The best choice for high-performance pickleball paddles is a composite core1 solution that delivers superior shock absorption, optimal weight distribution, and enhanced durability compared to traditional core materials.

In modern paddle manufacturing, selecting the correct core material is crucial to enhance performance and durability while meeting cost and production efficiency goals. For decision-makers evaluating manufacturing options, composite core technology offers the perfect balance between strength, playability, and longevity. In this article, we will break down the technical and practical benefits of composite cores compared to traditional cores, and we will examine how different production processes (hot pressing, cold pressing, and thermoforming) impact paddle performance.

When evaluating manufacturing options, product managers and procurement specialists face a common dilemma: how to combine cost efficiency with superior product performance. Traditional core choices, such as Nomex2, aluminum, or polymer honeycomb, offer specific advantages but often fall short when it comes to balancing shock absorption, precision engineering, and overall durability. Composite core technology addresses these issues by merging the best properties of various materials into a single, high-performance solution.

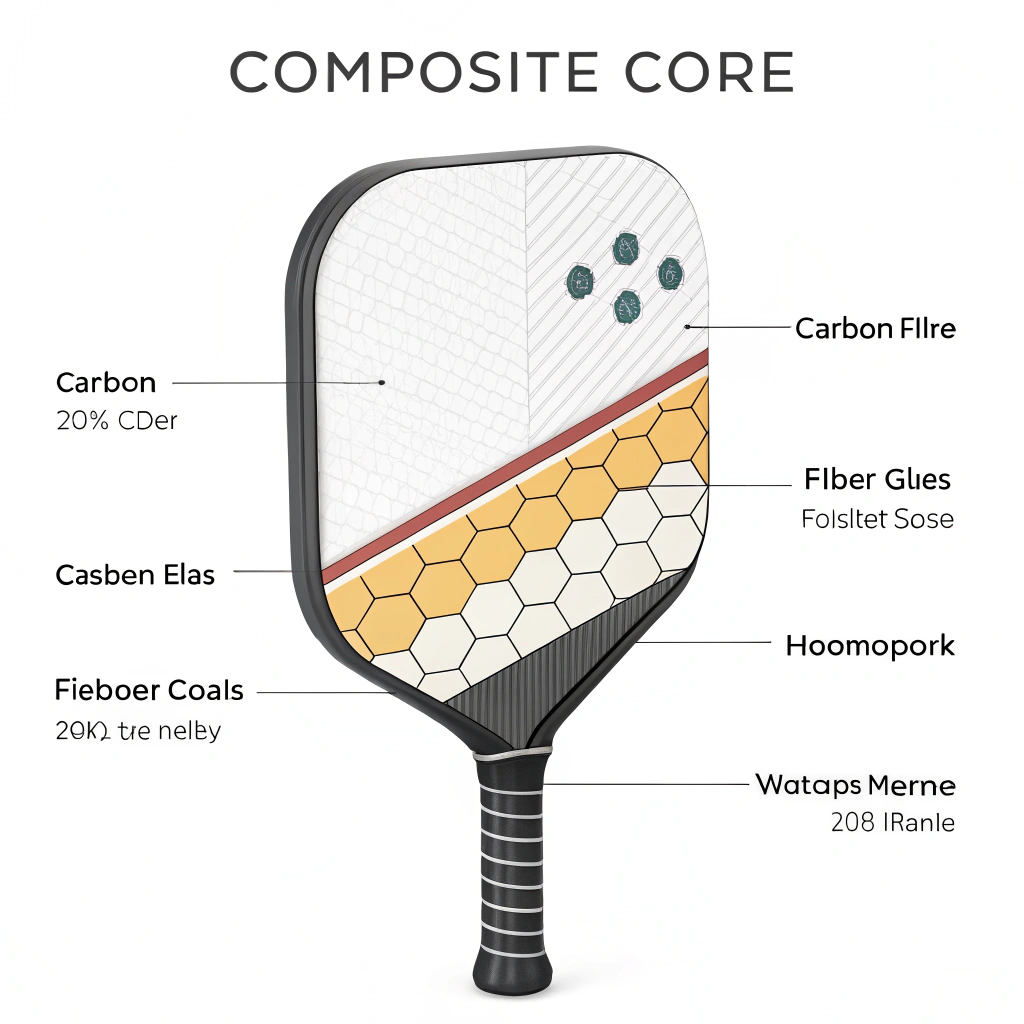

Composite cores typically blend materials like carbon fiber with advanced substrates (fiberglass, bamboo, or honeycomb structures) to create paddles that maintain a high level of performance during rapid gameplay. This approach not only elevates the playability of the paddle but also improves stability, resulting in less vibration and a more responsive hitting experience.

To help clarify the differences for B2B decision-makers, consider the following table that outlines key performance factors associated with different core technologies:

| Feature | Composite Core | Nomex Honeycomb Core | Aluminum Honeycomb Core | Polymer Honeycomb Core |

|---|---|---|---|---|

| Shock Absorption | Excellent – blends multiple materials for superior damping | Good – offers stable impact absorption | Moderate – balances power and precision | Good – provides elasticity and reduces vibration |

| Weight Distribution | Optimized – ensures balanced feel and control | Consistent – reliable but lacks fine-tuning | Precision – supports power with balanced weight | Light – enhances comfort for longer gameplay |

| Durability | High – combines strength with innovative materials | High – proven in extreme conditions | Moderate – good but can fatigue over time | Moderate – ideal for recreational use |

| Production Complexity | Higher – requires synchronizing multiple materials | Lower – established process | Moderate – requires careful quality control | Lower – simple and fast production cycles |

| Customization Options | Extensive – adaptable to various performance needs | Limited – standard industrial applications | Limited – best for predefined performance ranges | Extensive – suitable for entry-level and customized designs |

This table illustrates that while traditional cores are sufficient for many purposes, composite cores offer a unique blend of performance traits that can be tailored to meet the demanding needs of competitive and upscale paddle lines.

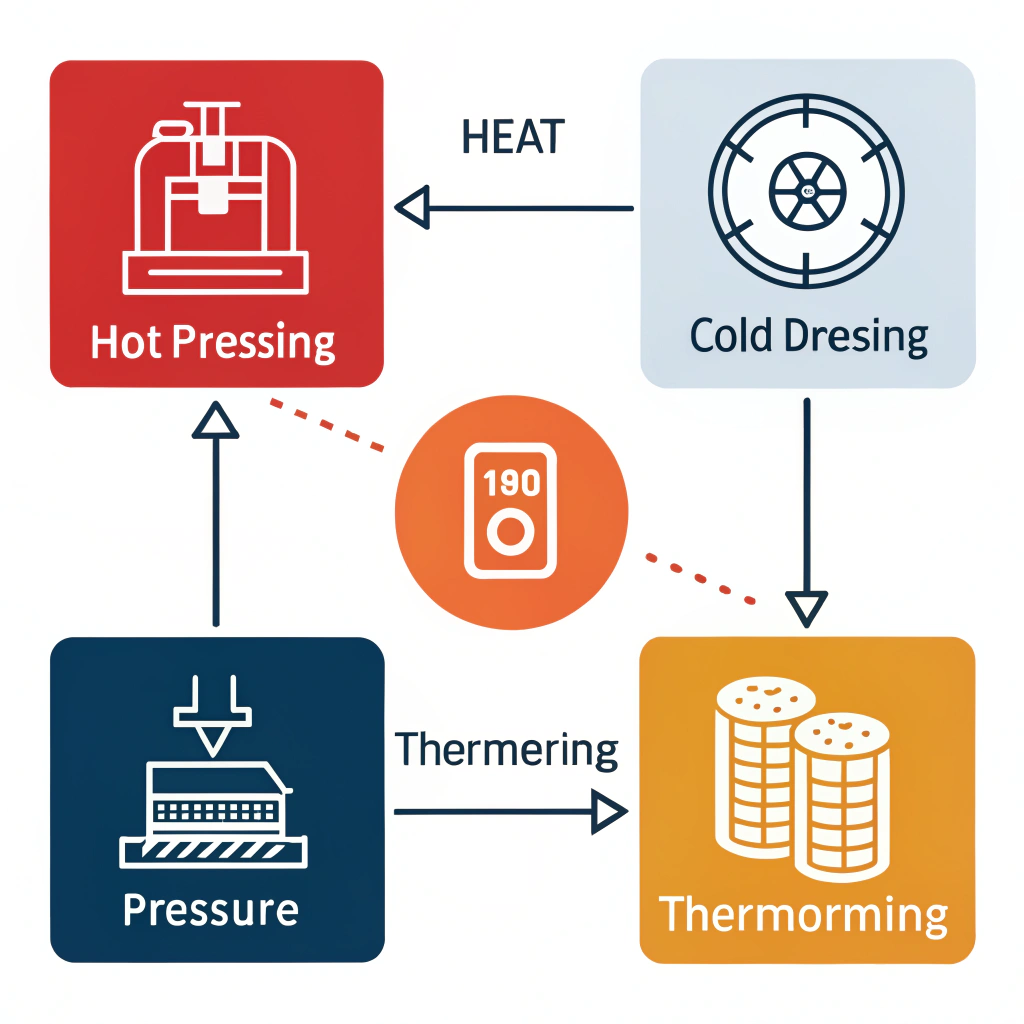

One of the key factors affecting paddle quality is the manufacturing process. NEX Pickleball utilizes three main production methods, each with distinct advantages and disadvantages when applied to composite core paddles.

Hot pressing involves heating and applying pressure to the materials, effectively fusing them together. This process is ideal for producing paddles with tight molecular bonds and improved impact resistance.

Key Advantages:

• High production efficiency perfect for large-scale manufacturing.

• Results in a denser, stronger composite structure that withstands heavy impacts.

• Promotes excellent structural integrity for high-performance play.

Disadvantages:

• The high temperature may cause alterations in some material properties, subtly affecting the paddle’s feel.

• High initial capital investment in equipment is required.

Cold pressing shapes paddle materials at room temperature using controlled mechanical pressure. This method preserves the inherent properties of the materials, ensuring optimal elasticity and responsiveness.

Key Advantages:

• Allows precise control over paddle thickness and density distribution.

• Maintains the original characteristics of combined materials, ensuring a better ball feel.

• Particularly useful for achieving an enhanced tactile response and improved playability.

Disadvantages:

• The process is slower and less efficient for mass production.

• Requires precision machinery and skilled operation to maintain consistency.

Thermoforming softens materials through heating before shaping them in molds, which is perfect for complex designs and detailed customization.

Key Advantages:

• Capable of producing paddles with intricate designs and exact material placement.

• Ensures stability and uniform performance by maintaining consistent material distribution.

• Supports the integration of multiple high-performance components into one paddle.

Disadvantages:

• Involves longer production cycles, which can increase manufacturing time.

• Higher equipment costs make it more suitable for premium or niche product lines.

NEX Pickleball’s blend of these advanced production processes ensures each paddle is engineered to optimize both performance and durability.

When reviewing the production process and core material options, it is important to balance three main factors:

• Performance: Ensuring that the paddle delivers superior shock absorption, weight distribution, and responsiveness on the court.

• Cost Efficiency: Minimizing production expenses while maintaining high quality, allowing for competitive pricing in the B2B market.

• Production Flexibility: Adapting to varying order sizes and customization options for diverse customer requirements.

Composite cores, when manufactured using advanced processes like cold pressing or thermoforming, emerged as the top choice for high-performance paddles. They seamlessly blend the strengths of carbon fiber, fiberglass, and other high-grade materials to architect a product that not only enhances a player’s on-court experience but also meets stringent quality and durability benchmarks required by modern equipment distributors.

Customizing paddle features is another area where composite cores excel. Companies like NEX Pickleball enable businesses to choose specific paddle characteristics, including grip design, balance, and weight distribution, to better match the demands of different gameplay styles. By leveraging advanced production techniques, manufacturers can incorporate decorative options, custom branding, and even player-specific performance tuning. This level of customization is particularly appealing in a competitive B2B landscape where differentiation is critical.

For instance, a paddle designed for high-intensity, competitive play may require a combination of 12K Carbon Fiber5 integrated into a composite structure for maximum rigidity and stability. In contrast, a paddle aimed at recreational players might employ a hybrid design using fiberglass for better ball control and a polymer honeycomb core for enhanced comfort and reduced vibration.

| Production Process | Best Suited Core Materials | Ideal For | Main Benefit |

|---|---|---|---|

| Hot Pressing | Composite cores with high-impact materials | High-performance paddles | Superior impact resistance and durability |

| Cold Pressing | Custom composite cores combining carbon fiber and fiberglass | Precision-controlled play | Enhanced tactile response and custom feel |

| Thermoforming | Complex composite layouts including bamboo or honeycomb | Premium niche and high-end paddles | Intricate design integration and aesthetic appeal |

Such detailed comparisons can assist B2B decision-makers in choosing a production process and core material that align perfectly with their market and customer requirements.

Consider a scenario where a sports equipment distributor is looking to refresh its product portfolio with premium pickleball paddles. A comparative analysis reveals that paddles built with composite cores not only meet but exceed the performance standards set by traditional cores in areas such as shock absorption and fatigue resistance.

Using data-driven insights, manufacturers can adjust production parameters to achieve an optimal balance. For instance, tests conducted in controlled environments have shown that composite core paddles reduce vibration by up to 30% compared to paddles with single-material cores. This reduction translates into less player fatigue and improved precision, giving distributors a strong selling point when pitching to professional and amateur markets alike.

This case highlights why a sophisticated approach to material science and manufacturing processes is essential. By choosing composite cores and leveraging advanced technologies, distributors can offer paddles that are both a technological leap forward and a strategic market differentiator.

For B2B purchasers evaluating the manufacturing of high-performance pickleball paddles, adopting composite core technology represents a pragmatic, future-proof decision. The discussed methodologies—hot pressing, cold pressing, and thermoforming—each have inherent trade-offs, but when integrated with composite core strategies, they deliver unmatched performance, durability, and customization potential.

Key recommendations include:

• Prioritize composite core designs to boost shock absorption and overall paddle performance.

• Evaluate production processes based on specific business needs, considering the balance between cost, efficiency, and customization capability.

• Use data-driven insights from quality control tests to fine-tune manufacturing protocols, ensuring that every paddle meets the highest standards.

In conclusion, composite core technology, combined with precise manufacturing methods, is a robust solution for distributors aiming to offer top-of-the-line pickleball paddles. Its ability to integrate multiple high-performance materials into a single, optimized product makes it the ideal choice for companies striving to lead in a competitive market. Embracing these innovations not only improves product offerings but also enhances customer satisfaction and long-term business growth.

People Also Ask

Q: What are the benefits of composite cores in pickleball paddles?

A: Composite cores offer superior shock absorption, optimized weight distribution, and increased durability by combining multiple high-performance materials. This results in enhanced control and reduced vibration, making paddles ideal for both competitive and recreational play.

Q: How do different production processes affect paddle performance?

A: Production processes such as hot pressing, cold pressing, and thermoforming each influence paddle construction uniquely. Hot pressing provides strong impact resistance, cold pressing preserves material properties for better tactile feedback, and thermoforming allows for intricate designs and custom material placement.

Q: How does composite core technology compare with traditional core materials?

A: Composite core technology outperforms traditional cores by integrating the strengths of various materials. Unlike single-material cores like Nomex or polymer honeycomb, composite cores offer a balanced approach that maximizes durability, performance, and customizable design options, giving them a clear edge in high-performance paddle manufacturing.

-

composite core: Reading this article will help you understand the benefits of advanced material integration for enhanced shock absorption and durability in paddle manufacturing. ↩ ↩

-

Nomex: Reading this article will provide insights into Nomex honeycomb technology, its applications, and why it may be favored for certain performance characteristics. ↩ ↩

-

Cold Pressing: Reading this article will explain the cold pressing process and how it preserves material properties for improved elasticity and tactile feedback in manufacturing. ↩ ↩

-

Thermoforming: Reading this article will detail the thermoforming process and its benefits for producing intricate, custom-designed paddle components. ↩ ↩

-

12K Carbon Fiber: Reading this article will offer a deeper understanding of 12K Carbon Fiber, its properties, and how it enhances rigidity and stability in high-performance paddles. ↩ ↩