Laser engraving offers a precise and durable method for adding customized branding and design details on pickleball paddles, making it an excellent value-add for businesses seeking product differentiation.

In today’s competitive B2B landscape, manufacturers and distributors must continuously innovate to deliver products that not only meet functional needs but also provide a unique brand experience. Laser engraving1 is emerging as a key technology in the sports equipment sector, particularly for pickleball paddles. By offering superior customization options, laser engraving improves product aesthetics, durability, and branding, setting a new industry standard for quality control and technical precision.

For procurement managers and product designers, ensuring product quality, durability, and cost-effectiveness is paramount. The challenge lies in selecting a customization method that offers high precision and does not compromise the integrity of the paddle. Traditional marking techniques often fall short in terms of resolution, speed, consistency, and integration with modern production lines. When it comes to pickleball paddles, the surface material and the manufacturing process require a method that can withstand impacts while retaining a pristine look over prolonged usage.

- Material Compatibility: Many marking techniques may affect the paddle's surface, altering its tactile feel and performance.

- Production Efficiency: Techniques like stamping and manual carving can slow down production cycles and introduce inconsistencies.

- Durability of Markings: Markings need to endure repeated impacts without fading or chipping, particularly in high-performance sports.

Laser engraving has become the solution of choice because it directly addresses these challenges through its unique technological advantages. Let’s dive into how laser engraving transforms pickleball paddle customization:

Laser engraving employs high-intensity beams that vaporize material at a microscopic level. This means that every detail—from intricate logos to fine text—can be reproduced exactly as designed. This precision technology is crucial for achieving consistency across large production volumes, an essential requirement for B2B operations.

When compared to traditional marking techniques, laser engraving creates markings that are part of the paddle surface rather than an applied layer. This improves the durability of the marking, ensuring that it remains intact even under repeated high-impact conditions. For paddles that undergo rigorous use in competitive environments, this durability directly translates to longer product life and better performance.

Laser engraving provides a clean, modern look that appeals to both professional athletes and recreational players. It enables manufacturers to integrate complex designs and personalized information without altering the essential play characteristics, such as the grip texture or balance of the paddle. For manufacturers like us at NEX Pickleball, offering laser engraving as a customization option is a clear competitive advantage in the market.

Though the initial investment in laser engraving technology might be higher compared to simpler techniques, the long-term benefits include reduced waste, decreased production time after setup, and minimal maintenance costs. Further, the enhanced product value allows manufacturers to command premium pricing, offsetting the initial expenditure.

To assist B2B procurement managers and product designers in making an informed decision, we provide a detailed comparison table of laser engraving versus alternative techniques commonly used in pickleball paddle customization.

| Feature | Laser Engraving | Handwritten Markings | Mechanical Stamping2 | Ink Printing3 |

|---|---|---|---|---|

| Precision | High (microscopic accuracy) | Low (depends on manual skill) | Medium (limited by tooling precision) | Medium (resolution dependent on inkjet precision) |

| Durability | Superior (integrated into surface) | Low (easily smudged or erased) | High (permanent deformation) | Low to medium (subject to fading) |

| Production Efficiency | High (automated with fast cycle times) | Low (labor intensive) | Medium (requires tooling changes) | High (automated, fast application) |

| Material Compatibility | Excellent (suitable for carbon fiber, fiberglass, composites) | Variable (may damage sensitive surfaces) | Good (if correctly calibrated) | Good (may not perform well on porous surfaces) |

| Customization Level | Very high (complex designs possible) | Limited | Limited (dependent on mold design) | Moderate (design modifications possible) |

This table highlights that laser engraving not only outperforms other methods in terms of precision and durability, but it also provides the flexibility needed for intricate branding designs. Manufacturers can confidently employ this technique without fearing negative impacts on paddle performance.

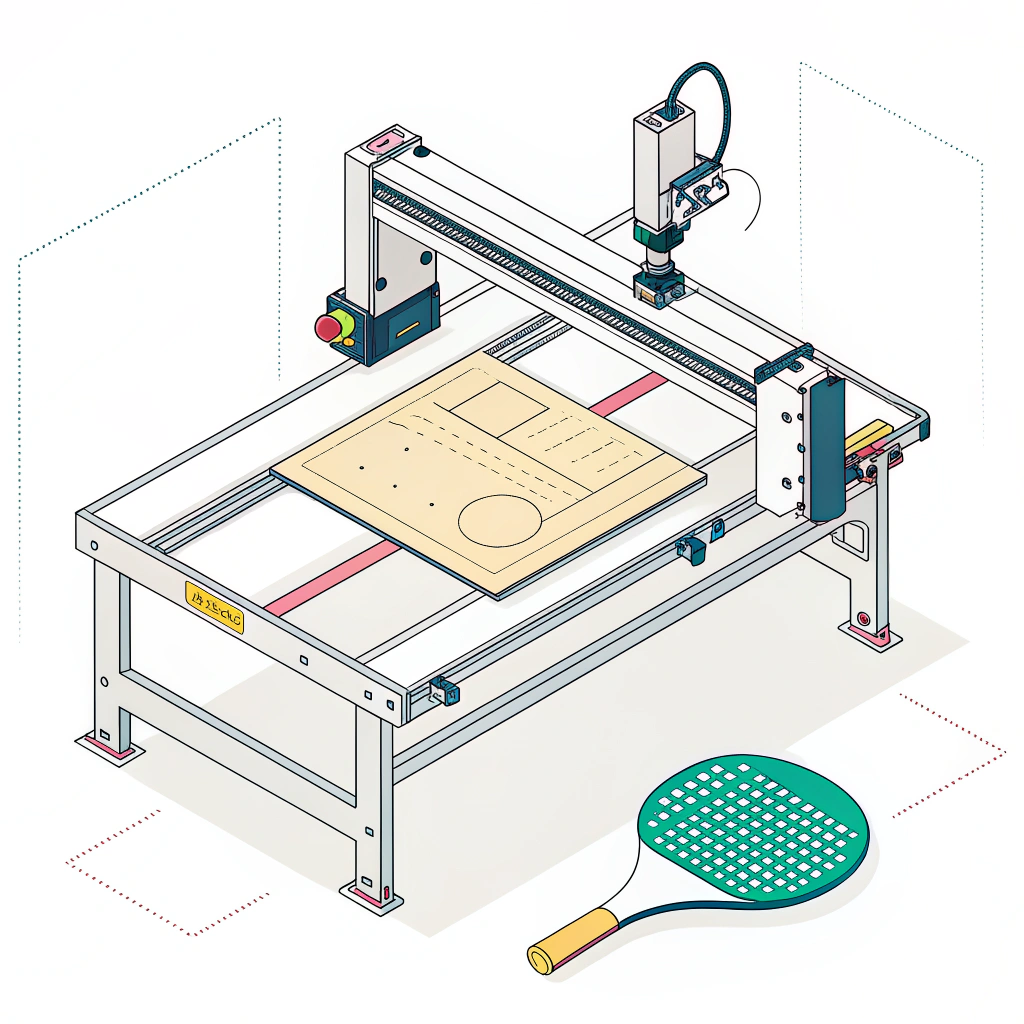

Implementing laser engraving in the production process involves several critical steps to ensure quality and efficiency. Here’s a brief guide outlining the best practices:

-

Material Preparation

- Surface Cleaning: Ensure surfaces are free of contaminants to avoid engraving defects.

- Material Testing: Conduct trial runs on different materials used in the paddle such as 3K Carbon Fiber4, 12K Carbon Fiber, T300 Carbon Fiber, and Fiberglass. Testing helps in fine-tuning laser parameters for optimal results.

-

Laser Parameter Optimization

- Adjust power, speed, and frequency settings according to the material type. For example, materials like fiberglass may require lower power settings to prevent surface damage.

- Use automation systems to monitor and adjust parameters in real-time, ensuring consistency across batches.

-

Quality Control Measures

- Integrate in-line quality control to inspect each paddle post-engraving.

- Use high-resolution cameras and measurement instruments to verify that the engraved design meets both aesthetic and functional standards.

-

Integration with Existing Production Lines

- Design modular systems where laser engraving stations can be easily integrated with hot pressing, cold pressing, or thermoforming production lines.

- Train production staff on the specifics of laser equipment handling and maintenance.

-

Environmental and Safety Considerations

- Implement proper ventilation and safety measures as lasers produce fumes and require controlled environments.

- Regular equipment calibration is necessary to maintain safe and effective operation.

Let’s consider a practical example from our own experience at NEX Pickleball. A leading sports equipment distributor approached us with the need to offer premium, customized pickleball paddles that could be branded for professional tournaments.

The client required a customization method that could reliably incorporate complex logos, player names, and specific design motifs directly into the paddle surface without compromising the paddle’s structural integrity or performance attributes. Traditional marking methods had failed to deliver on these requirements due to issues with durability and production speed.

By integrating laser engraving into our production process, we achieved the following:

- Optimized laser settings tailored for Nomex Honeycomb Core5 and Composite materials to ensure detailed yet durable engravings.

- Developed an automated quality control system to check each paddle, ensuring compliance with both aesthetic and functional requirements.

- Reduced printing time per paddle by over 30%, allowing for efficient mass production while maintaining a high standard of customization.

The client reported higher customer satisfaction as the customized paddles enhanced brand recognition. Furthermore, the precision of the engraving helped reduce maintenance costs and extended the product lifecycle, translating to a stronger return on investment (ROI).

Laser engraving represents a vital advancement in the customization of pickleball paddles for B2B manufacturers. The technique’s superior precision, durability, and versatility make it an ideal solution for businesses looking to achieve product differentiation and enhance brand identity. The steps outlined above—from material preparation to quality control—ensure that laser engraving is not only technically feasible but also highly beneficial from an economic perspective.

For procurement managers and product designers, adopting laser engraving can improve product performance and market competitiveness, meeting the demands of today’s discerning sports equipment buyers. NEX Pickleball is committed to leveraging this cutting-edge technology to deliver high-performance, customized paddles that stand out in value and quality.

If your company is exploring customization technologies that can elevate product differentiation and brand recognition, consider how laser engraving can be integrated into your manufacturing process. Evaluate your current processes, compare alternative methods using our detailed comparison, and consult with experts to determine the best approach for your needs.

People Also Ask

• Can I write on my pickleball paddle?

Yes, handwritten markings are allowed on pickleball paddles, but they must be in good taste and not affect the paddle's surface texture. Precision techniques like laser engraving provide a more durable and consistent alternative for customization.

• What to do with used pickleball paddles?

Used pickleball paddles can be donated or saved as spares for recreational play. However, enhancing product longevity through durable customization methods, like laser engraving, may reduce the rate at which paddles become unusable.

• Can you laser engrave a pickleball?

Yes, laser engraving is used for personalized items such as pickleball paddles and related sports equipment. This precise technique enables intricate designs and personalizations, offering both functional benefits and unique branding opportunities.

-

Laser engraving: Read the article to learn how this technology uses focused laser beams to permanently etch designs into various materials for superior precision and durability. ^Return ↩

-

Mechanical Stamping: Read the article to explore how mechanical stamping works as a traditional method for marking materials and its trade-offs in precision and speed. ^Return ↩

-

Ink Printing: Read the article to learn about the ink printing process for product customization, including its benefits and limitations compared to laser engraving. ^Return ↩

-

3K Carbon Fiber: Read the article to understand the properties of 3K Carbon Fiber, a high-strength material often used in advanced manufacturing for its excellent strength-to-weight ratio. ^Return ↩

-

Nomex Honeycomb Core: Read the article to discover how Nomex Honeycomb Core technology contributes to lightweight yet strong structural components in high-performance sports equipment. ^Return ↩