Competitive pickleball paddles must strike a delicate balance between power, control, and durability. To decide on the best option, procurement managers need to compare materials and manufacturing processes carefully. This article provides a detailed, side-by-side comparison, helping you make an informed bulk buying decision that aligns with your product portfolio and market demands.

When evaluating high-performance pickleball paddles, the main decision factors are the materials used and the manufacturing processes. Today’s competitive paddles largely rely on advanced materials like various types of carbon fiber1, fiberglass, and innovative composites. In addition, production techniques such as hot pressing, cold pressing, and thermoforming have a significant impact on the paddle’s final performance. Let’s dive into these aspects to help you navigate your choices.

High-performance paddles are made using premium materials that cater to different performance requirements. In this section, we explain the advantages and limitations of various materials.

Carbon fiber is a popular choice due to its strength and light weight. Different carbon fiber types offer unique performance attributes:

- 3K Carbon Fiber: Known for its strength and flexibility, providing a high rebound force ideal for paddles requiring a strong impact response. It also minimizes vibration, contributing to better control during play.

- 12K Carbon Fiber: This variety has a higher thread density, resulting in a smoother surface. It delivers superior hardness and improved durability, which is crucial for competitive play under high stress.

- T300 Carbon Fiber: Recognized for its outstanding tensile strength and balanced performance, T300 offers an excellent mix of power and control while maintaining a low weight.

Each of these options meets different competitive needs. For instance, 3K is often chosen for overall durability and vibration reduction, while 12K is preferred in tournaments where high impact resistance is required.

Fiberglass provides an excellent balance between power and control. Paddles constructed with E-Glass Fiberglass offer increased elasticity and ball control, making them appropriate for players who value a larger sweet spot and enhanced playability. Its flexibility compared to carbon fiber also results in a unique feel while striking the ball.

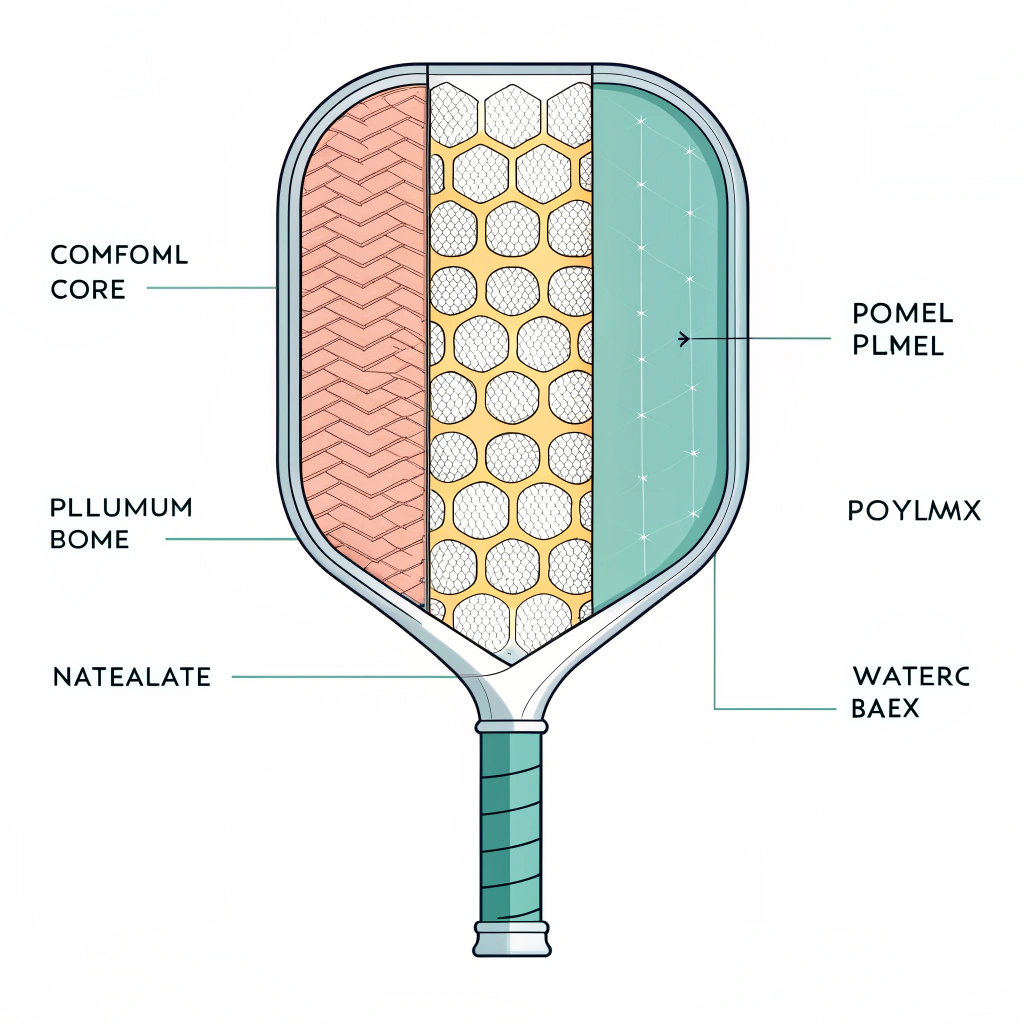

To integrate the benefits of multiple materials, many paddles employ composite technologies2:

- Carbon Fiber and Fiberglass Composite: By merging the strength of carbon fiber with the ball control of fiberglass, this composite is suited for players seeking both power and precise control.

- Bamboo Core Composite: Bamboo cores yield lightweight paddles with notable impact resistance and a crisp hitting feel, particularly appealing to long-duration play.

- Honeycomb Core: Constructed from high-density polymers, these cores provide excellent shock absorption while reducing vibration. This feature is beneficial for both competitive and recreational players alike.

Utilizing composites allows manufacturers to optimize performance characteristics in ways that single materials cannot, delivering paddles that adapt to diverse play styles.

A paddle’s performance is also heavily influenced by its core material. The core not only affects the paddle’s weight but also its control, ball feel, and durability.

- Nomex Honeycomb Core3: This durable polymer core offers high shock absorption, making it ideal for players who demand stability and longevity.

- Aluminum Honeycomb Core: Known for providing a balanced mix of weight, power, and control, aluminum cores are suitable for players who want precision combined with strength.

- Polymer Honeycomb Core: With its superior elasticity and vibration reduction properties, the polymer core is especially appealing to recreational players and those prioritizing a softer impact feel.

Manufacturers like NEX Pickleball optimize these core materials to enhance the overall paddle performance. For distributors and product strategists, understanding these differences is critical when selecting paddles for various competitive segments.

The manufacturing process plays a critical role in a paddle's performance characteristics. Let’s review the three main production methods and compare their benefits and limitations.

In the hot pressing process, materials are heated and compressed simultaneously.

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Results in strong, durable paddles with excellent impact resistance.

- Ensures structural integrity, making the paddles fit for high-performance play.

Limitations:

- Elevated temperatures may alter some material properties, potentially affecting the paddle’s touch.

- High capital investment is required for specialized equipment.

The cold pressing4 method uses mechanical pressure at room temperature. This technique is ideal for maintaining material properties and offers:

Advantages:

- Precise control over the paddle thickness and overall structure.

- Maintains inherent material qualities, leading to improved ball feel and responsiveness.

Limitations:

- Production cycles are generally longer, affecting overall efficiency.

- Requires precision equipment to ensure consistent pressure levels.

Thermoforming5 involves heating the material to a softening point and then molding it into shape with precision:

Advantages:

- Allows the creation of paddles with intricate designs and precise material distribution.

- Contributes to a stable paddle structure, enhancing overall performance.

- Well-suited for premium products or custom paddle designs.

Limitations:

- Longer production times and higher equipment costs compared to other methods.

- Typically reserved for high-performance paddles due to increased production expenses.

To summarize these processes, consider the following comparison table:

| Production Process | Advantages | Limitations | Best Application |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structure, impact resistance | May alter material feel, costly equipment | Mass production and competitive play paddles |

| Cold Pressing | Precise control, maintains material properties, excellent responsiveness | Longer cycle times, requires precision equipment | Paddles requiring superior ball control and texture |

| Thermoforming | Intricate design capability, uniform material distribution, enhanced stability | Extended production time, high equipment costs | Custom and high-end competitive paddles |

This table illustrates that each technique has distinct features that manufacturers can leverage depending on production volume, desired paddle characteristics, and market positioning.

For purchasing managers and sports equipment distributors, the key takeaway is clear: different paddle compositions and production methods cater to distinct segments of the pickleball market. Here are three strategic insights to guide your procurement:

-

Align with Target Customers:

- For high-level competitive tournaments, paddles made with 12K Carbon Fiber or Nomex Honeycomb Cores3 offer the durability and performance required in rigorous play.

- If your customers demand a softer touch or enhanced control, paddles featuring E-Glass Fiberglass or Polymer Honeycomb Cores may better suit their needs.

-

Consider Production Scalability vs. Customization:

- Manufacturers using hot pressing can supply large orders quickly, making them ideal for large retailers targeting competitive segments.

- If customization is a key differentiator for your business, paddles produced via thermoforming5 might be a better investment, as they allow tailored designs and precise material distributions.

-

Assess Long-Term Value and Performance Stability:

- While advanced composites and cutting-edge production processes often come with a premium cost, the long-term benefits of reduced vibration, improved durability, and enhanced user comfort can justify the initial investment.

- Pay close attention to data on material performance and reliability. Suppliers with transparent quality control processes, like NEX Pickleball, offer a strategic advantage through consistent performance testing and robust after-sales support.

For decision-makers, ensuring that your product portfolio matches the latest market trends in competitive pickleball is crucial. In today’s dynamic market, combining innovative materials with advanced production techniques not only enhances player performance but also strengthens your competitive positioning in a rapidly growing sport.

The comparative insights and detailed breakdown provided in this article should help you confidently navigate the competitive landscape of pickleball equipment. Remember, every purchase decision should consider long-term value, customer satisfaction, and the potential for future innovation in paddle design.

People Also Ask

• How do different carbon fiber types affect paddle performance?

Carbon fiber variants, such as 3K, 12K, and T300, offer varying levels of strength, flexibility, and surface smoothness. For instance, 3K carbon provides excellent durability and low vibration, while 12K carbon delivers superior hardness and a smoother finish, enhancing paddle performance in competitive play.

• What are the advantages of using fiberglass in pickleball paddles?

Fiberglass provides a balanced combination of power and control. Its elasticity and larger sweet spot make it ideal for players seeking enhanced ball control without sacrificing durability. This material is especially appealing to those looking for a softer, more forgiving hit.

• How does the production process influence a paddle’s overall performance?

The production process—whether it is hot pressing, cold pressing, or thermoforming—directly impacts the paddle’s structural integrity, material properties, and overall feel. Hot pressing offers high efficiency and strong construction, cold pressing maintains material integrity for better control, and thermoforming allows for intricate design customization, all of which affect performance outcomes.

-

Carbon fiber: Click to learn how different carbon fiber variants enhance product performance through lightweight strength and vibration damping, critical for advanced manufacturing decisions. ↩ ↩

-

Composite technologies: Click to explore articles on how blending materials creates composites with optimized performance, offering insights into material innovation and application in B2B product development. ↩ ↩

-

Nomex Honeycomb Core: Click to read about the benefits and applications of Nomex honeycomb cores, including detailed performance analyses and long-term value for high-quality sports equipment. ↩ ↩ ↩2

-

Cold pressing: Click to understand the cold pressing process, its advantages in preserving material properties, and its relevance in producing high-precision components for competitive products. ↩ ↩

-

Thermoforming: Click to dive into the thermoforming process and its capability for intricate design and precise material distribution, essential for creating premium, customizable products. ↩ ↩ ↩2