Lightweight pickleball paddles offer enhanced agility and maneuverability while reducing player fatigue, making them a smart investment for distributors seeking high-performance sports equipment.

In today’s competitive sports equipment market, a lightweight paddle doesn’t just reduce weight—it transforms performance, durability, and production efficiency. For procurement managers and product development specialists striving to offer state-of-the-art gear, understanding what makes a lightweight paddle truly effective is crucial. In this article, we compare various material technologies, analyze production processes, and offer a decision-making guide tailored for B2B buyers of high-performance sports equipment.

A lightweight paddle is more than just a reduction in weight. It contributes to:

- Enhanced agility and maneuverability: Quick responses with less effort, which is especially important in fast-paced play.

- Improved ball control: Reduced paddle weight can enable finer adjustments during play, leading to more accurate shots.

- Reduced player fatigue: A lighter paddle requires less energy to swing, which means players can maintain a high level of performance over prolonged sessions.

- Better shock absorption and vibration control: Integrating advanced materials such as carbon fiber1, fiberglass, and composite cores ensures that the paddle not only feels light but also absorbs impact efficiently.

These benefits are fundamental when selecting a paddle for competitive play and retail inventory. Distributors and retailers can use these insights to source products that address players’ needs for both performance and comfort.

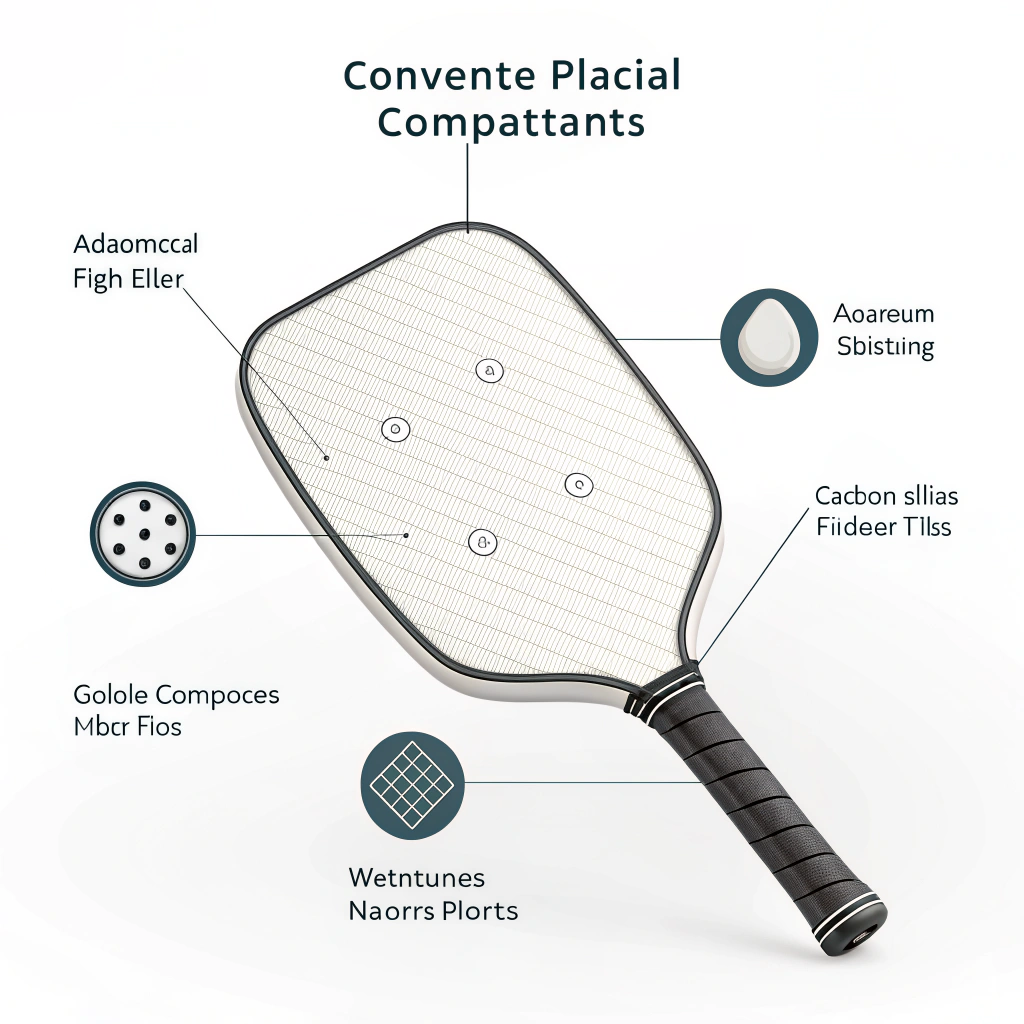

Choosing the right material is at the heart of producing a lightweight paddle that does not compromise on strength or durability. Let’s explore the primary materials used and their respective benefits:

- 3K Carbon Fiber: Known for its excellent strength and flexibility. It provides high rebound force, making it great for power players while reducing vibration.

- 12K Carbon Fiber: Offers smoother surfaces due to its higher thread density, delivering improved hardness and impact resistance.

- T300 Carbon Fiber: Balances strength and light weight, offering superior tensile strength for a stable yet agile paddle.

Each of these variants contributes to a lightweight paddle that maintains its structural integrity under high-performance conditions.

- E-Glass Fiberglass: Provides an expansive sweet spot due to its elasticity. Although fiberglass is inherently more flexible than carbon fiber, its enhanced ball control and vibrational damping make it a suitable choice for both recreational and competitive players.

- Composite Combinations: By merging carbon fiber and fiberglass, manufacturers can achieve a well-balanced solution that offers both power and control.

- Bamboo Core Composite: Adds an element of eco-friendliness while delivering a clear hitting feel and remarkable impact resistance.

- **Honeycomb Core2 Variants (Nomex, Aluminum, Polymer): These cores are designed to absorb shock and reduce vibration while preserving the paddle’s lightweight nature. For instance:

- Nomex Honeycomb Core: Prioritizes durability and impact absorption.

- Aluminum Honeycomb Core: Strikes a balance between power and control.

- Polymer Honeycomb Core: Focuses on reducing vibration and improving player comfort.

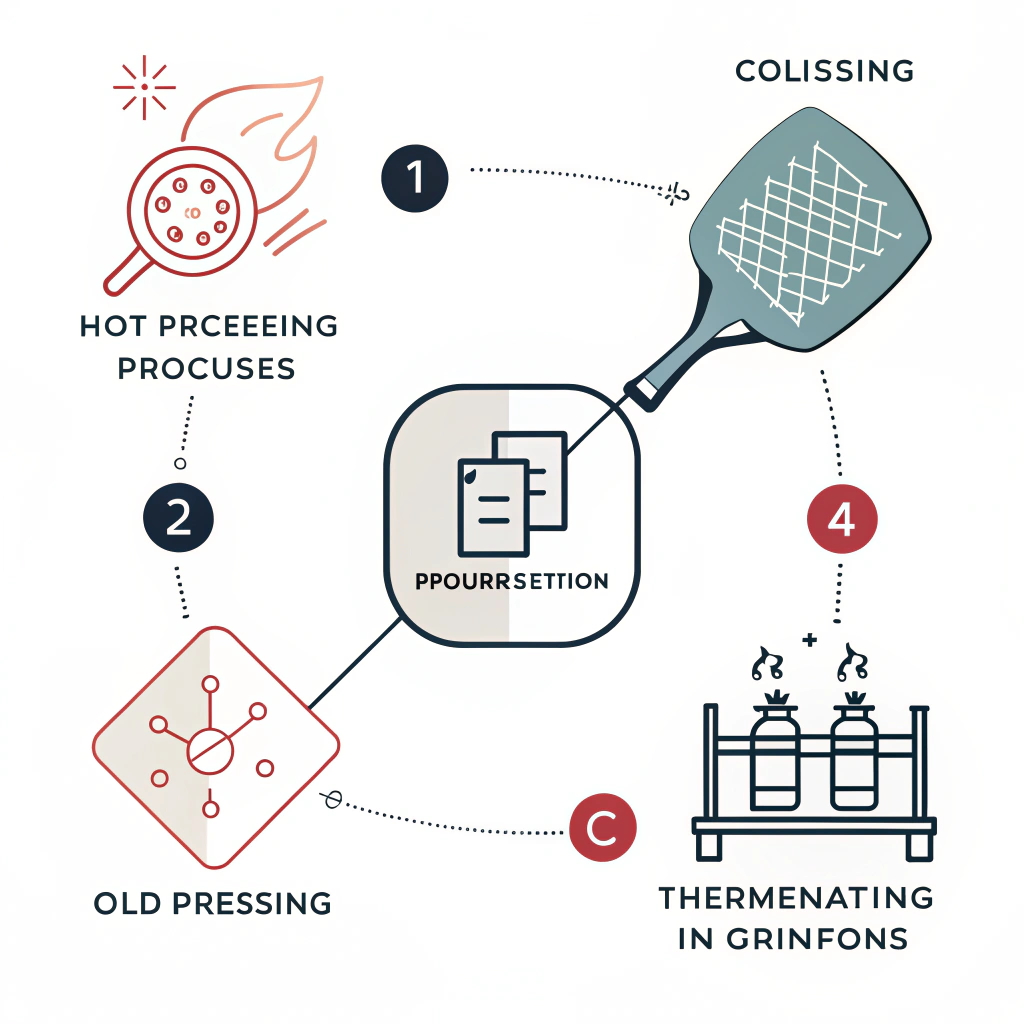

The production process is a critical factor in ensuring that a lightweight paddle meets performance expectations. NEX Pickleball employs advanced methods to craft paddles that are both high-performance and cost-effective. Let’s delve into the three main production techniques:

Hot pressing involves heating materials under pressure to achieve remarkable impact resistance and structural stability.

Advantages:

- High production efficiency, ideal for scalable manufacturing.

- Produces paddles with superior strength to withstand intense gameplay.

- Ensures a robust structure suitable for high-performance play.

Disadvantages:

- The high temperatures involved may slightly alter material properties, potentially affecting the tactile feel of the paddle.

- Requires significant upfront investment in specialized equipment.

Cold pressing utilizes mechanical pressure at room temperature, preserving the intrinsic properties of the raw materials for precise control.

Advantages:

- Maintains the natural properties of materials, resulting in a paddle with excellent ball feel.

- Allows for fine-tuned adjustments in thickness and balance.

- Delivers a lightweight design without sacrificing material integrity.

Disadvantages:

- Production cycles are longer, which might affect overall output efficiency.

- Demands high-quality control to ensure pressure consistency throughout production.

Thermoforming softens the materials by heating them to a pliable state before molding them into intricate paddle shapes.

Advantages:

- Allows for highly detailed designs that distribute material evenly.

- Maintains paddle stability and enhances performance with optimized material distribution.

- Suitable for both high-performance and custom paddle designs.

Disadvantages:

- Leads to longer production times and higher equipment costs.

- Best suited for premium projects, potentially increasing the final product cost.

The choice of manufacturing process plays a pivotal role in balancing production efficiency with the high standards demanded by B2B clients.

A well-informed purchasing decision for lightweight pickleball paddles requires a detailed comparison of performance parameters. Below is a table comparing key aspects of different core materials and their production methods:

| Feature | 3K Carbon Fiber | 12K Carbon Fiber | Fiberglass (E-Glass) | Bamboo Core Composite | Polymer Honeycomb Core |

|---|---|---|---|---|---|

| Weight | Very Light | Light | Moderate | Light | Very Light |

| Strength & Flexibility | High strength & flex | Superior hardness | Elastic, good control | High impact resistance | Excellent shock absorption |

| Vibration Damping | Good vibration control | Superior damping | Moderate damping | Clear hitting feel | Best for reducing vibrations |

| Production Efficiency | Suitable for hot pressing | Suitable for hot/cold pressing | Best with cold pressing | Custom composite process | Often paired with cold pressing |

| Cost-Effectiveness | Moderate | Slightly higher | Highly cost-effective | Varies based on composition | Cost-effective for mass production |

This table is designed for quick reference, helping procurement professionals assess which material and production process best aligns with their performance needs and budget constraints.

For B2B stakeholders, several key points must be considered when investing in lightweight paddles:

-

Enhanced On-Court Performance:

Lightweight paddles, due to their reduced mass, enable faster swings and precise ball placement. This gives players a competitive edge during high-speed rallies and extended gameplay. -

Production and Cost Efficiency:

Advanced production processes such as cold pressing and thermoforming not only preserve the material’s quality but also lead to streamlined manufacturing—a vital factor when large volumes are required. By choosing the appropriate process, businesses can optimize cost-effectiveness without compromising durability. -

Customization and Market Differentiation:

With options like custom paddle designs and varying grip sizes, companies can cater to niche market segments. Tailored features, ranging from ergonomic grips to specialized surface textures, help distributors stand out in crowded markets. -

Quality Assurance Through Rigorous Testing:

At NEX Pickleball, every paddle undergoes stringent quality control to ensure that it meets the highest standards in durability, performance, and consistency. This commitment to quality minimizes risks and supports long-term customer satisfaction.

For procurement managers seeking to update or expand their product lines, the following steps are recommended:

- Assess Consumer Needs: Understand the primary demands of your target market. Lightweight paddles are ideal for dynamic play and cater to competitive as well as recreational segments.

- Evaluate Material Options: Use the comparison table as a guideline to match core material benefits with your customers’ expectations. Consider whether the performance benefits of high-end carbon fiber outweigh its cost relative to fiberglass or composite options.

- Consider Manufacturing Processes: Balance the need for swift production with the quality of the finished product. If maintaining the natural feel of materials is critical, lean towards cold pressing or a hybrid approach.

- Pilot Small Batches: Before placing large orders, consider running a pilot study with a select group of players to gauge performance feedback. This real-world input can be critical in making final procurement decisions.

- Leverage Customization: Use on-demand printing and other customization services to differentiate your product offerings. This not only enhances brand identity but also meets the diverse needs of your clientele.

In conclusion, lightweight pickleball paddles combine advanced material science with innovative manufacturing processes to deliver superior performance. Distributors and retailers can benefit enormously from paddles that not only offer improved agility and reduced fatigue but also maximize cost-effectiveness through efficient production. By understanding the trade-offs and benefits laid out here, decision-makers can confidently select the right paddle solution that meets both market demands and performance standards.

Q: What are the benefits of a lightweight pickleball paddle for performance?

A: Lightweight pickleball paddles improve agility, enhance ball control, and reduce player fatigue. They allow for quicker swings and more precise movements, which are essential in competitive play.

Q: How do different materials influence the paddle's performance and durability?

A: The choice of materials—such as various types of carbon fiber, fiberglass, and composite cores—affects the paddle’s strength, vibration damping, and overall durability. Higher thread density carbon fibers and advanced composites contribute to a balance of power, control, and longevity.

Q: How do manufacturing processes impact the quality and efficiency of lightweight paddles?

A: Advanced techniques like hot pressing, cold pressing, and thermoforming directly shape the paddle's performance. Each method offers unique benefits—whether it’s production speed, material preservation, or design precision—which ultimately influence the paddle's quality and cost-effectiveness.

-

Carbon Fiber: Click to read an article detailing the manufacturing, benefits, and advanced applications of carbon fiber in high-performance sports equipment. Back to text ↩

-

Honeycomb Core: Click to explore honeycomb core technologies, their benefits in shock absorption and vibration control, and their application in lightweight paddle design. Back to text ↩

-

Hot Pressing: Click to learn about how hot pressing works, its advantages in production efficiency, and its impact on material properties in sports equipment manufacturing. Back to text ↩

-

Cold Pressing: Click to discover the cold pressing process, including its role in preserving material integrity and producing high-quality sports gear. Back to text ↩

-

Thermoforming: Click to understand thermoforming, its process steps, and how it enables intricate design and balanced material distribution for premium products. Back to text ↩