Achieving certification for pickleball paddles in the USA and international markets requires a clear understanding of regulatory frameworks1, rigorous product testing, and adherence to industry standards. In essence, manufacturers must develop robust quality control measures, ensure manufacturing compliance, and pursue continuous improvement in production processes to secure proper certifications.

For B2B product development managers and executives, certification is not just a regulatory hurdle—it is a crucial element in establishing brand credibility and market acceptance. Certification pathways2 ensure that pickleball paddles meet rigorous safety, performance, and quality standards required by the USA Pickleball association as well as by international regulatory bodies.

Key elements of certification include:

- Compliance with USA Pickleball standards and other international regulations.

- Detailed product testing procedures to verify performance and safety.

- Documentation and traceability3 of production processes.

By achieving these standards, manufacturers can confidently address market demands, enhance product reputation, and facilitate smoother export in both domestic and international markets.

Many manufacturers encounter challenges during the certification process. These challenges may include:

- Complex Regulatory Frameworks: Navigating through multiple regulatory bodies and understanding the specific guidelines required for each market.

- Stringent Testing and Quality Control: Maintaining consistency in testing protocols for impact resistance, shock absorption, and performance is a significant responsibility.

- Production Process Variability: Different production methods such as hot pressing, cold pressing, and Thermoforming4 each have distinct advantages and limitations, making process standardization a challenge.

- Diverse Global Standards: Products entering the USA market must comply with set guidelines, while international markets may impose additional requirements, thus complicating the certification process.

- Manufacturing Process Complexity: With advanced technologies at play, maintaining the balance between performance and durability often requires fine-tuning production techniques.

- Lack of Unified Testing Protocols: Without consistent testing standards across jurisdictions, manufacturers have to perform additional assessments that may increase the time and cost to market.

Manufacturers must strategically address these factors to ensure regulatory compliance and high performance of their products.

To streamline the certification process and ensure robust compliance, a solution-oriented approach is recommended. Below is a clear pathway for certification, summarized in the table below:

| Certification Step | Description | Key Considerations | Estimated Time Frame |

|---|---|---|---|

| Initial Regulatory Assessment | Analyze USA and international certification guidelines | Understand differences between domestic and international standards | 2-4 weeks |

| Product Testing and Analysis | Conduct rigorous performance tests (impact resistance, durability) | Use certified testing labs, maintain traceability | 4-6 weeks |

| Process Documentation | Prepare detailed reports and quality control documentation | Ensure documentation matches regulatory claims | 1-2 weeks |

| Manufacturing Process Review | Evaluate production methods (hot pressing, cold pressing, thermoforming) | Optimize for both consistency and performance | 3-5 weeks |

| Final Certification Submission | Submit documentation and test results to regulatory authorities | Verify all data is accurate and complete | 2 weeks |

This structured process not only demystifies the certification pathway but also underscores the systematic approach needed by B2B stakeholders when planning for regulatory compliance.

At NEX Pickleball, we understand that achieving certification is intertwined with the quality of the manufacturing process. Our advanced production techniques are designed to support stringent certification requirements. Consider the following core aspects:

-

Hot Pressing:

- Advantages: Efficient large-scale production, high impact resistance, and solid structural integrity.

- Disadvantages: Alterations in material properties may affect the paddle feel; high initial investment in equipment.

-

Cold Pressing:

- Advantages: Precise control over thickness, maintains material properties, and improves overall ball feel and responsiveness.

- Disadvantages: Longer production cycles due to reduced efficiency.

-

- Advantages: Ideal for complex designs, ensures even material distribution, and enhances paddle stability.

- Disadvantages: Higher equipment costs and longer production time.

Each of these techniques requires careful calibration and quality control measures to ensure that every paddle meets the required certification standards.

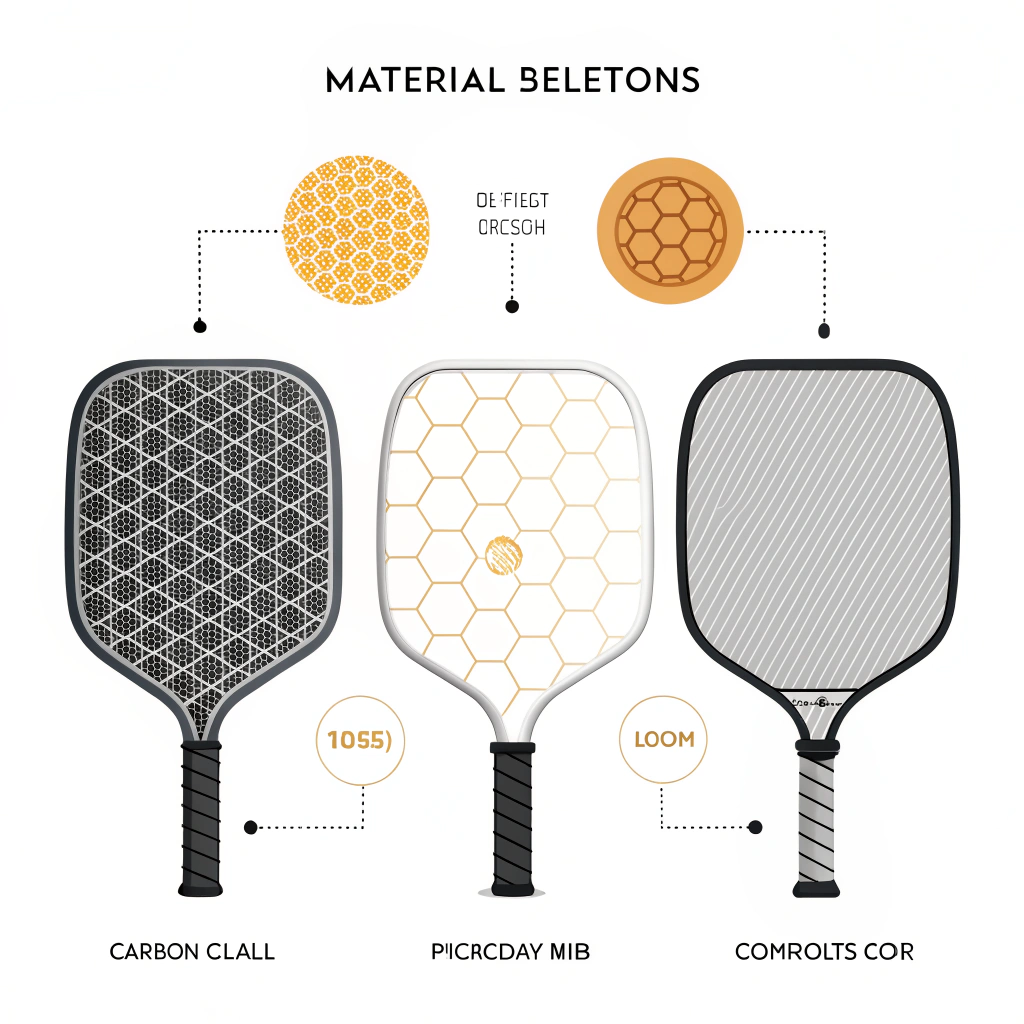

The selection of materials is fundamental to regulatory compliance. Key materials include carbon fiber variants (3K, 12K, T300), fiberglass, and various composite materials5 such as Bamboo Core and Honeycomb Core. The benefits of these materials include:

- Enhanced durability and strength.

- Optimized weight distribution and ergonomic comfort.

- Superior impact resistance and vibration absorption.

Understanding the properties of these materials helps manufacturers design products that not only perform well in play but also pass critical safety and performance tests required for certification.

The core material is another essential factor in certification. Different cores—such as Nomex Honeycomb, Aluminum Honeycomb, and Polymer Honeycomb—offer varying benefits in terms of shock absorption, resilience, and overall playability. Selecting the appropriate core material can have a significant impact on the paddle’s performance during standardized testing.

Manufacturers must ensure that every material utilized is consistently applied and documented throughout the production process to support the certification process. This documentation assures regulatory bodies that the product meets or exceeds market standards.

A successful certification strategy involves several key steps:

Before initiating the certification process, companies must conduct a comprehensive gap analysis to identify any disparities between current manufacturing practices and regulatory requirements. This analysis should cover:

- Material performance under regulatory tests.

- Process consistency in production techniques.

- Documentation accuracy for traceability and quality control.

Based on the gap analysis, companies can establish actionable steps to bridge any compliance gaps.

Maintaining a robust quality control system is paramount. Regular internal audits and third-party inspections can help maintain compliance. The quality control process should involve:

- Routine inspections of production lines.

- Periodic re-testing of products for performance consistency.

- Continuous training for staff on compliance protocols and regulatory updates.

These measures ensure that the paddles consistently meet regulatory standards and quickly identify any deviations before products reach the market.

Collecting and analyzing production and performance data is crucial for continuous improvement. Manufacturers should implement a feedback loop that involves:

- Monitoring product performance in real-world conditions.

- Gathering feedback from regulatory inspections and certification bodies.

- Adjusting production protocols based on data insights and compliance requirements.

This data-driven approach not only supports certification efforts but also fosters innovation and product optimization.

Several industry case studies highlight how manufacturers have successfully navigated the certification process. For example, companies that integrated advanced quality control systems, robust product testing, and precise documentation practices have seen:

- Faster market entry timelines.

- Reduced costs related to re-testing and certification rejections.

- Improved product reliability and customer satisfaction.

A recent study showed that companies prioritizing certification compliance experienced up to a 30% reduction in product returns and warranty claims. Documenting these results and sharing best practices can inspire confidence in potential B2B partners and regulatory bodies alike.

Table 2 below outlines a comparative analysis of certification timelines for companies employing different strategies:

| Strategy | Certification Time | Rejection Rate | Cost Efficiency |

|---|---|---|---|

| Traditional Approach | 16 weeks | 15% | Moderate |

| Advanced Quality Control | 10 weeks | 5% | High |

| Integrated Data Feedback | 8 weeks | 3% | Very High |

This data underscores the value of integrating quality control and data feedback mechanisms in the certification process.

Certification of pickleball paddles is a multi-step process that demands thorough understanding of regulatory requirements, careful planning, and meticulous quality control. By following the outlined certification pathway, manufacturers can streamline product approval, reduce time to market, and ensure superior product quality.

Key takeaways include:

- Understand the regulatory landscape: Familiarize yourself with USA Pickleball standards and export certification requirements.

- Optimize manufacturing processes: Utilize advanced production techniques and maintain stringent quality control.

- Adopt a data-driven approach: Regularly monitor product performance and adjust processes based on continuous feedback.

- Document thoroughly: Keep detailed records of all processes, testing protocols, and material selections to support certification submissions.

For businesses ready to pursue certification and ensure market compliance, taking a proactive and systematic approach is essential. We encourage you to review your current processes, identify potential gaps, and adopt best practices to achieve efficient and successful certification. Our in-depth understanding of both manufacturing and certification processes positions us as a strategic partner, ready to support your journey to market excellence.

-

What are the key certification requirements for pickleball paddles?

Answer: The key certification requirements include compliance with USA Pickleball standards and international regulations, rigorous product testing for impact and durability, and comprehensive documentation of production processes to ensure quality and safety. -

Why is regulatory compliance important for manufacturers in the sports equipment industry?

Answer: Regulatory compliance is crucial because it ensures product safety, enhances market acceptance, builds customer trust, and helps manufacturers avoid costly recalls or legal issues by adhering to established industry standards. -

How can manufacturers ensure their products meet USA and international standards?

Answer: Manufacturers can meet these standards by implementing strict quality control measures, utilizing advanced production techniques such as hot pressing, cold pressing, and thermoforming, conducting thorough product testing, and maintaining detailed documentation throughout the production process.

-

regulatory frameworks: Click here to explore detailed analyses on navigating complex regulatory environments and understanding compliance requirements for international markets. ↩ ↩

-

Certification pathways: Click here to learn about various certification methods, their benefits, and how they contribute to product credibility and market success. ↩ ↩

-

traceability: Click here to explore the importance of traceability in quality management and regulatory compliance, and how it enhances production transparency. ↩ ↩

-

Thermoforming: Click here for an in-depth explanation of thermoforming technology, its processes, advantages, and challenges in manufacturing. ↩ ↩ ↩2

-

composite materials: Click here to understand the different types of composite materials used in manufacturing, their properties, and applications in product design and performance improvement. ↩ ↩