A quick answer: Edge beveling1 in pickleball paddles can significantly influence swing speed by optimizing weight distribution and reducing resistance during the swing. By carefully adjusting manufacturing techniques such as hot pressing2, cold pressing3, and thermoforming4, and leveraging advanced materials like carbon fiber5 and fiberglass, manufacturers can fine-tune paddle performance to meet the precise needs of competitive players and technical product managers.

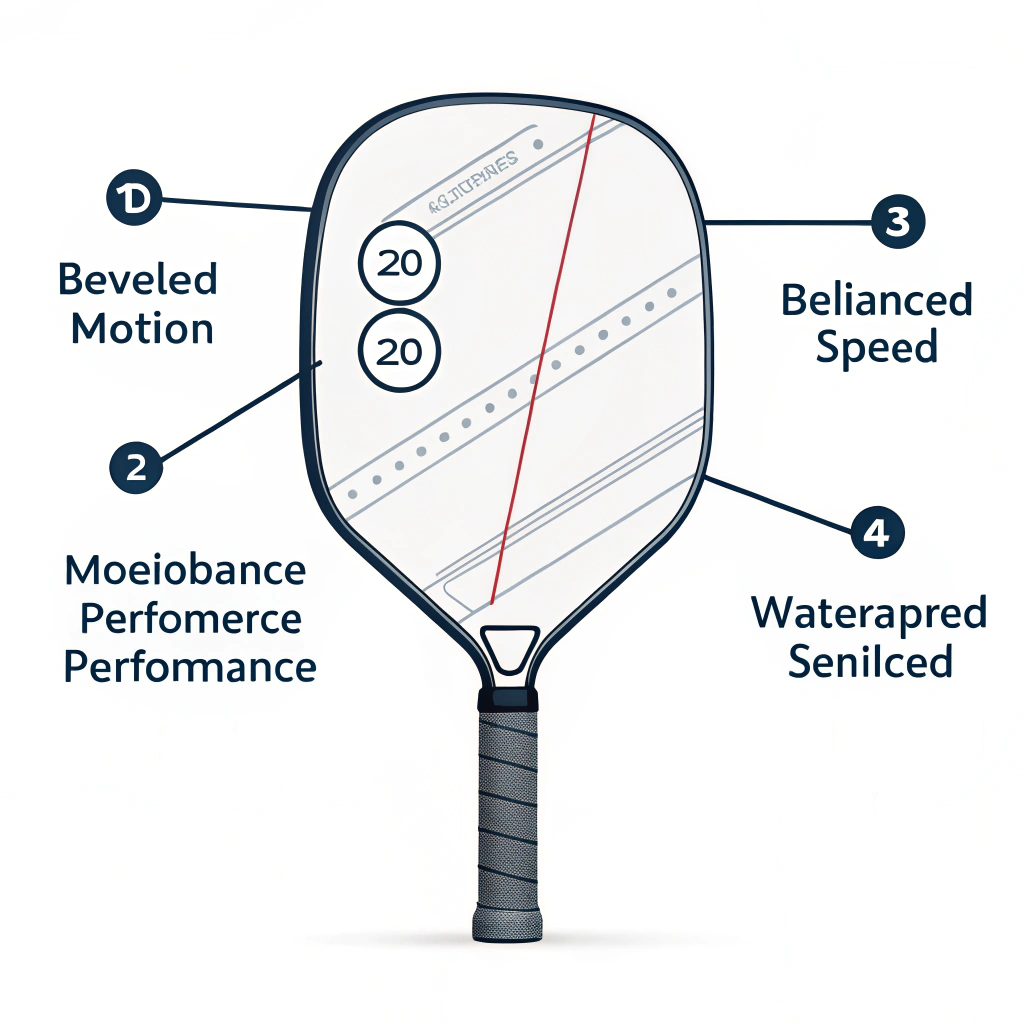

Edge beveling is a critical design element that not only enhances the aesthetics of a pickleball paddle but also affects its swing speed and overall performance. In this technical exploration, we will discuss the problem of optimizing swing speed, analyze the factors involved, compare production techniques, and offer practical solutions for achieving the ideal blend of power and control.

Modern pickleball paddles must balance strength, durability, and speed. Engineers face the challenge of optimizing swing speed while ensuring that the paddle feels comfortable in the hand. Key issues include:

• Maintaining structural integrity when adding or removing edge materials

• Achieving an optimal weight distribution that minimizes inertia

• Addressing the friction and resistance associated with different edge shapes

Edge beveling—a process where the edges of the paddle are slightly angled—can improve swing mechanics by reducing air resistance and optimizing the paddle’s balance. However, this design change requires a careful review of the materials used and manufacturing techniques applied.

Several factors determine how edge beveling affects swing speed:

-

Weight Distribution:

When a paddle’s edge is beveled, it often removes some material from the outer perimeter. This change in mass distribution can lower the moment of inertia, allowing for faster and more precise swings. The removal or redistribution of weight can lead to reduced resistance during rapid movements. -

Aerodynamics:

A smoother transition at the paddle’s edge may reduce drag. With edge beveling, sports engineers observe improved maneuverability since the paddle cuts through the air more efficiently. -

Material Response:

The properties of carbon fiber5, fiberglass, and composite materials play a significant role. For example, advanced materials such as 12K carbon fiber provide a smoother, stiffer surface, which, when combined with precise edge beveling, can offer superior control and power during impact. -

Manufacturing Process:

Production methods like hot pressing2, cold pressing3, and thermoforming4 affect the final product’s material distribution and structural properties. Each method has a different impact on how the edge beveling techniques can be implemented without compromising material integrity.

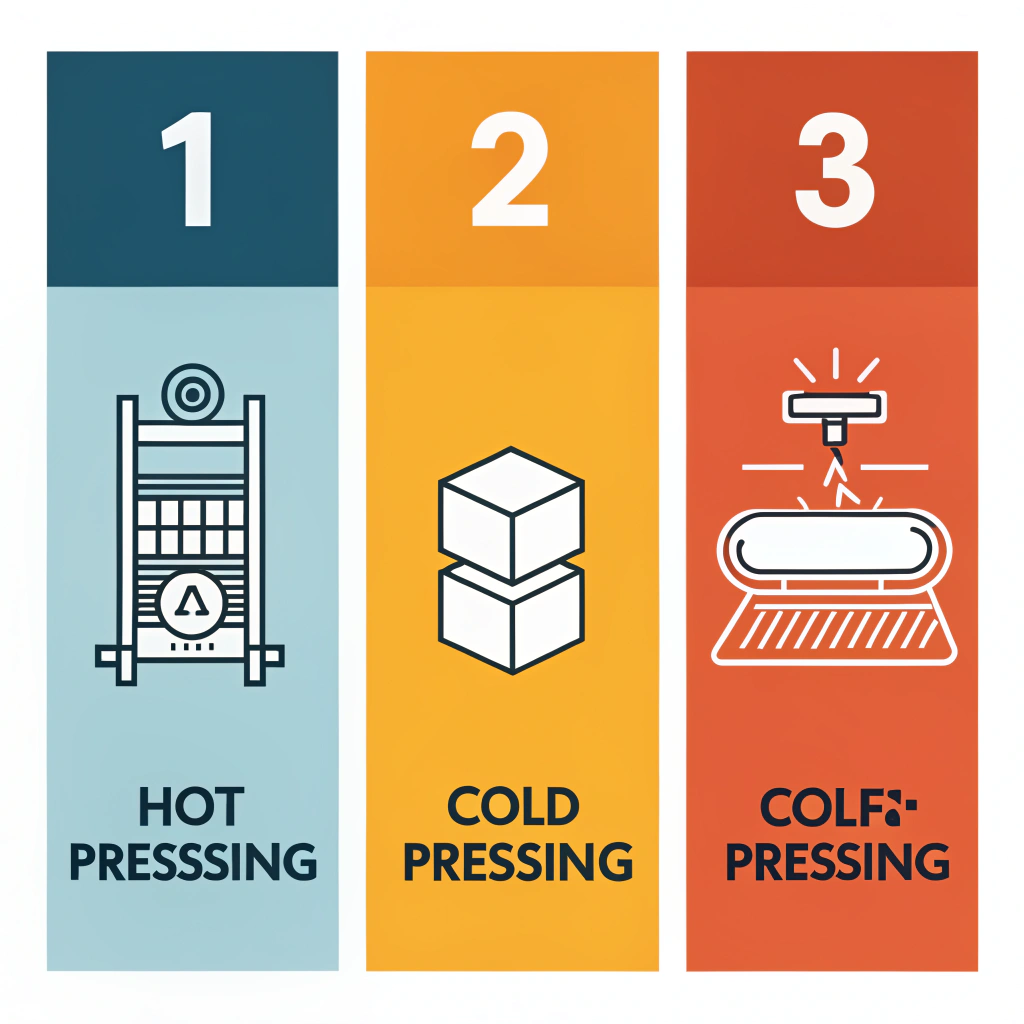

The choice of production technique directly influences how edge beveling impacts the paddle’s performance. Manufacturers employ several methods, each with its advantages and limitations:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Strong, durable paddles - Enhanced impact resistance | - Possible alteration in material properties - Requires high initial investment |

| Cold Pressing | - Precise control over thickness and structure - Maintains original material properties - Superior ball feel and responsiveness | - Slower production cycles - Demands high-quality, precise equipment |

| Thermoforming | - Accommodates complex designs - Enables even material distribution - Can enhance paddle stability | - Longer production times - Higher equipment costs |

Manufacturers need to balance these methods to achieve the optimal edge beveling effects. For example, hot pressing might create robust paddles with thicker edges, whereas cold pressing can preserve the desirable tactile feel necessary for sensitive swing adjustments. Thermoforming, on the other hand, allows for innovative designs that can incorporate edge beveling without sacrificing the paddle’s form and function.

To address the challenge of optimizing swing speed through edge beveling, a systematic approach is necessary. Below is a checklist and table to help technical teams review and adopt potential production improvements:

-

Weight Calibration:

• Analyze weight reduction at the bevel to ensure ideal balance

• Model different bevel designs using simulation software -

Material Selection:

• Test different grades of carbon fiber5 such as 3K, 12K, and T300

• Consider fiberglass for enhanced control without sacrificing strength

• Evaluate composite combinations to balance flexibility and rigidity -

Manufacturing Consistency:

• Maintain precision in edge shaping using controlled pressure

• Regularly calibrate the equipment used in hot pressing, cold pressing, and thermoforming

• Incorporate quality control checkpoints during and after production -

User Feedback Integration:

• Gather data from advanced players regarding paddle handling and swing speed

• Use iterative design adjustments based on performance tests and user reviews

| Focus Area | Action Item | Expected Outcome |

|---|---|---|

| Weight Distribution | Simulate various bevel designs | Lower moment of inertia and improved swing speed |

| Material Testing | Compare performance of 3K vs. 12K vs. T300 carbon fiber in paddles | Optimal power-to-weight ratio |

| Process Optimization | Evaluate differences between cold pressing and thermoforming | Enhanced production efficiency with better paddle feel |

| Quality Assurance | Introduce real-time testing post-production | Reduced variability and consistent product performance |

This structured approach helps technical product managers and engineers identify the interplay between design, materials, and production techniques. By scrutinizing these factors, businesses can justify further R&D investments to achieve both performance improvements and cost-effective manufacturing.

Consider a scenario where a leading manufacturer undertakes redesigning its paddle to enhance swing speed. Initially, the design incorporates minimal beveling to preserve the paddle's strength. However, through computational modeling and prototype testing, the company discovers that a 15% bevel reduction at the paddle’s edge results in a 5% improvement in swing speed without compromising durability.

The production team uses cold pressing to maintain the paddle's original feel while fine-tuning the bevel geometry. By integrating feedback from advanced players, the design is iteratively refined. In parallel, the manufacturing process is adjusted to enhance precision, ensuring that each paddle's weight distribution is optimized.

Results from performance tests indicate:

• Faster swing initiation due to decreased rotational inertia

• Improved handling in high-speed scenarios

• Consistent performance across multiple production batches

This real-world case highlights the significance of advanced production techniques. The data-driven approach not only reinforces the benefits of edge beveling but also showcases how companies like NEX Pickleball are staying ahead in the competitive sports equipment market.

While edge beveling shows promise in enhancing swing speed, there are several considerations and limitations:

-

Material Degradation:

Repeated stress on beveled edges might lead to premature wear if not designed correctly. Continuous quality control is necessary to monitor long-term durability. -

Production Variability:

Slight deviations in manufacturing techniques can lead to inconsistencies. High-precision equipment and regular calibration are critical to mitigate this risk. -

Cost Implications:

Advanced production methods and superior materials, such as T300 carbon fiber, may drive up initial costs. However, these can be justified by improved performance and longer product lifecycles in high-performance markets. -

User-Specific Needs:

Not all players may benefit equally from beveled edges. While competitive and elite players might see significant gains in swing speed, recreational players might prioritize feel and comfort. -

Environmental Factors:

Temperature and humidity during production can affect resin curing and material performance. Consistent environmental controls are necessary to guarantee product quality.

Edge beveling, when optimized with the right materials and production processes, plays a pivotal role in enhancing pickleball paddle swing speed.

As a leading manufacturer, NEX Pickleball leverages advanced techniques—hot pressing for strong and durable products, cold pressing for superior control, and thermoforming for design flexibility—to create paddles that meet the needs of both recreational and professional players. Our data-driven approach ensures that every paddle is tested for balance, performance, and durability.

Based on our analysis, technical product managers and engineers are encouraged to:

• Evaluate current paddle designs for potential improvements through edge beveling

• Collaborate with material specialists to select the best reinforcement options

• Invest in precision manufacturing tools and regular quality audits

• Pilot new designs with a control group of advanced players to gather real-world performance data

By incorporating these strategies, companies can achieve measurable improvements in swing speed, enhance overall paddle performance, and ultimately drive a competitive edge in the fast-growing sports equipment market.

• Is it better to have an edge or no edge on a pickleball paddle?

Edgeless paddles can enhance maneuverability and offer a wider range of shots, while edged paddles may provide extra protection and potentially a larger sweet spot. The choice depends on the player's level and gameplay style.

• How to increase swing speed pickleball?

To increase swing speed, adopt a stance with feet shoulder-width apart, bend your knees slightly for stability, keep your weight on the balls of your feet, relax your muscles, and use a loose grip to facilitate greater wrist movement.

• How much weight does edge guard tape add to a pickleball paddle?

Edge guard tapes are available in different weights; typically, a ¼-inch tape adds either 0.25 grams per inch or 0.5 grams per inch, while a ½-inch tape adds either 1 gram or 2 grams per inch. Choosing the appropriate weight is critical to maintaining overall paddle balance while ensuring durability.

-

Edge beveling: Click to explore detailed insights on how edge beveling optimizes weight distribution and swing mechanics in sports equipment design, providing competitive performance benefits. ↩ ↩

-

Hot pressing: Click to understand the hot pressing process, its advantages in production efficiency, and how it influences material properties in manufacturing. ↩ ↩ ↩2

-

Cold pressing: Click to discover cold pressing techniques, emphasizing its role in maintaining material integrity and precision in product manufacturing. ↩ ↩ ↩2

-

Thermoforming: Click to investigate thermoforming methods and their contribution to achieving complex designs and consistent material distribution. ↩ ↩ ↩2

-

Carbon fiber: Click to learn about carbon fiber’s properties, including its strength-to-weight ratio and applications in high-performance manufacturing. ↩ ↩ ↩2 ↩3