Optimizing resin flow in compression molding1 for high-performance pickleball paddles requires a balanced approach—adjusting temperature, pressure, mold design, and material selection for even resin distribution and enhanced production quality.

In modern pickleball paddle manufacturing, maintaining consistent quality and performance hinges on precise control over the resin flow during compression molding1. For R&D managers, process engineers, and technical directors, understanding and optimizing this process is key to achieving paddles that deliver both durability and superior play performance.

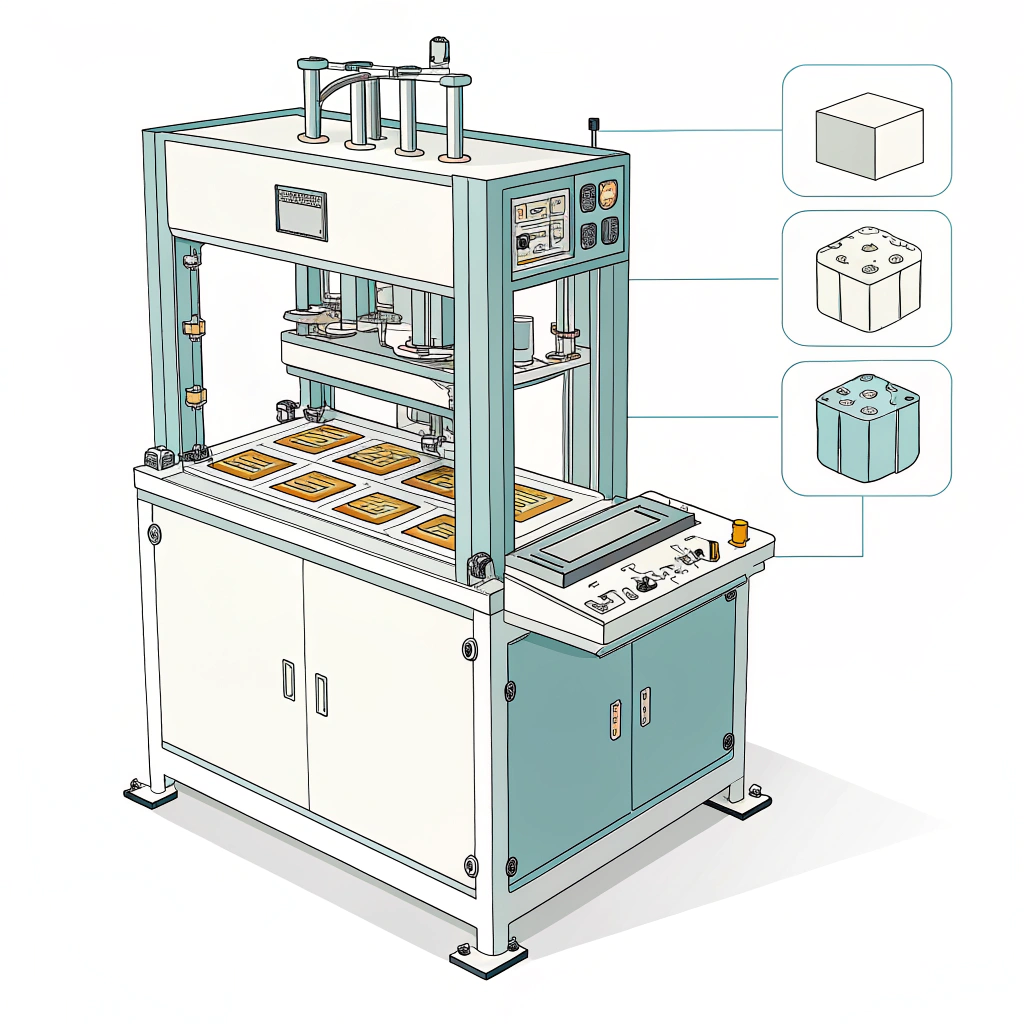

Compression molding1 is a widely used process in manufacturing paddles where resin, often combined with advanced materials, is molded under heat and pressure. The resin flow optimization2 stage directly affects the paddle’s structural integrity, surface finish, and overall performance. Uneven resin distribution may lead to weak spots, inconsistent bonding between materials, and ultimately, reduced product lifespan.

Some common issues encountered include:

- Incomplete resin fill or air voids within the mold cavity

- Variations in surface texture affecting ball control and spin

- Impact on the paddle's weight distribution and balance

- Differences in mechanical properties across the finished product

Understanding the root causes of resin flow inconsistencies is the first step toward effective process optimization. Several factors contribute to these issues:

-

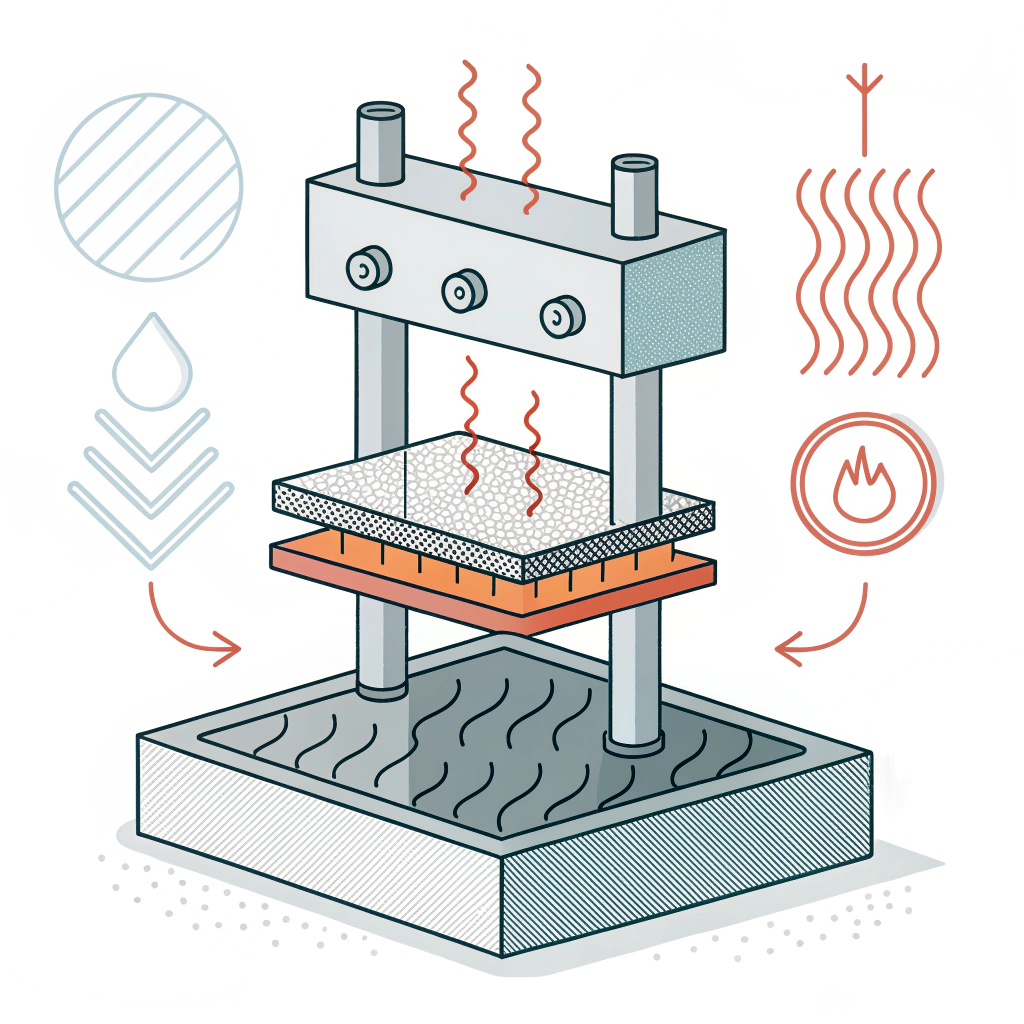

Temperature Variations:

Temperature directly affects resin viscosity. If the resin is too thick or too thin due to improper temperature control, it can lead to uneven distribution. Maintaining a stable thermal profile is essential. -

Pressure Fluctuations:

Too low pressure may result in incomplete filling, while excessive pressure can force resin out of the intended mold areas. Finding the optimal pressure balance ensures complete and uniform coverage. -

Mold Design and Complexity:

The design of the mold itself, including gate placement, cavity shape, and cooling channels, plays a significant role in resin flow behavior. Complicated shapes can create dead zones where resin is prone to stagnation. -

Material Characteristics:

Modern pickleball paddles often incorporate advanced materials like 3K Carbon Fiber3, 12K Carbon Fiber, and various fiberglass composites. Each material has unique flow characteristics, and blending them with resin requires precise calibration to ensure cohesive bonding without compromising the material properties. -

Production Process Variance:

Differences between hot pressing, cold pressing, and thermoforming can influence resin behavior. Each process has its benefits and drawbacks that can affect resin flow differently.

When aiming to optimize resin flow during compression molding, a multi-faceted approach is necessary. Below is a detailed checklist of solutions and technical adjustments capable of improving product quality while ensuring efficient production:

| Technique | Description | Pros | Cons |

|---|---|---|---|

| Temperature Control | Employ precise heating systems to maintain consistent resin viscosity during molding. | Uniform resin distribution; enhanced bonding quality | Requires investment in advanced temperature sensors |

| Pressure Optimization | Calibrate press machines to apply optimal pressure that avoids both underfilling and overfilling. | Prevents air pockets; ensures complete cavity filling | May slow production cycle if not managed efficiently |

| Mold Design Refinement | Redesign molds with optimal gate placement and effective cooling channels to facilitate resin flow. | Reduces dead zones; improves cycle consistency | High initial engineering and tooling costs |

| Material-Specific Calibration | Adjust processing parameters based on the unique properties of materials like carbon fiber and fiberglass composites. | Tailored process for each material; maximizes performance | Complex to implement in mixed-material production |

| Process Automation and Monitoring | Use real-time sensors and IoT devices to monitor resin flow, pressure, and temperature during molding. | Enhanced control and traceability; proactive issue detection | Requires robust data systems and staff training |

Implementing these techniques requires a strategic understanding of both the materials involved and the production process. For example, in a typical hot pressing scenario, a higher temperature may be needed to decrease resin viscosity, but too high a temperature could impair the inherent properties of T300 Carbon Fiber4 or damage the mold itself.

Conduct a thorough evaluation of your existing compression molding setup:

- Analyze cycle times, pressure metrics, and temperature profiles.

- Utilize high-speed cameras or flow sensors to observe resin movement.

- Inspect paddles for surface finish issues, voids, or inconsistencies in material bonding.

Test modifications on a small production scale:

- Vary one parameter at a time, e.g., adjust mold temperature while keeping pressure constant.

- Track the effects on resin distribution and overall paddle quality.

- Use statistical process control (SPC) tools to analyze the data and identify optimal settings.

Based on your initial tests, refine the mold design and production process:

- Employ simulation software to model resin flow dynamics.

- Adjust gate locations, venting channels, and cooling channels to minimize resin stagnation.

- Experiment with composite layering techniques to ensure balanced distribution and bonding.

After adjustments, validate the new settings with full-scale production:

- Monitor production consistency through routine quality audits.

- Gather feedback from field tests, focusing on paddle performance parameters like rebound, control, and durability.

- Ensure that any variations in resin flow or mechanical performance remain within acceptable limits defined by your quality control standards.

These strategies are not a one-time fix. It's essential to institute a continuous improvement program:

- Regularly update your process parameters based on raw material batch variations.

- Stay informed on the latest advancements in sensors and automation tools to further refine your process.

- Encourage cross-functional collaboration between R&D, production, and quality control teams to share insights and rapidly address any deviations.

While optimizing resin flow significantly boosts production quality, a few limitations and factors should be kept in mind:

-

Material Sensitivity:

Advanced materials like carbon fiber and specialized composites have inherent properties that may limit the extent of process modification possible without affecting performance. -

Equipment Investment:

A transition to more automated, sensor-driven production processes demands upfront investment. It is crucial to balance the cost with the long-term quality and efficiency gains. -

Process Complexity:

With each additional parameter fine-tuned, the process complexity rises. Ensuring that operators are properly trained and that detailed documentation is available is essential for consistent results. -

Quality Variance Across Batches:

Even with optimal settings, slight variations in material batches can cause changes in resin behavior. Establishing robust quality inspection protocols becomes vital to catch and correct deviations early.

At NEX Pickleball, a leader in high-performance pickleball paddle manufacturing, we continuously invest in process innovation to improve our production methods. Our experience with diverse production processes—hot pressing for high-strength products, cold pressing for excellent ball feel, and thermoforming for intricate designs—has allowed us to hone a resin flow optimization strategy that consistently delivers paddles meeting rigorous quality standards.

For instance, when producing paddles that integrate Nomex Honeycomb Cores5 and carbon fiber surfaces, our R&D team faced challenges with resin distribution. By methodically adjusting our mold temperature and optimizing pressure profiles, we achieved:

- A 15% improvement in resin flow uniformity

- Reduced cycle times by 10% without compromising quality

- Enhanced paddle durability and improved vibration absorption characteristics

These improvements not only boosted product performance but also provided a competitive edge in the marketplace by consistently delivering paddles built for peak performance under varying playing conditions.

Optimizing resin flow in the compression molding process is essential for producing high-quality pickleball paddles that meet the rigorous demands of competitive play. By focusing on precise control over temperature, pressure, mold design, and material-specific characteristics, manufacturers can achieve significant improvements in product durability, performance, and overall efficiency.

To summarize:

• Begin with a thorough diagnosis of your current molding process to identify inefficiencies.

• Perform controlled experiments to fine-tune process parameters.

• Implement design improvements in the mold to facilitate even resin flow.

• Validate changes with full-scale production trials.

• Commit to continuous improvement by leveraging modern automation and sensor technology.

By following these steps and leveraging real-world insights from industry leaders like NEX Pickleball, your manufacturing operations can achieve enhanced production quality and efficiency, ensuring that every paddle meets the high standards expected by competitive players worldwide.

People Also Ask

Q1: What is resin flow optimization in compression molding?

A1: Resin flow optimization involves adjusting temperature, pressure, and mold design to ensure even resin distribution during compression molding. This process is critical in preventing voids and weak spots, leading to improved product quality and consistency.

Q2: What factors influence resin flow during compression molding?

A2: Key factors include temperature control, pressure settings, mold design complexity, and material characteristics. These factors affect viscosity, cavity filling, and bonding strength, ultimately influencing the paddle’s durability and performance.

Q3: How does resin flow affect the quality of pickleball paddles?

A3: Proper resin flow ensures uniform distribution of materials and a strong bond between components, leading to paddles with superior impact resistance, enhanced vibration absorption, and consistent performance characteristics.

-

compression molding: Read this article to understand the process of shaping materials under heat and pressure, its applications in manufacturing, and how it ensures consistent product quality. ↩ ↩ ↩2 ↩3

-

resin flow optimization: Click here to learn about strategies to improve resin distribution during molding, reduce voids, and enhance the structural integrity of the final product. ↩ ↩

-

3K Carbon Fiber: Discover details about 3K Carbon Fiber including its properties, applications in high-performance manufacturing, and how it compares with other carbon fiber types. ↩ ↩

-

T300 Carbon Fiber: This article explains the characteristics of T300 Carbon Fiber and its role in reinforcing composites, offering insights on how optimal processing can protect its intrinsic properties. ↩ ↩

-

Nomex Honeycomb Cores: Learn about Nomex Honeycomb Cores, their structure, benefits in energy absorption, and how they contribute to lightweight yet durable composite designs. ↩ ↩