Quick Answer: High-performance pickleball paddles combine premium materials and advanced production processes to achieve the perfect balance of power, control, and durability. By comparing materials such as various types of carbon fiber1, fiberglass, and composite cores, procurement managers can identify the most cost-efficient and technically superior solution for their business needs.

In today’s competitive sports equipment landscape, selecting the right pickleball paddle is a nuanced process. Procurement and product managers must compare both the material composition and the production techniques to ensure performance, durability, and cost efficiency. This guide provides a detailed analysis to help you make informed sourcing decisions when considering high-performance pickleball paddles.

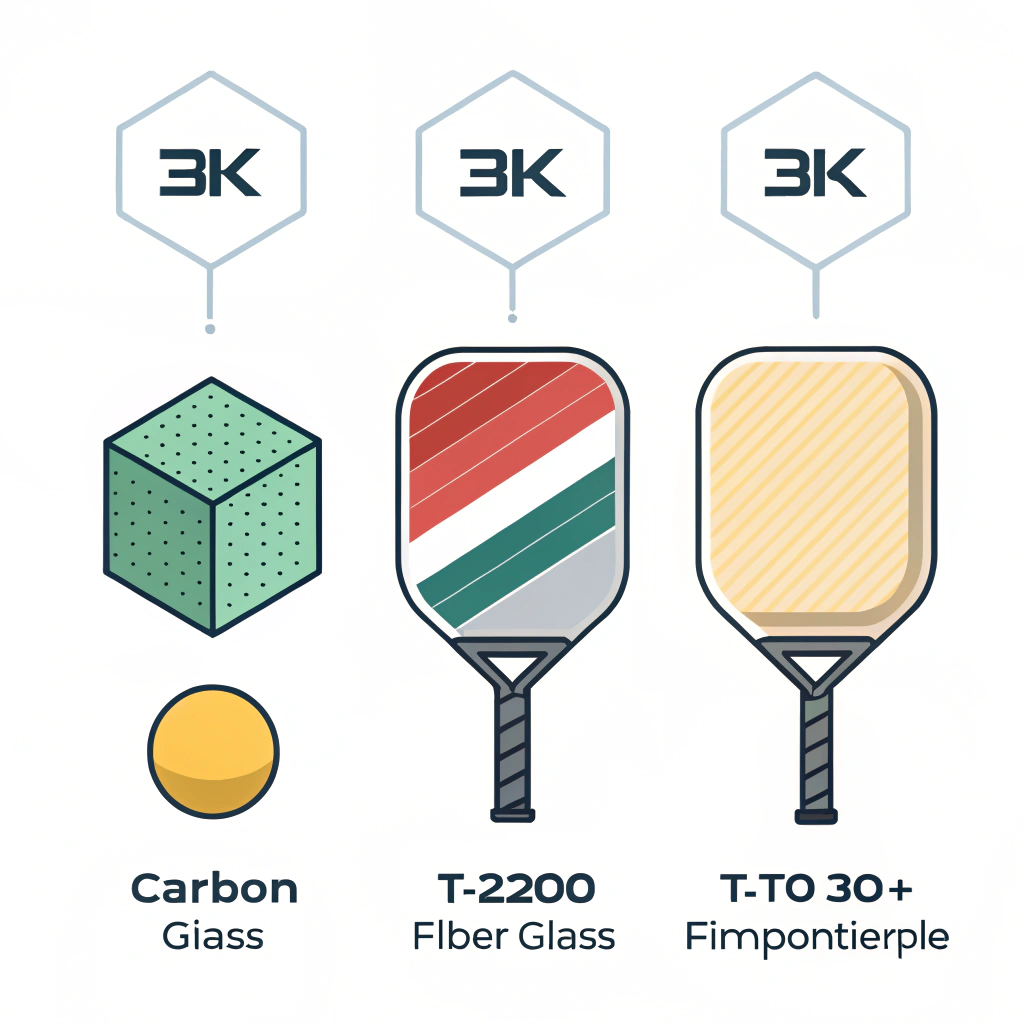

The performance of a pickleball paddle largely depends on the materials used. The most prominent materials in paddle manufacturing include carbon fiber, fiberglass, and various composite materials2. Each material has unique properties, and understanding these can help balance factors such as strength, flexibility, weight, rebound force, and vibration reduction.

Among the premium materials, carbon fiber is often highlighted for its exceptional performance. There are several variants:

-

3K Carbon Fiber:

Known for its strength and flexibility, this variant provides robust rebound force and durability. It minimizes vibration, making it a preferred choice for paddles that require high impact resistance. -

12K Carbon Fiber:

With a higher thread density, 12K offers a smoother surface, greater hardness, and improved durability. Its enhanced impact resistance makes it suitable for competitive play where precision and strength are paramount. -

T300 Carbon Fiber:

This variant stands out for its high tensile strength, offering a balanced mix of strength and lightweight design. It is ideal for paddles that need rapid response without sacrificing durability.

Fiberglass paddles are an excellent alternative for players seeking a balance between power and ball control. The E-Glass Fiberglass provides:

- Superior elasticity and tensile strength.

- A broader sweet spot, resulting in enhanced control.

- Improved flexibility that can translate to better overall ball feel, particularly beneficial for recreational players.

Composite materials combine the best of multiple materials to cater to diverse performance requirements:

-

Carbon Fiber and Fiberglass Composite:

By merging the advantages of both components, this composite delivers power without compromising control. It is an ideal solution for those looking to maximize performance while managing production costs. -

Bamboo Core Composite:

Incorporating bamboo cores means leveraging a lightweight yet highly impact-resistant foundation. The natural structure of bamboo offers unique shock absorption properties and ensures sustained performance over time. -

Honeycomb Core Composite:

Utilizing high-density polymers or pulp, honeycomb cores significantly reduce vibration and provide excellent shock absorption. This is especially advantageous for players who face frequent high-impact shots.

The core material is fundamental to a paddle’s overall performance. It defines the hitting feel, the extent of impact resistance, and the level of vibration control. Common core options include:

-

Nomex Honeycomb Core3:

Constructed from robust polymers, Nomex cores are known for superior shock absorption and long-lasting durability. They are ideal for players requiring a stable yet responsive paddle. -

Aluminum Honeycomb Core:

Offering a balanced weight, aluminum cores deliver both power and precise control. This makes them suitable for environments where consistency and precision are critical. -

Polymer Honeycomb Core:

Polymer cores tend to provide enhanced elasticity, reducing vibration and delivering a comfortable hitting experience. They are often preferred by recreational players and beginners who value comfort and ease of play.

The table below outlines key attributes of these materials:

| Material/Component | Key Benefits | Ideal For | Trade-offs |

|---|---|---|---|

| 3K Carbon Fiber | High strength and flexibility | High impact resistance | May yield slightly higher cost |

| 12K Carbon Fiber | Smoother surface, improved hardness | Competitive play, precision | Higher thread density cost |

| T300 Carbon Fiber | Outstanding tensile strength | Balanced power and lightweight | Specialized manufacturing process |

| E-Glass Fiberglass | Superior elasticity and ball control | Recreational play, ball feel | Slightly lower strength than carbon |

| Carbon Fiber-Fiberglass Composite | Balanced combination of power and control | Versatile performance | Complexity in production |

| Bamboo Core Composite | Lightweight, high impact resistance | Extended play, shock absorption | May require additional quality control |

| Honeycomb Core Composite | Excellent shock absorption, vibration reduction | High-performance and durability | May increase production time |

| Nomex Honeycomb Core | Superior shock absorption, long-lasting durability | Professional play | Higher material cost |

| Aluminum Honeycomb Core | Balanced weight distribution | Precision-focused play | Potential trade-off in flexibility |

| Polymer Honeycomb Core | Enhanced elasticity, reduced vibration | Recreational play, comfort | May not offer optimum impact resistance in all cases |

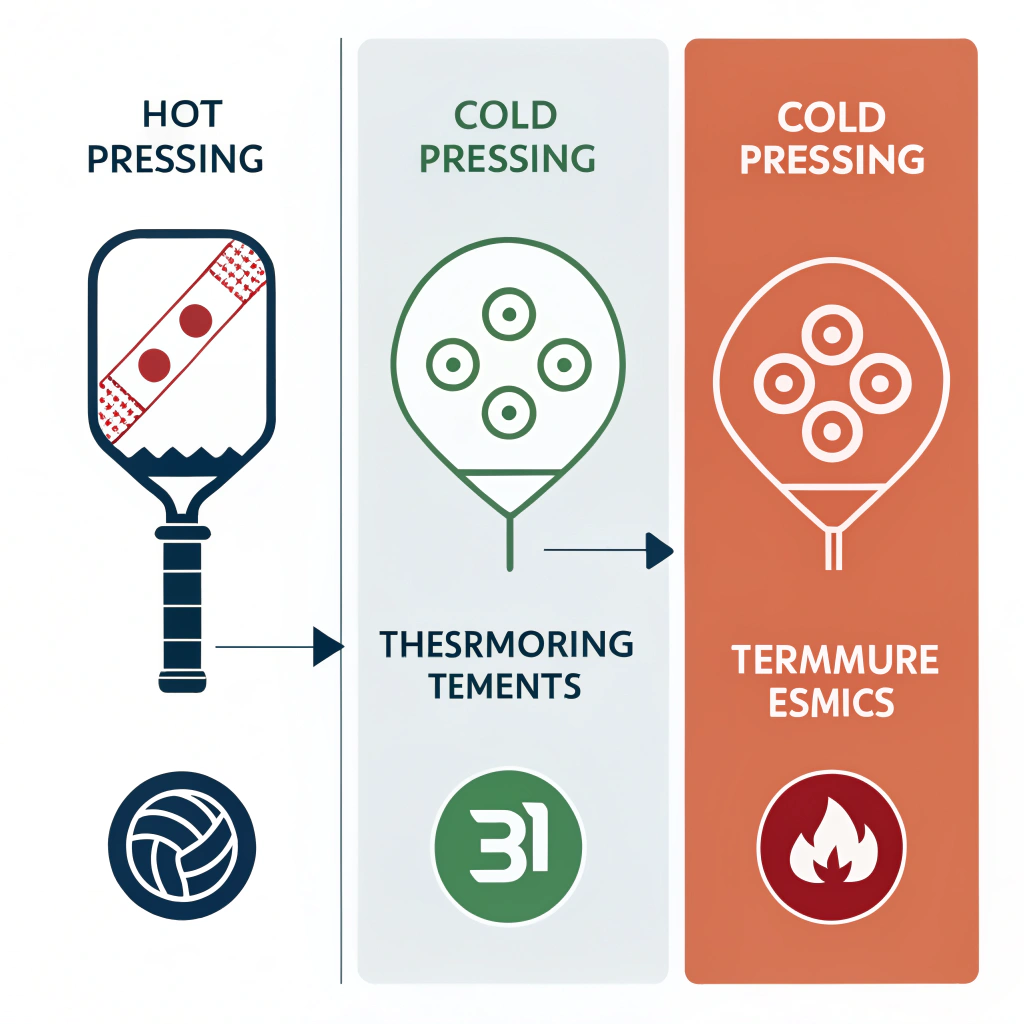

Production methods significantly influence the final paddle performance. NEX Pickleball employs three primary production techniques: hot pressing4, cold pressing, and thermoforming5. Each method has its advantages and limitations.

Hot pressing involves applying heat combined with pressure to fuse the paddle materials. This process is widely adopted for its rapid production capabilities and robust results.

-

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Results in strong, durable paddles with excellent impact resilience.

- Ensures structural integrity ideal for high-performance uses.

-

Disadvantages:

- Potential alteration of certain material properties, which may affect the paddle’s feel.

- Requires significant investment in high-end machinery.

Cold pressing is a method where paddle materials are shaped at room temperature under controlled mechanical pressure. This method ensures precision and maintains the original properties of the materials.

-

Advantages:

- Offers precise control over paddle thickness and structure.

- Preserves the inherent properties of the material, providing superior ball control and flexibility.

- Enhances the tactile feedback, crucial for competitive gameplay.

-

Disadvantages:

- Extended production cycles can limit overall efficiency.

- Demands high-quality equipment for precise pressure control, which may increase initial costs.

Thermoforming involves heating the paddle materials until they soften and then molding them into the desired shape using specialized molds. This process is especially effective in creating paddles with complex designs.

-

Advantages:

- Allows for intricate design details and precise material distribution.

- Maintains paddle stability and enhances performance through uniformly structured material layers.

- Ideal for producing high-performance paddles with unique customizations.

-

Disadvantages:

- Longer production times and consequently higher equipment costs.

- Best suited for premium or custom-made paddle lines, making it less cost-effective for mass production.

Below is a table summarizing the advantages and disadvantages of each production process:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, structural integrity, excellent impact resistance | Potential material property changes, high equipment cost |

| Cold Pressing | Precise thickness control, superior ball feel, material integrity preserved | Longer production cycles, expensive precision machinery |

| Thermoforming | Intricate designs, stable material distribution, customizability | Longer production time, higher production costs |

When making procurement decisions, the interplay between the selected materials and production methods is critical. Below are some key considerations for aligning these elements to achieve optimal paddle performance:

-

Material Selection Based on Player Needs:

If the goal is to maximize power and control, choosing a blend of high-performance carbon fiber variants (such as 12K or T300) with a Nomex Honeycomb Core3 might be ideal. Alternatively, for products targeting recreational players, combining E-Glass Fiberglass with a Polymer Honeycomb Core can provide the necessary balance between durability and cost. -

Production Process Adaptability:

Evaluate your production needs. For large-scale manufacturing where output volume matters, hot pressing4 could be the most efficient process. However, for products that require a premium feel or unique customizations, thermoforming5 might justify the higher production costs with its design flexibility. -

Quality Control and Consistency:

Advanced production processes demand strict quality control. For instance, using cold pressing allows manufacturers to maintain precise control over the paddle’s structure, ensuring that the intended performance benefits of premium materials are fully realized.

Consider a scenario where a B2B client requires a versatile line of paddles for both competitive play and recreational use. By comparing the materials and production techniques:

- For competitive paddles, the integration of 12K Carbon Fiber with a Nomex Honeycomb Core3 produced via cold pressing results in a paddle optimized for rapid response and durability.

- In contrast, a recreational paddle developed using E-Glass Fiberglass paired with a Polymer Honeycomb Core through hot pressing4 ensures high production efficiency, cost-effectiveness, and excellent ball control.

This dual approach not only broadens the product range but also caters to diverse market segments, ensuring that the products meet the specific needs of each playing level.

The sports equipment industry is dynamic, prompting continuous innovation. Looking ahead, manufacturers are exploring additional composite materials and hybrid production techniques to further enhance paddle performance and durability. For example, integrating real-time data from performance tests can help refine the design and material formulation, paving the way for even more effective production strategies.

As you evaluate your next purchase or product development strategy, consider the following best practices:

-

Comprehensive Material Assessment:

Compare the inherent properties of various materials, considering not only performance but also cost and production scalability. -

Aligning Production Techniques with Product Goals:

Choose a production method that complements the desired paddle characteristics. For example, if maintaining material integrity is paramount, cold pressing is preferable despite longer production cycles. -

Quality Over Quantity:

High-quality paddles result from a careful balance between material selection and process precision. Ensure that quality control processes are diligently followed to meet industry standards and achieve consumer satisfaction. -

Adaptability and Customization:

With emerging technologies in composite materials and production processes, manufacturers can now offer more customized solutions. This flexibility enables tailored paddle solutions that meet both high-performance needs and cost constraints. -

Data-Driven Decision Making:

Utilize real-world performance data and case studies to continuously refine both material selection and production processes. This iterative approach not only improves product quality but also optimizes cost efficiency over time.

By considering these factors, procurement managers can not only secure superior pickleball paddles but also stay ahead in a competitive market. The synthesis of advanced materials and state-of-the-art production processes represents a future-proof strategy for any company dedicated to delivering top-tier sports equipment.

Q1: What are the main production processes for pickleball paddles?

A1: The primary production processes include hot pressing, cold pressing, and thermoforming. Hot pressing offers high efficiency and strong structural integrity, cold pressing ensures precise material control and excellent ball feel, while thermoforming allows for intricate design details and customizations.

Q2: Which core material provides superior shock absorption for high-performance play?

A2: Nomex Honeycomb Core3 is often recognized for its superior shock absorption and long-lasting durability, making it ideal for high-performance panels. Polymer Honeycomb Core also provides reduced vibration and enhanced comfort, especially for recreational play.

Q3: How does composite material technology enhance paddle performance?

A3: Composite materials, such as the combination of carbon fiber with fiberglass, blend the strengths of both components. This approach delivers a balanced mix of power, control, and durability. Additional composites like bamboo or honeycomb cores improve impact resistance and reduce paddle vibration, offering tailored performance for various play styles.

-

Carbon Fiber — Reading this article will provide insights into the advanced properties of carbon fiber, its various grades, and how its integration enhances the performance and durability of high-end sporting goods. ↩

-

Composite Materials — This resource explains the benefits and engineering behind composite materials, detailing how combining different components can yield superior performance and cost efficiency in manufacturing. ↩

-

Nomex Honeycomb Core — Explore the technical details and benefits of Nomex Honeycomb Core, including its superior shock absorption and longevity, which are crucial for professional-grade sporting equipment. ↩ ↩2 ↩3 ↩4

-

Hot Pressing — Learn more about hot pressing, a manufacturing technique that fuses materials under heat and pressure, offering rapid production and robust end-product performance. ↩ ↩2 ↩3

-

Thermoforming — Discover the thermoforming process, which allows for intricate design and customization by heating and shaping materials, ideal for producing high-performance paddles with unique features. ↩ ↩2