Quick Answer: This article provides a detailed comparison guide for pickleball paddles, breaking down key materials and manufacturing processes to help purchasing managers and product developers make informed decisions based on performance, durability, and production efficiency.

In today's competitive sports equipment market, selecting the right pickleball paddle is crucial for achieving optimal performance and customer satisfaction. This guide compares various paddle materials—such as carbon fiber, fiberglass, and Composite Materials1—and production methods including Hot Pressing2, Cold Pressing3, and Thermoforming4. By understanding the pros and cons of each option, purchasing managers and product development specialists can confidently determine which paddle design best meets the needs of their clientele.

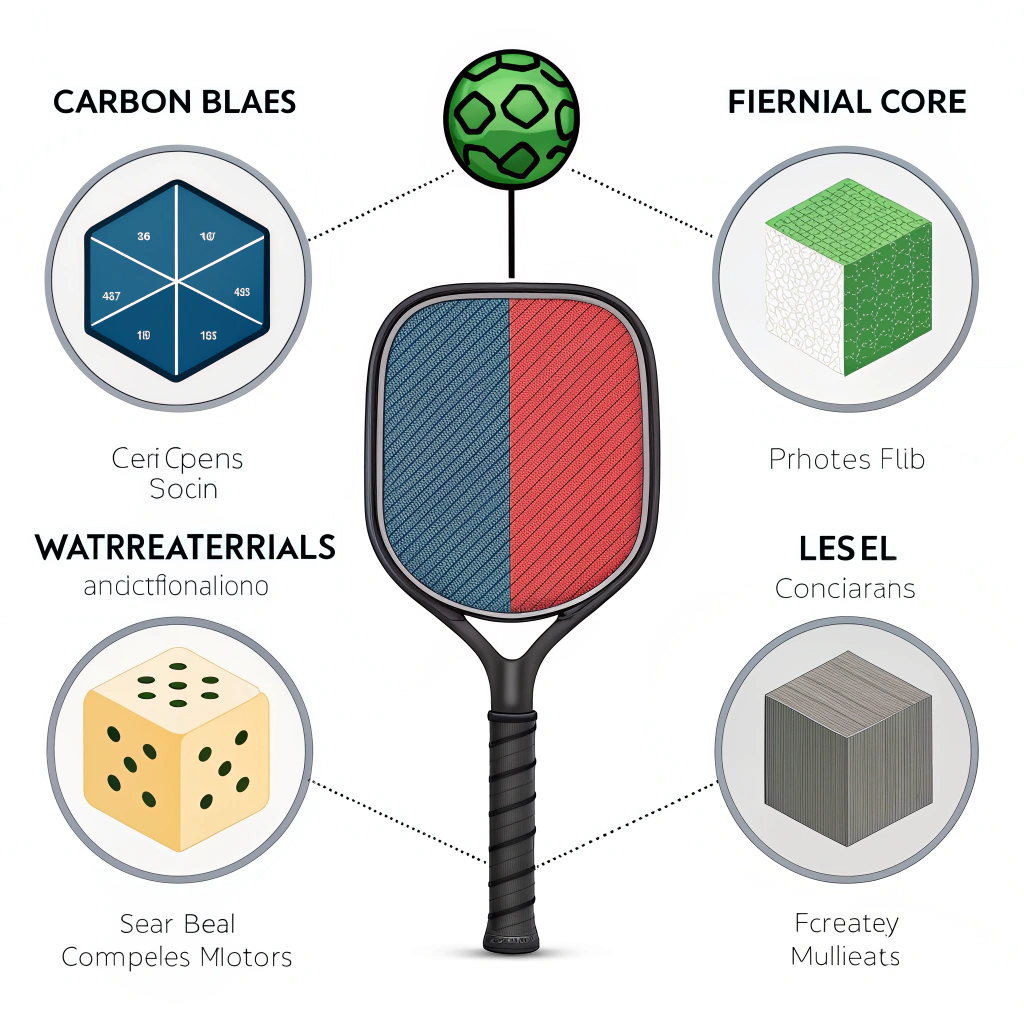

Pickleball paddles are manufactured using several premium materials. Each material offers unique advantages when it comes to power, control, and durability. The primary materials include:

-

Carbon Fiber

- 3K Carbon Fiber: Known for its high strength and flexibility. It produces paddles with excellent rebound force and reduces vibration during play.

- 12K Carbon Fiber: Provides a smoother surface with greater hardness and impact resistance, ideal for competitive play.

- T300 Carbon Fiber: Offers an excellent balance between tensile strength and weight, ensuring both power and responsive control.

-

Fiberglass

- Offers a larger sweet spot and a balanced mix of power and control. E-Glass Fiberglass in particular provides excellent elasticity and tensile strength, making it well-suited for players looking for superior ball control.

-

- Carbon Fiber and Fiberglass Composite: Merges the strengths of both materials to deliver power along with enhanced control.

- Bamboo Core Composite: Lightweight with high impact resistance, providing a clear hitting feel.

- Honeycomb Core: Manufactured using high-density polymer or pulp, offering superior shock absorption and reduced paddle vibration.

The paddle’s core plays a significant role in determining its overall performance. Key core materials include:

- Nomex Honeycomb Core5: Renowned for excellent shock absorption and long-lasting durability.

- Aluminum Honeycomb Core: Balances weight and power, ideal for players seeking an optimal mix of precision and strength.

- Polymer Honeycomb Core: Provides better elasticity with reduced vibration, preferred by recreational players for a comfortable hitting experience.

A concise table below summarizes the key differences:

| Core Material | Key Advantage | Best For |

|---|---|---|

| Nomex Honeycomb | Superior shock absorption | Long-lasting, high-performance play |

| Aluminum Honeycomb | Balanced weight & power | Precision and strength combination |

| Polymer Honeycomb | Reduced vibration | Recreational play and beginner comfort |

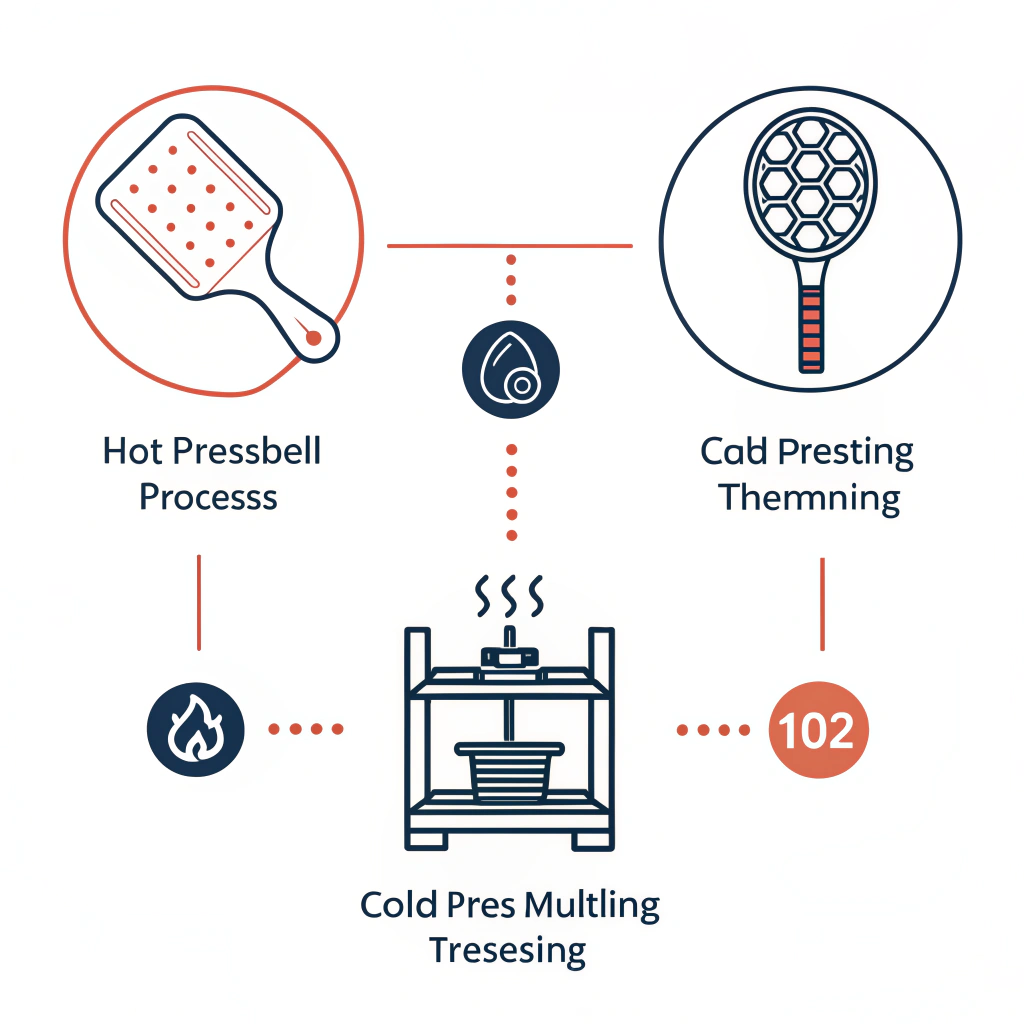

The manufacturing process is as critical as the material selection. NEX Pickleball employs three main production methods, each catering to different design goals and performance attributes.

Hot pressing involves heating materials and then applying pressure to form the paddle. This technique offers several benefits:

-

Advantages:

- High production efficiency makes it ideal for large-scale manufacturing.

- Produces strong, durable paddles with excellent impact resistance.

- Maintains structural integrity under high-performance demands.

-

Disadvantages:

- The high temperatures might alter certain material properties, potentially affecting the paddle’s “feel”.

- The capital investment for equipment is significant.

Cold pressing is an alternative process where materials are shaped at room temperature under mechanical pressure. This method allows for precise control over the paddle’s structure.

-

Advantages:

- Superior control over the paddle’s thickness and overall structure.

- Maintains the inherent properties of raw materials, resulting in enhanced control and responsiveness.

- Provides a better “ball feel” due to the preservation of material flexibility.

-

Disadvantages:

- The production process is slower compared to hot pressing.

- Requires high-precision equipment to maintain consistent pressure, which can increase production costs.

Thermoforming employs heat to soften the material and molds it into the desired shape. This process is particularly beneficial for intricate paddle designs.

-

Advantages:

- Enables the creation of paddles with complex designs and precise material distribution.

- Enhances paddle stability and performance by ensuring a balanced weight distribution.

- Suitable for premium products due to its ability to work with various high-performance materials.

-

Disadvantages:

- Longer production time and higher equipment costs compared to the other methods.

- Best suited for custom or high-end products, limiting its use for lower-cost manufacturing.

When assessing paddle performance, it is essential to consider:

- Material Properties: Carbon fiber paddles (especially T300 and 12K types) deliver outstanding power and control, making them favorable for competitive and high-level gameplay.

- Paddle “Feel”: The choice between hot pressing and cold pressing can affect the tactile feedback a player experiences. Cold pressing preserves the material’s natural properties for better ball contact, while hot pressing might slightly alter surface characteristics.

- Composite Balance: Composite materials can combine the strengths of their constituent elements. For instance, carbon fiber and fiberglass composites provide both rigidity and enhanced ball control.

Durability is a key concern for distributors and manufacturers alike. Important factors include:

- Impact Resistance: Materials like 12K carbon fiber and Nomex honeycomb cores offer superior resistance to impacts and maintain structural integrity.

- Wear and Tear: Fiberglass and polymer cores tend to provide a smoother experience over time, particularly in recreational settings where the paddle is subjected to frequent use.

- Production Process Implications: Hot pressing provides excellent durability due to strong bond formation under heat and pressure, while cold pressing can offer better longevity by preserving material properties.

The decision on production method not only affects the paddle’s performance but also impacts the manufacturing efficiency and cost:

- Hot Pressing vs. Cold Pressing: Hot pressing stands out for large-scale production due to its speed and consistency. In contrast, cold pressing, while slower, enables the creation of paddles with tighter tolerances for competitive play.

- Thermoforming: Ideal for customization and complex designs, thermoforming may not be as efficient in mass production scenarios but offers unparalleled design flexibility, appealing particularly to high-end markets.

A summary table of manufacturing process comparisons is provided below:

| Manufacturing Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency, excellent impact resistance | High equipment cost, material alteration risk |

| Cold Pressing | Precise control, preserves material properties | Longer production cycle, needs high-precision control |

| Thermoforming | Custom design potential, balanced weight distribution | Longer production time, higher equipment cost |

For B2B purchasers, selecting the ideal paddle demands aligning product specifications with market needs. Here is a structured framework to assist in your decision-making:

-

Define Your Market Segment:

Understand whether your clientele are professional athletes, recreational players, or beginner enthusiasts. High-performance paddles with advanced carbon fibers suit competitive players, while fiberglass and polymer core paddles may better serve recreational markets. -

Evaluate Material Requirements:

- For maximum power and durability, opt for paddles manufactured with 12K carbon fiber or a blend of carbon and fiberglass.

- For cost-effective solutions that still offer good performance, consider composite paddles with bamboo core or polymer honeycomb cores.

-

Consider Manufacturing Efficiency:

- If high-volume production is a priority, hot pressing may be the optimal choice.

- For products that require a unique feel or custom design, cold pressing or thermoforming might provide the necessary manufacturing flexibility.

-

Review Performance and Testing Data:

Leverage performance test results and user feedback. For example, paddles using Nomex honeycomb cores have demonstrated excellent longevity during stress tests, while T300 carbon fiber paddles often excel in competitive environments. -

Balance Cost and Innovation:

While high-end materials and advanced manufacturing methods might come with higher initial costs, the long-term benefits in performance and durability can lead to better client satisfaction and market competitiveness.

Based on our detailed analysis, here are some actionable insights:

- Innovation Investment: Companies looking to lead the pickleball market should invest in advanced manufacturing techniques like thermoforming to develop unique paddle designs tailored to elite performance needs.

- Material Mix Optimization: Consider blending different materials, such as combining carbon fiber with fiberglass, to capture the benefits of both power and control. Customizing the core material depending on the target market can also yield enhanced product value.

- Strategic Process Selection: Align your production process with your market strategy: use hot pressing for bulk, durable products and cold pressing for paddles requiring a premium touch. For premium lines, thermoforming offers the customization necessary to stand out.

By applying these recommendations, purchasing managers and product development specialists can ensure their product portfolio not only meets the rigorous demands of modern pickleball players but also remains competitive in terms of cost and innovation.

Q1: What are the benefits of using carbon fiber in pickleball paddles?

A1: Carbon fiber offers superior strength, reduced vibration, and excellent rebound force, making it ideal for competitive play.

Q2: How do manufacturing processes like hot pressing, cold pressing, and thermoforming affect paddle performance?

A2: Hot pressing allows for efficient production and strong impact resistance, cold pressing preserves material properties for enhanced control, and thermoforming offers design customization and balanced weight distribution.

Q3: Which core material is best for balancing durability and performance in pickleball paddles?

A3: The choice depends on specific requirements; Nomex honeycomb cores provide high durability and shock absorption, while polymer cores offer superior ball control and comfort for recreational users.

-

Composite Materials: Click to learn how the combination of different materials, such as carbon fiber with fiberglass, can optimize paddle performance by merging power and control. Back to Composite Materials ↩ ↩2

-

Hot Pressing: Click to learn about a heat-assisted process that uses pressure to form materials, ensuring production efficiency and enhanced impact resistance. Back to Hot Pressing ↩ ↩2

-

Cold Pressing: Click to explore how this room temperature process preserves material properties for optimal control and responsiveness in high-precision manufacturing. Back to Cold Pressing ↩ ↩2

-

Thermoforming: Click to understand the heat-based molding process ideal for crafting complex designs with balanced weight distribution in premium products. Back to Thermoforming ↩ ↩2

-

Nomex Honeycomb Core: Click to read about this high-performance core material known for superior shock absorption and long-lasting durability in sports equipment. Back to Nomex Honeycomb Core ↩