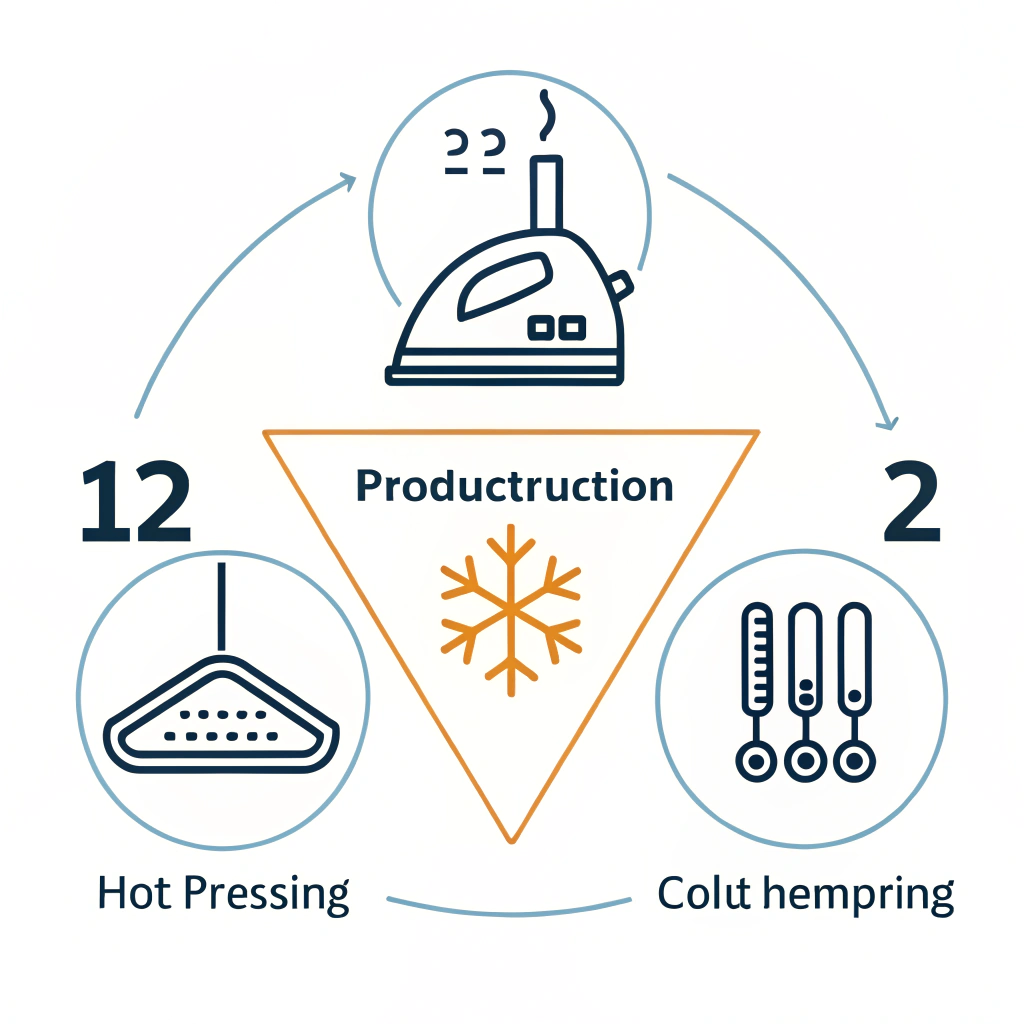

Pickleball paddles are produced using advanced processes like hot pressing1, cold pressing2, and thermoforming3 – each selected for specific performance, durability, and quality benefits that enhance the overall play experience.

Understanding the production methods behind pickleball paddles is essential for procurement and product development managers seeking reliable, high-performance sports equipment. In this article, we will discuss the challenges of paddle manufacturing, analyze key production processes, compare materials, and provide actionable insights to help you make well-informed decisions when selecting a manufacturing partner.

In the competitive world of pickleball, equipment quality can directly impact performance on the court. However, not all paddle manufacturers can maintain consistent quality, precision, or durability in their production processes. As a procurement manager, you may face challenges such as:

• Ensuring that the chosen production process delivers the desired playing characteristics.

• Finding a manufacturer with detailed quality control and testing standards.

• Balancing cost, production efficiency, and performance parameters.

Manufacturing consistency becomes particularly crucial when dealing with premium materials like carbon fiber4 and fiberglass5, or when employing critical methods such as hot pressing, cold pressing, and thermoforming. Each process comes with its specific set of advantages and limitations that directly influence the final product performance.

Various factors can affect the performance and durability of pickleball paddles. The key elements include:

-

Material Properties:

The intrinsic properties of base materials such as carbon fiber (3K, 12K, T300), fiberglass types like E-Glass, and composite combinations dictate the paddle's strength, flexibility, and overall feel. Different core compositions like Nomex, aluminum, or polymer honeycomb each offer unique benefits in weight, shock absorption, and responsiveness. -

Manufacturing Processes:

The choice of manufacturing techniques (hot pressing, cold pressing, thermoforming) determines the paddle’s structural integrity and production efficiency. A mismatch between material properties and production method can degrade the paddle’s performance. -

Quality Control:

Inconsistent quality control can lead to variations in paddle performance. Each paddle must undergo rigorous testing to ensure that it meets the highest standards – a critical requirement for B2B buyers looking to serve professional athletes or competitive sports facilities. -

Customization and Flexibility:

With increasing demand for custom paddle options (ranging in grip size, weight distribution, and design), manufacturers must have adaptable production environments without sacrificing product precision.

To address these challenges, high-performance pickleball paddles are typically produced using three main manufacturing processes. Below is a detailed comparison:

| Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | • High production efficiency; strong, durable paddles • Excellent impact resistance • Ensures structural integrity for high-performance play | • May alter material properties • Requires high investment in equipment | Mass production, competitive-grade paddles |

| Cold Pressing | • Precise control over paddle thickness • Maintains material integrity for better control and flexibility • Provides superior ball feel | • Longer production cycles • Demands high-quality pressure control equipment | Custom designs, paddles prioritizing precision |

| Thermoforming | • Capable of creating intricate designs • Optimal material distribution • Enhances paddle stability | • Longer production times • Higher equipment costs and complexity in manufacturing processes | Premium, custom-made paddles with complex shapes |

Each process requires a careful balance between production efficiency and the desired tactile and performance characteristics of the final product.

Carbon fiber is a popular choice in high-performance paddle manufacturing due to its superior strength and lightweight properties. Manufacturers typically use:

-

3K Carbon Fiber:

Known for its strength and flexibility, this variant is excellent for paddles that need a high rebound force. It reduces vibration and enhances overall durability. -

12K Carbon Fiber:

With a higher thread density, it provides a smoother surface and greater hardness. Ideal for competitive play where impact resistance is crucial. -

T300 Carbon Fiber:

Offers a balanced combination of tensile strength and low weight, making it perfect for paddles requiring both power and control.

Choosing the right type of carbon fiber depends on the specific performance requirements of the paddle, whether for high-speed competitive play or improved vibrational damping for recreational use.

Fiberglass paddles, specifically those made from E-Glass, provide a wide sweet spot and enhanced control. They are more flexible than carbon fiber, lending themselves well to players who prioritize ball control and finesse over sheer power.

Composite materials, such as a blend of carbon fiber and fiberglass, or innovative solutions like bamboo core composite, cater to a broader range of performance needs. They combine the benefits by enhancing strength, reducing weight, and providing sufficient flexibility.

The core of the paddle is a critical component that influences weight and impact sensitivity. Common core materials include:

-

Nomex Honeycomb Core:

Made from a durable polymer, it is valued for its excellent shock absorption and stability, making it suitable for competitive play. -

Aluminum Honeycomb Core:

Balances weight and power, ensuring that paddles offer the necessary strength and precise control. -

Polymer Honeycomb Core:

Provides superior elasticity and substantially reduces vibration, making it an excellent choice for players who require a comfortable hitting experience.

Manufacturers often combine advanced cores with premium face materials to achieve the best balance of power, control, and comfort.

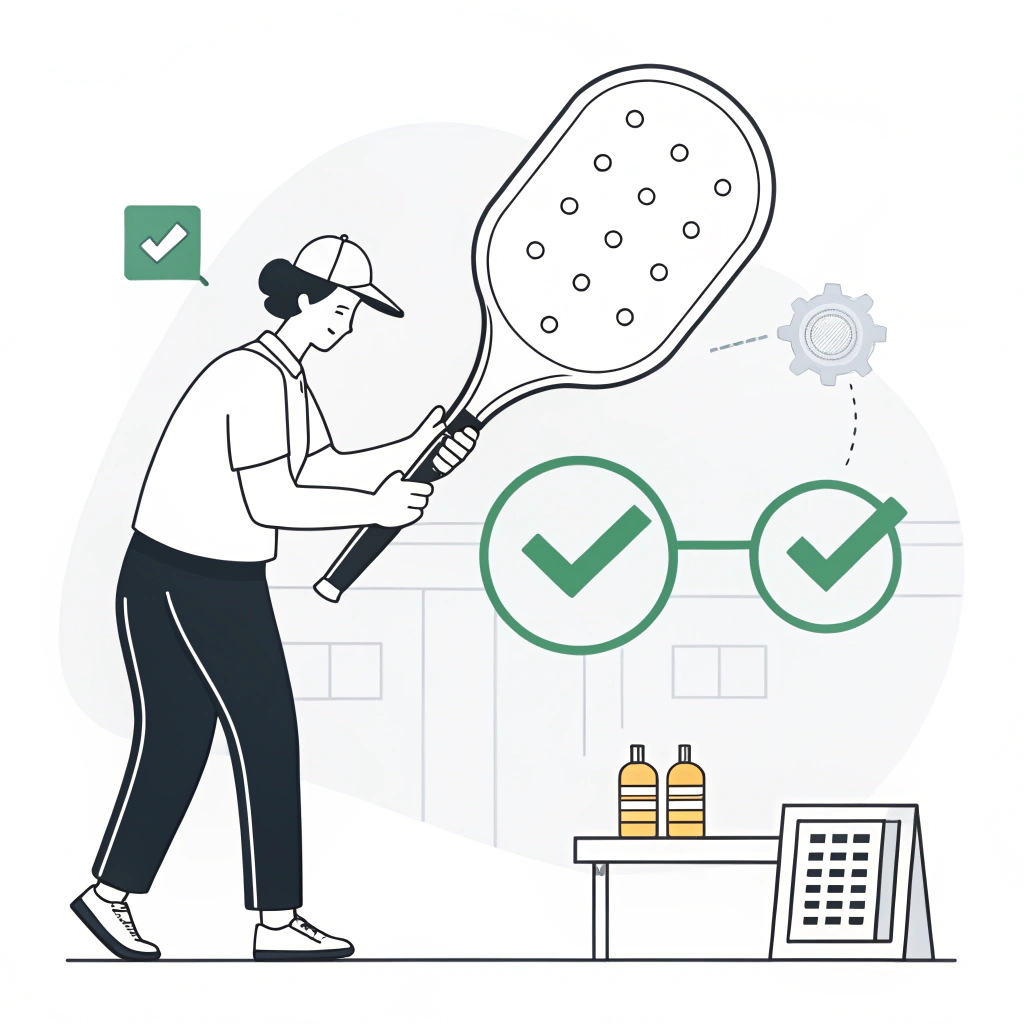

In industries where performance is critical, quality control is the backbone of the manufacturing process. At NEX Pickleball, robust quality assurance methods ensure that every paddle is crafted to meet stringent performance standards. These include:

-

Rigorous Testing:

Each paddle is subjected to tests measuring strength, flexibility, and ball response to ensure consistency across batches. -

Material Inspection:

The raw materials – be it carbon fiber, fiberglass, or composite blends – are carefully vetted for quality and performance parameters before entering the production line. -

Process Monitoring:

During the manufacturing phases, especially in processes like thermoforming and cold pressing, precise control over temperature, pressure, and material distribution is essential. This ensures that the final product not only meets but exceeds industry standards. -

Customization Options:

For clients looking for tailored solutions, custom paddle manufacturing processes are available. Whether it’s a specific grip size or a modified weight distribution, the production line is designed for flexibility without compromising performance.

Consider a sports equipment distributor who aimed to enhance the competitive quality of their pickleball paddles. They faced challenges with inconsistent ball response and paddle durability. By collaborating with a manufacturer utilizing a mix of hot pressing and thermoforming, the outcomes were dramatic:

-

Enhanced Paddle Strength:

The hot pressing method contributed to improved structural integrity through high-pressure molding, resulting in paddles that consistently delivered greater impact resistance. -

Improved Control and Feel:

The thermoforming process allowed for intricate design adjustments, ensuring a more controlled material distribution. This directly translated into a paddle with superior control and user comfort. -

Flexible Production Capabilities:

By integrating cold pressing for custom batches, the distributor was able to offer paddles tailored to the preferences of different market segments, ranging from amateur to professional competitive play.

These improvements not only enhanced the performance of the paddles but also contributed to a reduction in post-production defects and overall production costs. This case study underlines the importance of matching the right production technique with material characteristics and desired paddle performance.

For businesses looking to source high-performance pickleball paddles, here are several recommendations:

-

Evaluate Production Methods:

Ensure that your manufacturing partner clearly explains their production techniques, quality control routines, and customization options. Understanding processes like hot pressing, cold pressing, and thermoforming can provide insight into the paddle’s final performance. -

Assess Material Quality:

Inquire about the types of carbon fiber, fiberglass, and composite materials used in production. Reliable suppliers will offer detailed technical specifications that demonstrate how their materials contribute to paddle durability and performance. -

Prioritize Quality Assurance:

Look for a supplier with comprehensive testing procedures. Regular quality assessments and adherence to performance benchmarks help guarantee consistent product quality. -

Consider Customization Needs:

If your client or end-user requires specific paddle characteristics, a manufacturing partner capable of custom paddle production provides significant competitive advantage. Specifications like grip size, weight, and balance should be adaptable to different playing styles. -

Review Case Studies and References:

Request case studies or references that demonstrate how the manufacturer has optimized production techniques to meet specific performance criteria. Real-world examples can offer valuable insights into the manufacturer’s reliability and commitment to quality.

In conclusion, understanding and leveraging the advanced manufacturing processes behind pickleball paddles can transform the way your business approaches product quality and innovation. By ensuring that your manufacturing partner employs proven techniques, adheres to rigorous quality standards, and offers customization flexibility, you set a strong foundation for competitive differentiation in the sports equipment market.

Q: What are the main manufacturing processes used in pickleball paddle production?

A: The primary manufacturing methods include hot pressing, cold pressing, and thermoforming. Each process offers distinct advantages in terms of production efficiency, precision, and durability, ensuring high-performance paddles.

Q: How does hot pressing differ from cold pressing in paddle production?

A: Hot pressing uses heat and pressure to form a strong, durable paddle, making it ideal for mass production, whereas cold pressing shapes the paddle at room temperature, preserving material properties and ensuring precise control for custom designs.

Q: What materials contribute most to the durability and performance of pickleball paddles?

A: High-performance paddles typically incorporate premium materials such as various types of carbon fiber (3K, 12K, T300), fiberglass, and advanced composite materials combined with specialized cores like Nomex, aluminum, or polymer honeycomb for optimal shock absorption and balance.

-

hot pressing: This article explains how the hot pressing process uses heat and pressure to mold materials, enhancing durability and structural integrity in paddle manufacturing. Go back ↩

-

cold pressing: This article details the cold pressing method, which preserves material properties through precise pressure control, ideal for custom paddle designs. Go back ↩

-

thermoforming: This article explores the thermoforming process that uses heat to form intricate paddle shapes while ensuring a balanced material distribution. Go back ↩

-

carbon fiber: This article provides insights into carbon fiber types and their benefits, including strength, lightweight properties, and performance enhancements in sports equipment. Go back ↩

-

fiberglass: This article explains the properties of fiberglass, highlighting its flexibility and control benefits in composite paddle construction. Go back ↩