Edge beveling is a design innovation that can significantly reduce aerodynamic drag, optimize weight distribution, and ultimately enhance the paddle’s swing speed and overall performance. In this article, we explore the technical benefits and production considerations of Edge beveling1 in pickleball paddle design, providing actionable insights for engineering managers and product development specialists.

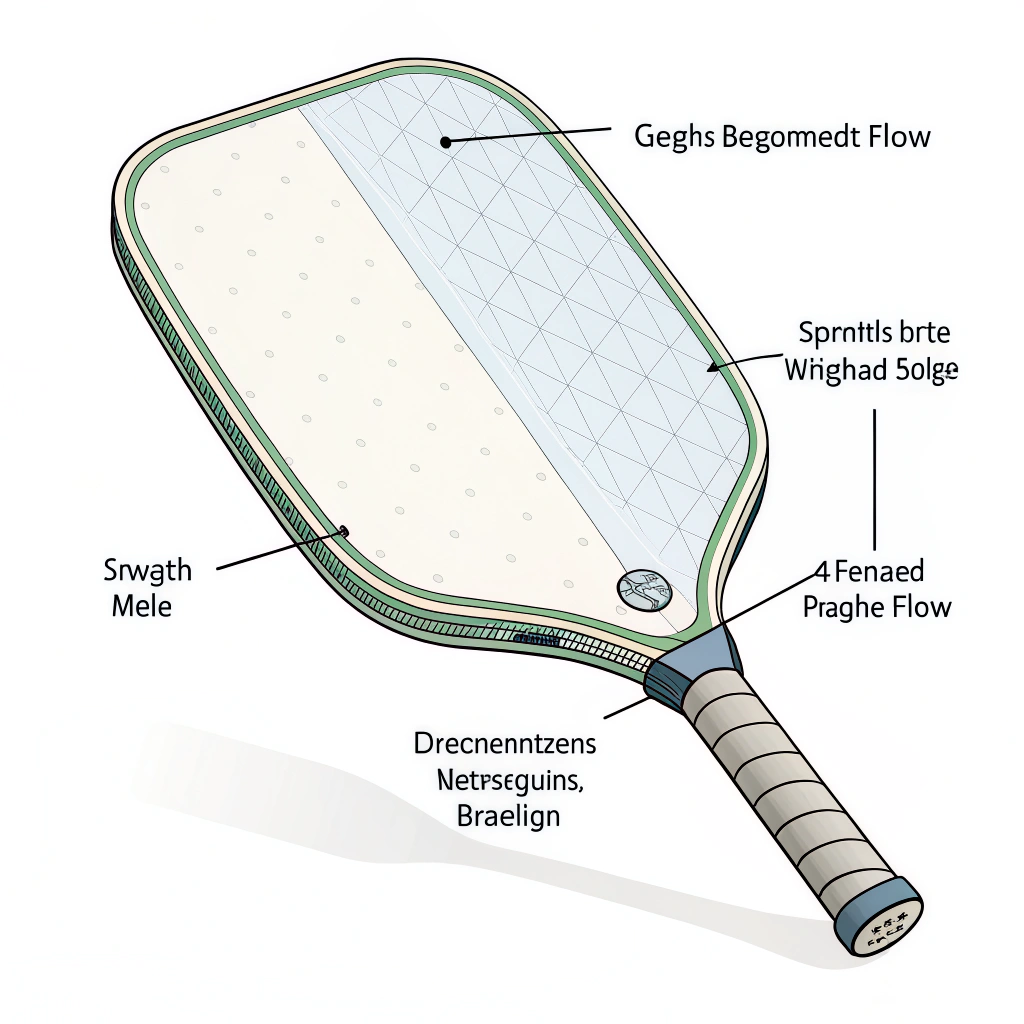

Edge beveling refers to the process of chamfering or tapering the edges of a paddle to create a smoother transition between the playing surface and the paddle’s perimeter. This modification not only refines the paddle’s aesthetics but also influences key performance aspects by affecting airflow, weight distribution, and impact dynamics.

The main benefits of edge beveling include:

• Reduced aerodynamic drag during swift swings

• Improved weight distribution that contributes to balance and maneuverability

• Enhanced compatibility with various production processes such as hot pressing2, cold pressing3, and thermoforming4

These benefits allow manufacturers to offer paddles that meet high-performance standards without compromising durability or structural integrity.

When designing high-performance pickleball paddles, one of the core challenges is optimizing both swing speed and control. Traditional paddle edges, which are often squared off, may create additional air resistance and uneven weight distribution, especially at high speeds. This is particularly problematic in competitive play, where even slight delays in paddle movement can affect ball control and overall game performance.

Key challenges include:

• Combatting unintended aerodynamic drag during rapid swings

• Achieving a balanced center of gravity without sacrificing paddle strength

• Adapting traditional production processes to accommodate precision edge modifications

Engineering teams need to address these issues while maintaining cost efficiency and production scalability. The emergence of edge beveling solutions meets these technical challenges by offering a modification that enhances both performance and manufacturability.

Edge beveling influences paddle performance through several mechanisms:

-

Aerodynamic Efficiency:

A beveled edge creates a gradually curved surface rather than an abrupt corner. This design reduces air turbulence around the paddle, contributing to smoother, faster swings. The absence of sharp edges minimizes drag, allowing the paddle to accelerate through the air more effectively. -

Optimized Weight Distribution:

Subtle tapering along the edge can help shift weight more evenly across the paddle. A balanced weight distribution means that the paddle can be swung with less effort while still generating significant power on impact. This efficiency is particularly important in paddles made from premium materials like 3K Carbon Fiber5, 12K Carbon Fiber, or Fiberglass. -

Enhanced Structural Integrity:

Although edge beveling changes the physical profile of the paddle, it is designed to preserve — and in some cases, reinforce — structural integrity. By reducing stress concentration at the edges, beveling helps prevent premature wear or failure, particularly in high-impact situations.

The interplay between these factors makes edge beveling a compelling design consideration for companies aiming to improve paddle performance without extensive compromises in other areas.

For a technology-driven production facility like NEX Pickleball, the introduction of edge beveling needs to align with established manufacturing processes. Let’s examine how each method can adapt to this innovative design:

• Advantages:

- High production volume with consistent replication of design features.

- The application of heat and pressure helps in shaping intricate beveling details without compromising material properties.

• Considerations: - High investment in equipment capable of precise temperature and pressure control.

- Potential alteration of some material characteristics, which may need recalibration when introducing edge beveling.

• Advantages:

- Greater precision in achieving exact bevel angles since the process occurs at room temperature.

- Retention of material’s inherent properties, resulting in better control and responsiveness on the court.

• Considerations: - Longer production cycles, which might affect scalability.

- Requires extremely precise pressure calibration to ensure uniform beveling across paddles.

• Advantages:

- Capability to produce complex, curved designs with smooth edge transitions.

- Suitable for premium products where a high level of detail is crucial for performance enhancements.

• Considerations: - Investment in molds and additional equipment may be necessary to capture the bevel design consistently.

- Extended production time compared to hot and cold pressing methods.

Manufacturers can leverage a comparative analysis table to decide the most suitable process for incorporating edge beveling:

| Production Process | Advantages | Considerations | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Equipment cost, potential material changes | High-volume, competitive paddles |

| Cold Pressing | Precise bevel formation, maintains material properties | Longer cycle time, high calibration demands | Optimal control and balanced weight |

| Thermoforming | Intricate designs, stable material distribution | High equipment costs, longer production time | Premium, custom-made paddles |

By understanding these factors, engineering and production managers can tailor their approach based on both performance criteria and operational constraints.

The incorporation of edge beveling in paddle design offers several tangible benefits for enhancing swing speed and overall performance. Let’s break down these advantages with supporting data and real-world application scenarios:

-

Improved Swing Dynamics:

In high-speed gameplay, paddles with beveled edges experience lower aerodynamic drag, enabling quicker follow-throughs and faster racquet transitions. This can directly impact the game by providing players with a more responsive tool. -

Enhanced Ball Control:

With optimized weight distribution, beveled-edge paddles help maintain a tighter control range when striking the ball. This becomes crucial during rapid exchanges in competitive matches where precision is key. -

Material Compatibility:

The design benefits extend across a spectrum of premium materials including Carbon Fiber variants and Fiberglass composites. For instance, using a T300 Carbon Fiber in conjunction with edge beveling can yield a paddle that is both lightweight and robust. Such combinations are especially favored in competitive play, catering to athletes who demand both speed and durability. -

Production and Customization Flexibility:

NEX Pickleball sustains a reputation for custom paddle options where clients can specify design modifications. Edge beveling is an ideal candidate for customization, allowing production teams to tailor paddle characteristics for different player profiles or performance requirements. Advanced manufacturing techniques support this flexibility, ensuring each paddle meets stringent quality and performance standards.

Add-on benefits include enhanced ergonomics, as the softened edges contribute to a more comfortable grip and reduced risk of hand fatigue during prolonged play.

For companies contemplating the integration of edge beveling into their production lines, a methodical approach is recommended. Consider the following guidelines:

• Perform pilot tests by producing a limited series of beveled-edge paddles. Compare these against traditional designs in terms of swing speed, control, and durability.

• Utilize simulation software to model the aerodynamic effects of different bevel angles. This will help in forecasting performance improvements and potential structural impacts.

• Collaborate with material suppliers to ensure that the chosen materials can undergo beveling processes without adverse changes in properties.

• Train production teams on the nuances of integrating edge beveling within hot pressing, cold pressing, or thermoforming processes so that consistency across batches is maintained.

• Collect player feedback and performance data through controlled matches to evaluate real-world benefits and identify areas for further refinement.

The combination of technical tests and in-game performance analytics will offer comprehensive insights, aiding in the eventual decision to roll out the design modification on a larger scale.

Edge beveling offers a promising opportunity for businesses aiming to optimize pickleball paddle performance. By carefully analyzing both the aerodynamic and ergonomic benefits alongside the production considerations, engineering managers and product development specialists can make an informed decision about incorporating this feature into their product lines.

To summarize:

• Edge beveling reduces aerodynamic drag, enhancing swing speed and responsiveness.

• It contributes to a more balanced weight distribution, which improves overall control and precision.

• Successful integration depends on aligning the bevel design with existing manufacturing processes such as hot pressing, cold pressing, or thermoforming.

• A methodical, data-driven approach is essential—pilot testing, simulation modeling, and real-world feedback are key steps in the decision-making process.

For companies looking to stay at the forefront of innovation, edge beveling represents a strategic enhancement that meets the performance demands of both competitors and recreational players alike. We encourage industry professionals to evaluate this design adjustment in their production processes and consider pilot testing to fully realize its potential benefits.

Q: What is edge beveling in pickleball paddle design?

A: Edge beveling is the process of tapering or chamfering the edges of a pickleball paddle to create a smoother transition on the perimeter. This reduces drag and improves weight distribution, resulting in enhanced swing speed and improved ball control.

Q: How does edge beveling affect paddle swing speed?

A: By reducing aerodynamic drag during rapid swings and optimizing weight distribution across the paddle, edge beveling allows for faster acceleration and smoother follow-through. This leads to a more responsive paddle that can deliver quick and powerful strikes.

Q: Are there any disadvantages to incorporating edge beveling in paddle performance?

A: While edge beveling offers several performance benefits, its implementation requires precise manufacturing adjustments. Inadequate control during processes like hot pressing, cold pressing, or thermoforming could lead to inconsistencies. However, with proper calibration and testing, these potential drawbacks can be managed effectively.

-

Edge beveling: Click to learn about how this design innovation refines paddle geometry to reduce drag and improve weight distribution, enhancing overall performance. Back to Edge beveling ↩

-

hot pressing: Click to explore how hot pressing utilizes heat and pressure for efficient, high-volume production while maintaining intricate design details. Back to hot pressing ↩

-

cold pressing: Click to understand how cold pressing achieves precise bevel angles with better retention of material properties, ideal for controlled production environments. Back to cold pressing ↩

-

thermoforming: Click to discover how thermoforming enables the production of complex, curved designs with smooth transitions, essential for premium paddle manufacturing. Back to thermoforming ↩

-

3K Carbon Fiber: Click to gain insight into the properties and benefits of Carbon Fiber materials used in high-performance paddles, including strength, lightweight, and durability characteristics. Back to 3K Carbon Fiber ↩