Pickleball paddle surface friction plays a critical role in both lab measurements and on-court performance—balancing an optimal surface roughness (around 40 micrometers or less) ensures precise control while providing the necessary grip for spin execution.

In the world of pickleball, ensuring that paddle surfaces provide the best interaction with the ball is essential. Surface friction analysis1 is the process of comparing the measured friction and roughness in controlled laboratory tests with real-world play conditions to optimize paddle performance. Despite rigorous lab testing that defines precise properties, such as a target surface roughness limit of no greater than 40 micrometers, discrepancies often emerge when players take the paddle onto the court.

Lab testing typically measures frictional coefficients and surface roughness under controlled conditions. However, play data reveals factors that influence performance in real-time: wear and tear, humidity, and ball impact behaviors. This article delves into the engineering nuances of how lab tests compare with in-game performance, offering technical insights alongside practical recommendations and case studies to empower R&D engineers and product managers in sports equipment manufacturing.

In lab conditions, paddle surfaces are measured with precision instruments. Engineers use instruments like profilometers2 to determine surface roughness with micron-level accuracy. A common benchmark for high-performance pickleball paddles is to maintain an average surface roughness of no more than 40 micrometers. This strict parameter helps to control two critical performance aspects:

- Control: A smoother surface minimizes unpredictable spin variations.

- Spin: It limits excessive ball rotation by reducing micro-texturing that might grab the ball.

Laboratory tests isolate the paddle material properties—using materials such as 3K Carbon Fiber3, 12K Carbon Fiber, T300 Carbon Fiber, and fiberglass composites—to ensure consistency in performance and durability. These tests also simulate various environmental conditions. However, no controlled metric can perfectly capture the dynamics of a fast-paced game.

In practice, a paddle’s performance may diverge from lab expectations due to factors like:

- Impact Dynamics: Repeated impacts can slightly alter surface integrity over time.

- Environmental Variability: Variations in temperature, humidity, and even court type (for example, comparing hard courts to the artificial grass-like surfaces of padel courts) affect both friction and ball rebound.

- Wear and Tear: Continual play wears down the surface texture, potentially increasing friction unpredictably.

Real-world performance data often comes from rigorous field testing and player feedback. For instance, players mention that while a paddle may show excellent results in friction tests, factors like grip comfort, vibration reduction, and even subtle changes in the paddle’s texture can impact their gameplay experience. In balancing these observations, manufacturers like NEX Pickleball refine their production processes to ensure that the paddles not only perform well in labs but also stand up under intense, sustained play.

Understanding the root causes of discrepancies between lab and field performance is crucial. Several aspects of production directly influence paddle performance:

The core material is the heart of a paddle, determining its weight, control, and impact absorption. Here are some examples used in the industry:

| Core Material | Key Property | Ideal For |

|---|---|---|

| Nomex Honeycomb Core4 | Excellent shock absorption | High-performance and durability |

| Aluminum Honeycomb Core | Balanced weight distribution | Enhanced power and control |

| Polymer Honeycomb Core | Reduced vibration, more elasticity | Recreational play and comfort |

By combining or selecting specific core materials, manufacturers can target specific player needs by tuning the paddle’s feel and performance. For example, a bamboo core composite offers a lighter paddle with superior impact resistance, while a honeycomb core reduces vibration and improves ball control.

The production methods employed—hot pressing, cold pressing, and thermoforming5—each contribute unique characteristics. Here is a breakdown of their effects on surface friction:

-

Hot Pressing:

- Provides highly durable, strong paddles.

- May alter some material properties that influence the paddle’s feel.

- Ideal for mass production, though control over surface micro-texture can sometimes be reduced.

-

Cold Pressing:

- Yields paddles where material properties remain intact, resulting in excellent control and a refined tactile feel.

- Offers greater precision over the paddle’s thickness and structural integrity.

- Typically results in a surface with consistent friction, balancing lab specifications with practical play data.

-

Thermoforming:

- Allows detailed shaping and intricate design that maintain uniformity across the surface.

- Best suited for premium paddles where both aesthetics and performance are critical.

- Optimizes material distribution, which can help maintain a consistent friction interface during play.

The production process, coupled with the choice of composite materials, directly influences the paddle’s surface friction characteristics. Fine-tuning these parameters requires a deep understanding of both lab results and field performance metrics.

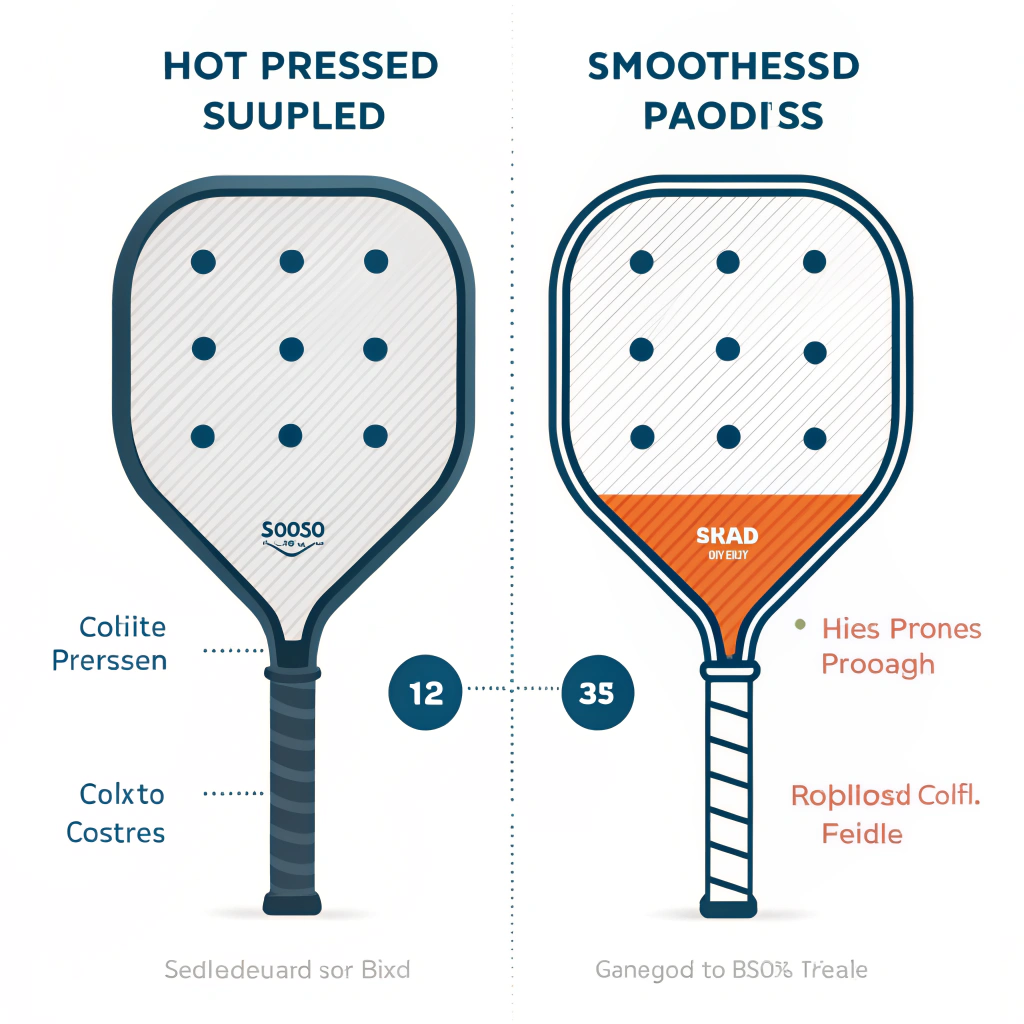

At NEX Pickleball, the integration of lab testing with field feedback is key to product validation and improvement. Consider a case study comparing two paddle variants:

| Feature | Paddle A (Hot Pressed) | Paddle B (Cold Pressed) |

|---|---|---|

| Surface Roughness | 35 micrometers (measured in lab) | 38 micrometers (measured in lab) |

| Field Feedback | High durability, slight vibration during play | Superior control with excellent ball feel |

| Impact Resistance | Excellent, suited for aggressive play | Balanced resistance, optimized for precision |

| Player Preference | Preferred by power hitters | Chosen by control-oriented players |

Despite both paddles meeting the lab specification of under 40 micrometers roughness, field tests revealed that Paddle B’s cold pressing process contributed to a more stable friction interface under varied environmental conditions. Its surface maintained consistency despite repeated play, resulting in a more predictable ball response. This feedback loop allowed engineers to adjust the hot pressing parameters for future batches, aiming to combine strength and refined control.

Such insights underscore the importance of incorporating both lab test data and comprehensive play data. This iterative approach ensures that production techniques meet theoretical benchmarks while addressing the real-world needs of athletes at all skill levels.

For decision-makers and engineers aiming to optimize paddle design and procurement, here are actionable recommendations:

-

Integrate Multi-Stage Testing:

Combine lab-based friction analysis with field testing early in the product development process. This ensures that any variances are quickly identified and addressed. -

Customize Production Processes:

Select production techniques that align with desired performance outcomes. For instance, opt for cold pressing when precise control over surface texture is crucial. -

Leverage Composite Data:

Use material performance data to create custom composite configurations. This provides a balanced solution that meets the demands of both high-performance and recreational players. -

Continuous Quality Monitoring:

Implement rigorous quality control checkpoints that evaluate both surface roughness and impact performance during production cycles. This helps maintain consistency from batch to batch. -

Feedback-Driven Iteration:

Regularly collect user feedback and correlate it with lab metrics. This iterative approach supports continuous improvement and enables rapid adjustments in manufacturing protocols. -

Benchmark Against Competitors:

Compare your paddle’s performance with industry standards and competitors’ products. This benchmarking informs necessary design tweaks and production modifications.

Through these strategic actions, businesses can ensure that their paddle designs provide optimal performance while undergoing minimal degradation during use. This alignment between controlled testing and dynamic field performance not only enhances product reliability but also builds customer trust in the brand’s quality.

In summary, understanding and optimizing the frictional properties of pickleball paddle surfaces is a nuanced task that demands both precise laboratory testing and a deep appreciation for on-court performance variables. By closely monitoring the effects of production techniques—whether hot pressing, cold pressing, or thermoforming—manufacturers can fine-tune the balance between surface roughness and control. This ensures that every paddle not only meets strict lab standards but also performs reliably in the fast-paced, impact-intensive environment of competitive play.

The key takeaway is that bridging the gap between lab test data and actual gameplay results is essential. For product managers and R&D engineers, continuous feedback loops, rigorous quality assessments, and adaptive production processes are crucial. Keeping surface friction optimal (at or below the 40 micrometer threshold) is just one aspect of delivering a high-performance sports equipment solution that satisfies both theoretical models and practical demands.

By implementing these strategies and embracing a holistic approach that merges scientific analysis with practical insights, companies can position themselves as leaders in innovation within the sports equipment manufacturing landscape.

Q: What is the surface roughness of a pickleball paddle?

A: Surface roughness testing in professional pickleball verifies that the paddle’s surface ideally remains no greater than 40 micrometers, ensuring enough smoothness to limit unexpected spin while providing necessary control.

Q: What is the surface of a padel court compared to a pickleball court?

A: While padel is generally played on an artificial grass-like surface, pickleball is typically played on a hard court; these differences in surface composition can influence ball behavior and play dynamics.

Q: What are the surface regulations for pickleball paddles?

A: Regulations for pickleball paddles specify that the material must be a rigid, non-compressible substance. The hitting surface should be free of holes, indentations, rough texturing, or any features that could allow players to impart excessive spin on the ball.

-

Surface friction analysis: Click to learn more about how scientific testing of friction and roughness in controlled environments helps optimize equipment performance for competitive play. ↩ ↩

-

Profilometers: Click to explore how profilometers are used in precision laboratory measurements to determine surface characteristics at the micron level. ↩ ↩

-

3K Carbon Fiber: Click to understand the properties of 3K Carbon Fiber and how it contributes to the durability and performance of high-end sporting equipment. ↩ ↩

-

Nomex Honeycomb Core: Click to discover the advantages of Nomex Honeycomb Core in paddle construction, including improved shock absorption and durability. ↩ ↩

-

Thermoforming: Click to read about the thermoforming process and its benefits in producing intricately designed surfaces while maintaining material consistency. ↩ ↩