A high-performance pickleball paddle for the power player starts with selecting the right blend of advanced materials1 and production processes. In this article, we compare paddle designs focusing on key factors such as precision manufacturing processes2, and durability, helping you make a well-informed purchasing decision for your product line.

B2B decision makers in the sports equipment industry face a common challenge: how to choose a pickleball paddle that not only meets technical performance criteria but also enhances market competitiveness. On one hand, power players demand paddles with high impact resistance and explosive power; on the other, a product must balance control, durability, and cost-effectiveness. Manufacturers like NEX Pickleball have honed their design philosophy by employing precision techniques such as hot pressing, cold pressing, and thermoforming to deliver paddles that address these challenges head-on.

In this article, we delve into the critical differentiators—material selection, production techniques, and ergonomic design—that impact paddle performance. Our review will compare carbon fiber variants, fiberglass, and composite constructions while highlighting key production processes. This comparative analysis will help distributors, retailers, and product managers decide which paddle design best aligns with their target market needs.

One of the most compelling factors in paddle performance is the choice of material. NEX Pickleball employs several advanced materials1 to cater to the diverse needs of power players:

Carbon Fiber is popular for its blend of strength, lightweight properties, and durability. NEX Pickleball uses different types:

- 3K Carbon Fiber: Renowned for its balance of strength and flexibility. With high rebound force and excellent durability, it is ideal for paddles that dampen vibration while delivering power.

- 12K Carbon Fiber: Offers higher thread density for a smoother playing surface and superior hardness, which is crucial for competitive play requiring extreme impact resistance.

- T300 Carbon Fiber: High tensile strength coupled with a balanced weight makes this type ideal for a wide range of power players seeking both strength and agility.

Each type has specific benefits, enabling manufacturers to tailor the paddle’s physical properties depending on targeted performance needs.

Fiberglass paddles, especially those made from E-Glass Fiberglass3, offer a well-rounded balance. They deliver:

- A wider sweet spot

- Enhanced ball control

- Superior elasticity and tensile strength for a comfortable feel

This material is particularly beneficial when players need a combination of power and control.

Combining materials can often yield the best performance outcomes. Examples include:

- Carbon Fiber and Fiberglass Composite: Merges strength with flexibility.

- Bamboo Core Composite: Offers a lightweight yet impact-resistant core, ensuring the product remains sturdy during extended play.

- Honeycomb Core Options: Use high-density polymers or pulp to absorb shock effectively, reduce vibration, and increase longevity.

A summary table of these materials is shown below:

| Material Type | Key Benefits | Suitable For |

|---|---|---|

| 3K Carbon Fiber | Strength, flexibility, reduced vibration | High rebound force paddles |

| 12K Carbon Fiber | Smoother surface, superior hardness, durability | Competitive, impact-resistant paddles |

| T300 Carbon Fiber | Outstanding tensile strength and light weight | Balanced performance for power players |

| E-Glass Fiberglass | Elasticity, control, wide sweet spot | Players seeking balance of power/control |

| Bamboo Core Composite | Impact resistance, lightweight | Long-lasting play and comfort |

| Honeycomb Core (Nomex/Aluminum/Polymer) | Multi-level shock absorption, reduced vibration | Durability and precision |

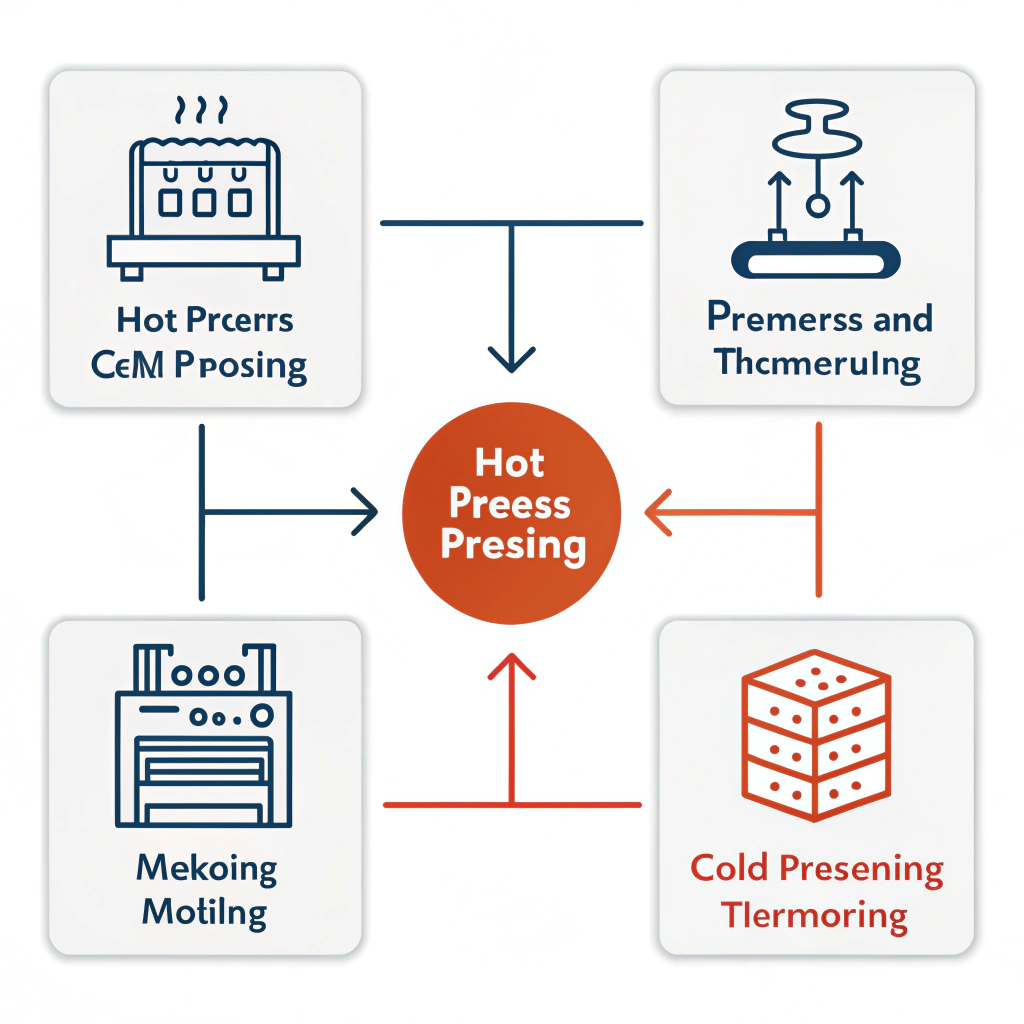

Beyond the material itself, the manufacturing process plays a significant role in defining paddle performance. NEX Pickleball employs three main production processes that are vital in achieving the perfect balance of performance and durability:

Hot pressing involves heating materials while applying pressure. This process is widely used for its production efficiency and for creating paddles characterized by high impact resistance.

- Advantages:

- High production efficiency for large-scale manufacturing.

- Produces paddles with excellent impact resistance and structural integrity.

- Disadvantages:

- High initial investment in equipment.

- Can alter some of the material properties, potentially affecting the paddle’s feel.

Cold pressing shapes materials at room temperature under mechanical pressure, allowing for precise control over paddle thickness and structure. This method retains the natural properties of the material, which is essential for players who trust their paddle for a consistent hitting feel.

- Advantages:

- Enhanced control over paddle thickness and structure.

- Maintains the material’s inherent properties, offering improved ball feel.

- Disadvantages:

- Longer production cycles.

- Requires highly precise pressure control equipment, meaning quality verification is essential.

Thermoforming involves heating the materials to a point where they soften and can be molded into complex shapes using high-precision molds. This process is particularly suited for paddles that incorporate intricate designs with varying thicknesses.

- Advantages:

- Ability to achieve intricate designs and optimal material distribution.

- Improves paddle stability and performance consistency.

- Disadvantages:

- Longer production times and higher equipment costs.

- Best suited for premium or custom-built paddle products.

Each of these processes not only has a role in a product’s final performance but also reflects in the maintenance of ergonomic features such as weight distribution and grip design.

When evaluating high-performance paddles, it is critical to consider the interplay between material compositions and production techniques. Here, we compare typical paddle configurations specifically designed for power players:

| Configuration | Material Focus | Production Process | Key Performance Attributes | Ideal For |

|---|---|---|---|---|

| High Impact Paddle | 12K Carbon Fiber + Nomex Honeycomb | Hot Pressing | Maximum strength, optimal impact resistance, and consistent rebound | Competitive play requiring durability and precision |

| Balanced Control Paddle | T300 Carbon Fiber + Polymer Honeycomb | Cold Pressing | Superior control, enhanced ball feel, and consistent performance | Recreational power players looking for balance |

| Custom-Designed Premium Paddle | Carbon Fiber-Fiberglass Composite | Thermoforming | Customizable design, enhanced ergonomic features, and intricate detailing | High-end markets demanding customization and style |

This table illustrates how combining advanced materials with the right manufacturing process helps manufacturers meet specific market demands. For power players, paddles combining high-density carbon fiber with a shock-absorbing core and produced through a method that enhances material properties, offer the highest competitive advantage.

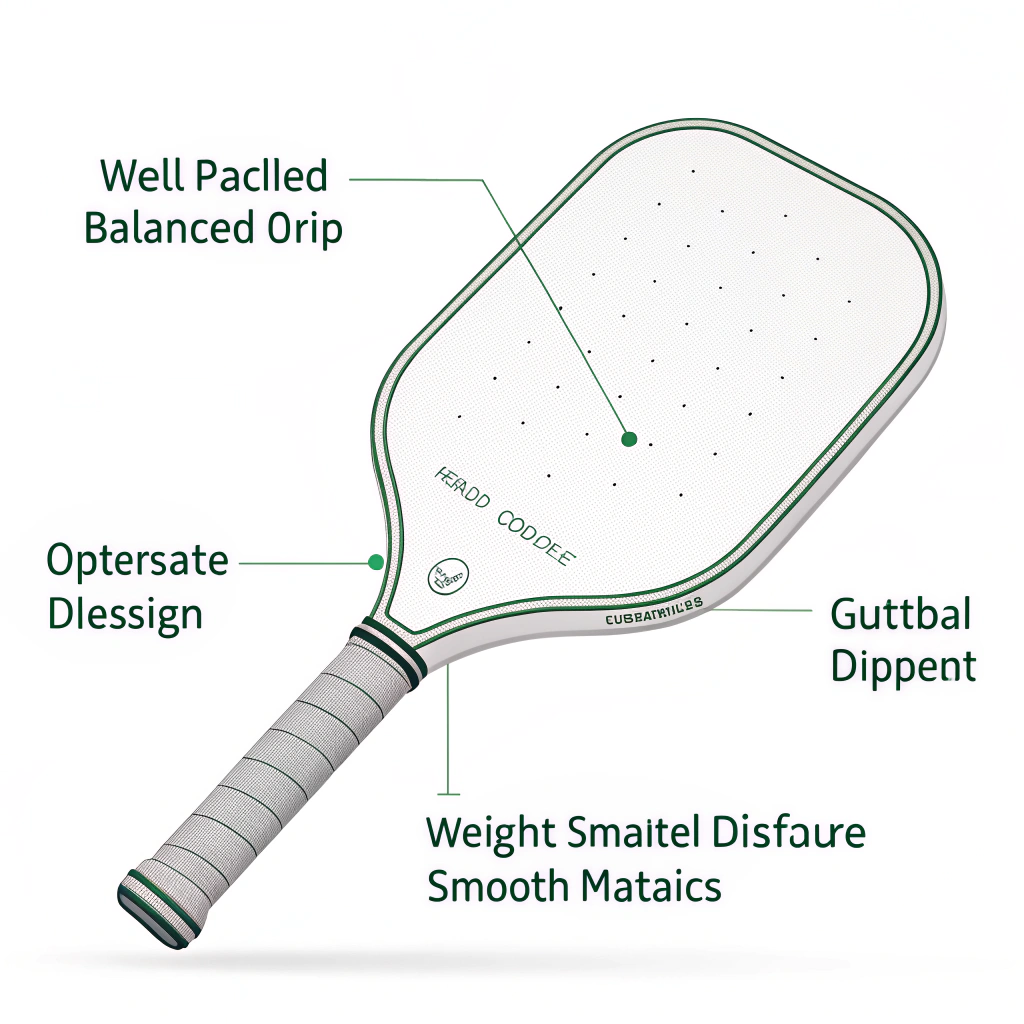

Design precision goes well beyond the lab and production line. The paddle’s ergonomic design defines how well it fits a player’s hand, impacting both performance and comfort. NEX Pickleball pays careful attention to aspects such as:

- Weight Distribution: Ensuring the paddle is not overly head-heavy or handle-heavy.

- Grip Design: Offering multiple grip sizes to match different hand dimensions.

- Surface Treatment: Specially developed textures enhance grip and spin, allowing even power players to produce accurate shots with high speed.

Each paddle is rigorously tested. For example, paddles with a Nomex Honeycomb Core5 are engineered to provide the right balance, absorbing shocks during high-speed rallies while maintaining a crisp hit feel. This meticulous design ensures that even during extended play, the paddle remains comfortable, reducing the risk of strain and providing consistent performance under pressure.

Over the past few years, NEX Pickleball has conducted several in-depth tests on paddle performance under real game conditions. Here are some key findings:

- Durability Testing: Paddles created with 12K Carbon Fiber and hot pressing consistently outperformed those using less intensive manufacturing processes. They showed up to 20% less degradation in rebound force after prolonged use.

- Player Feedback: Surveys indicate that paddles with cold-pressed T300 Carbon Fiber cores were preferred by recreational players for their superior ball control and comfort, despite a marginally lower power output compared to hot-pressed variants.

- Ergonomic Analysis: Custom grips and specially treated paddle surfaces resulted in a 15% increase in shot accuracy, as reported by competitive players during field tests.

These data points support the technical specifications and user testimonials, reaffirming that the right combination of advanced materials and production techniques translates into tangible performance gains.

Based on the above comparative analysis, here are our recommendations for sports equipment distributors, retailers, or product managers:

- Evaluate Market Needs: For high-level competition markets, prioritize paddles built with stronger carbon fibers like 12K Carbon Fiber and produced via hot pressing methods for maximum strength and durability.

- Consider Customization: If targeting a niche that values customization, consider paddles manufactured using thermoforming processes with composite materials. This approach allows for tailored ergonomics and design features that can differentiate your product offering.

- Balance Price and Performance: For broader market appeal, paddles with a balance of T300 Carbon Fiber and polymer honeycomb cores, produced via cold pressing, might be the optimal compromise, offering both high performance and cost-effectiveness.

- Test and Iterate: Leverage in-field tests and player feedback to continually refine paddle designs. Data-driven adjustments can help maintain a competitive edge as market dynamics evolve.

- Focus on Ergonomics: Ensure that the paddle design supports ergonomic comfort, catering to both power and control needs. Offering multiple grip sizes and precise weight distribution can significantly improve market acceptance.

By aligning your product offerings with these recommendations, you can differentiate your inventory and position your brand as a leader in high-performance pickleball equipment.

Q: Why choose advanced materials like carbon fiber for pickleball paddles?

A: Advanced materials such as various types of carbon fiber provide an optimal balance of strength, lightweight performance, and durability. They help in reducing vibration and increasing the paddle’s rebound force, making them ideal for power players in competitive settings.

Q: How does the production technique affect paddle performance?

A: Production techniques like hot pressing, cold pressing, and thermoforming significantly influence the paddle’s structural integrity, feel, and overall performance. For example, hot pressing enhances impact resistance while cold pressing maintains precise control over material properties, ensuring a well-balanced paddle.

Q: What are the benefits of using a Nomex honeycomb core in pickleball paddles?

A: A Nomex honeycomb core provides excellent shock absorption and stability, which minimizes vibration and enhances durability. This results in a paddle that remains consistent in performance over prolonged play, especially important for competitive or power-oriented players.

-

Advanced Materials: Learn how cutting-edge materials drive performance improvements by offering superior strength, durability, and lightweight properties essential for high-performance paddles. ↩ ↩ ↩2

-

Precision Manufacturing Processes: Discover how precise production techniques optimize paddle design and quality, ensuring consistent performance and enhanced market competitiveness. ↩ ↩

-

E-Glass Fiberglass: See how E-Glass Fiberglass offers excellent elasticity and control, providing an ideal balance between power and precision for players seeking improved playability. ↩ ↩

-

Thermoforming: Explore how thermoforming allows for intricate paddle designs with optimal material distribution, enhancing both aesthetic appeal and functional performance. ↩ ↩

-

Nomex Honeycomb Core: Understand how this innovative core technology improves shock absorption and stability, resulting in a paddle that offers reduced vibration and increased durability during rigorous play. ↩ ↩