Pickleball paddle performance largely depends on the careful selection of materials and production processes that directly affect power, control, durability, and player comfort.

In today’s beginner’s guide, we will explore the key components and manufacturing methods used in high-performance pickleball paddles. Whether you are a procurement manager or a product development specialist at a sporting goods company, understanding these fundamentals will help you make informed sourcing and quality assessment decisions. This guide dives into the roles of various materials—such as carbon fiber1, fiberglass, and composite mixtures—and explains the three primary production techniques: hot pressing, cold pressing, and thermoforming. By understanding these aspects, you can better evaluate the performance characteristics and longevity of pickleball paddles before making a purchase.

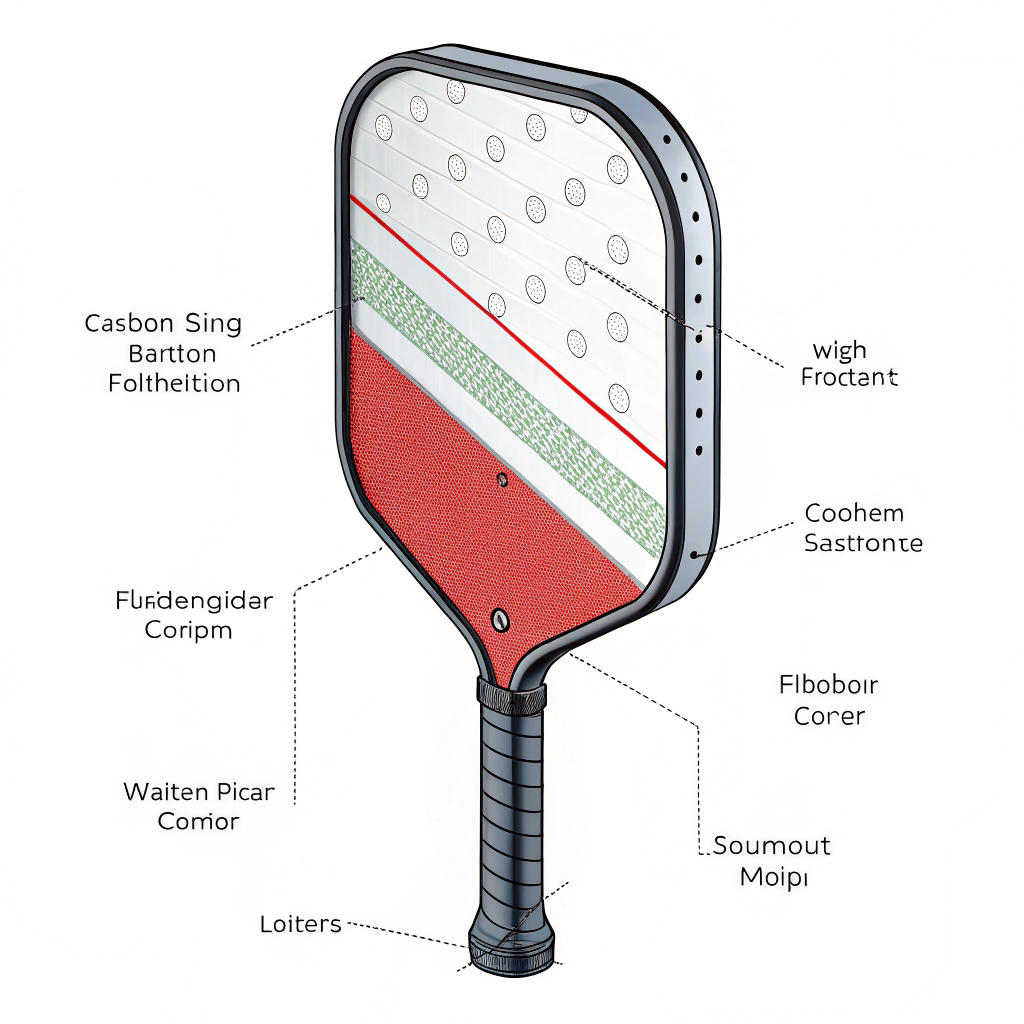

Pickleball paddles are not merely simple tools. They are engineered products that combine advanced materials and precision manufacturing to meet the challenges of fast-paced games. The overall performance of a paddle is determined by two main factors: the materials used and the production process implemented.

-

Carbon Fiber

Carbon fiber is a popular choice among paddle manufacturers for its impressive strength-to-weight ratio and durability. There are several types of carbon fiber:- 3K Carbon Fiber: Often used when flexibility and strong rebound are essential. It provides a robust yet flexible structure, reducing vibration during play.

- 12K Carbon Fiber: With a higher thread density than 3K, it delivers a smoother surface and enhanced stiffness. Its excellent durability makes it a favorite in competitive settings.

- T300 Carbon Fiber: Known for its superior tensile strength, T300 is ideal for balancing light weight with high performance, offering a consistent hitting experience.

-

Fiberglass

Fiberglass paddles strike a balance between power and control. They provide a wider sweet spot and are known for their flexibility, which translates into better ball control. A common variant used in paddle manufacturing is E-Glass Fiberglass, prized for its elasticity and tensile strength. -

Composite Materials2

Combining various materials can further enhance paddle performance. Examples include:- Carbon Fiber and Fiberglass Composite: This blend takes advantage of the high strength of carbon fiber and the control offered by fiberglass.

- Bamboo Core Composite: Bamboo cores ensure a lightweight design and improve impact resistance while delivering a distinct hitting feel.

- Honeycomb Core Composite: Usually constructed from high-density polymers, honeycomb cores are designed for superior shock absorption and vibration reduction.

-

Core Materials

The paddle core significantly influences the feel and performance of the racket:- Nomex Honeycomb Core3: Known for its excellent shock absorption and durability, ideal for prolonged high-impact play.

- Aluminum Honeycomb Core: Provides a balance between power and precision, making it suitable for players who need both strength and control.

- Polymer Honeycomb Core: Favored for its elasticity and ability to reduce vibration, giving players a more comfortable experience.

Each of these materials plays a crucial role in defining the paddle’s performance characteristics. For instance, high-density polymers in the core can absorb vibrations effectively, while carbon fibers provide the strength necessary for powerful and accurate strikes.

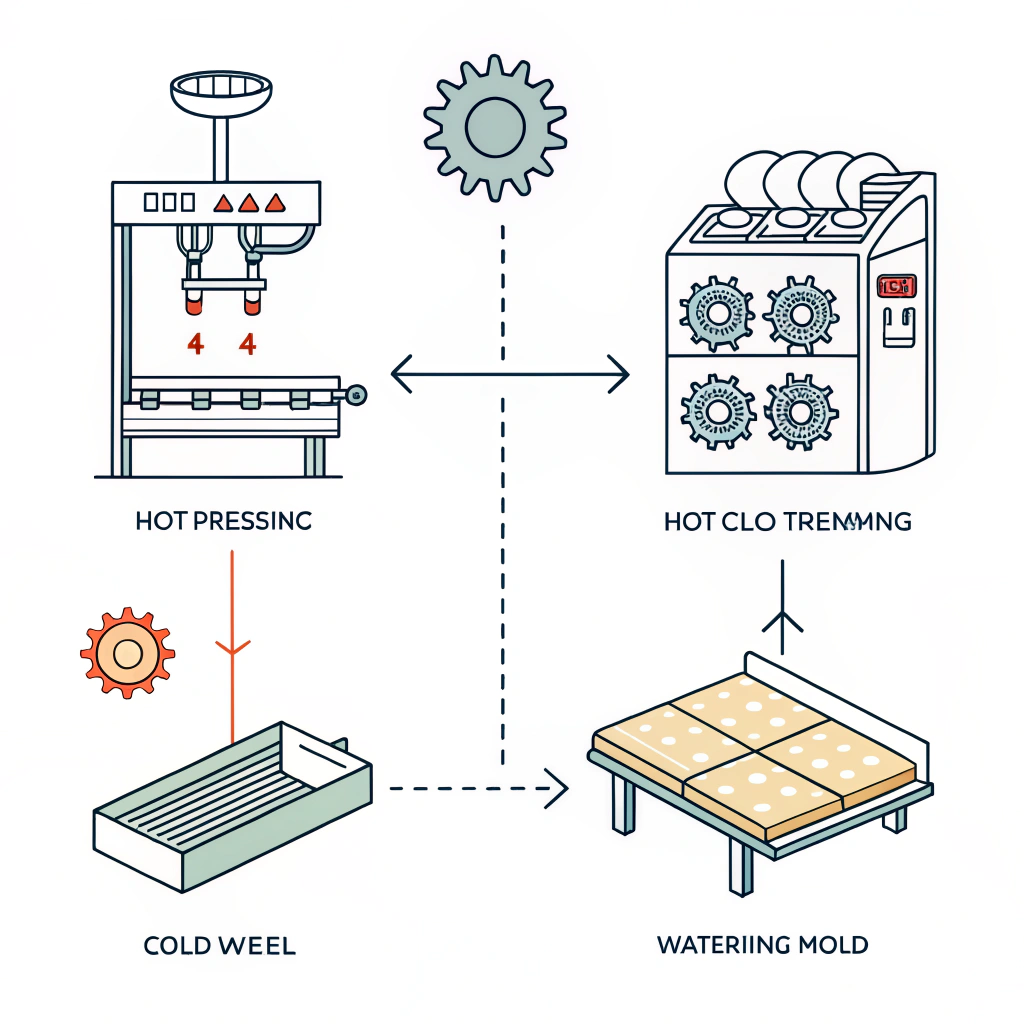

The manufacturing process is as critical as the choice of materials. At companies like NEX Pickleball, advanced production techniques ensure that every paddle meets performance and durability standards. Let’s break down the three major methods used:

-

Hot Pressing

In hot pressing, materials are heated and pressed to form a paddle. This process is ideal for creating strong, structurally sound paddles with excellent impact resistance.- Advantages:

◦ High production efficiency, which suits large-scale manufacturing.

◦ Results in a robust final product capable of withstanding high-impact play.

◦ Ensures consistent structural integrity across batches. - Disadvantages:

◦ The high temperatures involved can sometimes alter the inherent material properties, potentially affecting the paddle’s feel.

◦ Significant initial investment in specialized equipment is required.

- Advantages:

-

Cold Pressing4

Cold pressing involves shaping the materials under mechanical pressure without applying heat. This method maintains the natural properties of the materials, which can be particularly important for sensitive designs.- Advantages:

◦ Greater precision in controlling paddle thickness and structure.

◦ Maintains the innate qualities of the materials, which can enhance control and flexibility.

◦ Delivers a superior ball feel, making it popular for paddles focused on finesse. - Disadvantages:

◦ The production cycle is typically longer, reducing overall manufacturing efficiency.

◦ Requires high-quality pressure equipment to achieve consistent results.

- Advantages:

-

Thermoforming5

Thermoforming uses heat to soften the material, which is then molded into shape. This technique allows for complex designs and precise material distribution in the paddle.- Advantages:

◦ Facilitates the creation of paddles with intricate shapes and varying thicknesses to fine-tune performance.

◦ Maintains the paddle’s structural stability, enhancing on-court reliability. - Disadvantages:

◦ Longer production times and higher equipment costs make it a less attractive option for high-volume production.

◦ Generally reserved for premium or custom-made paddles due to its detailed process.

- Advantages:

Below is a table summarizing the key advantages and disadvantages of the three production techniques:

| Production Method | Key Advantages | Potential Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, consistent quality | Possible alteration of material feel, high equipment cost |

| Cold Pressing | Precise control, preservation of material properties, excellent ball feel | Longer production cycle, demands high-quality pressure equipment |

| Thermoforming | Intricate design capability, precise material distribution, enhanced stability | Higher production time and cost, best suited for premium products |

Understanding the components and production methods used in pickleball paddles is essential when sourcing products. Here are the main benefits for procurement teams:

-

Informed Material Selection:

Recognizing the differences among carbon fibers, fiberglass, and composite materials allows procurement managers to evaluate which paddle designs meet the functional requirements of their target market. For example, products utilizing 12K Carbon Fiber might be ideal for competitive players needing a durable paddle, while E-Glass Fiberglass might suit recreational play with superior ball control. -

Understanding Manufacturing Constraints:

Familiarity with production processes such as hot pressing can help buyers assess production capacities, lead times, and potential cost implications. Moreover, knowing the precise control offered by cold pressing or the design flexibility in thermoforming positions you to choose products that best align with your operational needs. -

Customization Potential:

Advanced manufacturers like NEX Pickleball offer custom paddle options. With customization, elements such as design, weight, balance, and grip size can be tailored to meet specific customer or market demands, offering businesses a distinct competitive edge in the sporting goods market. -

Quality and Performance Assurance:

Knowledge of the materials and processes provides a benchmark for quality. By comparing the technical specifications—such as the type of carbon fiber or honeycomb core material used—you can be more confident in the paddle’s performance, longevity, and overall value proposition. Regular quality control protocols and rigorous testing further ensure that each paddle meets strict performance standards.

NEX Pickleball leverages its expertise in advanced production techniques to deliver paddles that meet the evolving demands of players at all levels. The use of multiple types of carbon fiber, combined with innovative manufacturing methods, positions NEX Pickleball as a reliable partner for businesses sourcing high-performance sporting goods.

For instance, our use of T300 Carbon Fiber in select paddles offers a perfect blend of strength and light weight. Meanwhile, the option to integrate composite core materials such as Nomex or Polymer Honeycomb not only enhances durability but also ensures a smooth playing experience even during extended games. This ability to customize both material selection and production technique has made NEX Pickleball a preferred supplier for renowned brands like Joola and Selkirk.

Manufacturers benefit from:

- Expert guidance on material selection.

- Transparent production processes that clearly link to product performance.

- Flexible customization options that allow businesses to meet niche market needs.

- A proven track record of timely delivery and rigorous quality control.

These factors create a compelling value proposition for companies looking to invest in a reliable supply of elite pickleball paddles in a competitive market.

Understanding the building blocks of pickleball paddle construction—from materials to production techniques—is essential for procurement and product development teams preparing to enter the niche sporting goods market. The choice between different types of carbon fiber, fiberglass, or composite materials can significantly influence a paddle’s overall performance and durability. Likewise, comprehending the manufacturing methods, whether it be hot pressing, cold pressing, or thermoforming, helps in assessing production timelines, costs, and final product quality.

For procurement managers, these insights are instrumental in making informed decisions. Consider these steps when evaluating potential suppliers:

- Assess the detailed specs provided by manufacturers regarding material types and production processes.

- Request samples to compare the feel, durability, and performance of different paddle models.

- Evaluate customization capabilities to ensure that the products can be tailored to meet your market’s unique demands.

- Leverage supplier expertise; companies like NEX Pickleball are not only manufacturers but also knowledgeable partners who can guide you through the sourcing and technical evaluation process.

By taking a structured approach to understanding these critical factors, you can confidently source high-quality pickleball paddles that enhance player performance and uphold your brand’s reputation in the competitive sporting goods market.

People Also Ask

Q: What are the common materials used in pickleball paddles?

A: Pickleball paddles are commonly made from carbon fiber (such as 3K, 12K, and T300), fiberglass, and various composite materials that often include bamboo cores or honeycomb cores. These materials are selected to balance strength, control, and durability.

Q: How do different manufacturing processes affect paddle performance?

A: Hot pressing creates strong, impact-resistant paddles at high production efficiency but may alter material feel, while cold pressing preserves material properties for better control but has a longer cycle time. Thermoforming, on the other hand, allows intricate designs and precise material distribution, making it ideal for premium products.

Q: Why is material selection important in paddle construction?

A: The choice of materials such as carbon fiber, fiberglass, and composite cores directly influences the paddle’s power, control, and durability. Understanding these aspects helps procurement managers and product developers choose paddles that best suit their performance requirements and market demands.

-

Carbon Fiber: Reading this article will help you understand how carbon fiber’s high strength-to-weight ratio and durability contribute to paddle performance, enabling better material selection for competitive sporting goods. ↩ ↩

-

Composite Materials: Reading this article will offer insights into how combining different materials can optimize performance by balancing power, control, and durability in engineered sports equipment. ↩ ↩

-

Nomex Honeycomb Core: Reading this article will shed light on how Nomex honeycomb cores enhance shock absorption and durability, contributing to a superior playing experience in high-impact scenarios. ↩ ↩

-

Cold Pressing: Reading this article will explain how cold pressing preserves the natural properties of materials while providing precise control over paddle structure, impacting playability and performance. ↩ ↩

-

Thermoforming: Reading this article will provide detailed information on how thermoforming allows for intricate designs and precise material distribution, offering customization benefits for premium paddle production. ↩ ↩