High-quality pickleball paddles are produced by combining advanced materials with state-of-the-art manufacturing processes. In short, by leveraging materials like carbon fiber1, fiberglass2, and high-performance composite core materials—paired with production techniques such as hot pressing, cold pressing, and thermoforming—manufacturers can deliver paddles that excel in durability, control, and overall performance.

Procurement managers and sports equipment distributors face several challenges when selecting pickleball paddles for competitive and recreational use. Key considerations include:

• Achieving a balance between power, control, and durability

• Understanding the performance benefits of different advanced materials

• Ensuring manufacturing processes do not compromise the paddle’s ergonomic design and overall reliability

These challenges underscore the need to carefully evaluate both the materials used and the production techniques employed. In our in-depth analysis, we will address these issues by detailing material properties and the advantages and limitations of various fabrication methods.

Materials used in paddle construction play a critical role in performance. At NEX Pickleball, our paddles incorporate premium elements such as various types of carbon fiber, fiberglass, and composite cores to meet the diverse needs of our clients.

Carbon Fiber is a premium material known for its strength and light weight. Each variant offers distinct performance characteristics:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| 3K Carbon Fiber | High strength and flexibility; offers excellent durability and reduced vibration. | Paddles requiring high rebound force and robustness. |

| 12K Carbon Fiber | Higher thread density for a smoother surface with greater hardness and impact resistance. | Competitive play where extreme strength is needed. |

| T300 Carbon Fiber | Outstanding tensile strength and balanced lightness | Paddles demanding both power and maneuverability. |

The table above summarizes the principal advantages and typical use cases for each carbon fiber type, ensuring that distributors can make informed decisions based on performance priorities.

Beyond carbon fiber, other materials significantly contribute to paddle performance:

- Fiberglass:

- Fiberglass paddles feature enhanced flexibility, a wider sweet spot, and excellent ball control.

- The E-Glass Fiberglass variant offers impressive elasticity and tensile strength, creating an excellent balance between power and finesse.

- Composite Materials:

- Combining carbon fiber with fiberglass can create paddles that successfully merge the benefits of each material.

- Bamboo Core Composite and Honeycomb Core options provide lightweight designs with superior shock absorption and clear hitting feel.

Each material, whether it is used alone or in a composite form, brings its unique set of performance enhancements. This selection allows manufacturers to tailor paddles for diverse player profiles, from beginners to seasoned athletes.

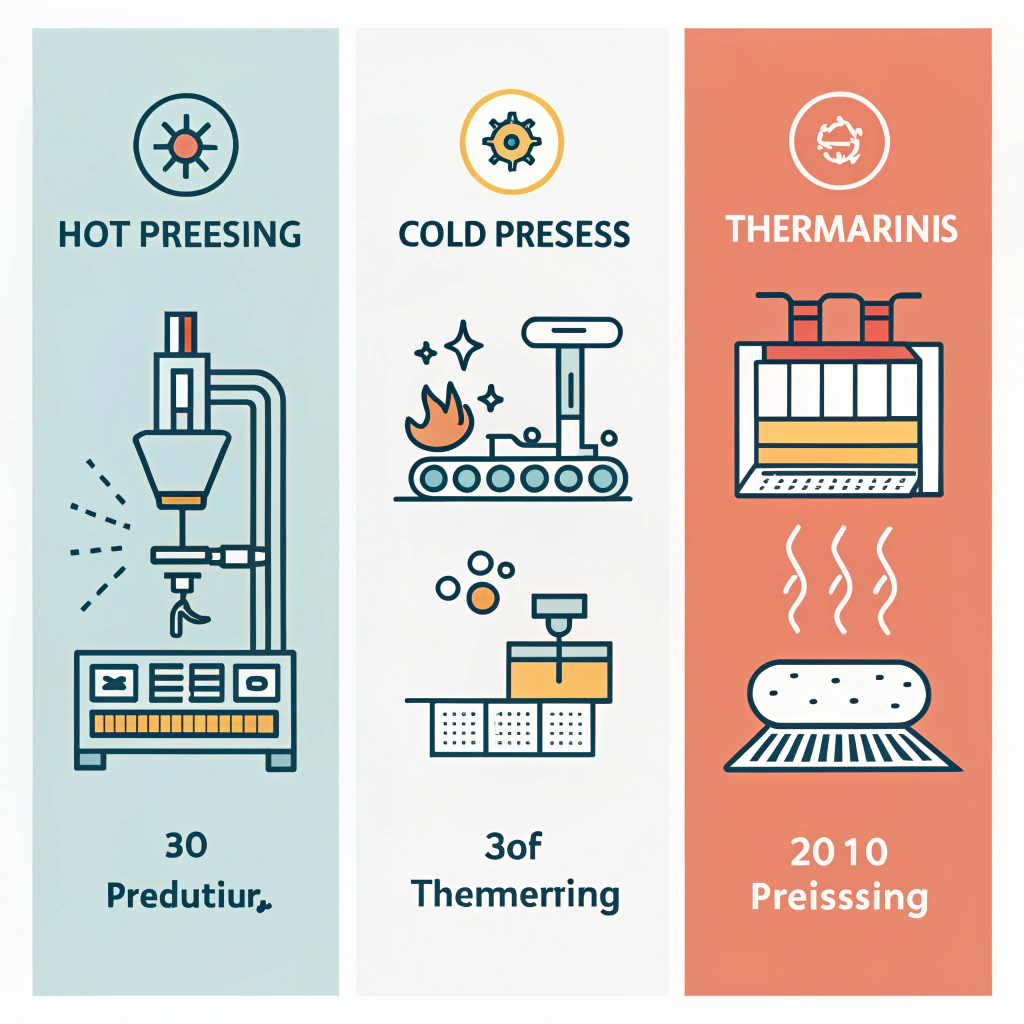

The method used to shape raw materials into a finished paddle is equally crucial as the materials themselves. NEX Pickleball uses three key production processes, each with distinct advantages and challenges:

Hot pressing involves heating the materials combined with pressure, inducing chemical and physical changes that enhance material bonding.

- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Produces strong, durable paddles with excellent impact resistance.

- Ensures structural integrity necessary for high-performance use.

- Disadvantages:

- The heating process can slightly alter material properties, potentially impacting the paddle's feel.

- Requires an initial high investment in equipment and consistent temperature control.

Cold pressing uses mechanical pressure at room temperature to shape the paddle, allowing for precise manipulation of material thickness and structure.

- Advantages:

- Preserves the natural properties of materials, which can enhance control and responsiveness.

- Offers precise control over the paddle's design, ensuring optimal performance characteristics.

- Disadvantages:

- Extended production cycles can reduce overall manufacturing efficiency.

- Demands high-quality equipment to maintain exact pressure control.

Thermoforming heats a material to its softening point before molding it into the required shape, facilitating intricate design profiles and even material distribution.

- Advantages:

- Enables the creation of paddles with complex shapes and refined material distribution.

- Maintains paddle stability and improves its overall performance.

- Disadvantages:

- Involves longer production times and higher production costs.

- Best suited for premium or custom-made paddles, limiting rapid large-scale production.

The table below offers a comparison of these processes:

| Production Process | Efficiency | Material Integrity | Complexity of Design | Equipment Investment | Ideal Use Case |

|---|---|---|---|---|---|

| Hot Pressing | High | Moderate | Moderate | High | Large-scale production, high impact use |

| Cold Pressing | Moderate | High | High (precision) | Moderate | Designs requiring careful control |

| Thermoforming | Low | High | Very High | Very High | Premium products, custom shapes |

This structured comparison helps procurement managers understand the trade-offs between the three techniques, ultimately guiding them to select a method that aligns with their market and performance goals.

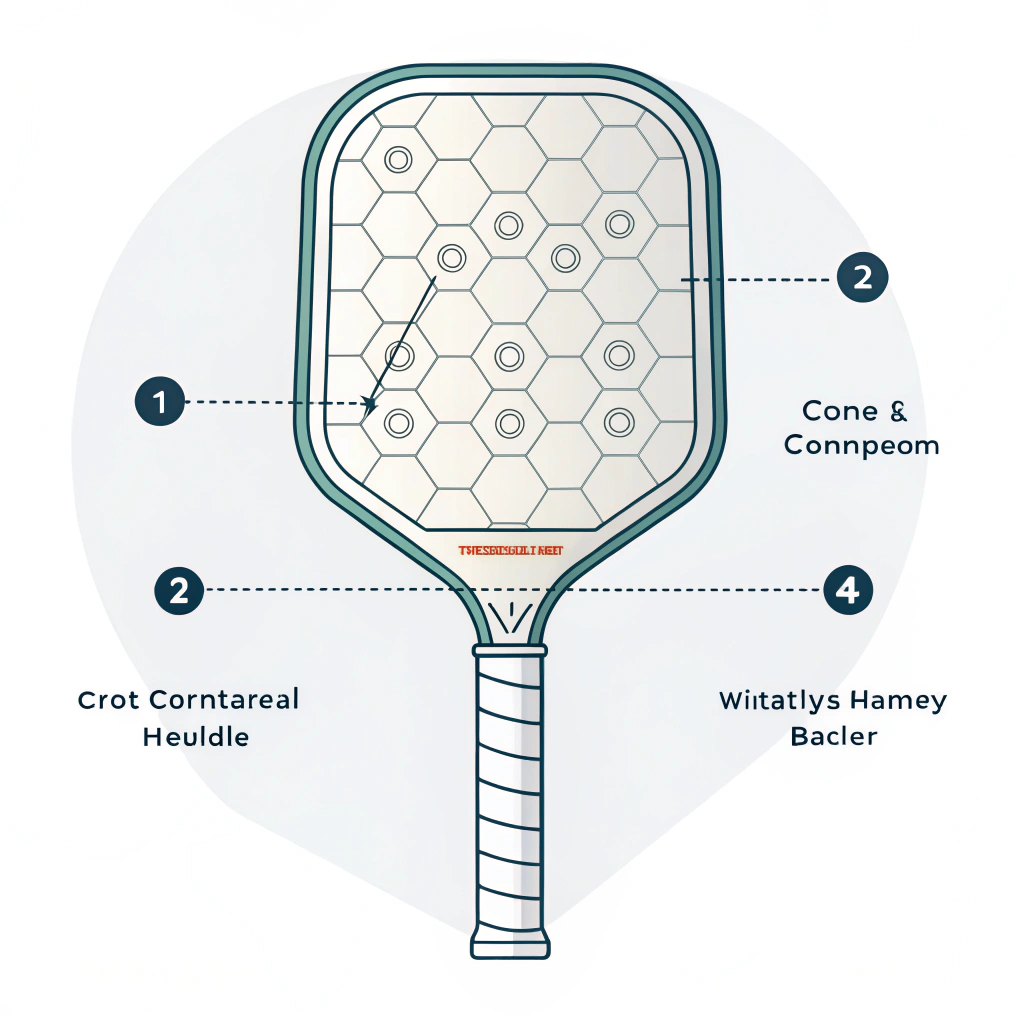

The performance of a pickleball paddle is influenced not only by its external materials but also by its core structure and ergonomic features. Key aspects include:

- Nomex Honeycomb Core5:

- Offers exceptional shock absorption, ensuring longevity and maintaining paddle stability under high-impact play.

- Aluminum Honeycomb Core:

- Provides an excellent balance of weight distribution, facilitating power and precision.

- Polymer Honeycomb Core:

- Ensures enhanced elasticity and minimizes vibration, which is ideal for players prioritizing comfort and control.

Selecting the appropriate core is crucial to tailor the paddle’s response, making it possible to customize products for specific player requirements, whether for power or finesse.

- Ergonomic Grip Design:

- The handle design of a paddle affects player comfort and control, especially during extended play sessions.

- Our paddles are designed with various grip sizes to accommodate different hand sizes, ensuring that players experience less fatigue and improved performance.

- Surface Texture Treatments:

- Special treatments to the paddle’s surface enhance grip on the ball, subsequently improving spin control and shot accuracy.

- Customization Options:

- B2B clients can specify detailed design parameters such as weight, balance, and aesthetic components to align with team branding or personal preferences, further differentiating their products in a competitive market.

By focusing on these critical attributes, manufacturers like NEX Pickleball ensure that every paddle not only meets but exceeds the expectations of high-level performance and durability.

Quality control is an integral aspect of achieving consistent high performance in paddle manufacturing. At NEX Pickleball, each paddle undergoes several rigorous testing protocols to verify key performance attributes such as:

- Strength and Flexibility: Ensuring paddles can handle high-speed impacts while maintaining responsiveness.

- Impact Resistance: Validating that the core structure and surface material can withstand repeated use.

- Ergonomic Validation: Confirming that all designs offer the promised comfort and grip quality through user trials and assessments.

Such stringent quality control protocols contribute to heightened product reliability, a critical requirement for procurement managers in the B2B market who depend on consistent product performance to satisfy their clientele.

Consider a scenario where a leading sports distributor seeks paddles for competitive use. Their primary concerns include durability, enhanced control, and production efficiency. By analyzing the key differentiators in advanced materials and production techniques, they found that:

- Using T300 Carbon Fiber: Delivered a balanced combination of strength and lightness, critical for both power shots and fast reflex play.

- Cold Pressing Technique: Provided the necessary control over material behavior and precise measurements, essential for competing at a high level.

- Nomex Honeycomb Core: Contributed substantially to reducing vibration and extending the paddle's lifespan under intense use.

The distributor’s decision to adopt this combination enabled them to offer a paddle that thrived under the demands of competitive play, leading to increased customer satisfaction and market competitiveness. This case study underscores the value of aligning material and production choices with specific performance and usage outcomes.

In summary, achieving high performance in pickleball paddles depends on a detailed understanding of both advanced materials and production techniques. Through the combined use of carbon fiber, fiberglass, and diverse core materials—and by selecting the optimal production processes such as hot pressing, cold pressing, or thermoforming—manufacturers can address the challenges faced by sport organizations and distributors.

For procurement managers and sports equipment distributors, the following recommendations can guide your decision-making:

• Evaluate the specific performance requirements of your target market (e.g., competitive versus recreational play).

• Consider the trade-offs between manufacturing efficiency and product quality when choosing a production process.

• Prioritize suppliers with rigorous quality control processes to ensure consistent product performance.

• Leverage customization options to tailor paddle designs that align with brand identity and player needs.

By implementing these insights, you can ensure that your equipment offering will not only meet current market demands but also set new benchmarks in the industry.

People Also Ask

Q1: What are the advantages of using carbon fiber in pickleball paddles?

A1: Carbon fiber provides enhanced strength while reducing vibration, ensuring a lightweight yet powerful paddle that offers excellent rebound and durability during play.

Q2: How does thermoforming impact the design and performance of pickleball paddles?

A2: Thermoforming enables complex designs with precise material distribution, allowing manufacturers to create paddles that offer improved stability and overall performance, especially for premium or custom-made models.

Q3: Which production technique delivers the best balance between efficiency and paddle quality?

A3: While hot pressing offers high manufacturing efficiency and strong impact resistance, cold pressing delivers superior control and material integrity. The optimal choice depends on the specific performance requirements and production scale.

-

Carbon Fiber: Click to explore an external guide on the properties, manufacturing innovations, and strategic advantages of carbon fiber in high-performance sporting equipment. ↩ ↩

-

Fiberglass: Click to learn about fiberglass, its role in enhancing durability and control, and how it complements other composite materials in product design. ↩ ↩

-

Hot Pressing: Click to understand the hot pressing process, including its benefits and challenges, in the context of high-efficiency production for sports equipment manufacturing. ↩ ↩

-

Thermoforming: Click to dive into thermoforming techniques, exploring how this method supports complex shapes and refined material distribution in premium paddle design. ↩ ↩

-

Nomex Honeycomb Core: Click to read more about the properties of Nomex honeycomb cores and how they contribute to improved shock absorption and paddle longevity in competitive play. ↩ ↩