In this article, we provide a quick overview of common failure modes in pickleball paddles and present a detailed FMEA analysis1 approach to help manufacturing professionals mitigate risks and enhance production quality.

Pickleball paddles, though designed for high performance, are subject to various failure modes during production and in-service use. Understanding these failure modes is critical for quality engineers, production managers, and technical product managers. By employing a structured Failure Modes and Effects Analysis (FMEA), companies can systematically identify potential defects, analyze their causes, and implement corrective actions. This article discusses typical failure modes in pickleball paddle manufacturing, examines the underlying causes, and presents a comprehensive FMEA framework that will aid you in optimizing your quality assurance systems.

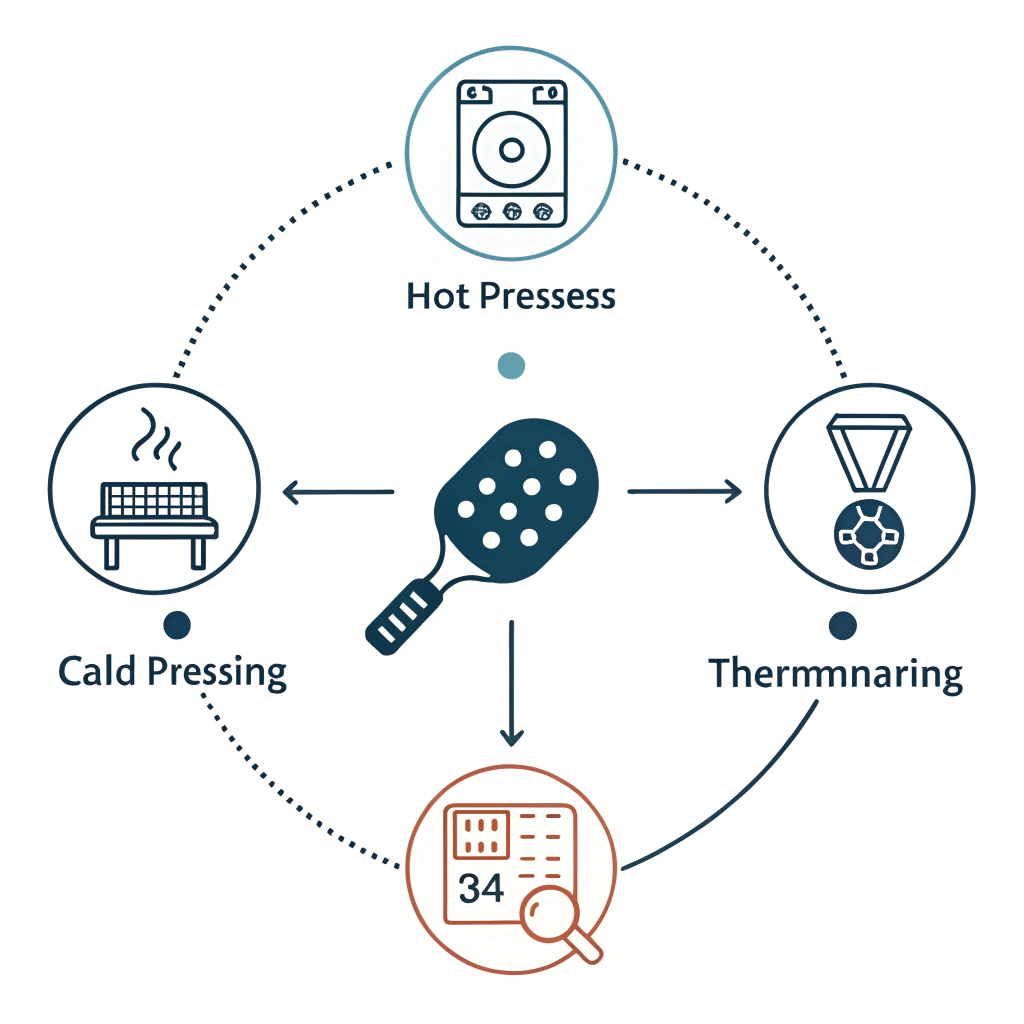

At its core, FMEA is a proactive tool that forecasts manufacturing or operational risks by evaluating the severity, occurrence, and detectability of each identified failure mode. In the context of pickleball paddle production, failures can occur at multiple stages—from raw material selection to the final production processes (hot pressing, cold pressing, or thermoforming). For instance, issues such as delamination2, fiber breakage, or core material degradation may not be immediately visible but have a significant impact on paddle durability and performance.

Pickleball paddles are manufactured using various advanced processes. Each method has its own advantages and potential pitfalls:

-

Hot Pressing

This process involves applying heat and pressure to form paddles. It is highly efficient and produces robust products. However, excessive heat may alter the material properties, potentially leading to:- Delamination within composite materials

- Warping or slight deformation of the paddle shape

- Residual stresses3 that could impact impact resistance

-

Cold Pressing4

The cold pressing process is used primarily for designs requiring precise material control. By maintaining the material’s original properties, manufacturers benefit from excellent control in terms of thickness and structure. However, the longer cycles and need for precise mechanical alignment may lead to:- Inconsistent pressure distribution causing material defects

- Imperfect bonding between layers, especially in composite structures

- Misalignment issues affecting paddle balance

-

Thermoforming5

In thermoforming, materials are heated to a pliable state and formed into shapes using molds. This method is ideal for intricate designs and complex material distributions, but it poses challenges such as:- Extended production times that may lead to inconsistencies

- Higher equipment costs

- Variability in the final surface finish and paddle stability

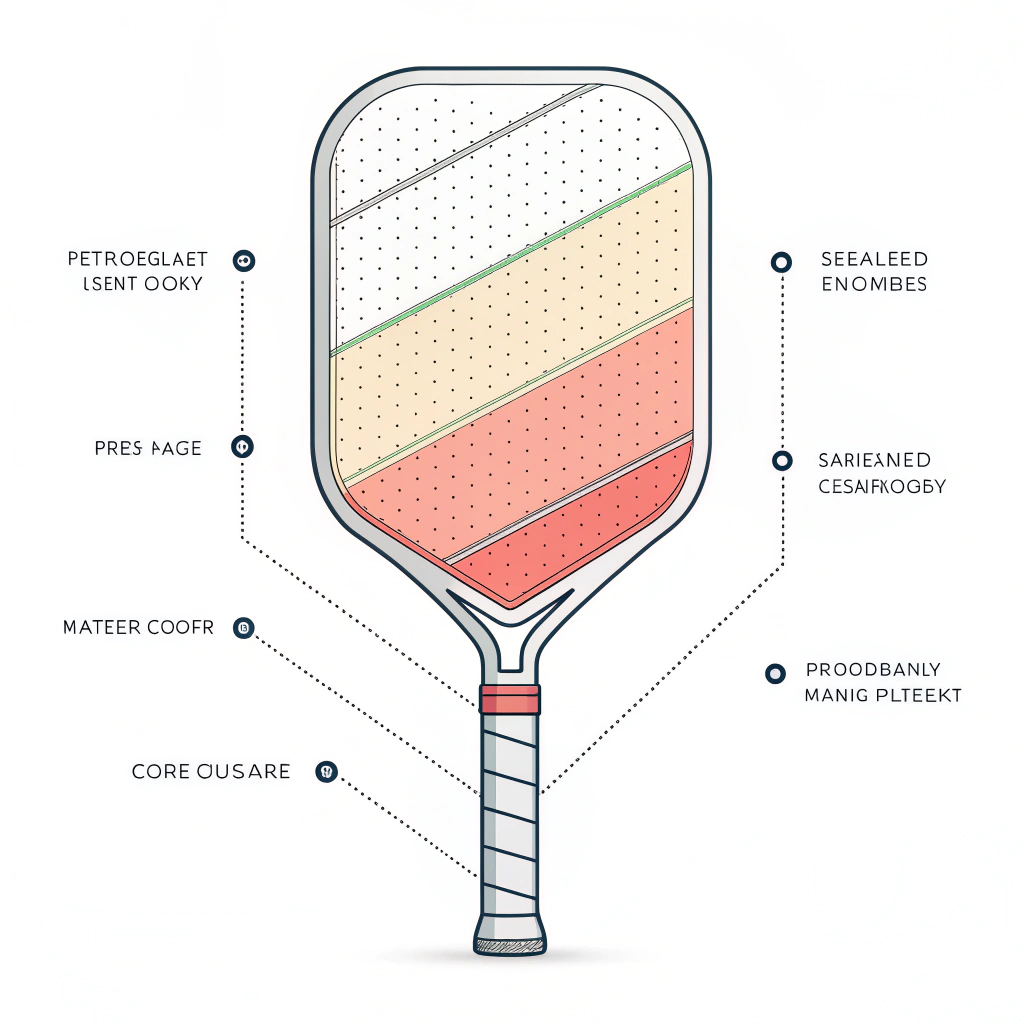

Each of these processes interacts with specific materials used in paddle production. Our materials include several types of carbon fiber (3K, 12K, T300), fiberglass, and various composite materials (e.g., Carbon Fiber and Fiberglass Composite, Bamboo Core Composite, Honeycomb Core), as well as different cores (Nomex, Aluminum, Polymer Honeycomb). Any slight imperfection in these materials or their processing can propagate significant failure modes in the final product.

Before diving into FMEA, let’s outline some of the critical failure modes observed in pickleball paddle manufacturing:

-

Delamination:

Occurs when the layers of composite materials (such as carbon fiber or fiberglass layers) separate. Causes include inadequate bonding, inconsistent pressure during forming, or improper curing. This failure affects both the durability and performance of the paddle. -

Core Degradation:

The paddle’s core (Nomex, Aluminum, or Polymer Honeycomb) is responsible for providing structural stability. Inconsistencies in core density, impact damage, or manufacturing stress can lead to cracks or deformations. This compromises paddle stiffness and the overall ball response. -

Fiber Breakage:

During high-pressure forming or due to improper handling of the paddle material, fiber breakage can occur, reducing both strength and impact resistance. This is especially problematic in high-performance paddles made from T300 Carbon Fiber. -

Surface Imperfections:

Imperfections such as uneven surfaces or surface chipping can result from suboptimal thermoforming parameters or issues in cold pressing. These defects affect not only the paddle's aesthetics but also its grip and control during play. -

Residual Stress and Warping:

Particularly in hot pressing, residual stresses may remain if the process parameters are not rigorously controlled. This may lead to warping or slight dimensional inaccuracies that affect performance.

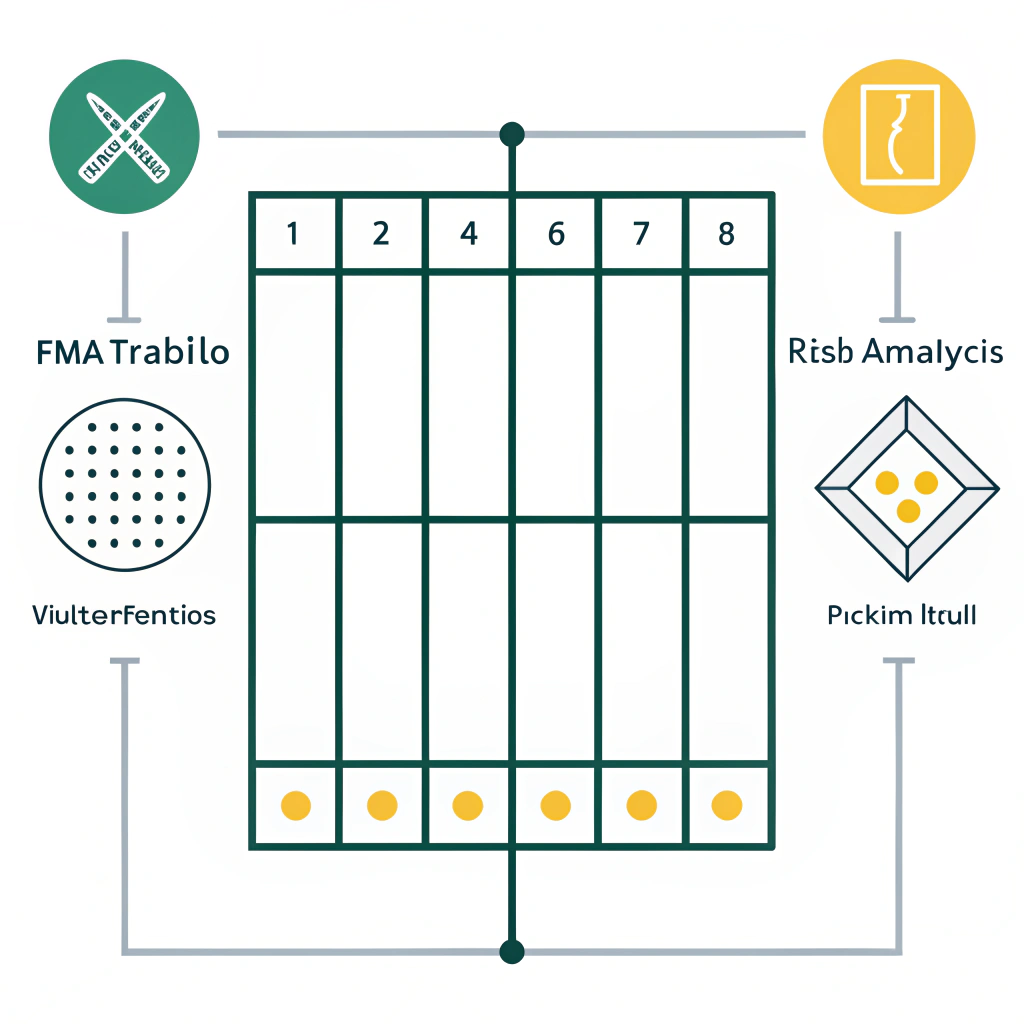

FMEA allows manufacturers to systematically examine each failure mode using a risk management perspective. The process typically involves:

a. Identifying potential failure modes

b. Analyzing the causes and effects of those failures

c. Rating the failure modes on factors such as Severity, Occurrence, and Detection

d. Calculating the Risk Priority Number (RPN) for each failure mode

e. Implementing corrective actions to minimize risk

Below is an example table highlighting common failure modes and their associated FMEA analysis for pickleball paddle production:

| Failure Mode | Cause | Effect | Severity (S) | Occurrence (O) | Detection (D) | RPN (S×O×D) | Proposed Action |

|---|---|---|---|---|---|---|---|

| Delamination | Inadequate bonding, excess heat | Reduced durability, poor performance | 9 | 4 | 3 | 108 | Optimize bonding process, better adhesive control |

| Core Degradation | Material inconsistency, impact | Loss of stiffness, deformation | 8 | 3 | 4 | 96 | Improve core quality inspection, adjust process parameters |

| Fiber Breakage | Excessive pressure, poor handling | Reduced impact resistance | 7 | 5 | 3 | 105 | Refine pressing parameters, enhance quality training |

| Surface Imperfections | Inconsistent thermoforming | Poor grip, compromised aesthetics | 6 | 4 | 4 | 96 | Enhance mold maintenance and process standardization |

| Residual Stress | Suboptimal thermal cycles | Warping, dimensional instability | 8 | 3 | 3 | 72 | Adopt controlled cooling systems, refine press cycle |

This table is a concise representation of how FMEA can help prioritize areas for improvement. By continuously monitoring RPN values, manufacturers can focus on implementing corrective actions where they yield the highest risk reduction.

Implementing FMEA effectively in pickleball paddle manufacturing requires a deep understanding of each production process coupled with rigorous quality controls. Here are several mitigation strategies you may consider:

-

Enhanced Process Control:

- For hot pressing, maintain precise temperature and pressure thresholds to avoid compromising material integrity.

- For cold pressing, ensure alignment precision and consistent mechanical pressure across the entire paddle surface.

- For thermoforming, invest in advanced molds that guarantee uniform heating and cooling, reducing the risk of residual stress.

-

Material Quality Assurance:

- Regularly verify the quality of primary materials such as carbon fiber types (3K, 12K, T300), fiberglass, and composite layers.

- Conduct batch testing on core materials (Nomex, aluminum, polymer honeycomb) to detect any discrepancies before production scaling.

-

In-Process Inspections:

- Integrate in-line inspection systems to monitor surface finish, layer bonding, and core integration.

- Utilize non-destructive testing methods where applicable to detect delamination or internal voids without interfering with production flow.

-

Continuous Improvement Programs:

- Employ lean manufacturing principles and Six Sigma methodologies to identify process variations and drive continuous quality improvements.

- Encourage feedback loops from quality engineers to production teams, ensuring any deviation is addressed immediately.

These strategies, when combined with systematic FMEA analysis, will not only reduce failure rates but also extend the product lifecycle, thereby enhancing customer satisfaction in competitive markets.

Consider a scenario where a leading pickleball paddle manufacturer faced high rates of surface imperfections and delamination in their premium paddle line. After implementing an FMEA approach, the team identified that the adhesive used in the composite bonding process was operating near its temperature limit during hot pressing. By switching to a more temperature-resistant adhesive and adjusting the pressing cycle parameters, the failure mode associated with delamination was significantly reduced. The improvements led to a 30% decrease in warranty claims and a notable enhancement in customer feedback regarding paddle performance.

Parallel to this, the adoption of better inspection techniques during cold pressing ensured that early signs of fiber breakage were detected and rectified. The integration of a real-time monitoring system during the pressing stage enabled the production team to identify anomalies immediately, resulting in a reduction of the overall RPN by 20%.

Such case studies emphasize the importance of a disciplined approach to risk analysis and process optimization. In today’s competitive market, adopting a data-driven FMEA methodology is not just recommended; it is essential for ensuring reliability and performance in sports equipment manufacturing.

In summary, understanding and mitigating the failure modes in pickleball paddle manufacturing is essential for maintaining high-quality products and achieving operational excellence. The structured FMEA methodology provides a robust framework to:

• Identify potential failure points early in the production process

• Quantify risks through systematic scoring of severity, occurrence, and detection

• Prioritize and implement corrective actions based on the calculated RPN

• Continuously monitor process improvements to enhance overall production quality

For quality engineers and production managers, integrating FMEA within your quality assurance systems can provide the necessary insights to pivot production processes for better reliability. We recommend starting with a pilot project focusing on a particularly problematic failure mode, then gradually expanding the scope to cover all critical processes. This step-by-step approach ensures that improvements are sustainable and in line with industry best practices.

If your current production process is experiencing inefficiencies or quality issues, consider a deeper dive into FMEA techniques. Engage with experts, conduct thorough material inspections, and leverage real-time monitoring systems. Ultimately, these efforts will not only reduce costs associated with defects but also reinforce your competitive edge in the market.

People Also Ask

Q1: What are the common failure modes in pickleball paddles?

A1: Common failure modes include delamination of composite layers, core degradation or deformation, fiber breakage, surface imperfections, and residual stresses causing warping. These often result from suboptimal processing parameters and material inconsistencies.

Q2: How does FMEA analysis help improve paddle manufacturing quality?

A2: FMEA analysis helps by identifying potential failure modes, rating them based on severity, occurrence, and detection, and providing a framework to implement corrective actions. This systematic approach reduces risk and enhances product reliability.

Q3: What role do production processes such as hot pressing, cold pressing, and thermoforming play in paddle failure?

A3: Each process affects the paddle differently. Hot pressing can lead to delamination due to excessive heat; cold pressing requires precise pressure control to avoid inconsistent bonding; and thermoforming may introduce residual stresses and surface imperfections if parameters are not properly managed.

-

FMEA analysis: Reading this article will explain how to systematically identify potential defects, analyze risks, and implement corrective actions using FMEA methodology. ↩ ↩

-

Delamination: Learn about the separation of composite material layers, its causes, and how to mitigate this failure mode. ↩ ↩

-

Residual stresses: Understand how internal stresses remain after production processes, affecting material performance and product quality. ↩ ↩

-

Cold Pressing: Explore this precise manufacturing method that preserves material properties and its role in ensuring product integrity. ↩ ↩

-

Thermoforming: Discover the process of shaping materials with heat, including its benefits and challenges in manufacturing. ↩ ↩