Quick Answer: The evolution of pickleball paddle design has been fueled by innovations in shape, material selection, and manufacturing processes such as hot pressing1, cold pressing2, and thermoforming3. These advancements lead to enhanced performance, durability, and ergonomic comfort, which are vital for competitive play and market differentiation.

Pickleball, a fast-growing sport, has experienced significant growth in both recreational and competitive arenas. As the game evolves, so do the needs of players and the expectations for equipment performance. Traditional paddle designs have gradually given way to more advanced shapes and material combinations. Today’s B2B decision-makers in the sports equipment industry are tasked with incorporating these innovations to maintain a competitive edge and meet market demand.

The challenge for many manufacturing companies lies in balancing design innovation with cost-effectiveness. At the heart of these advancements are production processes and material choices that directly affect paddle performance. Companies like NEX Pickleball have leveraged cutting-edge techniques and premium materials such as carbon fiber4, fiberglass, and composite materials5 to create high-performance paddles that maximize playability and durability.

There are several underlying factors driving the evolution of pickleball paddle design:

-

Increased Demand for Enhanced Performance: Players require paddles that deliver greater power, improved control, and reduced vibration. This has led to the exploration of stronger yet lighter materials.

-

Ergonomic Design Expectations: The need for paddles that offer ergonomic comfort and reduce injury risks has pushed manufacturers to experiment with new shapes and grip designs.

-

Technological Advancements in Production: Innovations in manufacturing processes such as hot pressing, cold pressing, and thermoforming allow for precise control over paddle attributes, from weight distribution to surface texture.

-

Competitive Market Positioning: In an increasingly competitive market, suppliers must distinguish their products not only by performance but also by incorporating durable and aesthetically appealing designs.

These market drivers compel manufacturers to continually refine their production techniques and material formulations to meet the demands of sophisticated buyers.

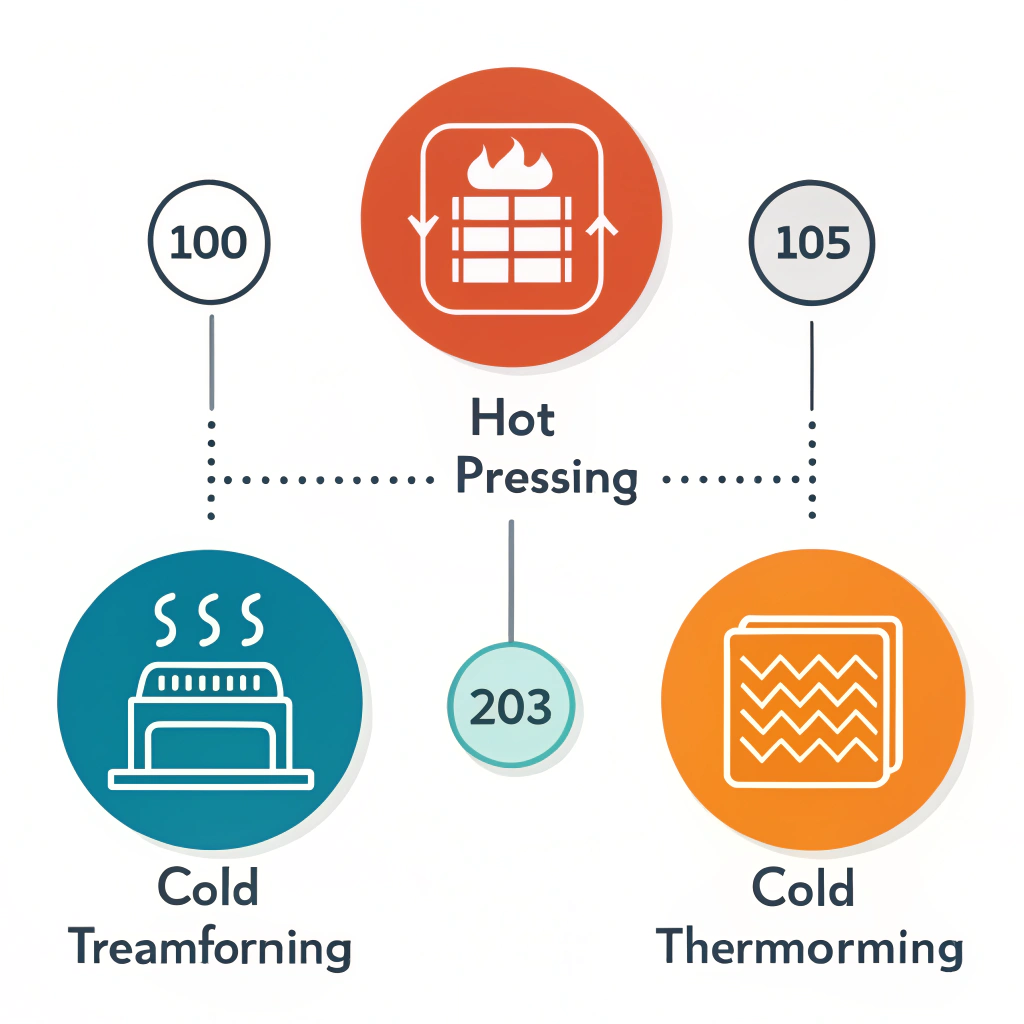

To address these market challenges, advanced manufacturing techniques play a pivotal role in paddle evolution. Let’s take a closer look at the three main processes used in production:

Hot pressing involves heating materials and applying uniform pressure to form the paddle structure.

• Advantages:

- High production efficiency suitable for mass production.

- Creates a strong bond between layers, leading to excellent durability and impact resistance.

- Enhances the paddle’s structural integrity, making it ideal for high-performance products.

• Disadvantages: - The high temperature can slightly alter material properties, potentially affecting the paddle’s feel.

- Significant initial investment in specialized equipment is required.

Cold pressing shapes paddle materials at room temperature with mechanical pressure.

• Advantages:

- Enables precise control of paddle thickness and distribution, ensuring excellent ball feel.

- Maintains the inherent properties of materials, preserving flexibility and control.

- Ideal for producing paddles that require nuanced performance characteristics.

• Disadvantages: - The process is generally slower, leading to longer production cycles.

- Requires meticulously managed pressure control, which entails high-quality machinery.

Thermoforming involves heating the paddle material just enough to soften it before forming it into intricate shapes using molds.

• Advantages:

- Provides greater design flexibility, accommodating complex shapes and innovative material distributions.

- Enhances stability and performance by ensuring consistent material thickness.

- Particularly suited for premium products and custom designs.

• Disadvantages: - Typically involves longer production times and higher equipment costs.

- Best applied for specific product lines rather than mass-market productions.

Below is a comparative table summarizing the key points of each process:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, structural integrity | Material property alteration, high equipment cost |

| Cold Pressing | Precise control, preserved material properties, excellent ball feel | Longer production cycles, requires high-quality equipment |

| Thermoforming | Design flexibility, stable material distribution, premium quality | Extended production time, higher cost |

Modern pickleball paddles today utilize innovative materials to enhance performance. Here are some key materials and design techniques that have transformed paddle production:

The use of carbon fiber4 in paddles has soared due to its impressive strength and light weight. Manufacturers deploy various carbon fiber types to cater to different needs:

- 3K Carbon Fiber: Offers a balance of flexibility and strength, providing a high rebound force while maintaining durability.

- 12K Carbon Fiber: Known for its smooth surface, higher hardness, and impact resistance, it is ideal for competitive play where precision is essential.

- T300 Carbon Fiber: Combines excellent tensile strength with lightweight properties, ensuring enhanced responsiveness and control.

For manufacturers looking to balance power and control, fiberglass remains a prime material. Its elasticity and broader sweet spot contribute significantly to ball control. Additionally, composite materials5 that blend carbon fiber and fiberglass are gaining popularity. They merge the strengths of both fibers to create paddles with the right mix of durability and flexibility.

Composite cores, such as Bamboo Core or Honeycomb Core, also contribute to the overall paddle performance:

- Bamboo Core Composite: Offers remarkable impact resistance and a natural feel for long-lasting play.

- Honeycomb Core (Nomex/Aluminum/Polymer): Provides superior shock absorption, reducing vibrations and increasing durability while delivering consistent hitting performance.

Ergonomic innovation has become integral in modern paddle design. The evolution in paddle shapes is not only about aesthetics but also about providing a comfortable grip and balanced weight distribution. Ergonomic considerations ensure that paddles fit various hand sizes and reduce fatigue during prolonged play. Manufacturers are increasingly incorporating custom paddle options where clients can specify design, weight, balance, and grip size, further enriching market value.

While the innovations in paddle design and manufacturing are impressive, companies must be mindful of several limitations and concerns:

-

Equipment Investment: Advanced techniques like thermoforming and high-precision cold pressing require significant capital expenditure in machinery and technology, which can impact overall production costs.

-

Production Cycle Time: Processes like cold pressing and thermoforming may lengthen production cycles. B2B decision-makers need to consider these factors when planning large-scale production orders.

-

Quality Consistency: Maintaining high-quality standards throughout advanced manufacturing processes is a challenge. Rigorous quality control protocols must be in place to ensure every paddle meets strict performance criteria.

-

Material Supply Chain: The availability and cost of premium materials such as high-grade carbon fiber and specialized composites can fluctuate. Strategic sourcing and long-term supply agreements are vital to mitigate these risks.

Understanding these constraints helps in making informed decisions that align with both production capacity and market demand.

NEX Pickleball has positioned itself as a leader in high-performance pickleball paddle manufacturing by addressing these challenges head-on. By implementing a combination of hot pressing, cold pressing, and thermoforming, the company tailors its production processes to match specific product requirements. Their strategic use of premium materials such as various types of carbon fiber4, fiberglass, and composite cores ensures that each paddle delivers superior performance and durability.

For instance, in the development of their latest paddles, NEX Pickleball conducted rigorous testing to optimize weight distribution and ergonomic grip design. This was supported by advanced quality control measures that ensured consistent product output—an essential factor for both recreational players and competitive professionals.

The company’s expertise in custom paddle design has also allowed them to cater to specific needs of teams and retail distributors. By offering customizable options, NEX Pickleball not only meets diverse market demands but also builds strong B2B partnerships, providing technical support and innovation-driven insights to enhance product portfolios.

Through these initiatives, NEX Pickleball illustrates that understanding and integrating advanced manufacturing and innovative design can create products that stand out in a crowded market.

The evolution of pickleball paddle design is a multifaceted process influenced by technology, material science, and market dynamics. Key takeaways include:

-

Advanced Manufacturing Techniques: Incorporating processes such as hot pressing, cold pressing, and thermoforming optimizes paddle performance and durability. Each process offers distinct advantages and limitations, which must be carefully balanced based on product requirements and market needs.

-

Material Innovations: The use of premium materials such as carbon fiber4, fiberglass, and advanced composites has significantly improved paddle performance. Manufacturers must choose materials that best meet the demands for power, control, and longevity.

-

Ergonomic Considerations: Evolving paddle shapes are not solely about visual appeal; they are critical in creating comfortable, balanced, and performance-enhancing equipment. Custom solutions further tailor the supply to meet varied consumer demands.

-

Operational and Cost Considerations: Investment in advanced production technologies and sustainable supply chain management is essential to mitigate the challenges associated with longer production cycles and quality consistency.

For B2B decision-makers, evaluating these factors can lead to better procurement decisions. It is advisable to:

- Conduct a detailed cost-benefit analysis of the different manufacturing processes.

- Engage with suppliers who offer customization options to align with specific market needs.

- Leverage technical partnerships for long-term innovation and quality improvements.

By integrating these strategies, companies can enhance their product portfolios, improve market positioning, and ultimately deliver superior value to end users. Manufacturers should continuously monitor technological developments and industry trends to remain agile and competitive in this fast-evolving market.

-

What manufacturing process is best for high-performance pickleball paddles?

Answer: High-performance paddles often benefit from processes like hot pressing, cold pressing, and thermoforming. Each process offers distinct advantages—hot pressing for efficiency and strength, cold pressing for precision and ball feel, and thermoforming for complex, premium designs. -

How do advanced materials like carbon fiber enhance paddle performance?

Answer: Advanced materials such as various types of carbon fiber improve paddle performance by providing a balance of strength and lightness, improved rebound force, impact resistance, and reduced vibration—making them ideal for competitive play. -

What factors should be considered when choosing a production method for pickleball paddles?

Answer: Key factors include production efficiency, equipment cost, desired material properties, cycle time, and consistency in quality control. Manufacturers must balance these considerations to achieve optimal performance while meeting market demands.

-

hot pressing: Reading this article will help you understand how the hot pressing process uses heat and pressure to bond materials effectively, offering efficiency and durability in high-volume production environments. ↩ ↩

-

cold pressing: Discover more about cold pressing to learn how it preserves the natural properties of materials, allowing for precise control and a superior ball feel in specialized manufacturing contexts. ↩ ↩

-

thermoforming: Click here to gain insights into thermoforming, a technique that heats materials to form complex shapes, providing enhanced design flexibility for premium sports equipment. ↩ ↩

-

carbon fiber: This resource explains the benefits of carbon fiber, including its strength-to-weight ratio and durability, which are critical for high-performance sports products. ↩ ↩ ↩2 ↩3 ↩4

-

composite materials: Explore composite materials to understand how combining fibers can merge distinct advantages, offering balanced performance and longevity in a range of applications. ↩ ↩ ↩2