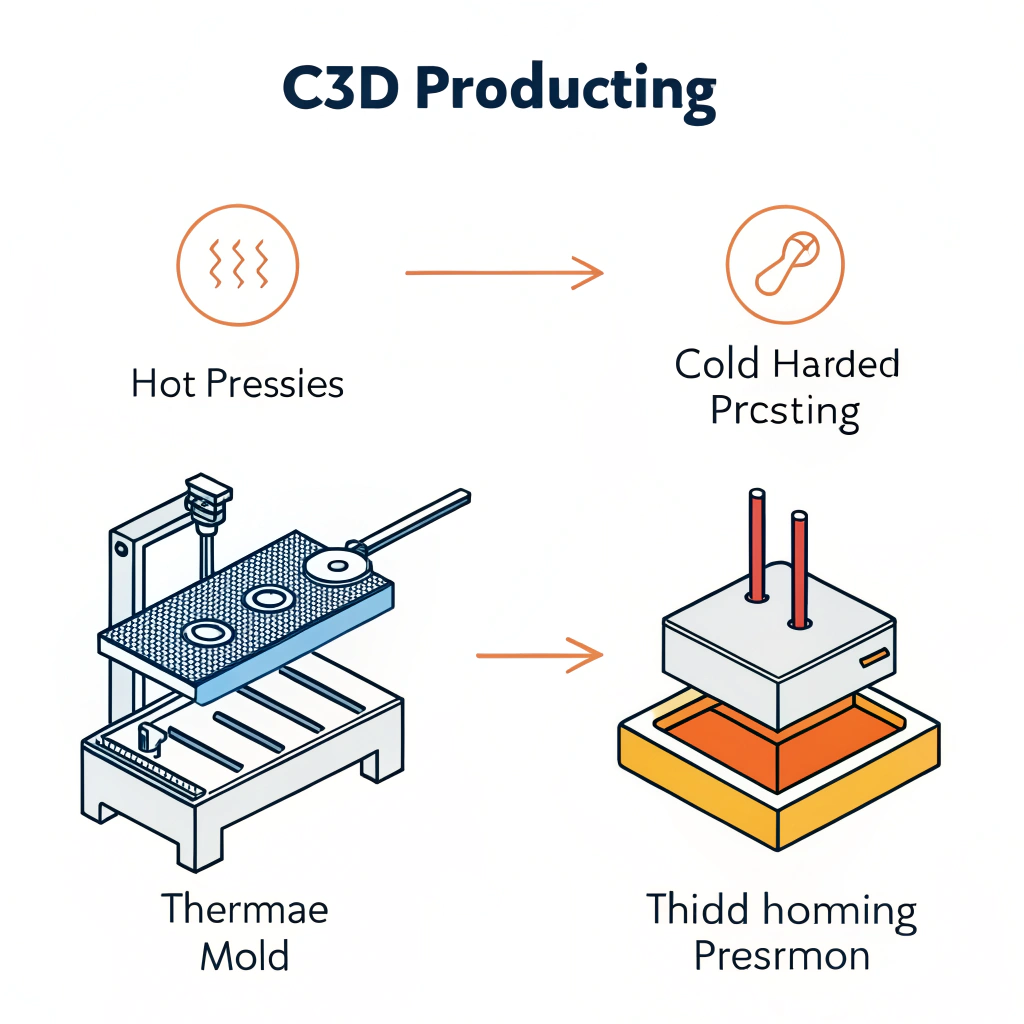

NEX Pickleball uses three core production methods, each optimized for different paddle requirements:

-

Hot Pressing:

- Benefits: High production efficiency, enhanced impact resistance, and structural integrity.

- Limitations: May alter some material properties and requires substantial equipment investment.

-

Cold Pressing:

- Benefits: Precise control over paddle thickness and structure, ensuring the natural feel of the materials.

- Limitations: Lower production speed and demands for precise pressure controls.

-

Thermoforming:

- Benefits: Enables intricate paddle designs and even material distribution for superior performance.

- Limitations: Longer production times and higher equipment costs.

A quick comparison table is provided below:

| Production Method | Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency, enhanced strength, excellent impact resistance | Potential material property changes, high equipment cost |

| Cold Pressing | Precise structure control, retains natural material feel | Longer production cycle, precise machinery required |

| Thermoforming | Allows complex designs, optimal material distribution | Increased production time, premium equipment costs |

This multi-method strategy enables NEX Pickleball to select the best process based on paddle type, order volume, and specific client needs.

The choice of materials is integral to delivering a high-performance paddle. NEX Pickleball incorporates:

-

Carbon Fiber Variants:

- 3K Carbon Fiber4: Provides excellent rebound force and durability with reduced vibration. Ideal for paddles emphasizing power.

- 12K Carbon Fiber: Offers a smoother surface, better hardness, and extreme strength for competitive play.

- T300 Carbon Fiber: Balances light weight with high tensile strength, suitable for balanced performance.

-

Fiberglass and Composite Materials:

- E-Glass Fiberglass: Ensures elasticity and control.

- Carbon Fiber and Fiberglass Composites: Create an optimal balance of power and control.

- Bamboo and Honeycomb Cores: Provide lightweight impact resistance and enhanced paddle feel.

-

Critical Core Materials:

- Nomex Honeycomb Core5: Offers excellent shock absorption and stability.

- Aluminum Honeycomb Core: Balances weight and control.

- Polymer Honeycomb Core: Known for elasticity and reduced vibration, ideal for beginners and recreational players.

These materials are carefully chosen based on the paddle’s intended use, highlighting our commitment to delivering top-tier performance across diverse playing conditions.

To meet and exceed bulk order standards, every paddle undergoes a series of quality tests:

- In-Process Inspections: Monitoring at each production stage, particularly during molding and pressing, ensures that any anomalies are detected early.

- Post-Production Testing: Rigorous testing includes vibration analysis, impact resistance tests, and ergonomic evaluations.

- Customized Quality Assurance: For custom orders, clients can specify detailed performance criteria, and our testing protocols adapt accordingly.

Quality control minimizes defects and secures consistency—critical factors when shipping large volumes to international markets.

Large volume orders require scalable production without compromising quality. NEX Pickleball ensures scalability through:

- State-of-the-Art Equipment: Modern machinery for hot pressing, cold pressing, and thermoforming guarantees faster cycle times.

- Bulk Material Sourcing: Long-term partnerships with suppliers guarantee consistency and quality in raw materials.

- Agile Workforce Training: Continuous training ensures that our staff adapts efficiently to varying production methods.

- Automated Handling & Assembly: Implementation of semi-automated processes helps reduce human error while sustaining high production rates.

Adopting these strategies enables seamless transition from small to large orders, ensuring delivery deadlines are met even for orders as large as 10,000 paddles.

Meeting diverse market needs is crucial in B2B wholesale. NEX Pickleball offers:

- Custom Paddle Design: Clients can specify design elements, grip size, weight, balance, and even logo imprinting in an on-demand printing service.

- Tailored Performance Adjustments: For competitors and recreational players alike, paddle features can be optimized for distinct playing styles.

- Flexible Order Configurations: Clients have the freedom to mix different paddle types within a single large order based on market demand.

Customization enhances customer satisfaction and loyalty, making the procurement decision process smoother for distribution companies.

To illustrate our process in action, consider the recent large-scale order handled by NEX Pickleball:

-

Order Evaluation:

The order was segmented based on paddle specifications: a mix of high-performance carbon fiber paddles for competitive play and fiberglass paddles for controlled, smooth gameplay. -

Method Selection and Material Allocation:

- Competitive paddles underwent a combination of thermoforming and hot pressing for optimum power balance.

- Recreational paddles were produced using cold pressing to retain a superior ball feel.

-

Quality Inspection Milestones:

Each production line was assigned specific checkpoints, ensuring integrity at material handling, molding stages, and final testing. -

Operational Logistics:

Coordination between production lines allowed for continuous output, while our upgraded automation reduced manual handling delays. -

Delivery and After-Sales Support:

Post-production, a dedicated logistics team managed shipping schedules. Follow-up quality surveys ensured the paddles met end-user satisfaction.

This case study demonstrates our commitment to balancing high-volume production with uncompromised quality, thereby meeting the rigorous demands of a large-scale B2B procurement.

For procurement managers evaluating suppliers for high-volume orders, consider the following:

-

Assess the Production Techniques:

Verify if the manufacturer uses a mix of hot pressing, cold pressing, and thermoforming. This diverse approach ensures flexibility and optimal paddle performance across different market segments. -

Review Material Specifications:

Check the manufacturer’s detailed breakdown of materials used—especially different grades of carbon fiber and composite options—to ensure they meet your performance criteria. -

Insist on Quality Control Transparency:

A reliable supplier will provide clear insights into their quality assurance protocols and testing regimes. Documentation detailing in-process inspections and post-production tests is a positive indicator of product consistency. -

Confirm Scalability and Customization Capabilities:

Ensure that the supplier demonstrates a proven record of handling large orders without sacrificing precision or the ability to customize products based on your market needs. -

Leverage Case Studies:

Ask for real-world examples or case studies where the supplier has efficiently managed similar orders. Documented success stories enhance confidence in the supplier’s ability to meet bulk orders.

By considering these recommendations, procurement managers can make informed decisions that balance quality, performance, and cost-effectiveness in B2B transactions.

NEX Pickleball’s comprehensive approach towards managing large-scale paddle orders reflects its commitment to precision, quality, and performance. By integrating advanced production methods, premium material selection, stringent quality controls, and flexible customization options, we have positioned ourselves as a reliable partner for bulk procurement in the sports equipment industry.

Our experience handling orders of 10,000 paddles and beyond reinforces our capacity to deliver top-notch, performance-enhancing products on time and within budget. For sports equipment distributors seeking a manufacturing partner who can blend technical precision with scalable production, NEX Pickleball offers the expertise, technology, and quality assurance needed to meet and exceed market expectations.

Take the next step and contact us for detailed production insights or to discuss your bulk order requirements. Our team is ready to help you achieve a seamless integration of high-performance products into your market portfolio.

Q: How to judge a pickleball paddle?

A: To judge a pickleball paddle, evaluate its weight classification, material composition, and production process. Typically, paddle weights are classified as midweight (7.3-8.5 ounces), lightweight (7.3 ounces and below) for enhanced control, and heavy (above 8.5 ounces) for increased power. Additionally, consider the construction process—whether it uses hot pressing, cold pressing, or thermoforming—and the quality of materials like carbon fiber or fiberglass to ensure the paddle meets durability and performance standards.

-

hot pressing: Reading this article will explain how hot pressing uses heat and pressure to enhance material bonding and production efficiency, resulting in improved product strength and durability. Back to hot pressing ↩ ↩2

-

cold pressing: Reading this article will help you understand how cold pressing maintains the natural properties of materials, offering greater precision in molding without altering intrinsic qualities. Back to cold pressing ↩

-

thermoforming: Reading this article illustrates how thermoforming allows for complex designs by heating and molding plastics or composites into specific shapes for enhanced performance. Back to thermoforming ↩

-

3K Carbon Fiber: Reading this article provides insights into the properties of 3K Carbon Fiber, detailing its balance of durability, performance, and vibration reduction ideal for high-performance equipment. Back to 3K Carbon Fiber ↩ ↩2

-

Nomex Honeycomb Core: Reading this article will explore how Nomex Honeycomb Core contributes exceptional shock absorption and structural stability, essential for quality and performance in advanced manufacturing. Back to Nomex Honeycomb Core ↩