Advanced bonding agents in pickleball paddle manufacturing offer improved adhesion, durability, and production efficiency compared to traditional adhesives. This article compares advanced bonding solutions with traditional methods, explains their technical benefits, and provides production insights to guide your decision when integrating these agents into your manufacturing process.

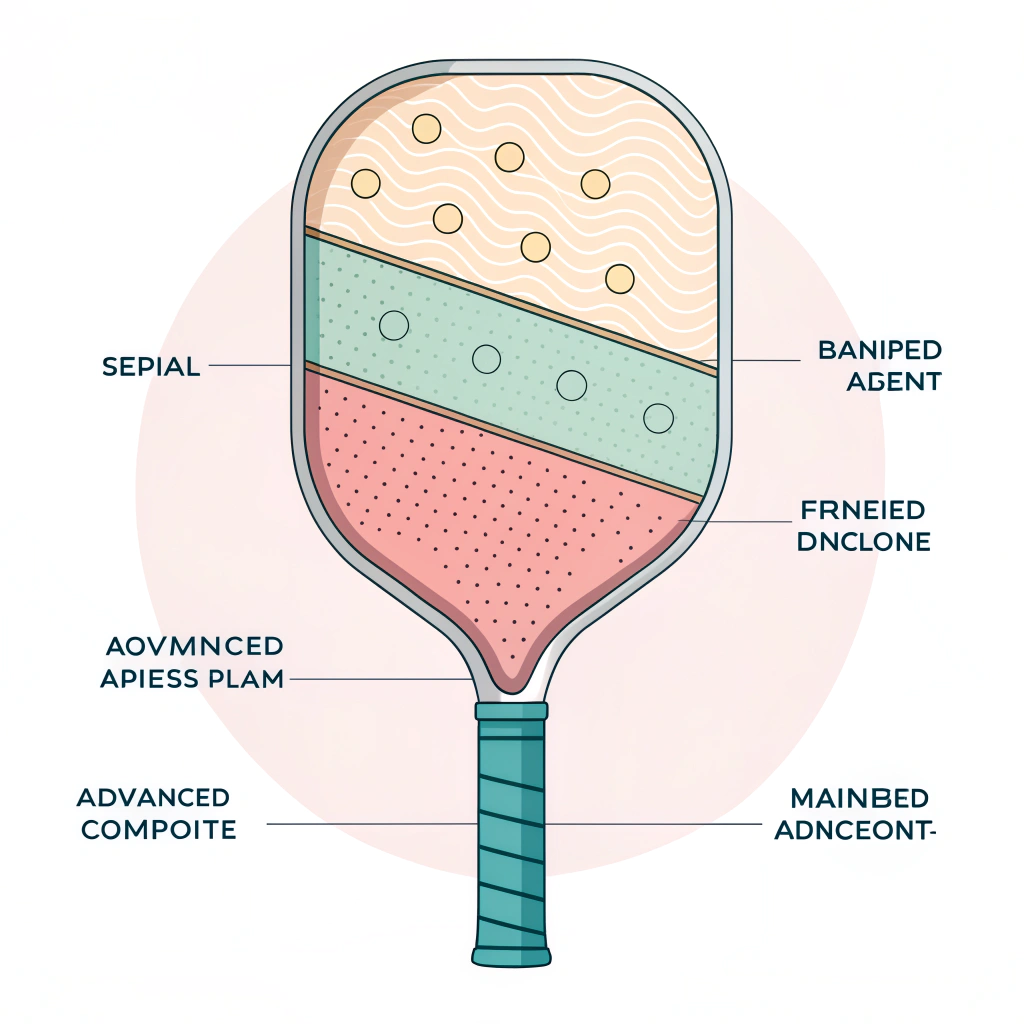

In the competitive field of sports equipment manufacturing, particularly in the niche of pickleball paddles, the choice of bonding agents can significantly influence both the quality of the final product and overall production efficiency. Manufacturers are increasingly turning to advanced bonding agents to meet the demands of modern paddle constructions that use materials like carbon fiber1, fiberglass, and composite cores2. These advanced adhesives not only enhance adhesion between layers but also contribute to improved structural integrity, impacting play performance and durability.

Pickleball paddles are engineered with multiple layers, each contributing unique properties—such as exceptional impact resistance, elasticity, and weight optimization. With traditional adhesives, manufacturers have sometimes faced issues like insufficient curing, inconsistent mechanical properties, and complexities in bonding with advanced substrate materials. Advanced bonding agents resolve many of these issues by providing superior compatibility with advanced composites and enabling faster, more consistent production processes.

The adoption of advanced bonding agents is supported by several factors. First, the complexity of modern paddle designs requires adhesives that can simultaneously bond varied materials without compromising flexibility or durability. Second, as production processes like hot pressing3, cold pressing4, and thermoforming5 are optimized for high output and performance, the adhesion method used must integrate seamlessly within these methods. For instance, during hot pressing, the adhesive must retain its properties even when exposed to high temperatures and pressures. Conversely, with cold pressing, the bonding agent must provide strong adhesion without the thermal activation offered by heat.

Below is a detailed comparison between traditional adhesives and advanced bonding agents used in pickleball paddle manufacturing:

| Feature | Traditional Adhesives | Advanced Bonding Agents |

|---|---|---|

| Adhesion Strength | Moderate, may suffer from weaker interlayer bonding | High, engineered for optimal inter-layer adhesion with advanced composites |

| Curing Process | Longer curing times, often requiring external cure environments | Faster curing times with in-situ activation, streamlining production cycles |

| Material Compatibility | Limited compatibility with materials like carbon fiber and fiberglass | Specifically formulated for a wide range of substrates ensuring robust adhesion |

| Vibration Reduction | May allow for higher vibration and less shock absorption | Superior damping properties reduce vibration, enhancing playing comfort |

| Production Efficiency | Can slow down the production cycle due to longer curing times | Facilitates shorter cycle times, especially in high-throughput environments |

| Durability | Susceptible to degradation under extreme conditions | Highly durable, maintains strength under varying temperatures and pressures |

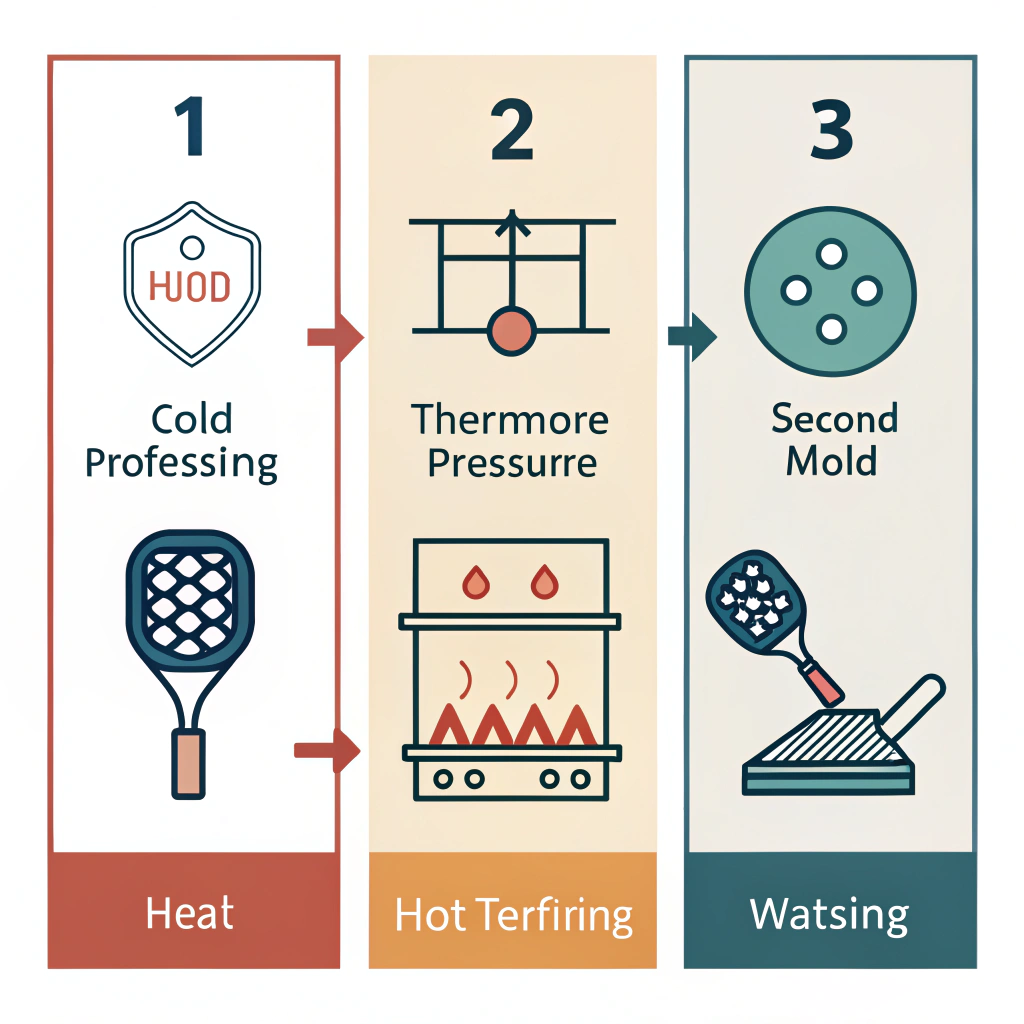

The production process itself plays a crucial role in determining which bonding agent to select. Let’s explore how each process interacts with bonding agents:

-

Hot Pressing3:

Hot pressing applies high temperatures and pressure to bond layers. Advanced bonding agents designed for hot pressing are formulated to withstand thermal stress while offering rapid curing. They ensure that the paddle maintains its structural power, a critical factor when using high-strength materials like 12K Carbon Fiber or T300 Carbon Fiber. However, these agents must be carefully balanced; too aggressive a formulation can compromise the tactile feedback of the paddle. -

Cold Pressing4:

Cold pressing relies on mechanical pressure at ambient temperatures. In this environment, the adhesive’s chemistry must allow for robust bonding without the additional activation offered by heat. Advanced bonding agents used in cold pressing preserve the material’s inherent properties, resulting in superior control over paddle thickness and greater surface consistency. This is particularly important for achieving a uniform feel during play, maintaining an optimal balance between hardness and responsiveness. -

Thermoforming5:

Thermoforming involves heating materials to form complex shapes using molds. Advanced bonding agents adapted for thermoforming provide uniform adhesion during the mold process, ensuring that intricate designs do not lead to weak spots. Such agents are optimized for precise material distribution, which is essential when using composite materials like carbon fiber and fiberglass composite options. Despite the longer production cycle and higher equipment requirements, advanced bonding agents enable manufacturers to produce aesthetically appealing and high-performance paddles.

Beyond just the technological compatibility, manufacturers must consider several practical aspects when transitioning from traditional adhesives to advanced bonding agents. Here are some key points to consider:

• Consistency in Production: Advanced bonding agents deliver repeatable performance, ensuring that each paddle exhibits the same level of adhesive strength and durability. This consistency is vital in high-volume production environments.

• Reduced Downtime: The rapid curing times associated with advanced adhesives reduce waiting periods between production cycles. This translates to increased manufacturing efficiency and lower production costs over time.

• Impact on Player Experience: Enhanced vibration reduction and improved shock absorption contribute directly to better on-court performance. For competitive athletes, even minor improvements in paddle responsiveness can make a significant difference.

• Integration with Current Processes: Transitioning to a new bonding agent should not disrupt the existing production workflow. It is essential for the selected adhesive to be compatible with current manufacturing equipment and quality control processes.

• Quality Control Measures: The use of advanced bonding agents often requires updated quality control protocols to monitor curing uniformity, bond strength, and material compatibility. This might involve investing in new testing equipment or adopting more stringent inspection routines.

A sample comparison table highlighting these factors during the bonding agent selection process is provided below:

| Factor | Traditional Adhesives | Advanced Bonding Agents |

|---|---|---|

| Consistency in Production | Variable quality due to curing discrepancies | Highly consistent performance across batches |

| Downtime Between Cycles | Longer due to extended curing periods | Reduced waiting time due to optimized curing processes |

| Impact on End-User Experience | Potential for inconsistent paddle performance | Enhanced player comfort with reduced vibration and better energy transfer |

| Integration with Equipment | May require additional curing chambers or modifications | Compatible with existing equipment with minimal adjustments |

| Quality Control Requirements | Basic inspection methods often suffice | May necessitate advanced QC tools for precise measurements |

Real-world case studies have demonstrated the benefits of switching to advanced bonding agents in high-performance paddle production. For instance, a manufacturing facility adopting newer adhesives observed a 20% reduction in production cycle time along with a significant improvement in paddle durability. The enhanced bonding performance also translated into lower warranty claims and enhanced customer satisfaction among professional pickleball players.

Combining advanced bonding agents with precision manufacturing processes such as hot pressing and thermoforming ensures that each paddle not only meets but exceeds rigorous performance standards. Moreover, by optimizing the bond between layers, manufacturers can achieve improved energy transfer, providing players with a more responsive and comfortable paddle during extended play.

In addition to performance improvements, advanced bonding technologies allow for greater flexibility in design. Custom paddle options become more feasible as manufacturers can fine-tune the adhesion properties according to specific design requirements and player preferences. Features such as ergonomic grip designs and tailored weight distribution benefit significantly from stable, high-performance adhesion, enabling innovations that were previously limited by the constraints of traditional adhesives.

Furthermore, integrating advanced bonding agents has allowed some companies to explore multifunctional layers in paddles, where each layer serves a specific role—from shock absorption to energy transfer. This multifunctionality is critical in today’s market where differentiation through technology and performance is key.

In summary, advanced bonding agents are proving to be a game-changer for the pickleball paddle manufacturing industry. They offer:

• Superior adhesion strength that meets the demands of high-performance materials

• Faster curing times which streamline production and reduce downtime

• Enhanced compatibility with advanced manufacturing processes such as hot pressing, cold pressing, and thermoforming

• Improved player experience through reduced vibration and superior energy transfer

• Greater consistency and reliability, which support high production volumes and stricter quality control standards

For technical product managers and R&D engineers, these benefits translate into a compelling case for transitioning to advanced bonding agents. By embracing these innovative adhesives, manufacturers can reinforce the structural integrity of their paddles while meeting increasingly sophisticated performance standards. Ultimately, the move towards advanced bonding agents is not just a technological upgrade—it is a strategic decision that aligns with the evolving demands of the sports equipment market, contributing to both operational efficiency and market differentiation.

As more companies adopt these adhesives, it will be essential to continuously monitor performance data and production metrics, ensuring that the benefits realized in initial deployments are maintained over the long term. Manufacturers should also consider engaging in pilot programs or small-scale trials before a full-scale transition, allowing time to adjust settings and calibrate the adhesive application process to their specific production needs.

By balancing innovation with proven manufacturing practices, sports equipment manufacturers can leverage advanced bonding agents to achieve a competitive edge. Whether your focus is on increasing manufacturing efficiency, enhancing product performance, or reducing overall production costs, advanced bonding technologies provide a valuable pathway to meeting these objectives.

People Also Ask

PAA1: What benefits do advanced bonding agents provide in pickleball paddle manufacturing?

Advanced bonding agents significantly improve the adhesion between paddle layers, offering enhanced durability, reduced vibration, and improved overall performance. They also contribute to faster curing times and increased production efficiency compared to traditional adhesives.

PAA2: How do advanced bonding agents compare to traditional adhesives for paddle production?

Advanced bonding agents offer superior adhesion strength, better compatibility with advanced materials, and streamlined curing processes. This results in a more consistent production process, improved durability, and enhanced player performance, making them a more effective choice than traditional adhesives.

PAA3: What production processes are best suited for advanced bonding agents in paddle manufacturing?

Advanced bonding agents are compatible with a variety of production processes including hot pressing, cold pressing, and thermoforming. Their formulation enables consistent bonding even under high temperature and pressure conditions, ensuring optimal material integration and performance.

-

Carbon Fiber: Click the marker to learn about the unique properties of carbon fiber, including its lightweight strength, common manufacturing applications, and role in enhancing the performance of high-tech products. ↩ ↩

-

Composite Cores: Click the marker to explore composite cores, their construction, benefits in multi-layered designs, and why they are essential for achieving superior structural performance. ↩ ↩

-

Hot Pressing: Click the marker to study the hot pressing process, its impact on material bonding, the influence of high temperatures and pressure, and best practices in its application. ↩ ↩ ↩2

-

Cold Pressing: Click the marker to understand cold pressing, including its operational principles, advantages in preserving material properties, and its importance in precision manufacturing. ↩ ↩ ↩2

-

Thermoforming: Click the marker to gain insights into thermoforming methods, the process of shaping heated materials, and how it is integrated in modern manufacturing for complex designs. ↩ ↩ ↩2